'RBFESSIONAL PRODUCTS

General

The SM5C

specifically for motion picture work. The

porating a

bly essentially eliminates low frequency transients re-

sulting from boom motion or wind. (These transients are

noted with many different microphones. While they

frequently occur at sub-audible frequencies, they can

overload the input stage of some recording channels

and some recorders-usually before the signal reaches

any equalizers-resulting in momentary blocking or

distortion.)

Features include:

is

a special version of the SM5A, designed

SMSC, incor-

I00 Hz hi-pass filter in the cartridge assem-

Directivity - cardioid, symmetrical about axis

and exceptionally uniform with frequency. Minimizes sound coloration due to off axis

such as from reverberation, reflections from

floor or scenery, and performers accidentally

"off-mike". Provides very effective rejection of

background noise and excellent reach.

Frequency response - wide range, especially

tailored to provide natural dialogue or vocal

music pickup with good presence.

Integral windscreen-very effective in outdoor

locations and for fast boom swings.

Mechanical suspension-two stage mechanical

isolation for any boom application. Suspension

elements are internal to windscreen to prevent

wind noise generation in the suspension assem-

bly.

Minimum electrical noise pickup-hum balancing

circuit for all cartridge elements (including

filter) assures very low susceptibility to electrical

hum. May be used in extreme hum fields.

pickup-

SPECIFICATIONS

Type:

Dynamic

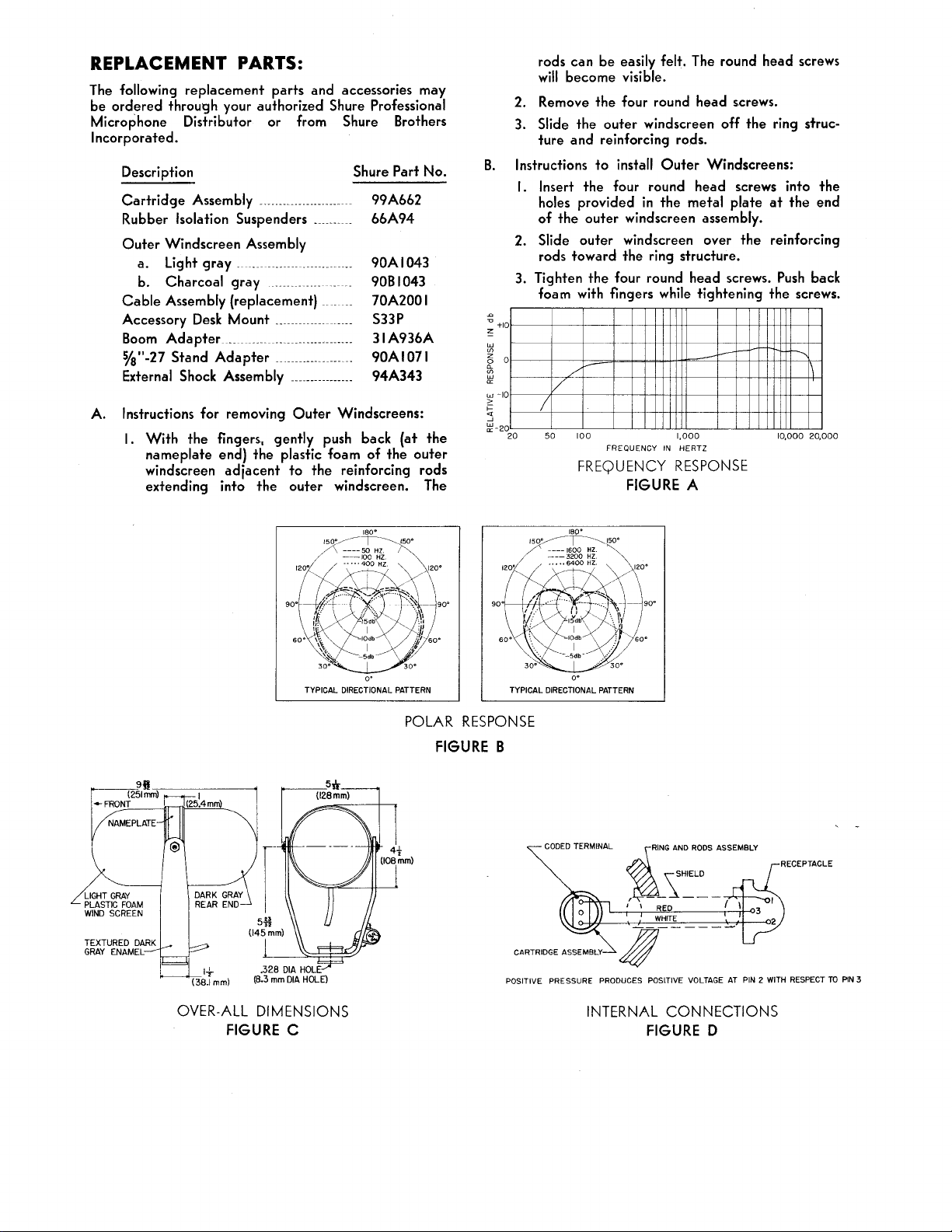

Frequency Response:

Polar Pattern:

Unidirectional. (See Figure

Microphone Rating

Impedance:

Output Level:

Model

SM5C (50 ohm impedance)

Open circuit voltage

(0

db

Power level into 50 ohms

(0

db

EIA

Microphone Rating

Gm (sensitivity)

(0

db = EIA

Model SM5C - 50 ohms

1,000 Hz response

=

I

volt per microbar)

=

I

milliwatt with I0 microbars)

.........

Standard SE-IO5/August, 1949)

70 to 15,000

Figure

-

-1

A)

84.0

db

57.0 db

50.0 db

DATA

HZ.

(See

B)

(.063 mv)

Perfectly balanced - excellent stability and

minimum overswing.

Ruggedness and dependability-under all oper-

ating conditions. Element and isolation assembly

are protected by the outer windscreens and

steel reinforcing rods.

Guarantee:

normal use to be free from electrical and mechanical

defects for a period of one year from the date of

purchase.

guarantee includes all parts and labor.

Shipping Ins+ruc+ions:

unit and return

the United States, return the unit to your dealer or

Authorized Shure Service Center for repair. The unit

will be returned to you prepaid.

Copyright

27A647

1969,

(LB)

This Shure product is guaranteed in

Please retain proof of purchase date. This

Carefully repack the

it

prepaid to the factory.

Shure Brothers Inc.

If

outside

Connector:

Finish:

Dimensions:

Professional three-pin male audio connector mounted on microphone de-

signed to mate with Cannon XL series

Switchcraft A3

equivalent connector.

Textured dark gray enamel. Light and dark

gray plastic foam windscreens.

See Figure

Other Mounting:

Net Weight:

Hum Level:

2

-130 dbm with field of I x

gauss at 60

(Q.G.)

C.

A

5/,"-27

Desk Mount available

accessory.

pounds (908 grams)

adapter is supplied.

Hz.

U.S.

Patents 3,132,713 and 3,240,883

Printed

series or

as

in

U.S.A.

REPLACEMENT PARTS:

The following replacement parts and accessories may

be ordered through your authorized Shure Professional

Microphone Distributor or from Shure Brothers

Incorporated.

Description Shure Part No.

Cartridge Assembly

Rubber Isolation Suspenders 66A94

.......................

..........

Outer Windscreen Assembly

a. Light gray

b.

Charcoal gray

Cable Assembly (replacement) 70A200

Accessory Desk Mount

Boom Adapterr

5/8"-27

Stand Adapter

External Shock Assembly

A.

Instructions for removing Outer Windscreens:

..............................

...................

........

....................

................................

....................

................

I. With the fingers., gently push back (at the

nameplate end) the plastic foam of the outer

windscreen adjacent to the reinforcing rods

extending into the outer windscreen. The

99A662

90A1043

90B 1043

S33P

3 1 A936A

90A107

9414343

I

1

rods can be

easily felt, The round head screws

will become visible.

2. Remove the four round head screws.

3.

Slide the outer windscreen off the ring structure and reinforcing rods.

B.

Instructions to install Outer Windscreens:

I.

Insert the four round head screws into the

holes provided in the metal plate at the end

of the outer windscreen assembly.

2. Slide outer windscreen over the reinforcing

rods toward the ring structure.

3. Tighten the four round head screws. Push back

foam with fingers while tightening the screws.

-

--

20 50 100 1,000 10.000 20,000

FREQUENCY IN HERTZ

FREQUENCY RESPONSE

FIGURE

A

PLASTIC

FOAM

WIND SCREEN

TEXTURED DARK

GRAY

ENAMEL-/

3

OVER-ALL DIMENSIONS

FIGURE

C

POLAR RESPONSE

FIGURE

B

y

CODED TERMINAL

cRlNG

AND

RODS ASSEMBLY

INTERNAL CONNECTIONS

FIGURE D

,

-

Loading...

Loading...