Shurflo 1000 GPH [3785 LPH] Installation Manual

Bilge Pump Installation & Operation

BILGE PUMP FEATURES

Manual

Automatic

Panel Switch

Brown

&

White

Brown

Black

Black

Make all electrical

Ground

--

+

Fuse

• Quick-disconnect baseplate for easy installation.

• Quick-change motor assembly for easy cleaning and wire routing.

• Strong nylon construction.

• Submersible, w/ 6 ft. tinned power leads to insure operation in the

wettest conditions.

• Waterproof heat-shrink wire connectors [Aftermarket]

• 2 second on delay, 10 second off delay for maximum removal

INSTALLATION

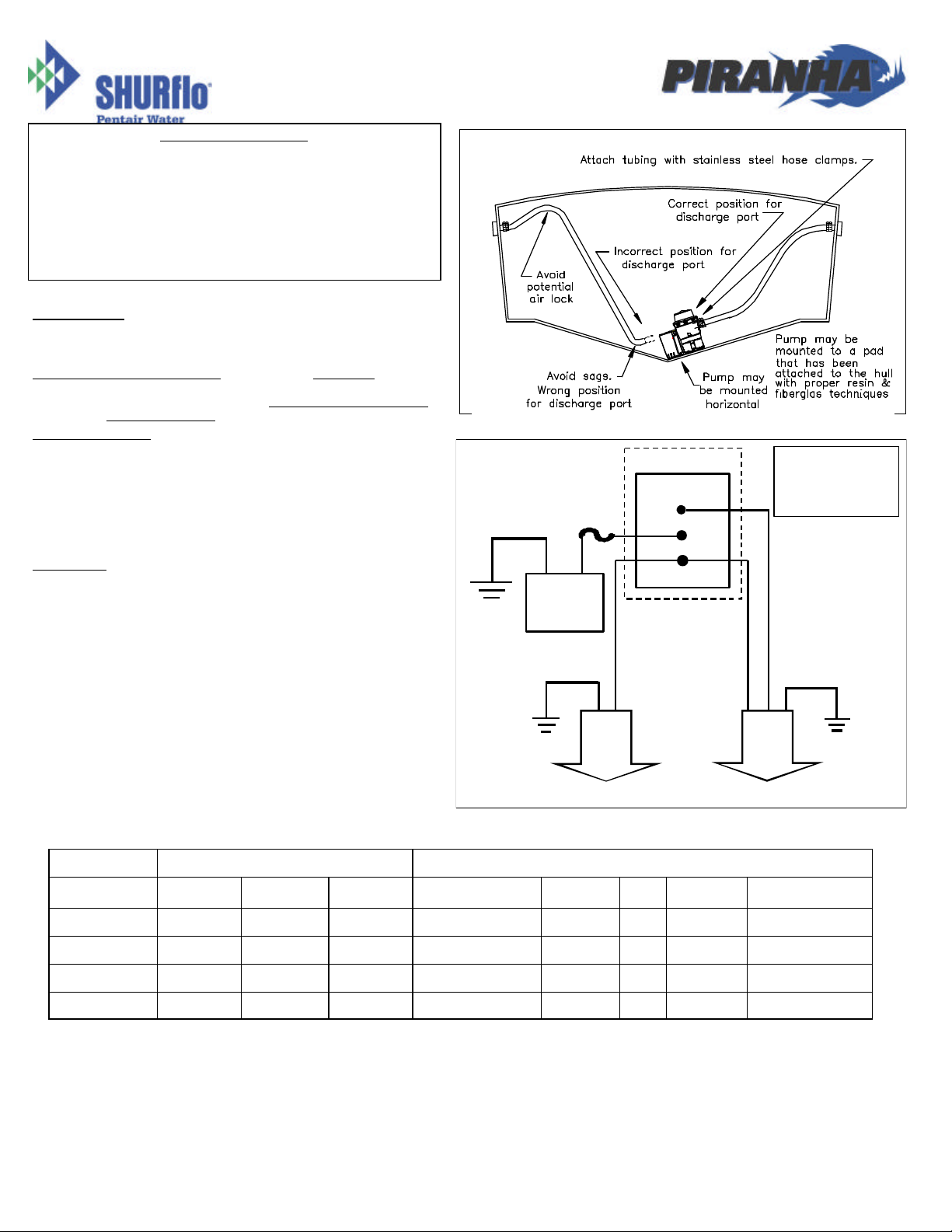

LOCATION: Locate pump at deepest position in the bilge. Keep away from

high heat source; engine, etc. MOUNTING: Mount quick-disconnect

bracket to hull or pad with stainless steel screws. Mount switch if equipped.

Do not drive screws through hull! TUBING: Route smooth I.D.

discharge tubing to a thru-hull fitting well above the water line. AVOID

AIRLOCK & MAXIMIZE PERFORMANCE: Avoid any sagging or loops

in the tubing. Tubing must go up from pump to thru-hull.

ELECTRICAL WIRE:

Use 16GA wire for all circuits. If installation is over 20 feet, use 14GA

wire. Brown pump wire must be hooked to positive power for maximum

flow. Wire is designed to prevent corrosion. Do not cut wires more than 1

inch. Reversed polarity will damage switch. PANEL SWITCH: Attach all

wires to UL Marine approved duty switch with auto-off-manual, rated at or

above 10 amps. FUSE: Install a fuse per pump label specifications .

CONNECTIONS: Wire connections should be made above highest possible

water level. Seal wire connections to prevent corrosion and electrolysis.

OPERATION

DO NOT RUN DRY MORE THAN 5 SECONDS. ALWAYS TEST PUMP

AND SWITCH BEFORE LEAVING DOCK.

12VDC

Battery

MANUAL MODE When brown wire from switch is not hooked up, the pump

float switch is bypassed. To turn pump on, turn switch on. If pump does

not turn on, turn switch off, check power, fuses, connections, wires. Retry. If

pump does not turn on, check pump motor.

AUTOMATIC MODE When the water level is above the float switch, the

pump will automatically start after 2 seconds. It will stop 10 seconds after

the water level falls below the float. If the float becomes jammed with debris, the pump will NOT STOP running. Turn the pump switch to the OFF

position. Remove the debris. Reset switch to the automatic or manual

ON position. Test. SWITCH TEST: Turn power ON to pump switch. Use

a quarter or flat head screwdriver wait 2 seconds, and pump turns on.

Lower float and pump turns off after 10 seconds.

Typical Electrical Installation with Pump and Switch

To

Pump

connections with

waterproof

connectors.

Brown

To

Switch

Model 0 Ft [0 M] 3 Ft [1 M] 6 Ft [2 M]

380 GPH [1438 LPH]

500 GPH [1892 LPH]

700 GPH [2649 LPH]

1000 GPH [3785 LPH]

Specifications given at design voltage 13.6 VDC per ABYC recommendations.

Pump Power leads: 6 ft. [1.8 M] #18 tinned stranded copper wire to minimize corrosion. Positive (+) brown; Ground (–) black

Switch Leads: Automatic (+) brown; Manual (+) brown & white; Ground (--) black

Temperature limits: 33ºF—140ºF [0ºC—60ºC]. All models rated for continuous duty.

Approvals: Ignition Protected (UL File MQ361), ISO 8846, ISO 8849 Listed for CE, QAI [ for RV Use where applicable ]

380 [1438] 340 [1157] 240 [817] 7.5 [2.2] 1.7 A 2.5 A 3/4” 4-12” x 3”

500 [1892] 430 [1464] 270 [918] 7.5 [2.2] 1.8 A 2.5 A 3/4” 4-1/2” x 3”

700 [2649] 600 [2043] 500 [1702] 10 [3] 3.2 A 5 A 3/4” 4-1/2” x 3’

1000 [2649] 840 [2861] 650 [2214] 11 [3.3] 3.4 A 6 A 1-1/8” 4-1/2” x 3”

FLOW

911-593-C 9/05 ECO#: 10658 Page 1 of 2

Max Head

Ft [ M ]

Max Amps Fuse Outlet Port Pump Dimensions

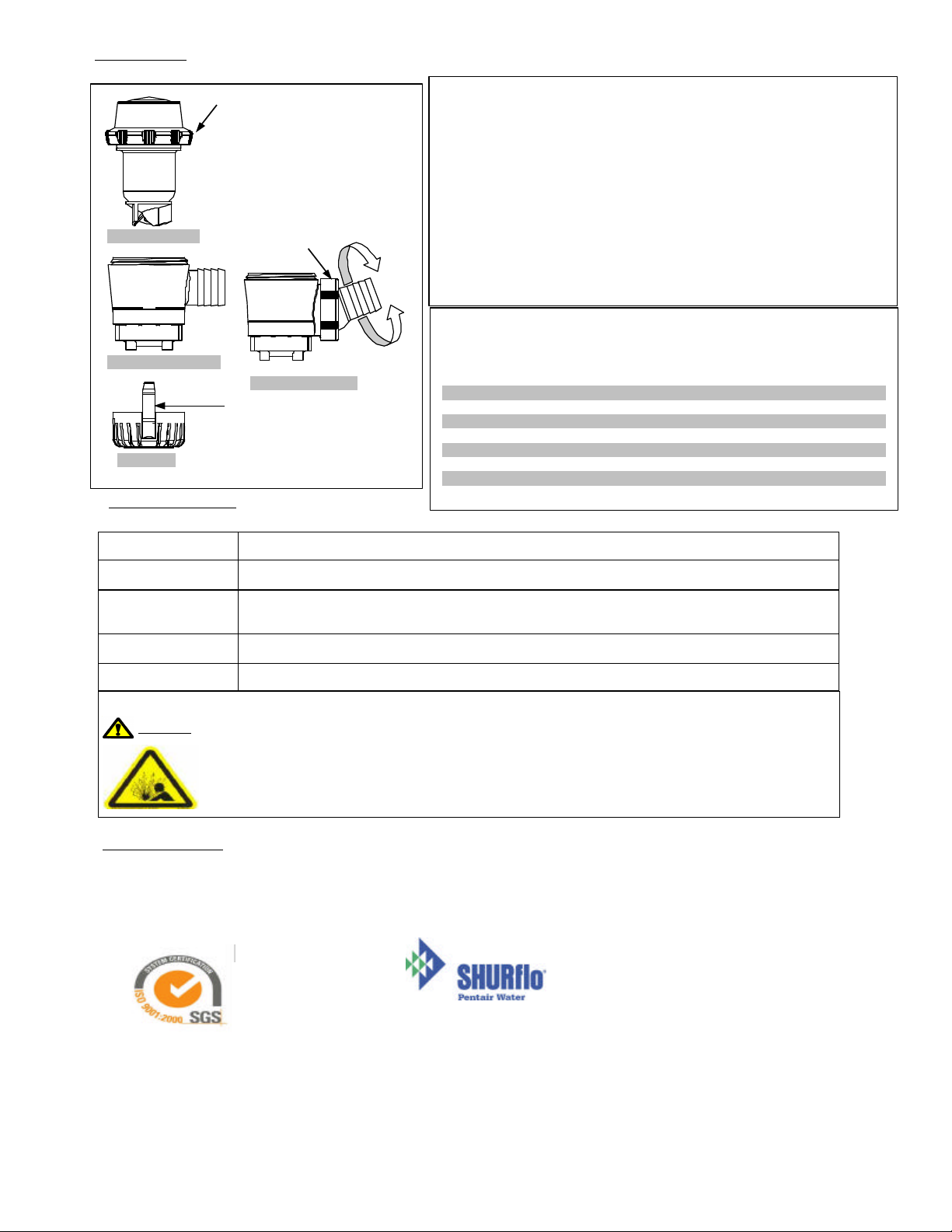

collar nut. Clean debris, press motor cartridge firmly into housing

n power on to pump switch. Use a quarter or flat

head screwdriver wire to lift float, wait 2 seconds, and pump turns

Knuckle Housing

nut.

MAINTENANCE

Knuckle swivels

hook-up

Motor Cartridge

Blue Motor Cartridge Collar Nut

unscrews ccw for easy impeller

cleaning and cartridge change.

May need a wrench to loosen

Knuckle Housing

Blue Collar Nut

to allow easy

CLEANING Impeller: Snap pump out of baseplate by pressing in on tabs.

Clean debris and snap back in place. Test.

Motor Cartridge: Remove motor cartridge by unscrewing blue

and tighten blue collar nut. (torque to 60-70 in lbs). Test pump.

Switch: Remove switch by snapping motor cartridge out of

baseplate and lifting switch out of baseplate. Remove debris or

build-up. SWITCH DOES NOT COME APART. Reinstall switch

and test.

Switch Test: Tur

WIRING Check all wire connections regularly. Repair signs of corrosion.

AFTERMARKET Please have pump model number and manufacture date of

PARTS KITS pump available when contacting SHURflo.

Fixed Port Housing

Baseplate tabs press in for

easy removal

Baseplate

TROUBLESHOOTING

Symptoms Check For

No water pumped

Pump not running

Reduced water flow

Runs continuously Check boat for leaks; Clean accumulated debris from float mechanism.

Low flow Polarity reversed [ on pump only ]; check wiring. Use smooth bore (I.D.) discharge tubing only.

WARNING

Reset pump switch. Blown fuse. Reversed polarity damaged switch board.

Wire connections. Impeller or float switch plugged with debris.

Impeller/screen plugged with debris. Pinched/clogged discharge tubing. Discharge tubing sagging below

pump causing air lock (trap). Tubing MUST go "UP" from pump to through hull fitting. Low voltage to pump;

check. Battery/wire connections.

Is through hull fitting I.D. smaller than pump discharge port?

Do not pump oil, diesel fuel, gasoline or other flammable liquids with this pump.

This pump does not prevent the discharge of oil or other chemicals into the water. Please take appropriate

measures to prevent discharging oil or other chemicals and safeguard the environment. Always disconnect

power before servicing pump. Always use fuse size specified in specifications. These bilge pumps are designed

to evacuate standing bilge water only. These pumps may not prevent boat sinkage due to storms, rough

weather, unsafe boating, improper installation procedures or hull damage.

380 / 450 94-005-00 94-007-00

500 / 600 94-005-00 94-007-00

700 / 800 94-006-00 94-007-00

1000 94-006-00 94-007-00

ALL PUMPS Switch Kit # 359-011-00

on. Lower float and pump turns off after 10 seconds.

Pump Model Motor Cartridge Baseplate

LIMITED WARRANTY

SHURflo warrants its Piranha™ series bilge pumps to be free of defects in material and workmanship

under normal use for a period of three (3) years from the date of manufacture, as indicated on the pump

label. Returns are to be shipped prepaid to SHURflo. This warranty is only a representation of the

complete marine products limited warranty, outlined by Service Bulletin #1050. Call or write for a copy.

«ISO Certified Facility SHURflo reserves the right to update specifications,

SHURflo *

5900 Katella Ave.

Cypress, CA 90630

(562) 795-5200 (800) 854-3218

FAX (562) 795-7564

Shipping: 5900C Katella Ave.

Cypress, CA 90630

911-593-C Page 1 of 2

SHURflo East

52748 Park Six Court

Elkhart, IN 46514-5427

(574) 262-0478 (800) 762-8094

FAX (574) 264-2169

http://www.shurflo.com

© 2002 All Rights Reserved

SHURflo Ltd. *

Unit 5 Sterling Park

Gatwick Road, Crawley

West Sussex, RH10 2QT

United Kingdom

+44 1293 424000

FAX +44 1293 421880

Loading...

Loading...