Page 1

SEK-2

Instruction Manual

for

Stylus Evaluation Kit

Manufactured by

SHURE BROTHERS INCORPORATED

222

Hartrey Avenue

Copyright

27A1339

1978,

(RE)

Shure Brothers Inc.

(95A851)

Evanston, Illinois

60204

Printed in

U.S.A.

Page 2

I.

INTRODUCTION

TABLE

OF CONTENTS

PAGE

.............................................................

1

II.

INSTALLATION AND ADJUSTMENT .2

A. Stylus Preparation

B.

Microscopeset-up ........................................................

Ill.

STYLUS EVALUATION .4

IV.

STYLUS PRESERVATION

V.

ADDENDA

A. Replacement Parts

B. 240-Volt Operation

C.

Guarantee

D. Shipping Instructions

...................................................................

...............................................................

........................................................

......................................................

....................................................

.......................................................

......................................................

....................................................

...........................................

2

3

-8

9

.9

9

.9

Page 3

/

ZOOM

EYEPIECE

X-

SSEMBLY

A

POS

LAM

FOCU

P

S

ING

MODEL

SEK-2

MICROSCOPE

Page 4

I.

INTRODUCTION

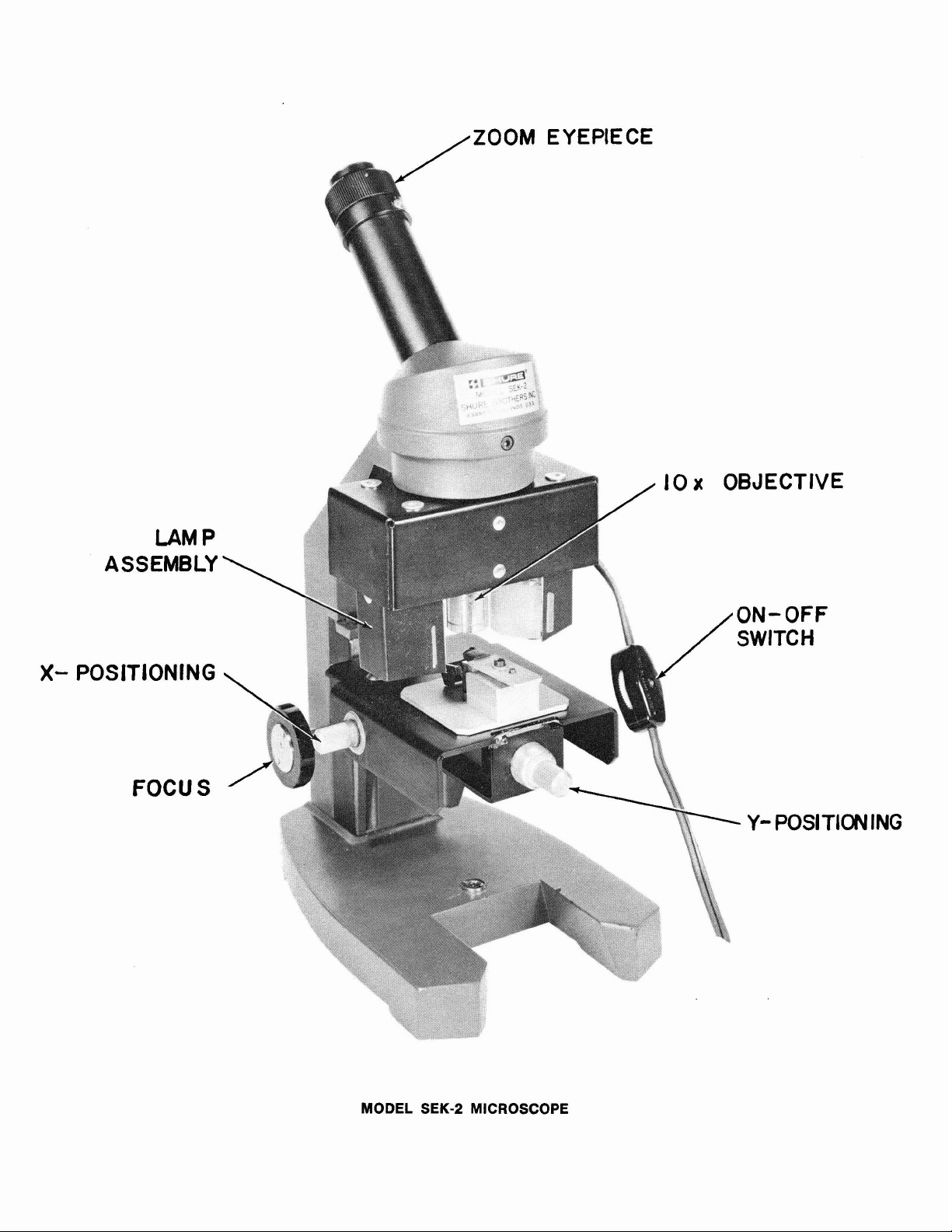

The Shure Model SEK-2 Stylus Evaluation Kit consists of a high-quality microscope designed to evaluate the condition of phonograph cartridge stylus

tips. The SEK-2 provides a visual indication of the amount of wear on stylus

tips, enabling the customer to judge the necessity for replacing his stylus.

The SEK-2 includes a

optics, 10 to

clined eyetu be, precision focus control with end-of-focus slip clutch, and tension control to maintain focus. In addition, the microscope has x- and y-plane

horizontal stage positioning controls, and locating screws and hole on the stage

to facilitate stylus positioning. The SEK-2 also includes a two-lamp stage illuminator, stylus mounting block, stylus mounting plate, pliable material for

mounting other than Shure styli, dust cover, pencil-type flashlight (uses two

penlite batteries), and two light diffusers for the lamp assembly.

The Shure SEK-2 Microscope is a high-quality optical instrument. Reasonable care will insure years of excellent service. Keep the Microscope covered

when not in use.

20x zoom eyepiece, lox objective, rigid

100-200x monocular microscope featuring coated

"L"

stand construction, in-

Page 5

II.

INSTALLATION AND ADJUSTMENT

A. Stylus Preparation

The stylus cannot be evaluated properly unless the stylus tip is clean. To

clean the stylus, use a camel's-hair brush (No.

2

size or smaller) dipped lightly in grain (ethyl) alcohol or alcohol-distilled water solution; one part alcohol to

three parts distilled water is recommended. (WARNING: Commercial record or

stylus cleaning solutions may cause corrosion and permanent stylus damage.)

The alcohol solution will remove any sludge deposits which may have coated

the stylus tip. The brush bristles should be trimmed to a length no longer than

6

mm

(1/4

inch). Always brush the stylus with a forward movement from the rear

(terminal end of the cartridge) to the front. Never brush or wipe the stylus from

front to back or side to side. NOTE: All Shure styli may be cleaned this way.

For other brands of styli, obtain manufacturer's procedure before using the alcohol solution, as permanent damage may result.

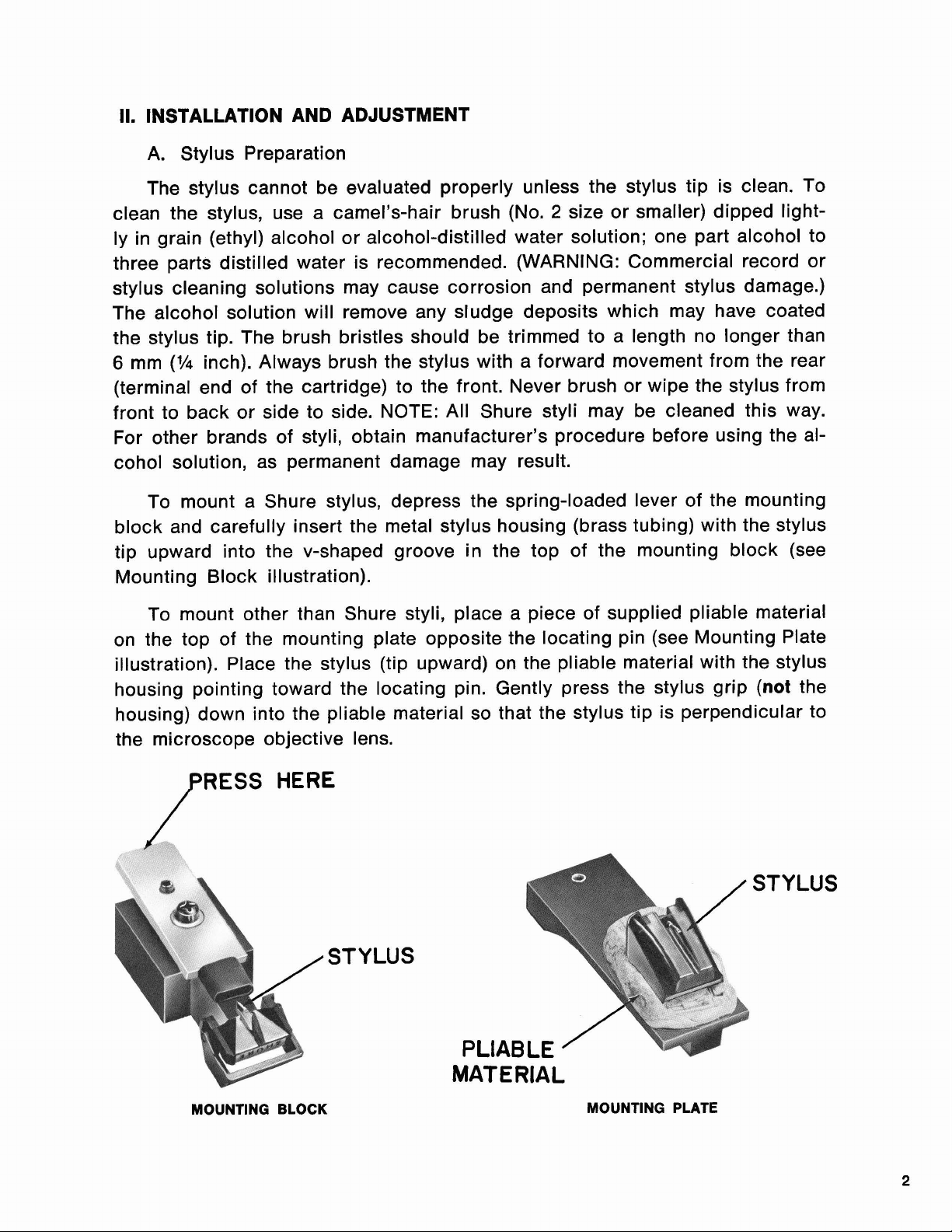

To mount a Shure stylus, depress the spring-loaded lever of the mounting

block and carefully insert the metal stylus housing (brass tubing) with the stylus

tip upward into the v-shaped groove in the top of the mounting block (see

Mounting Block illustration).

To mount other than Shure styli, place a piece of supplied pliable material

on the top of the mounting plate opposite the locating pin (see Mounting Plate

illustration). Place the stylus (tip upward) on the pliable material with the stylus

(not

housing pointing toward the locating pin. Gently press the stylus grip

the

housing) down into the pliable material so that the stylus tip is perpendicular to

the microscope objective lens.

STYLUS

MOUNTING BLOCK

MATERIAL

MOUNTING PLATE

Page 6

B.

Microscope Set-up

1. Place the microscope on a clean workbench or other firm surface

and install the lens barrel.

Lower the microscope stage by turning the black focus knob at

2.

either side of the vertical stand.

3.

Install the lamps in the lamp assembly. With the lamps pointing

downward, snap the lamp assembly over the vertical body tube and

slide the assembly upward as far as it will go.

4.

Plug the line cord into a 120 Vac, 50/60

cord switch to ON. Both lamps should light.

-

fective lamps with Type 6S6

6W, 120V, candelabra base; testing

Hz

outlet.* Rotate the line

(NOTE: Replace de-

cannot be performed unless both lamps are lit.)

5. If a Shure stylus is to be inspected, place the mounting block with

stylus on the microscope stage. With the mounting block centered

between the two raised socket-head capscrews and the mounting

block pin located in the hole in the platform, the stylus tip should

be almost directly below the objective lens.

6. If other than a Shure stylus is to be inspected, place the mounting

plate with stylus on the microscope stage. With the mounting plate

centered between the two raised socket-head capscrews and the

mounting plate pin located in the hole in the stage, the stylus tip

should be positioned near the objective lens.

7.

If a cartridge with a non-replaceable stylus is to be evaluated, first

determine whether the stylus tip, when the cartridge is lying upside-

down on the stage, will be perpendicular to the objective lens. If

it is perpendicular, proceed to step

8.

If it is not, place the cartridge

on top of a small piece of supplied pliable material on the mounting plate and gently press the cartridge body down until the stylus

tip is perpendicular to the objective lens.

8.

Turn the eyepiece zoom control to 10 (100x magnification) and use

the

x-

and y-positioning knurled knobs to center the stylus tip in

the eyepiece. The most convenient method of positioning the stylus

is to shine the beam of the pencil-type flashlight down through the

eyepiece to the stage. The stylus should be moved, using the x- and

y-positioning controls, until the beam shines directly on the stylus

tip. NOTE: Left to right and front to back movements are reversed

when viewed through the eyepiece.

9.

Using the black focus control at either side of the vertical stand,

3

mm

(%

bring the stylus tip to within

in.) of the objective lens.

CAUTION: Do not allow the stylus tip to touch the objective lens,

as the diamond tip will scratch the glass. Adjust the microscope

focus control to bring the tip into focus. When in focus, the stylus

(1h

tip should be approximately 6 mm

10. Rotate the eyepiece zoom control to 12

in.) from the objective lens.

(120x magnification).

*See

ADDENDA

for information on 240-volt operation.

Page 7

Ill.

STYLUS EVALUATION

Once the stylus tip is in focus, wear spots should be visible which correspond to the points of contact of the record surface. At

wear spots and the stylus tip are both in focus, resulting in so-called

eyes" where wear has occurred. Figures 1 through 4 illustrate the following stylus

conditions at this magnification:

120x magnification, the

"cat's

Figure

Figure 16.

Figure 2A.

Figure

Figure 3A.

Figure

Figure 4A.

Figure

IMPORTANT:

Study the wear areas of new and used

them with Figures 1 through

in three-dimensional views. In the microscope, only a small portion of the tip

-the tip wear area- is in focus at one time. The wear area appears as a

flat, two-dimensional representation (as in Figures 5 through 8). This is due to

the depth of field limitation and illumination of the microscope.

Increase the eyepiece zoom control to 20

as necessary. Figures 5 through 8 illustrate the following stylus conditions at

this magnification:

Figure 5A.

Figure 5B.

Figure 5C.

Figure 6A.

Figure 6B.

Figure 6C.

Figure 7A.

Figure 7B.

Figure 7C.

Figure 8A.

Figure

Figure 8C.

1A.

26.

36.

48.

8B.

Good spherical stylus

Worn spherical stylus

Good elliptical stylus

Worn elliptical stylus

Good hyperbolic stylus

Worn hyperbolic stylus

Good hyperelliptical stylus

Worn hyperelliptical stylus

New and used styli appear similar when casually observed.

styli in the microscope and compare

4.

Note that the figures show the entire stylus tips

(200x magnification) and refocus

Good spherical stylus

Slightly worn spherical stylus (recheck within 100 hours of

operation)

-

Badly worn spherical stylus (DO NOT USE

records)

Good elliptical stylus

Slightly worn elliptical stylus (recheck within

operation)

Badly worn elliptical stylus (DO NOT USE

records)

Good hyperbolic stylus

Slightly worn hyperbolic stylus (recheck within

operation)

Badly worn hyperbolic stylus (DO NOT USE

records)

Good hyperelliptical stylus

Slightly worn hyperelliptical stylus (recheck within

hours of operation)

Badly worn hyperelliptical stylus (DO NOT USE

age records)

will damage

100 hours of

-

will damage

100 hours of

-

will damage

-

100

will dam-

Page 8

GOOD SPHERICAL STYLUS

FIGURE

1A

WORN SPHERICAL STYLUS

FIGURE

1B

GOOD ELLIPTICAL STYLUS

FIGURE

2A

WORN ELLIPTICAL STYLUS

FIGURE

28

Page 9

GOOD HYPERBOLIC STYLUS

FIGURE

GOOD HYPERELLIPTICAL STYLUS WORN HYPERELLIPTICAL STYLUS

FIGURE 4A FIGURE 48

3A

WORN HYPERBOLIC STYLUS

FIGURE 38

A

good reference check on stylus condition is to use a new replacement

stylus as a standard. With the new stylus as a reference, it is easier to evaluate

the condition of the used stylus. Another useful test in demonstrating stylus

wear to a customer is to maintain a selection of new and worn styli near the microscope so the customer can readily compare his own stylus with both photos

and actual styli.

Remember that stylus wear is a continuing, not an overnight, process.

A

stylus used for only a relatively short time (a few hundred hours) will have small

wear spots. However, this does not mean that it must be replaced. After gaining

some experience with various degrees of wear, it will become easier to make

assessments of styli conditions. Note that there may be bubbles or crystal structure on the stylus shank; these are not important, as

record.

the

only the stylus tip touches

Page 10

GOOD SPHERICAL

STYLUS

FIGURE

5A

SLIGHTLY WORN

SPHERICAL STYLUS

FIGURE

5B

BADLY WORN

SPHERICAL STYLUS

FIGURE

5C

GOOD ELLIPTICAL

STYLUS

FIGURE

6A

GOOD HYPERBOLIC

STYLUS

FIGURE

7A

SLIGHTLY WORN

ELLIPTICAL STYLUS

FIGURE

6B

SLIGHTLY WORN

HYPERBOLIC STYLUS

FIGURE

78

BADLY WORN

ELLIPTICAL STYLUS

FIGURE

6C

BADLY WORN

HYPERBOLIC STYLUS

FIGURE

7C

GOOD HYPERELLIPTICAL

STYLUS

FIGURE

8A

SLIGHTLY WORN

HYPERELLIPTICAL STYLUS

FIGURE

8B

BADLY WORN

HYPERELLIPTICAL STYLUS

FIGURE

8C

Page 11

IV. STYLUS PRESERVATION

The following recommendations will help the customer to maximize the life

of his stylus.

1.

Follow the turntable or tone arm manufacturer's instructions when

adjusting antiskating force.

Do not handle the tone arm

2.

while it is in operation. Accidentally

touching the tone arm while the turntable is rotating can cause the

arm to sweep across the record.

3.

If it is necessary to manually place the tone arm in the record groove

while the turntable is rotating, be sure to release it as soon as the

Dynamic Stabilizer sets down on the record or as the stylus engages

the record groove.

4.

Correct any improper setdown adjustment or malfunction of the

turntable changing mechanism to prevent the stylus from striking the

edge of the turntable or the record.

5.

Take care to pr6perly insert the stylus into the cartridge assembly

and the cartridge and shell assembly into the tone arm receptacle.

6.

Use proper vertical tracking force setting for each cartridge. Misadjustment of the tone arm counterbalance can cause excessive

vertical force beyond specified limits.

7. Do not use damaged records.

8.

When dusting the turntable, be sure to protect the stylus with the

stylus guard or Dynamic Stabilizer.

Page 12

V.

ADDENDA

A. Replacement Parts

Lamp Assembly

Mounting Block

Mounting Plate

Pliable Material

Lamp

*

---..-.--...---....-----------------------------------------------------------------

Lamp Diffuser (2)

Flashlight

*Available commercially as Type

B.

240-Volt Operation

--.-.-...---.-.....---------------------------------------------------

....----.-.-.-.-.-.-------------------------------------------------

-...-----...----...-------------------------------------.-------

.....---..-..--..-------...----------------------------------------

------...-.-...-.-.-------------------------------------.-----------

90A2300

90A2303

90A2305

80A220

95A486

.-...-.-....-.....----------------------------------------------

90LE1371

80A309

6S6

(6W,

120V,

candelabra base).

The SEK-2 lamp assembly is supplied wired for 120-volt operation. To

provide for operation at 240

the lamps in series as follows.

Vac, rewire the lamp assembly placing

(NOTE:

Rewiring should be performed

by qualified service personnel.)

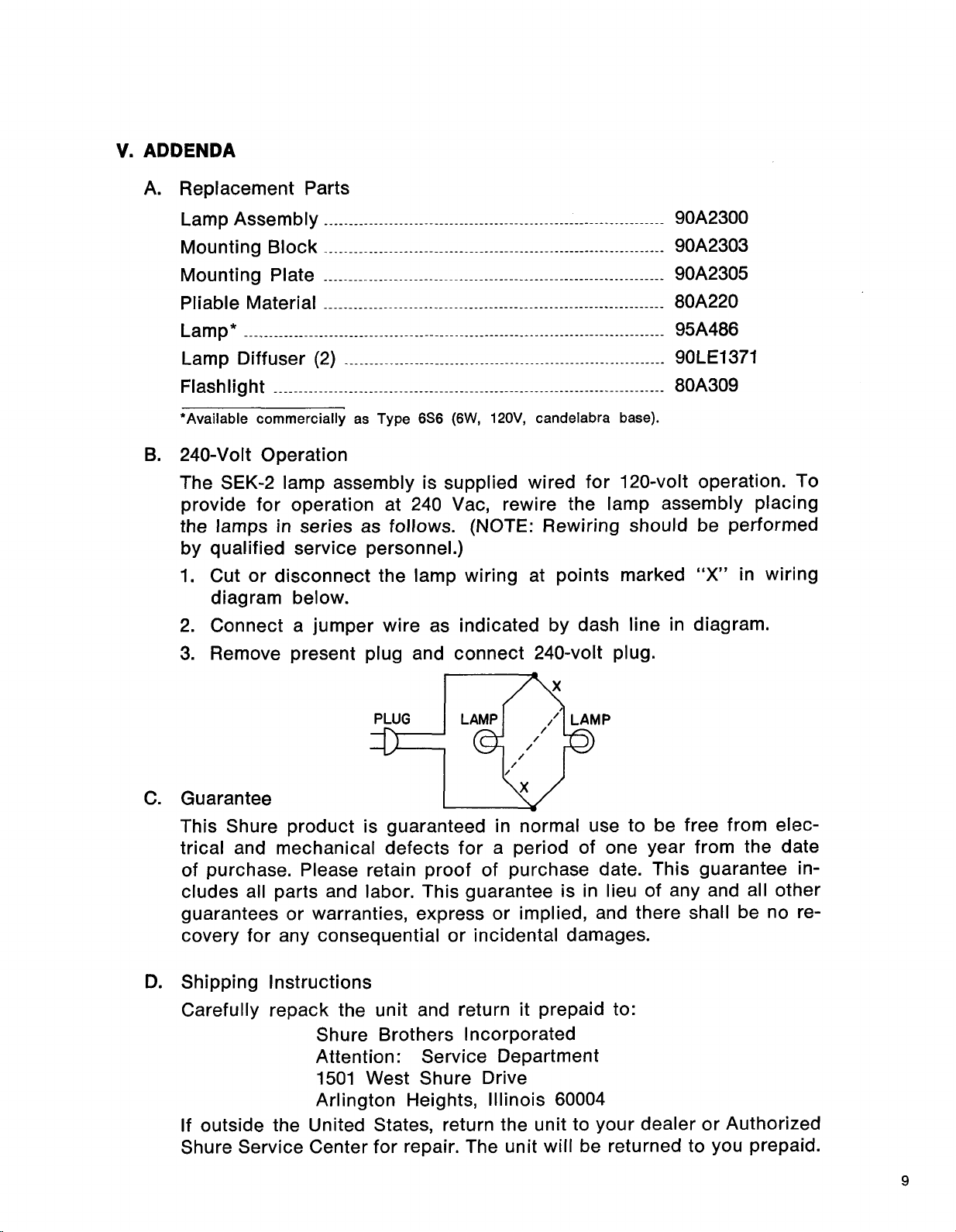

1.

Cut or disconnect the lamp wiring at points marked

"X"

in wiring

diagram below.

2.

Connect a jumper wire as indicated by dash line in diagram.

3.

Remove present plug and connect 240-volt plug.

C.

Guarantee

This Shure product is guaranteed in normal use to be free from elec-

trical and mechanical defects for a period of one year from the date

of purchase. Please retain proof of purchase date. This guarantee includes all parts and labor. This guarantee is in lieu of any and all other

guarantees or warranties, express or implied, and there shall be no recovery for any consequential or incidental damages.

D.

Shipping Instructions

Carefully repack the unit and return it prepaid to:

Shure Brothers Incorporated

Attention: Service Department

1501 West Shure Drive

Arlington Heights, Illinois 60004

If

outside the United States, return the unit to your dealer or Authorized

Shure Service Center for repair. The unit will be returned to you prepaid.

Loading...

Loading...