Shurflo 166-200-09 Installation Manual

JUICE GAS PUMP 166-200-XX (GREEN LABEL)

Installation and Operation Manual

The SHURflo model #166-200-09 (Standard Juice pump) is for concentrates that contain soft solids classed

as "round" (up to .025 in. dia.

Model

#

166-200-10 (Particulate Juice pump) is designed to transfer concentrates that contain, pulp

classed as long/string, seed particles, or soft solids up to ¼"

concentrates that are extremely viscous. The pumps valve cartridges minimize the collection of

particulates and promotes thorough flushing during sanitization.

Both models of the Juice pump are compatible with concentrates that are highly acidic (low pH value),

and are identified by black inlet and outlet fittings.

Juice concentrates are generally supplied in flexible plastic bags, packaged inside cardboard boxes

(Bag-In-Box). Juice concentrates g enerally requir e more f requent sanitization. The m anufact urer of the

concentrate should specify the interval for sanitizing; however, other factors such as system

configuration, and/or t em perature may affect concentr ate life.

The Juice pump pressurizes the concentrate to match the pressure of the gas supply. The pum p can be

operated on regulated CO

the pump and does not come in contact with the concentrate. The pump operates when concentrate is

needed, which is termed as its "automatic demand" feature. When the post-mix dispenser valve is

opened, the pump reacts to the drop in pressure by operating to maintain pressure in the line. When the

dispensing valve is closed, the input gas and output concentrate pressures equalize and the pump

stops. As the B-I-B empties, t he pump draws a vacuum collapsing t he bag evacuating it of concent rate.

The pump automatically shuts off once vacuum above 20 in/Hg.

B-I-B is connected the vacuum drops, the pump aut om at ically resum es pum ping.

[.6mm]) or for concentrates that are of higher viscosity than soda syrups.

[6mm] cube. It is also recommend for

(see page: 4)

2, nitrogen, or clean compressed air. The compressed gas is used to operate

[508 mm/Hg.] is obtained. W hen a new

PUMPING CAPABILITY

Due to diversity of both the installations and equipment used within beverage systems, it is difficult to

calculate/predict total pumping distance. The ability to deliver fluid is limited by the dynamics of the fluid (flow)

and pump displacement at pressure. Consider all the f ollowing fact ors when est imating pressure dr op within

a beverage system.

• Fluid viscosity (Centipose/cP.) @ temperature. • Inside diameter of the inlet/ outlet tubing, fittings, etc.

• Horizontal distance of the outlet tubing . • Total syrup flow rate of valve(s) supplied by a given pump.

• The pressure drop per foot within vertical tubing runs is significant. To estimate the losses use the

appropriate distance given by Max. Horz. Dist. Chart

Multiply the vertical distance by that number. Subtract the product f rom the or iginal Max. Horz. dist ance.

The result is the total tubing run (includes vertical) that should be attempted for that flow rate, tubing I.D. ,

and viscosity.

Example: The facility requires a total tubing run of 196 ft.

The product is 100% Grape juice dispensed by one fast flow valve (.5 oz/sec

The distance chart indicates 248 ft.

[76 M] (50-100 cP

1% of 248 is 2.48, which is then multiplied by 14 ft, equaling approximately 35 f t. Subtracted that product

from the 248 ft. (248–35 = 213). 213 ft. is the total tubing run that can be achieved including the 14 ft. vertical.

To calculate the vertical losses for distances measured in meters, t ak e 3% of the dist ance given [76

2.28. Multiply by the vertical meters (2.28 x 4.26 = 9.7). Subtract that product (76–9.7 = 66.3). 66.3

meters is the total tubing r un t hat can be achieved including the 4.26

(page: 2). Take 1% of that dist ance [3% if meters].

[60M]; included that run is a 14 ft.[4.26M] vertical.

.[14.8 cc/sec])

@

.5 oz/sec) wi th

M vertical.

3

/

" I.D.[10mm] tubing.

8

M] =

NOTE: Had the example above resulted in a value that was equal to, or less than the necessary total tubing

run, consider a larger I.D. tubing or installation of a pump(s) in series using a vacuum regulator.

911-437 Rev. F 1/98 Page: 1 of 6

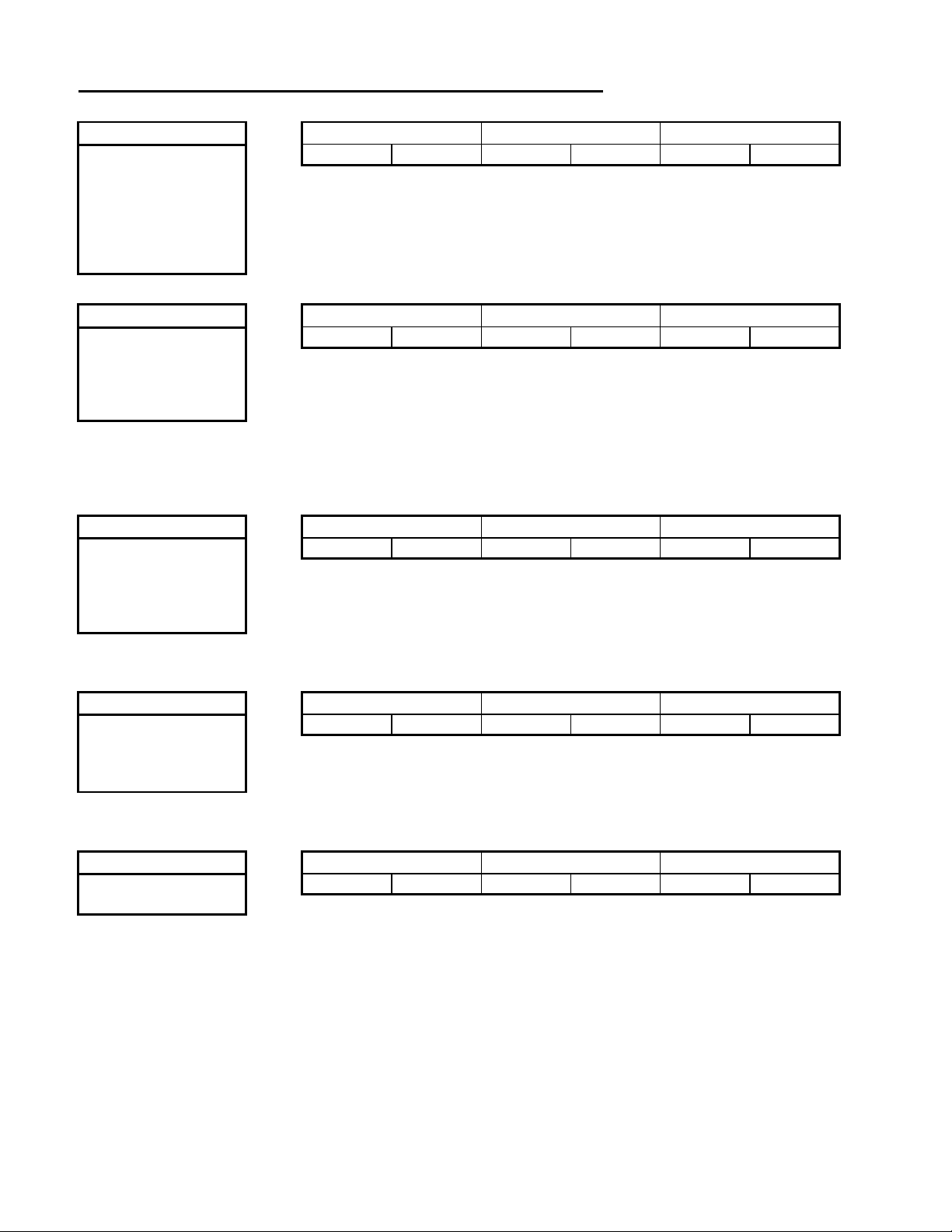

MAXIMUM HORIZONTAL DISTANCE by VISCOSITY (cP)

THE FOLLOWING TABLES ARE TO BE USED AS A GUIDELINE ONLY

*20-50 (cP)

50% Apple 5:1 .0Z /SEC. CC /SEC. FEET METER FEET METER

100% Apple 4:1

Fruit Punch 5:1

Lemonade 5:1

Pink Lemonade 5:1

Lemon lime Soda 5:1

Typ. Heavy Soda Bev. 5:1

* For further viscosity charts in this range refer to Standard Gas Pump Manual # 911-293

FLOW RATE 1

.25 7.4 272 83 500 152

.5 14.8 150 42 450 137

.75 22.2 101 31 303 92

1.0 29.6 50 15 153 47

1.25 37.0 - - - - 110 34

1.5 44.4 - - - - 62 19

" [6mm]

/

4

I.D. TUBING

3

" [10mm] I.D. TUBING

/

8

50-100 (cP)

50% Grape 5:1 .0Z /SEC. CC /SEC. FEET METER FEET METER

100% Grape 5:1

Grapefruit 5:1

Cranberry 5:1

Pineapple 5:1

FLOW RATE 3

.25 7.4 296 90 394 120

.5 14.8 248 76 347 106

.75 22.2 205 63 298 91

1.0 29.6 150 47 251 77

" [10mm]

/

8

I.D. TUBING

1

" [13mm] I.D. TUBING

/

2

1.25 37.0 78 24 206 63

1.5 44.4 54 16 153 47

1.75 51.8 - - - -

2.0 59.2 - - - -

100-500 (cP)

50% O.J. 5:1 .0Z /SEC. CC /SEC. FEET METER FEET METER

100% O.J. 4:1

100% O.J. 3.5:1

Margarita 4:1

Tomato 1.5:1

FLOW RATE 3

.25 7.4 122 37 246 75

.5 14.8 104 32 198 60

.75 22.2 77 23 153 47

1.0 29.6

1.25 37.0

1.5 44.4

500-1000 (cP)

O.J. (Natural) 3:1 .0Z /SEC. CC /SEC. FEET METER FEET METER

Tomato 2:1

Bloody Mary 2:1

Canadian Caesar 2:1

FLOW RATE 3

.25 7.4 56 17 123 37

.5 14.8

.75 22.2

" [10mm]

/

8

I.D. TUBING

56 17 105 32

2995015

134278

" [10mm]

/

8

I.D. TUBING

32 9.7 100 30

17 5.2 78 24

1.0 29.6 7 2

1.25 37.0 - - - -

112 34

59 18

1

" [13mm] I.D. TUBING

/

2

1

" [13mm] I.D. TUBING

/

2

52 16

27 8

1000-3500 (cP)

O.J. (Natural) 5:1 .0Z /SEC. CC /SEC. FEET METER FEET METER

Caesar 2:1

FLOW RATE 3

.25 7.4 49 15 96 29

.5 14.8

.75 22.2

1.0 29.6

" [10mm]

/

8

I.D. TUBING

2785818

1343210

- - - - 18 6

• Values in Bold create an inlet vacuum of 16" Hg. or higher at flow rates shown. Inlet tubing used was

[10mm] with a total length of 5 ft, with 3 ft. of vertical lift. Conditions of this kind should use

1

" [13mm] I.D. TUBING

/

2

1

/2" [13mm] I.D.

3

/8" I.D.

vacuum tubing with minimal vertical lift. Fittings such as Liquibox Q.C.D.™ III connector and bag fittment are

less restrictive and utilize a larger barb fitting/tubing which can minimize inlet vacuum.

• Product viscosity and solids content will vary, depending upon the manufacture and type of concentrate.

• The tables above are the results of test conducted with 70 psi. [4.8 bar] (to the pump) , with a minim um of 20 psi.

[1.4 bar] at the dispenser valve (to maintain brix). Ambient temperature was 70°F [20°C].

Page: 2 of 6

Loading...

Loading...