222

HARTREY AVE.. EVANSTON,

IL.

60204

U.S.A.

DATA

AREA

CODE

TWX:

312/866-2200

910-231.0048

.

CABLE:

SHUREMICRO

TELEX:

72-4381

OPERATION AND SERVICE INSTRUCTIONS

SHEET

I

MODEL SR112B AND SR116B

SPEAKER SYSTEMS

I

MODEL SR112B SPEAKER SYSTEM

FIGURE

1

DESCRIPTION

The Shure Model SR112B and SR116B Speaker Systems are compact, rugged, heavy-duty, two-way units.

They are designed for use with Shure Model

similar high-power amplifiers in studio monitor, night

club or other applications requiring a small, wide range

speaker system. When properly installed and connected,

SR112B and SR116B will provide outstanding per-

the

formance in critical applications due to their wide frequency response, low distortion, and smooth dispersion

characteristics. The Speakers have a nominal impedance

of 8 ohms and are designed to operate with amplifiers

capable of delivering up to 100 watts to an 8-ohm load.

They can be used either direct-coupled or with a constant-voltage 25-volt line, or 70-volt line using a Shure

A1 02A Transformer.

Quality sound reproduction is achieved through the use

of two 8-inch heavy-duty speakers and a high-frequency

driver coupled to a 120" radial horn. The front-ported

bass reflex design of the enclosure provides

cy enhancement. A built-in series-type passive crossover

network provides 6 dB per octave

frequency speakers and 18 dB per octave rolloff for the

high-frequency driver. A four-position attenuator switch

allows high-frequency level adjustments of -4, -2,

and

+2

dB.

The SR112B (see Figure 1) is a weather-resistant unit,

and is designed for permanent installation either indoors

or in a protected outdoor environment such as under the

roof of an open pavilion. Adhesives used in the

are moisture-resistant, and trim and fastening hardware

have a high corrosion resistance.

SR116B is a portable unit (see Figure 2), and is de-

The

signed for temporary installation either indoors or in a

rolloff for the low-

SR105 or

low-frequen-

SR112B

MODEL SR116B SPEAKER SYSTEM

FIGURE

protected outdoor environment. The SR116B is supplied

with a 15m (50 ft), 18-gauge, rubber-jacketed connecting

cable with locking phone plugs, and a black vinyl grille

cover. The corners of the

protectors. A retractile handle and balanced design

contribute to ease of transporting.

and covered in black, scuff-resistant, textured vinyl. The

attractive black sculptured fabric grille is rugged, cleanable, and replaceable if damaged. The radial horn and

baffle board assembly is ruggedly constructed of

resistant thermoplastic resin. Molded feet protect surfaces and permit stacking.

their own feet, or in a tilted position using an appropriate

support. The Shure

Wall Mount Swivel Bracket provide for tilting on a horizontal surface or wall or ceiling mounting. A slip-on

protective cover (Model

units are constructed of 15.9 mm

Both

SR112B and SR116B may be operated vertically on

The

A112A Tilt Bracket and the A112D

A112C) is also available.

2

SR116B are equipped with steel

(5h

in.) wood,

SPECIFICATIONS

.

. . .

.

.

.

. .

Power Rating

0

Power Load for

Constant-Voltage

Operation

Impedance

Frequency Response . .45

Crossover Frequency

High-Frequency

Attenuator

. .

.

.

. . .

.

. .

. .

. .

Maximum recommended ampli-

fier output to 8 ohms: 100

Watts continuous, 28 Vrms,

48V peak

.

. . .

.78 watts (25-volt input, 8 ohms)

.

. . .

.

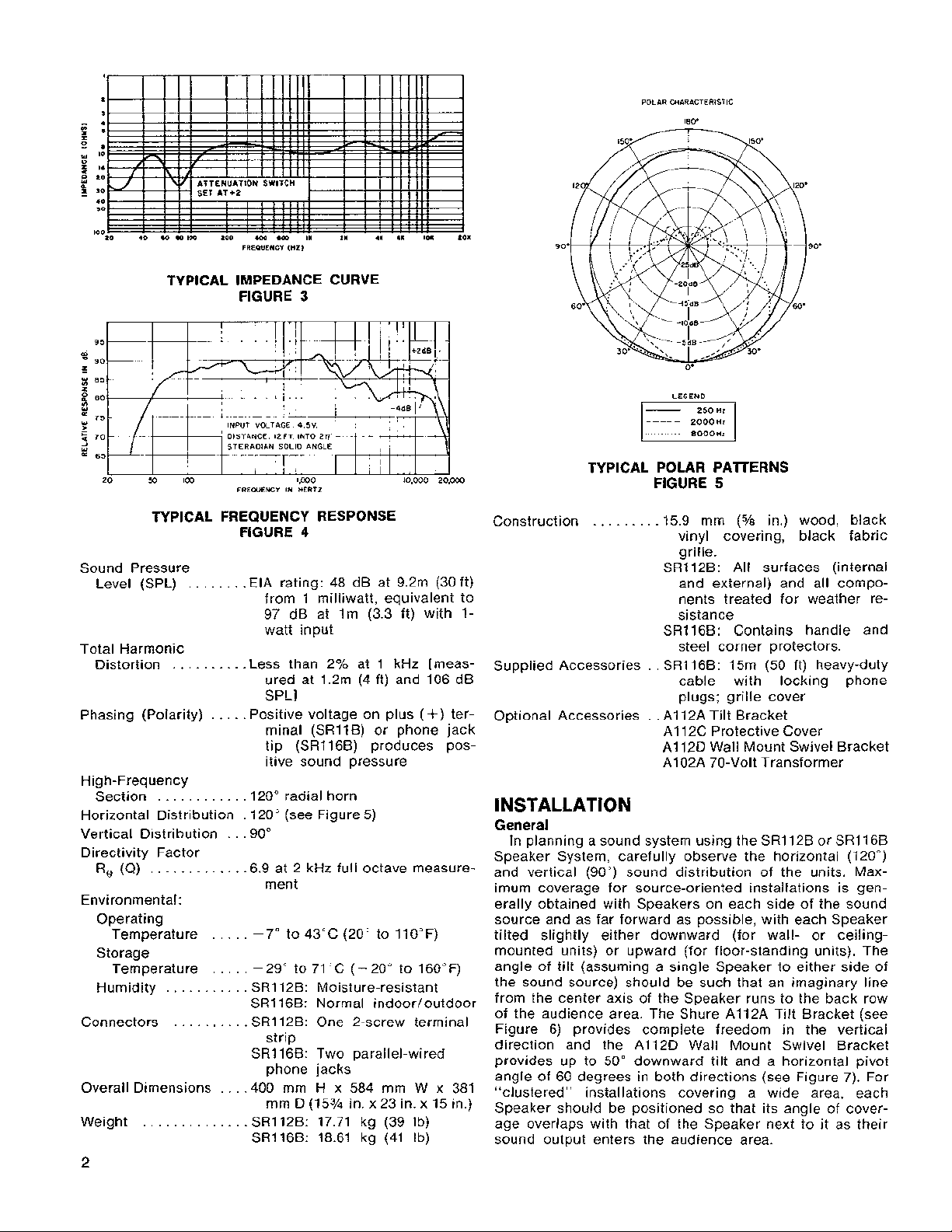

.8 ohms nominal (see Figure

Hz

-

.

,2600 Hz; high frequency: 18 dB/

. .

. .

.2 dB steps (+2 to - 4)

16 kHz (see Figure 4)

octave

6

rolloff; low frequency:

dB/octave rolloff

shock-

3)

Copyright

27Al631

1980.

(TG)

Shure Brothers

inc.

Printed

in

U.S.A.

m

-

Z

-

z

g

=

>

5

.""

95

90

a5

80

75

70

65

20

POLAR CHARACTERISTIC

18V

I

I

1

11

400

1111

.00

In21

1 I 1

11

Zl

4

11

1111

S

101

101

ATTENUATION SWITCH

10

40 60

W

100

ZOO

FREQUENCY

TYPICAL IMPEDANCE CURVE

FIGURE

M

100

FREWENCY IN HERTZ

3

lW0 10,000 20,000

LEGEND

-----

2000

HZ

TYPICAL POLAR PATERNS

FIGURE

5

TYPICAL FREQUENCY RESPONSE

FIGURE

4

Sound Pressure

Level (SPL) EIA rating: 48 dB at 9.2m (30 ft)

........

from 1

milliwatt, equivalent to

97 dB at lm (3.3 ft) with 1watt input

Total Harmonic

Distortion

..........

Less than 2% at 1 kHz [meas-

ured at 1.2m (4 ft) and 106 dB

SPLI

Phasing (Polarity)

Positive voltage on plus

.....

(+)

minal (SR11B) or phone jack

tip (SRll6B) produces pos-

itive sound pressure

High-Frequency

Section .120° radial horn

Horizontal Distribution

Vertical Distribution

...........

...

.

120" (see Figure 5)

90"

Directivity Factor

R,

(Q)

............

.6.9 at 2 kHz full octave measure-

ment

Environmental:

Operating

.....

-

Temperature

7" to 43°C (20" to 110°F)

Storage

Temperature

Humidity

.....

...........

-

29" to 71 "C (-20" to 160°F)

SR112B: Moisture-resistant

SR116B: Normal indoor/outdoor

Connectors

..........

SR112B: One 2-screw terminal

strip

SR116B: Two parallel-wired

phone jacks

Overall Dimensions

...

,400 mm H x 584 mm W x 381

mm D (15% in. x 23 in. x 15 in.)

Weight

..............

SR112B: 17.71 kg (39 Ib)

SR116B: 18.61 kg (41 Ib)

Construction 15.9 mm

.........

(%

in.) wood, black

vinyl covering, black fabric

grille.

SR112B: All surfaces (internal

and external) and all components treated for weather resistance

SR116B: Contains handle and

steel corner protectors.

.

.

Supplied Accessories

SR116B: 15m (50 ft) heavy-duty

cable with locking phone

plugs; grille cover

ter-

Optional Accessories

.

.

A1 12A Tilt Bracket

A1 12C Protective Cover

A1 12D Wall Mount Swivel Bracket

A102A 70-Volt Transformer

INSTALLATION

General

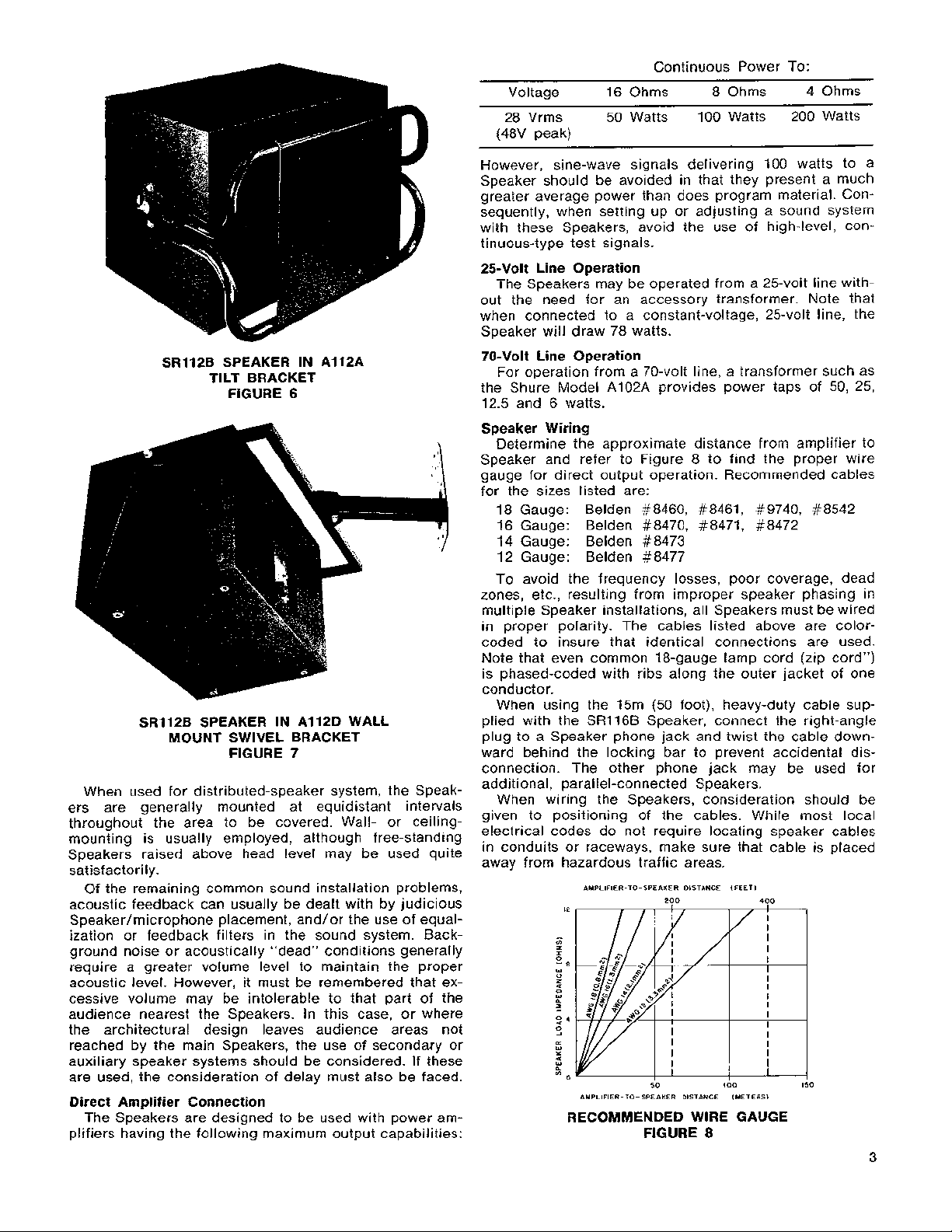

In planning a sound system using the SR112B or SR116B

Speaker System, carefully observe the horizontal (120")

and vertical (90") sound distribution of the units. Maximum coverage for source-oriented installations is generally obtained with Speakers on each side of the sound

source and as far forward as possible, with each Speaker

tilted slightly either downward (for wall- or

mounted units) or upward (for floor-standing units). The

angle of tilt (assuming a single Speaker to either side of

the sound source) should be such that an imaginary line

from the center axis of the Speaker runs to the back row

of the audience area. The Shure

Figure 6) provides complete freedom in the vertical

direction and the

provides up to

A112D Wall Mount Swivel Bracket

50" downward tilt and a horizontal pivot

angle of 60 degrees in both directions (see Figure 7). For

"clustered" installations covering a wide area, each

Speaker should be positioned so that its angle of cover-

age overlaps with that of the Speaker next to it as their

sound output enters the audience area.

A112A Tilt Bracket (see

ceiling-

SRl12B SPEAKER IN A112A

BRACKET

TILT

FIGURE

6

SRl12B SPEAKER IN A112D WALL

MOUNT SWIVEL BRACKET

FIGURE 7

When used for distributed-speaker system, the Speakers are generally mounted at equidistant intervals

throughout the area to be covered. Wall- or ceilingmounting is usually employed, although free-standing

Speakers raised above head level may be used quite

satisfactorily.

Of the remaining common sound installation problems,

acoustic feedback can usually be dealt with by judicious

Speakerlmicrophone placement, and/or the use of equalization or feedback filters in the sound system. Background noise or acoustically "dead" conditions generally

require a greater volume level to maintain the proper

acoustic level. However, it must be remembered that ex-

cessive volume may be intolerable to that part of the

audience nearest the Speakers. In this case, or where

the architectural design leaves audience areas not

reached by the main Speakers, the use of secondary or

auxiliary speaker systems should be considered. If these

are used, the consideration of delay must also be faced.

Direct Amplifier Connection

The Speakers are designed to be used with power am-

plifiers having the following maximum output capabilities:

Continuous Power To:

Voltage 16 Ohms 8 Ohms 4 Ohms

28

Vrms 50 Watts 100 Watts 200 Watts

(48V peak)

However, sine-wave signals delivering 100 watts to a

Speaker should be avoided in that they present a much

greater average power than does program material. Con-

sequently, when setting up or adjusting a sound system

with these Speakers, avoid the use of high-level, continuous-type test signals.

25-Volt Line Operation

The Speakers may be operated from a 25-volt line without the need for an accessory transformer. Note that

when connected to a constant-voltage, 25-volt line, the

Speaker will draw 78 watts.

70-Volt Line Operation

For operation from a 70-volt line, a transformer such as

the Shure Model A102A provides power taps of 50, 25,

12.5 and 6 watts.

Speaker Wiring

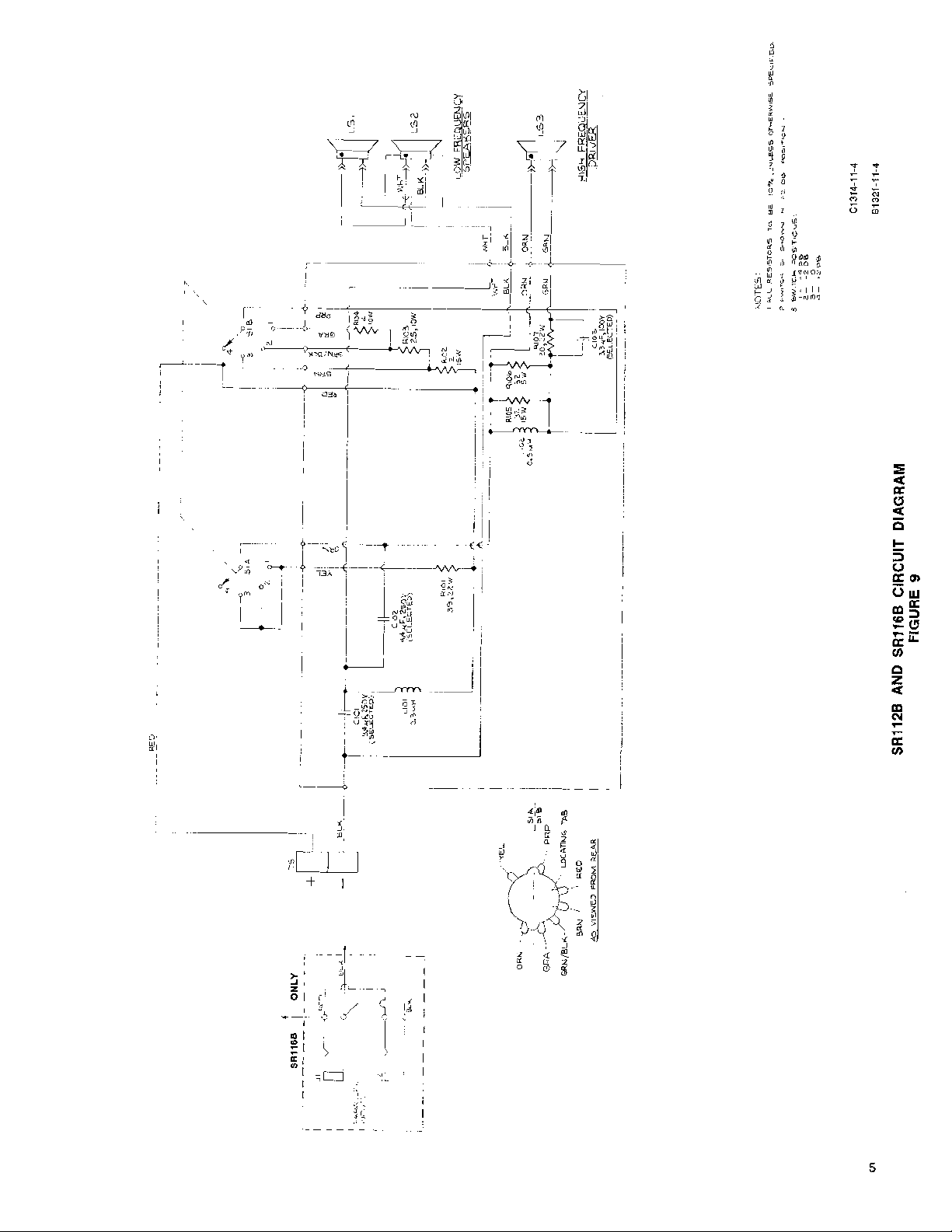

Determine the approximate distance from amplifier to

Speaker and

refer to Figure 8 to find the proper wire

gauge for direct output operation. Recommended cables

for the sizes listed are:

18 Gauge:

Belden #8460, #8461, #9740, #8542

16 Gauge: Belden #8470, #8471, #8472

14 Gauge: Belden #8473

12 Gauge: Belden #8477

To avoid the frequency losses, poor coverage, dead

zones, etc., resulting from improper speaker phasing in

multiple Speaker installations, all Speakers must be wired

in proper polarity. The cables listed above are

colorcoded to insure that identical connections are used.

Note that even common 18-gauge lamp cord (zip cord")

is phased-coded with ribs along the outer jacket of one

conductor.

When using the 15m (50 foot), heavy-duty cable sup-

plied with the

SRl16B Speaker, connect the right-angle

plug to a Speaker phone jack and twist the cable down-

ward behind the locking bar to prevent accidental dis-

connection. The other phone jack may be used for

additional, parallel-connected Speakers.

When wiring the Speakers, consideration should be

given to positioning of the cables. While most local

electrical codes do not require locating speaker cables

in conduits or raceways, make sure that cable is placed

away from hazardous traffic areas.

AMPLIFIER-TO-SPEAKER DISTANCE (FEET)

AMPLIFIER-TO-SPEAKER DISTANCE IMETERSl

200 400

50 100 150

RECOMMENDED WIRE GAUGE

FIGURE

8

Installation

The

SRll2B and SR116B may be operated free-standing,

either on their own feet or on a Shure

or suspended on a wall or ceiling using an

A112D Wall Mount Swivel Bracket. In positioning the

Speakers for optimum sound coverage, care must be

taken to locate the Speakers away from areas where

they may interfere with the movement of performers,

audience, curtains or stage sets.

If the Speaker is to be used at low power on a constant-voltage, 70-volt system, a Shure Model

70-Volt Transformer must be connected between the am-

plifier and Speaker. The transformer should be located as

close to the Speaker as possible; therefore the optimum

mounting location just above the connector panel should

be used. Mounting of the transformer adds approximately

82 mm

Checking Sound Coverage

have been installed and connected, apply a fairly constant level signal to the system (preferably program

material) and walk around the audience area. Listen for

a smooth, even output from the Speakers, with minimal

differences in volume and tone, and no distortion or

"dead spots." A dead spot-for audio purposes, an

audience area where no sound is heard, or where the

sound level is appreciably lower-may mean that the

Speakers are not covering that area, or that the speaker

wires are connected out-of-phase. Proper phasing may be

readily determined by checking the connections on each

Speaker, but inadequate coverage generally requires repositioning the Speakers. The dead area should be carefully examined to determine that the problem can be

corrected without resorting to auxiliary speakers.

(3Y4 in.) to the total depth of the Speaker.

When the Speakers, amplifier and other equipment

A112A Tilt Bracket,

A112A or an

A102A

SERVICE INSTRUCTIONS

Speaker Servicing

1. Disconnect speaker cables from phone jacks or

terminal strip.

2. Using an ohmmeter, measure the resistance be-

(+)

tween the plus

or tip and sleeve of phone jack. The dc resistance

should be

3. To gain access to the individual speakers, remove

the grille by pulling the two cloth tabs at the bottom of the grille. Remove the screws securing the

horn/baffle board assembly. Remove the horn/

baffle board assembly, taking care not to stress

the wiring.

4.

Using an ohmmeter, measure the resistance of each

speaker voice coil. A clicking sound will be made

by a "good" speaker when an ohmmeter is connected or disconnected. Note that the resistance of

each 8-inch speaker cannot be measured without

disconnecting one lead connecting the two speakers. Each 8-inch speaker should measure between

11 and 13 ohms. With its leads disconnected, the

high-frequency driver should measure between 6.7

and 7.7 ohms.

5.

If the above tests do not locate the problem unit,

apply a small ac voltage from an oscillator and amplifier to each speaker individually (approximately

4V,

mately 2V, 3 kHz to

speakers).

5.5

50 Hz to 5 kHz for 8-inch speakers; approxi-

and minus

to 7 ohms.

15

(-)

terminal screws

kHz for high-frequency

WARNING

Sound pressure levels generated by this test may

be damaging to your hearing. Aim speakers away

from listeners and toward sound-absorbent material

(curtains, blanket, etc.). Carefully adjust test signal

amplitude to avoid unnecessarily high sound pressure levels for prolonged periods.

As the test signal frequency is varied, any erratic

buzzes or rattles indicate possible failure.

6. Reconnect, replace and tighten the 8-inch speakers. Reconnect the high-frequency driver and replace the

hardware to avoid rattles.

High-Frequency Driver Replacement

To replace the high-frequency driver, follow these steps:

1. Remove grille assembly and

described in Speaker Servicing.

2. Remove leads from driver terminals. Note color

coding of speaker wires.

3. For earlier production units, remove three 6-32 x

1

Ye

horn/baffle board. For later production units, re-

move two 10-16 x 1 in. screws holding driver

mounting plate to

mounting plate and driver from

4.

Replace driver diaphragm and voice coil assembly

as described in High-Frequency Diaphragm and

Coil Replacement instruction sheet.

5.

For earlier production units, carefully place repaired

or new high-frequency driver in position over

baffle/board,

over holes in

terminals are positioned downward (toward

frequency speakers). Replace three 6-32 x 1% in.

screws, and tighten high-frequency driver assembly.

6. For later production units, carefully place repaired

or new high-frequency driver in position over horn/

baffle board with driver terminals downward (toward

low-frequency speakers). Position driver mounting

plate over driver, lining up holes in mounting plate

over threaded holes in

two 10-16

7. Replace removed driver leads. Note polarity marking on driver.

~ssemble horn/baffle board and grille to enclo-

8.

?

Nameplate

Should it become necessary to replace or re-fasten the

front-panel nameplate, be sure to use a heavy-duty

weather-resistant adhesive.

equivalent cement is recommended.

ACCESSORIES

The following optional accessories are available for use

SR112B and SRl16B Speakers:

with

A112A Tilt Bracket permits 360" rotation of the Speaker

about a horizontal axis. Heavy-duty tubular steel with a

flat steel baseplate that provides stable floor or shelf for

horn/baffle board and grille. Tighten all

horn/baffle board as

in. screws securing high-frequency driver to

horn/baffle board. Remove driver

horn/baffle board.

horn/

taking care to line up holes in driver

horn/baffle board. Be sure that driver

low-

horn/baffle board. Replace

x

1 in. screws, and tighten securely.

and fasten securely to avoid rattles.

Goodyear PLIOBOND or

portable positioning in stage monitor use, or wall or ceiling mounting for permanent installations.

A112D Wall Mount Swivel Bracket provides up to 50"

of downward tilt, and up to f 60" of horizontal rotation

when mounted on a vertical surface.

A112C Slip-On Cover is a heavy vinyl cover that pro-

vides protection for the Speaker. Has a handle cut-out

for the

50, 25, 12, and 6 watts for 70-volt distributed systems, and

impedance taps of 8 to 16 ohms. Mounts easily to the

back of a speaker or convenient surface.

GUARANTEE

free from electrical and mechanical defects for a period

of one year from date of purchase. Please retain proof of

purchase date. This guarantee includes all parts and

labor. This guarantee is in lieu of any and all other guar-

antees or warranties, express or implied, and there shall

be no recovery for any consequential or incidental

damages.

SHIPPING INSTRUCTIONS

If outside the United States, return the unit to your

dealer or Authorized Shure Service Center for repair.

The unit will be returned to you prepaid.

SRl16B Speaker.

A102A 70-Volt Transformer provides wattage taps of

This Shure product is guaranteed in normal use to be

Carefully repack the unit and return it prepaid to:

Shure Brothers Incorporated

Attention: Service Department

1501 West Shure Drive

Arlington Heights, Illinois 60004

ARCHITECTS' AND ENGINEERS'

SPECIFICATIONS

SR112B Speaker

The Speaker shall be a speaker designed for indoor or

outdoor use in sound reinforcement or studio monitor ap-

plications. The Speaker shall utilize two

speakers and one high-frequency driver. The Speaker

shall have an EIA sensitivity rating of

(30 feet) from 1 milliwatt (equivalent to 97 dB at lm-

3.3 feet-with a 1-watt input).

The sound pressure distribution shall be nominally uni-

form over a 120" angle in the horizontal plane and a

angle in the vertical plane.

The usable frequency response of the Speaker shall be

uniform and peak-free from 45 Hz to 16,000 Hz.

Nominal impedance of the Speaker shall be 8 ohms

and it shall be designed to operate with amplifiers delivering up to 100 watts to an

The speakers shall be wired with a 2600 Hz crossover

network in a series-parallel configuration and connected

to a two-terminal barrier terminal strip.

&ohm load.

&inch cone-type

48

dB at 9.2m

90"

(Ti

(Ye

in.) wood

(15% in.

Ib.).

in.) wood

Ib.).

The speaker enclosure shall be 15.9 mm

construction covered with black, scuff-resistant vinyl and

a removable, sculpture fabric grille. Molded feet protect surfaces and permit stacking. All surfaces (internal and external) and all components shall be treated for

weather resistance. The Speaker shall measure 400 mm in

height, 584 mm in width, and 381

x 23 in. x 15 in.). The weight shall be 16.75 kg (37

The operating temperature range of the Speaker shall be

-7°C to 43°C (20°F to 110°F). The storage temperature

range shall be -29°C to 71°C (-20°F to 160°F). The

Speaker shall meet all specifications when operating

within the operating temperature limits.

Any Speaker not meeting all the above specifications,

or having a sealed cabinet which prevents internal inspection and servicing, shall be deemed unacceptable

under this specification. The Speaker shall be a Shure

Model

SR116B

sound reinforcement or studio monitor applications. The

Speaker shall utilize two 8-inch cone-type speakers and

one high-frequency driver. The Speaker shall have an

EIA sensitivity rating of 48 dB at 9.2m (30 feet) from 1

milliwatt (equivalent to 97 dB at lm-3.3 feet-with

1-watt input).

uniform over a 120" angle in the horizontal plane and 90"

angle in the vertical plane.

uniform and peak-free from 45 Hz to 16,000 Hz.

it shall be designed to operate with amplifiers delivering

up to 100 watts to an 8-ohm load.

network in a series-parallel configuration and connected

to two phone jacks.

construction covered with black, scuff-resistant vinyl

and a removable, sculptured fabric grille. Molded feet

protect surfaces and permit stacking. The enclosure

shall have a retractile handle for portability. A plug-in 15m

(50 ft) speaker cable shall be supplied. The Speaker shall

measure 400 mm in height, 584 mm in width, and 381 mm

in depth (15% in. x 23 in. x 15 in.). The weight, less

supplied cable and grille cover, shall be 17.21 kg (38

-7°C to 43°C (20°F to 110°F). The storage temperature

range shall be -29°C to 71°C (-20°F to 160°F). The

Speaker shall meet all specifications when operated within the operating temperature limits.

tions, or having a sealed cabinet which prevents internal

inspection and servicing, shall be deemed unacceptable

under this specification. The Speaker shall be a Shure

Model

SR112B.

Speaker

The Speaker shall be a portable speaker designed for

The sound pressure distribution shall be nominally

The usable frequency response of the Speaker shall be

Nominal impedance of the Speaker shall be 8 ohms and

The speakers shall be wired with a 2600 Hz crossover

The speaker enclosure shall be 15.9 mm

The operating temperature range of the Speaker shall be

Any Speaker not meeting all of the above specifica-

SR116B.

mm in depth

a

REPLACEMENT PARTS LIST

(see

Figure

10)

Reference

Designation

A1

A2

C101

C102

C103

J1, J2

Ll 01

L102

LSI, LS2

LS3

MPI

MPI

M P2

M P2

M P3

M P4

P5

M

MP6

M P6

MP7

M P8

P9

M

MPlO

MP11

MP12

MP13

MP14

Replacement

Kit No.*

-

RKC153**

RKC156*

*

-

-

-

-

-

-

RKC162

-

-

-

-

-

RKC39

-

7

-

RKCI 59

-

-

-

-

-

-

-

RKCl61

-

Qty.

-

1

1

-

-

-

-

-

-

-

-

-

-

-

-

4

-

-

-

1

-

-

-

-

-

-

-

-

1

-

Part No.

90A2752

80231 6

80Y316

50F71

50E71

50G71

90BA2600

95A823

95A647

80A346

80A316*

80B316**

80C316*

60A73

60B73

65A1001

66A158

65A1338A

39A438

90B2756

53A1559

53A1576

90BC2600

53A1656B

30A1002B

30H903C

30A882B

30A1087A

95A888

53A1775

A

Replacement Kit Consists Of:

Description

Crossover Network Assembly (with Switch)

High-Frequency Diaphragm and Coil

Capacitor, Mylar, 9.4

Capacitor, Mylar, 4.4 pF, lo%, 250 WVdc *

Capacitor, Mylar, 3.3 pF, lo%, 100 WVdc *

Connector, Phone Jack, 2-Conductor, Open

Circuit (SRI

Inductor, 0.3

Inductor, 0.5 mH

8-inch Loudspeaker

*

*

High-Frequency Driver (see A2 for

replacement diaphragm and coil assembly)

SRI12B Speaker Enclosure Assembly (including Fiber Glass; without Speakers, Crossover

Network,

sembly, Nameplate)

SR116B Speaker Enclosure Assembly (includ-

ing Fiber Glass, Handle, Corner Protectors;

without Speakers, Crossover Network,

Baffle Board, Feet, Grille Assembly, Name-

plate)

Foot, Plastic

Foot, Rubber

HornIBaffle Board

Nameplate

Grille Assembly

Connector Plate (without Connectors)

Connector Plate (without Connectors) (SR116B)

Retractile Handle Assembly (SR116B only)

Corner Protector (SRI

Carriage Bolt, Aluminum, 2" (Crossover

Network)

Phillips Round Head Machine Screw,

3hn

(Feet)

Phillips Flat Head Wood Screw, #6,

1%'' (HornIBaffle Board)

Oval Head Steel Drive Screw, #6,

%

"

(Corner Protectors) (SR116B only)

Grille Cover

Driver Mounting Plate

I6B only)

mH

HornIBaffle Board, Feet, Grille As-

(SR116B only)

pF, lo%, 250 WVdc * * *

16B only)

* *

*

*

Horn/

(SRI 128)

#lo-32,

*

Parts listed as RKC Kits should be ordered by that kit number. Any orders received for piece parts where RKC Kit number

is shown will be shipped in RKC quantities.

**

Replacement diaphragm and coil assemblies

RKC156. Inspect driver for part number.

* * *

Selected for low dissipation factor.

not

interchangeable: 80A316 driver uses RKC153; 80B316 and 806316 use

7

REPLACEMENT PARTS LIST

(see

Figure

10)

Reference

Designation

MP15

R101

R102

R103

R104

R105, R106

R107

S 1

TSl

W1

*

Parts listed

shown will be shipped in RKC quantities.

as

RKC Kits should be ordered by that kit number. Any orders received for piece parts where RKC Kit number is

Replacement

Kit No.*

-

-

-

-

-

-

-

-

-

RKC4

Qty.

-

-

-

-

-

-

-

-

-

1

Part No.

30F1154A

45EC390G

45HC208E

45HC258D

45HC408D

45HC320F

45EC200G

55A125

56A211

90C1373

Replacement Kit Consists Of:

Description

Phillips Pan Head Thread-Forming Screw,

#lo-16, 1" (Driver)

Resistor, Wirewound, 39 ohms,

Resistor, Wirewound, 2 ohms,

Resistor, Wirewound, 2.5 ohms,

Resistor, Wirewound, 4 ohms,

Resistor, Wirewound, 32 ohms,

Resistor, Wirewound, 20 ohms,

Switch, Rotary, 2-Pole, 4-Position

Terminal Strip, 2-Screw

15m (50 ft) Cable Assembly with Male Phone

(SRI16B only)

Plugs

(SRl12B only)

22W, 10%

15W, 10%

10W, 10%

low, 10%

15W, 10%

22W, 10%

NOTE : SR112B SHOWN : SRIIGB PARTS DESCRIBED

IN REPLACEMENT PARTS LIST

EXPLODED VIEW

FIGURE

10

Loading...

Loading...