Page 1

The

meticulously optimized design of the SM91A in

cludes

a unique cartridge, developed at Shure. The re

is high sensitivity

sult

, exceptionally accurate sound re

production over the entire audio frequency range, and

freedom from of

f-axis coloration comparable to the fin

est unidirectional microphones.

The furnished ILP-1 preamplifier is a high-clipping

low-noise unit, phantom powered by 1

level

It

has selectable gain of 0 or +10 dB, and switchable low-

1 to 52

Vdc.

frequency response, flat or low cut (rolled off at 12 dB/

octave). The low cut is particularly useful to minimize

of ambient low-frequency noise from sources like

pickup

heating

or air-conditioner fans, for instance.

The SM91A consists of a small, rugged, surfacemounted microphone finished in professional durable

matte-black

enamel, a 7.6 m (25 ft) small diameter twoconductor shielded interconnecting cable with two

3-socket miniature Switchcraft connectors; and the

preamplifier

ILP-1

audio connector output.

sional

assembly with standard 3-pin profes

Features:

-

-

-

-

-

GENERAL

The

SM91A Microphone is

surface-mounted

applications. It is a professional-qual

designed specifically for

ity permanently-biased condenser microphone with a

half-cardioid

above

The SM91

pickup pattern (cardioid

the mounting surface.)

A t

ake

s a

dvantag

in the hemisphere

e of the w

ell-know

n p

rinciple that, at a barrier or boundary, sound pressure doubles

compared to its value if the boundary is removed. When

s

placed

ufficientl

y near the b

oundar

y s

urface

, a m

icrophone

has effectively 6 dB higher sensitivity and approximately 3

dB

g

reater rejectio

n o

f rando

m b

ackgroun

d n

oise.

Because of its half-cardioid polar pattern, the

SM91A surface-mounted microphone discriminates

against sounds originating from the rear, suiting the

SM91A

for conditions where an omnidirectional pattern

makes other surface-mounted microphones impractical.

The intrinsic unidirectionality of the SM91A can be

a

great benefit when it is desirable to isolate a particular

vocalist, instrument, or group from the rest of an ensemble being recorded. Because of a cardioid pickup

pattern, no physically isolating barriers are required,

and

directionality is maintained to low frequencies.

The SM91A can be used for individual instrument

pickup,

e.g., mounted inside the lid of a grand piano or

on the floor next to a bass drum. Experimental placement

and critical listening will help to determine the best

location

for any particular purpose or ef

fect desired.

• Wide flat frequency response for faithful sound reproduction

•

High sensitivity

across the audio spectrum

, low self-noise

-

• V

ery low distortion and high output clipping level

• Half-cardioid polar pattern minimizes pickup from

rear of microphone, permits aiming microphone,

toward performers and away from audience, or

e.g.,

toward

singers and away from instruments

•

Low susceptibility to RFI,

electrostatic and electro

magnetic hum

• Extremely

and

• Switch-selectable

off

permits tailoring response to suit conditions

•

Switch selectable preamp gain of 0 or +10 dB

• Accepts phanto

of

wide v

• Standard

preamp

rugged construction of both microphone

preamplifier for outstanding reliability

12 dB/octave low-frequency

m p

owe

r o

f 11 t

o 5

2 Vdc, p

ariet

y o

f a

mplifier

s o

r phanto

m s

3-pin male XLR-type output connector on

can

be directly connected to any 3-pin fe

male XLR-type phantom-powered input

• Low profile and matte black finish for unobtrusive

appearance on-camera or onstage; on floor,

ceiling, wall, or lectern

• Usable over very wide range of temperature and hu midity

ermit

upplies

table,

cut

s u

-

-

se

-

Copyright 1993, Shure Brothers Inc.

27A2669(MC)

Printed in U.S.A.

Page 2

SPECIFICATIONS

Type

d c

Cardioi

ondenser (electre

t b

ias) for surfac

e m

ounting

Frequency Response

20 to 20,000 Hz (see Figure 1)

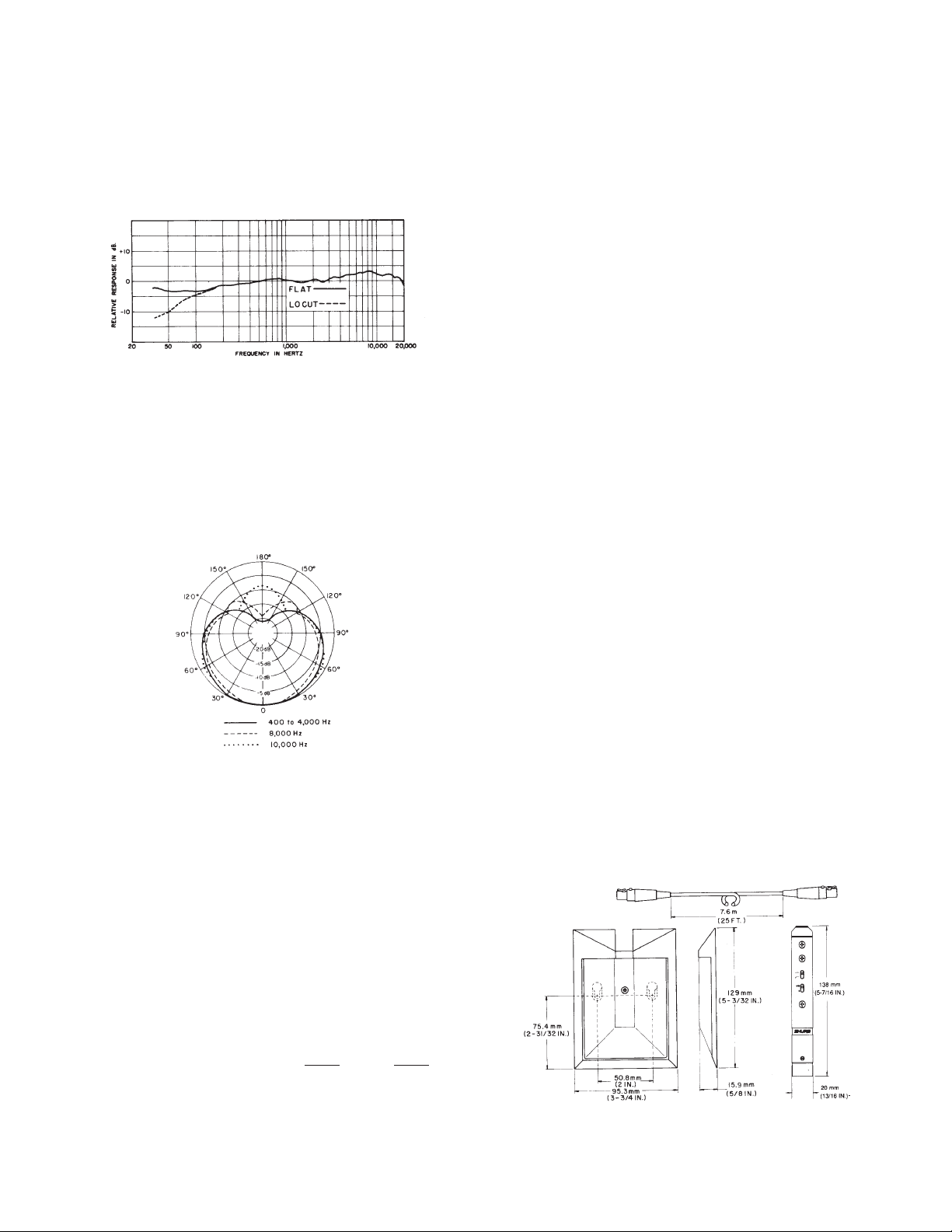

TYPICAL FREQUENCY RESPONSE

(measured at 30o incidence to infinite surface)

FIGURE 1

Polar Pattern

Half-cardioid

(cardioid in

hemisphere above mounting

surface), uniform with frequency, symmetrical about

axis (see Figure 2)

TYPICAL POLAR P

ATTERN

FIGURE 2

Output Impedance

Rated at 150

Recommended minimum load impedance: 800

(May

be used with loads as low as 150 Ω with reduced

clipping

Output

at

Level

30o incidence to flat surface)

Open Circuit V

0

dB = 1 V

Ω (90 Ω

actual)

level)

(at 1,000 Hz, measured

oltage

.

. . . . . . . .

/µbar

Ω

with sound source

–71.5 dB (0.27 mV)

Preamplifier Output Clipping Level (at 1,000 Hz, less

than

0.1% THD)

GAIN

800 Ω load

150 Ω load

.

. . . . . . . . . . . . . .

.

. . . . . . . . . . . .

–13.0 dBV –21.0 dBV

0

0 dBV

(1.0

V)

+10

–7.0 dBV

(0.45 V)

.

(0.22 V) (0.09 V)

Maximum SPL

(at 1,000 Hz, less than 1% THD)

800 Ω load

ILP-1 gain set at 0 dB

ILP-1

gain set at +10 dB

150 Ω

load

ILP-1 gain set at 0 dB

ILP-1

gain set at +10 dB

Electromagnetic

Hum Pickup

.

. . . . . . . . . . . . .

.

. . . . . . . . . .

.

. . . . . . . . . . . . .

.

. . . . . . . . . .

(maximum)

–0.5 dB equivalent SPL in 1 mOe field (60 Hz)

Preamplifier Controls

Selectable Low-Frequency Response: Flat/Low Cut

(12

dB/octave rollof

f below 80 Hz)

Selectable Gain: 0/+10 dB

Output Noise

25.5 dB SPL, A-weighted

32 dB SPL, C-weighted

28.5 dB SPL per DIN 45 405

Signal-to-Noise Ratio

68.5 dB re 94 dB SPL

Dynamic Range

121 dB (800 Ω load, gain set at 0 dB)

Phasing

Positive pressur

age

o

n pin 2 r

e on d

elativ

iaphrag

e t

o pin 3 o

m p

f p

roduce

ream

p o

s p

ositive volt-

utpu

t c

Power

to 52 Vdc phantom (simplex) voltage

11

(operational

down to 9 Vdc with reduced clipping level); current

drain

2.2 mA at 52 Vdc, 1.8 mA at 1

1 Vdc

Case

Microphone: Matte black enamel die-cast base and

perforated steel grille with replaceable or cleanable

fine

mesh screen and foam pad wind/dirt barrier

Preamplifier: Matte black enamel finished steel

Cable

7.6

m (25

ft) two-conductor shielded, small diameter

with Switchcraft Tini (Q.G.) 3-pin (female) connector

on

each end

Environmental Conditions

Operating Temperature: –18 to 57o C (0 to 135o F)

Storage T

emperature: –29 to 74o C (–20 to 168o F)

Relative Humidity: 0 to 95%

Dimensions

See Figure 3

OVERALL DIMENSIONS

FIGURE 3

146.5 dB

136.5 dB

129.5 dB

1

18.5 dB

onnector

,

2.

Page 3

Net W

eight

Microphone: 280 g (9.9 oz) less cable

ILP-1 Preamplifier: 170 g (6 oz)

LOCATION

To maintain the flattest possible low-frequency response

choose

th

and the best r

a flat s

e S

M91A

urfac

. The s

e a

urfac

ejectio

s l

arg

e can b

n o

e a

f r

s p

e a f

ando

ossibl

loor

m b

e o

, w

all

ackgroun

n w

hic

h t

, c

eilin

g o

d n

o l

r t

oise,

ocate

able.

Too small a mounting surface causes a low-frequency

rolloff beginning at the f

parable to the size of the s

rate of a

proximately

bou

t 3 dB per o

6 d

B l

owe

requenc

urface

ctav

r t

han th

y w

hos

. The r

e u

nti

l i

t r

e mid- and h

e w

avelengt

ollof

f c

eache

s a p

igh-frequenc

h i

ontinue

latea

s c

s a

u a

y r

om-

t a

p-

esponse. In a similar fashion, too small a mounting surface

decreases

the r

ejectio

n o

f l

ow-frequenc

y b

ackgroun

d n

oise.

MOUNTING

The

SM91A can be permanently mounted to a

lectern,

tabletop, floor, ceiling, or wall using two No. 6 screws located 50.1 mm (2 in.) apart. The location of two keyhole

slots in the base of the microphone is marked on the

nameplate. Cut through the marked slots before sliding

the

base onto the screws.

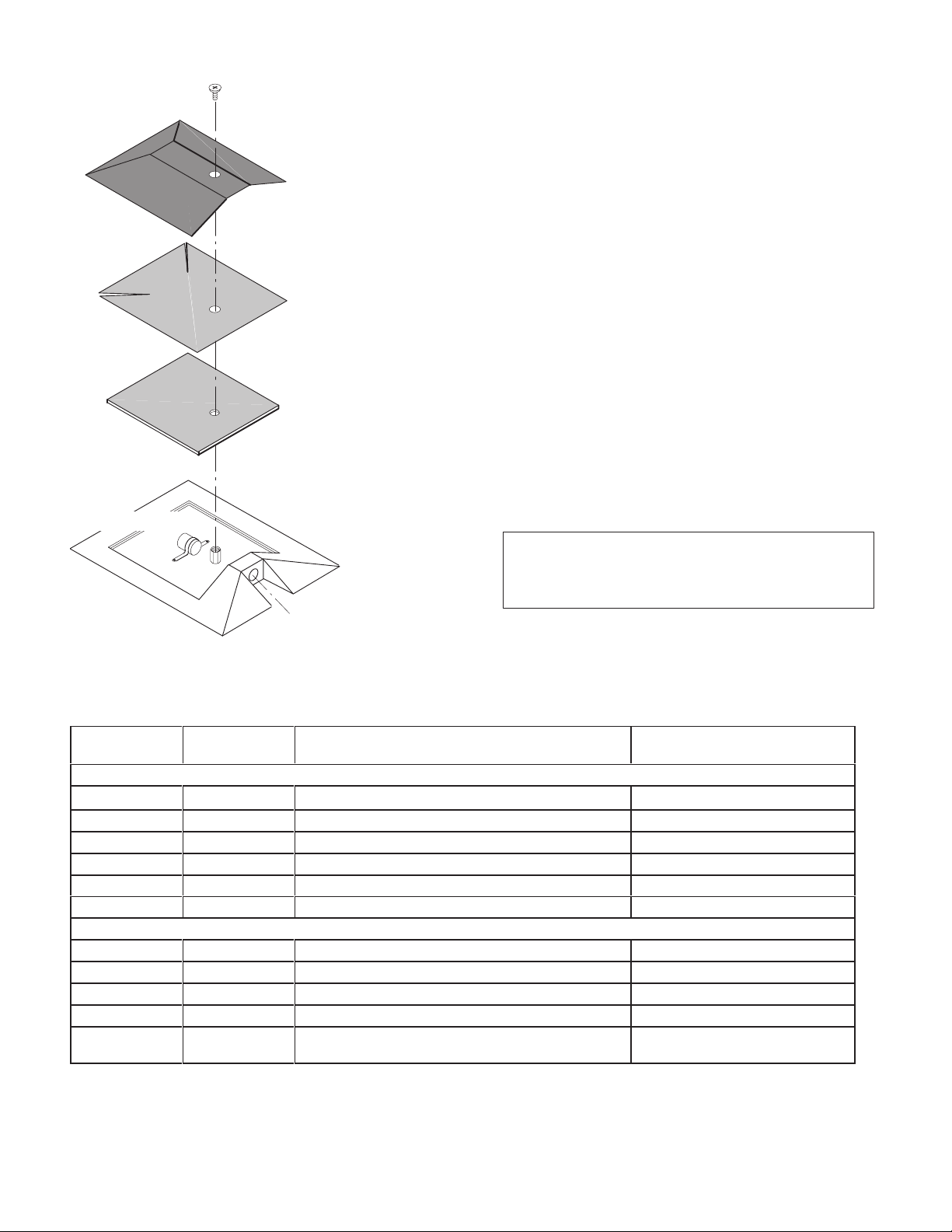

CLEANING

When the microphone is located in a dusty environment, periodic cleaning may be desirable. This can be

easily

accomplished by removing

on the grille, and lifting

of

f the grille, the fine mesh screen,

the Phillips-head screw

and the foam pad. Clean the fine stainless steel mesh

screen

by washing it in soapy water. Dry

replace

the

the foam pad, screen, and grille. Fasten firmly with

Phillips screw

.

it thoroughly

, and

DISASSEMBLING AND REASSEMBLING THE ILP-1

1. At the XLR-3 end of the preamplifier, turn the slotted

head setscrew fully inward (counterclockwise), and

use

a long-nose pliers to withdraw the connector from

the

case.

2. Unsolder

the three lead wires from the XLR-3 board.

3. Remove all four Phillips-head screws from the ILP-1

case

(three on the switch side, one on the back).

4. Grasp

board

the

case.

the end

cap and withdraw the cap assembly

assembly

, and

connecting wires and jacks from

, pc

REASSEMBLY

1. Make

2.

sure the pc board is seated in the slot

cap

and that no wires are pinched.

With the XLR-3

connecting wires foremost, feed the

of the end

endcap-board assembly into the case. Again, take

care

not to pinch the wires connecting the board to

the

endcap.

3. Rotate the assembly until the four holes for Phillips

screws

4.

Replace the four Phillips screws.

5. Resolder

board

line up with the holes in the case.

the three lead wires to the back of the XLR-3

as shown below

.

-

MOUNTING CLAMPS, PREAMPLIFIER

FIGURE 4

The supplied mountin

preamplifier in p

3). Us

e e

ithe

r one o

application.

To a

lac

voi

g c

lamp

e i

n p

ermanent installation

r two c

lamp

s d

d g

roun

d l

oop

s and hum, a

s are i

ntende

ependin

g o

d t

o hold t

s (see F

n l

ocatio

voi

d g

he

igure

n a

nd

rounding the microphone preamplifier housing to metal building

structures. Th

rectly

into a f

lus

e I

LP-

h m

1 p

reamplifie

ounte

d c

onnector i

r can a

lso be p

f d

esired.

lugge

d d

INTERCONNECTING CABLE

One

7.6 m (25 ft) cable

SM91A

cess

Microphone to the ILP-1 Preamplifier

to the controls located in the preamplifier

is supplied for connecting the

. T

o retain ac

, it is some

times desirable for the units to be located a greater distance

apart. Up to 15 m (50 ft) of additional cable can be

used

between the

plifier

with no loss in response or output.

SM91A Microphone and ILP-1 Pream

i-

-

-

-

3.

RED

WIRING T

2

O XLR-3 PC BOARD TERMINALS

1

3

BLACK

BLUE

FIGURE 5

6. Replace

case

the case. Take care not to engage the butterflyshaped

seating

7. Insert

setscrew

screw

the XLR-3 board-connector assembly in the

lining up the key in the

connector with the slot in

ground contact in the key slot as it will prevent

the connector properly

the connector fully in

.

the case until the slotted

can be seen in the case hole; tighten the set

firmly by turning it clockwise.

-

Page 4

PHILLIPS-HEAD SCREW

PERFORATED MET

GRILLE

AL

To paint the base:

1. Remove

of

and

2. Wrap

ment to perforate an opening for the screw, and replace

3.

Replace and tighten the screw

4. Carefully

the flat-head Phillips screw in

the perforated metal grille. Lift of

foam pad.

the grille in thin plastic film, use a pointed instru

the wrapped grille on the microphone.

paint the microphone base and screw

with the desired color. To avoid getting any paint on

STAINLESS FINE-MESH

SCREEN

the

connector

mating

plug to it.

5.

Allow the paint to dry thoroughly

, either mask it thoroughly or connect a

To paint the metal grille:

1. Once

FOAM PAD

2. Remove

3.

4. Use fine sandpaper to remove any paint that may

CARTRIDGE

BASE

CONNECTOR

5. Before replacing the grille, check that the fine-mesh

MICROPHONE PARTS

FIGURE 6

REPLACEMENT P

Reference

Designation

ARTS

Part

Number Description

Preamplifier

A1 90B4220

A2 90HZ2600

P1 95A8077

P2 90HV2600 XLR-3

MP1 66A264

MP2 80A476

ILP-1 Preamplifier Assembly

Pc Board Assembly

Plug Assembly

M C

, Male, Mini

onnector an

d P

Preamp Switch Cover

Mounting Clamp

Microphone

A3 98A144

A4 R129

Microphone Assembly

Cartridge and Impedance Converter

MP3 53A1879B Grille None

MP4 37A147

W1 C107

Inner Screen

Cable Assembly

, 7.6 m (25 ft), T

Shielded, Small Diameter

6. Replace

c B

oar

d A

again,

remove the flat-head Phillips screw in the

top center of the plastic-wrapped perforated metal

grille.

Lift of

f the grille.

the plastic wrap and paint the outside of the

grille. Take care to use a thin layer only; do not fill the

perforated

holes with paint.

Allow the paint to dry thoroughly

have

adhered

edging

around the screw-hole.

to the outer edges of the grille and the

IMPORTANT

For proper shielding it is extremely important to

maintain electrical continuity between the grille

and

the metal base.

screen is clean. Otherwise, wash it in soapy water.

Rinse

and dry it thoroughly

the foam pad, mesh screen, and perforated

grille; and fasten securely with the Phillips screw

None

None

Switchcraft, TB3M T

ssembly None

None

All States 3/4-HNB

None

None

None

wo Conductor

,

None

the top center

f the grille, screen,

-

.

head

.

.

.

.

Commercial Alternate

ini

4.

Page 5

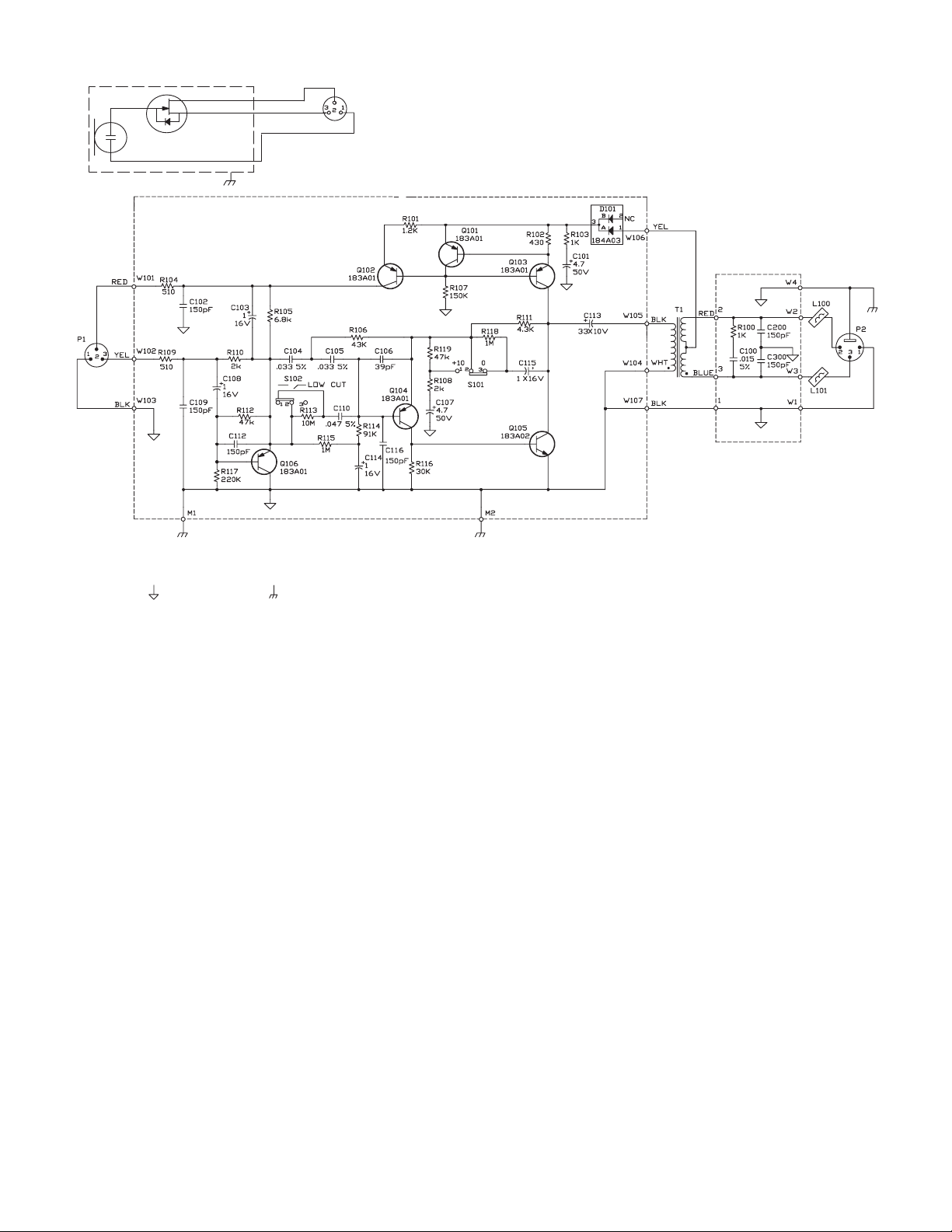

CONDENSER

CARTRIDGE

D

G

S

RED

BLUE

BLACK

GAIN

NOTES:

1 UNLESS OTHERWISE SPECIFIED, ALL RESISTORS ARE 1/8 WATT

2 UNLESS OTHERWISE SPECIFIED, ALL CAPACITORS IN F, 10%, 50 V OR GREATER. ELECTROLYTIC CAPACITORS SHOWN IN F

3 THE FOLLOWING SYMBOLS DENOTE:

PC BOARD GROUND CHASSIS GROUND.

.

, 5%.

GRN

OR

BROW

N

OR

X VOLTS, 20%.

CIRCUIT

FIGURE 7

DIAGRAM

5.

Loading...

Loading...