Page 1

MODELS SE30 & SE30-2E

GATED COMPRESSOR/MIXER

OPERATING AND SERVICE MANUAL

Copyright 1981, Shure Brothers Inc.

27A8025 (AK) (90A8103)

Printed in U.S.A.

Page 2

Table of Contents

List of Illustrations

WARNING

To reduce the risk of fire or electric shock, do not

expose this appliance to rain or extreme moisture.

Page 3

DESCRIPTION

The Shure Model SE30* Gated Compressor/Mixer is a

high-quality gated memory compressor combined with a

self-contained, portable, three-input mixer and remote

amplifier designed specifically for professional applications in AM, FM, and TV broadcasting, film, tape, and

disc recording, CATV, and sound reinforcement. An accessory cover is available (A100A) which covers the front

controls and provides a handle, as well as a support stand

for tilting the front panel upward for easier vision of controls during operation. An accessory rack-mount kit

(A100B) is available for permanently installed program

compressor applications.

Features include:

Three transformer coupled inputs, switchable, low im-

pedance microphone or line level.

Individual feedback-type level controls for each input

to provide maximum clipping and minimum noise levels

over a wide dynamic range.

Low-frequency roll-off switch for each input.

Input 1 switchable on front panel to low-distortion, 1 kHz

tone oscillator.

Mix bus jack for adding additional mixers for additional

input capability.

Feedback-type output control (located after compression attenuator) to provide optimum output noise level

regardless of setting.

Binding posts for balanced 600-ohm line output plus

professional three-pin male audio connector switchable

from line to microphone level output.

Two-level headphone monitor jack for 600 to 2,000 ohm

headphones.

Compression range of 40 dB, with a slope or compression ratio of approximately 10 to 1 in the normal operating range.

Gated Memory with a meter indicator to minimize

“pumping.”

True average-responding compression to maximize

output level regardless of peak-to-average ratio of program material, either music or speech. (Peak responding

circuit to reduce gain rapidly for significant increases in

the input signal.)

Response rate (averaging time constant) adjustment on

front panel to compensate for various types of program

material.

Extremely low distortion, noise, and RF susceptibility,

with wide, flat frequency response at any level of com-

pression.

+18 dB output capability.

Dual-scale illuminated meter for output VU indication

or dB compression.

+4 or +6 dBm range switch for VU meter.

AC or battery operation with built-in battery supply using

readily available 9-volt batteries.

*Unless otherwise noted, information applies to both SE30 and SE30-2E models.

(Model SE30 shown)

Automatic, noiseless switch-over to batteries in the

event of ac line failure.

Battery-check switch to check battery condition without interrupting operation of unit.

Detachable ac line cord.

Auxiliary meter lamp operates independently from a “D”

type dry cell for meter illumination when ac power is

not available.

Auxiliary high level input and output on phone jacks for

special applications (approximately --20 dBV).

Microphone and line inputs and outputs phase indicated.

Stereo parallel jack for synchronizing the compression

circuits of two units.

Listed by Underwriters’ Laboratories and Canadian

Standards Association (SE30 only).

GUARANTEE

This Shure product is guaranteed in normal use to be

free from electrical and mechanical defects for a period

of one year from date of purchase. Please retain proof of

purchase date. This guarantee includes all parts and

labor. This guarantee is in lieu of any and all other guarantees or warranties, express or implied, and there shall

be no recovery for any consequential or incidental

damages.

Carefully repack the unit and return it prepaid to:

If outside the United States, return the unit to your dealer

or Authorized Shure Service Center for repair. The unit

will be returned to you prepaid.

SHIPPING INSTRUCTIONS

Shure Brothers Incorporated

Attention:

1501 West Shure Drive

Arlington Heights, Illinois 60004

Service Department

SPECIFICATIONS

Frequency Response:

Flat ±2 dB, 30 to 20,000 Hz.

Gain:

(Below compression threshold, output terminated,

Line 600 ohms, Microphone 150 ohms, Aux. 47 K

ohms.)

Noise:

Equivalent input noise: -129.5 dBV maximum (Microphone input, 150 ohms, 20 kHz equivalent noise bandwidth with lower cutoff frequency of 300 Hz, at full

gain.)

Equivalent input hum and noise: -126 dBV maximum

(same as above, but lower cutoff frequency of 20 Hz.)

Output: (Input controls minimum):

3

Page 4

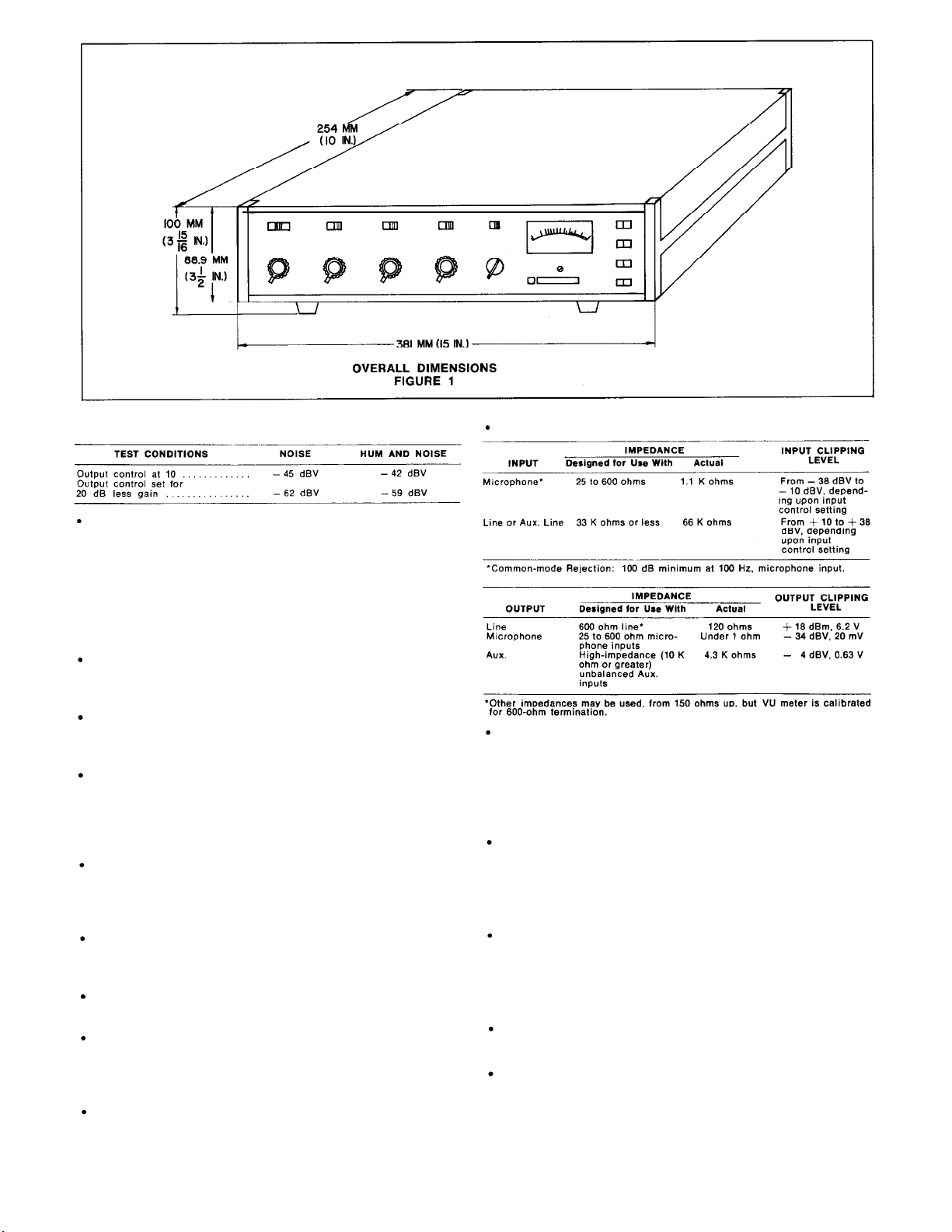

SPECIFICATIONS (Cont’d)

Distortion:

Below compression threshold, under 0.5% THD at

+15 dBm output, 30-20 kHz.

At 10 dB compression, under 1% THD at +15 dBm

output, Response Rate set to 7, 50-20 kHz. With Response Rate set to 0 (fast), under 2% THD at 50 Hz.

At 1 kHz, under 0.8% THD at any level of compres-

sion from 0 to 40 dB.

Compression Ratio:

8:1 minimum from 10 to 20 db compression.

5:1 minimum from 10 to 30 dB compression.

Compression Threshold:

Microphone: -96 dBV at maximum input gain.

Line: -48 dBV at maximum input gain.

Recovery Time:

Time required for gain to reach 90% of its final value

when input is reduced by 10 dB from 20 dB com-

pression is adjustable from approximately 100 milliseconds to 8 seconds by Response Rate control.

Attack Time:

Same as recovery time for increases up to 12 dB.

Maintains peak to average ratio at 12 dB (sine-wave

equivalent).

Gated Memory:

In “hold” condition, less than 20 dB gain recovery

after 1 minute.

Tone Oscillator:

1.0 kHz ± 10%, THD under 1%.

Input Control Interaction:

Under 0.1 dB with any combination, mix bus jack

open. Under 1.5 dB with mix bus terminated in 50 K

ohms or less.

Lo-cut Filters:

-6 dB per octave, 3 dB down at approximately 150

Hz.

4

Input/Output:

Mix bus:

Impedance 3.9 K ohms. Gain (through 3.9 K ohms)

from mix bus to line output, is 63 dB. Gain from microphone input to mix bus is 26 dB (terminated in 3.9 K

ohms). Overall gain drops by 10 dB with mix bus

terminated.

Circuit Protection:

Shorting the outputs, even for prolonged periods, will

not damage the unit.

Microphone inputs will not be damaged by signals

of up to 3 volts.

Temperature Range:

Operating:

-18°C (0°F) to 57°C (135°F).

Storage:

-29°C (-20°F) to 74°C (165°F).

Weight:

9 Ibs., 13½ oz. (4.5 kg) with batteries and line cord.

Operating Voltage:

AC Operation:

108-132 volts, 50/60 Hz (SE30 only).

108-132 or 216-264 volts, 50/60 Hz (SE30-2E

only).

DC Operation:

30 volts ± 20%.

Page 5

SPECIFICATIONS (Cont’d)

Battery Operation:

27 volts nominal, 21.5 volts minimum. Current consumption at 27 volts, 10 ma. at no signal; 12 ma. at

20 dB compression and +8 dBm output.

Battery Life:

Estimated 80 hours at 4 hours use per day.

Battery Complement:

9 volt, 6 Eveready type 222 or 216 or equivalent.

One heavy-duty 1.5 volt “D” size cell, Eveready type

D99 or equivalent to power Aux. Light approximately

8 hours continuously.

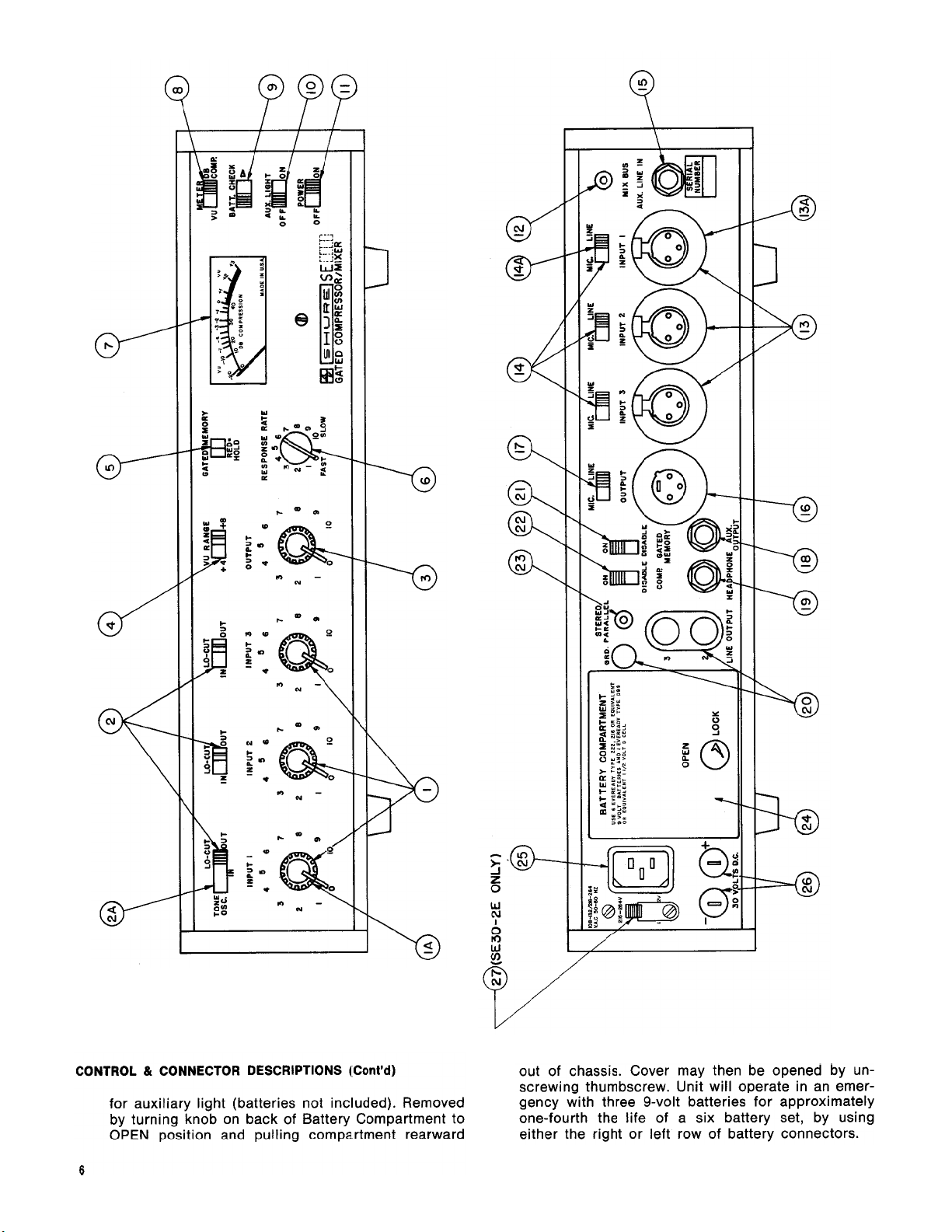

CONTROL AND CONNECTOR

DESCRIPTIONS (See Figure 2)

Input Controls: Control gain of individual input stages

(1)

to adjust relative levels between inputs and to adjust

amount of compression. Input 1 (1A) also controls

Tone Oscillator level when used.

Lo-cut Filter Switches: Low frequency response is re-

(2)

duced by 6 dB per octave below approximately 150 Hz

with switch set to IN. Input 1 switch (2A) also activates

tone oscillator.

Output Control: Controls output level when unit is

(3)

used in compression or acts as a master gain control

when compression is disabled. May be used for overall fading. Does not affect amount of compression.

VU Range Switch: Selects meter sensitivity so 0 VU

(4)

indicates results from either +4 dBm or +8 dBm line

output level.

Gated Memory Indicator: Will be red when Gated

(5)

Memory is “holding” prior amount of compression

during a low input signal. Will be white whenever in-

put signal is above compression threshold, or if either

Gated Memory or compression is disabled. Illuminated by ac operated lamps or independent battery

operated auxiliary light.

Response Rate Control: Adjusts time constant of

(6)

compression system to compensate for different types

of program material. Generally, a faster setting (lower

numbers) results in a more constant output level but

a more audible compression effect. Setting this control is a subjective matter, but the following guidelines may be used:

Meter: Indicates either VU output level (upper VU

(7)

scale) or compression due to input signal above thres-

hold by the amount indicated (lower DB Compression

scale). VU meter isolated from dc on line output. Illuminated by ac operated lamps or independent battery operated auxiliary light.

Meter Switch: Selects function of meter for VU out-

(8)

put level or DB Compression.

Battery Check Switch: Spring-return switch overrides

(9)

Meter switch, allows checking battery condition with-

out affecting operation of unit. A reading of 0 VU indi-

cates end-of-life.

(10) Aux. Light Switch: Spring-return switch allows illu-

mination of meter and Gated Memory indicator from

internal battery.

*Designed to mate with Cannon XL series, Switchcraft A3 (Q. G.) series. or equivalent connector.

Power Switch: Controls ac, external dc and internal

(11)

battery power applied to the unit, but will not prevent

power from being drawn from the internal batteries by

a load connected to 30 Volts DC jacks (26) when

switched to OFF.

REAR PANEL

Mix Bus Jack: Phono pin jack allows adding inputs by

interconnecting to a similar jack on another SE30

or M67 Mixer.

Input Connectors: Female professional three-pin au-

(13)

dio connectors* accept balanced low-impedance microphone or high-level line inputs. Wired with pins

2 and 3 “hot” and pin 1 ground.

Mic/Line Input Switches: Select either microphone

(14)

or line level input sensitivity for each input.

Aux. Line Input Jack: Three-conductor (tip, ring,

(15)

sleeve) phone jack provides a second balanced line

input for Input 1. May be used in conjunction with, or

instead of, three-pin input connector when input

switch (14A) is set to LINE. Inserting a two-conductor

phone plug will automatically unbalance the input

without otherwise affecting operation. Tip and ring

are “hot,” sleeve is ground, and tip is in phase with

pin 2 of input and output.

Output Connector: Male professional three-pin audio

(16)

connector* provides balanced output at either line

level or microphone level (50 dB below line level).

Wired with pins 2 and 3 “hot” and pin 1 ground, in

phase with input connectors.

Mic/Line Output Switch: Selects either microphone

(17)

or line level output at output connector.

Aux. Output: Two-conductor (tip-sleeve) phone jack

(18)

provides isolated unbalanced aux. level (20 dB below

line level) output, for use with tape and cassette re-

corders and power amplifiers with high level, high

impedance inputs. Tip of jack is in phase with tip of

Aux. Line Input jack (15).

Headphone Jack: Three-conductor (tip, ring, sleeve)

(19)

phone jack wired to provide two different output levels

for 600 to 2,000 ohm headphones. If a two-conductor

(tip, sleeve) phone jack is inserted partially (to the first

detent), output will be approximately .18 volts into

1,000 ohms at +4 dBm output. If the plug is inserted

fully, the voltage will be approximately .38 volts. If

stereo headphones are used, signal will appear in both

phones. The tip and ring are in phase with pin 3 of

the input and output.

Line Output Terminals: Thumbscrews for direct wire

(20)

connections to balanced line, wired in parallel with

three-pin Output connector (16) in LINE position of

switch only. Phase is indicated by pin number ref-

erences, and a ground thumbscrew is provided.

Gated Memory Switch: Will disable Gated Memory

(21)

function without affecting other operation.

Compression Switch: Will disable compression and

(22)

Gated Memory functions of the SE30, converting it to

a high-quality linear mixer and remote amplifier.

Stereo Parallel Jack: Phono pin jack allows two units

(23)

to be synchronized to compress equally the channel

sum (L + R) signal. See Service section.

Battery Compartment: Requires six readily available

(24)

O-volt batteries (Eveready type 222 or 216 or equiva-

lent) wired in series-parallel for 27 volts dc and one

heavy-duty D cell (Eveready type D99 or equivalent)

5

Page 6

FIGURE 2

CONTROLS AND CONNECTORS

Page 7

(25) AC Power Receptacle: Special internationally ac-

cepted connector for detachable ac line cord, threewire with safety ground pin.

(26) 30 Volts DC Jacks:

unit from an external 30 ± 20% dc source, or for

powering external equipment (up to 5 ma) from the

batteries or ac operated power supply of the SE30.

Controlled by front-panel Power switch (11) except

that an external load will discharge the batteries with

the unit OFF. In this case, remove the Battery Compartment (24) when unit is turned off.

(27) Voltage Selector Switch: Selects operating voltage

range of 108-132 V or 216-264 V (SE30-2E only).

May be used for powering the

GENERAL OPERATION

POWER CONNECTIONS:

AC Line Operation: Insert female end of ac line cord into

chassis power receptacle (25) and connect male plug to a

three-wire grounding ac power receptacle providing 108

to 132 V, 50/60 Hz (SE30 only). Model SE30-2E: Obtain

a suitable three-pin male plug and attach it to the line

cord. Plug should be installed by qualified service personnel. (Brown lead goes to “hot” or “live” terminal, blue

lead to neutral terminal, and green/yellow lead to ground

or earth terminal.) Select the proper operating voltage

(108-132 V or 216-264 V) using the voltage selector switch

(27). Insert female end of line cord into chassis power re-

ceptacle (25) and connect male plug to a three-wire

grounding ac power receptacle providing the proper ope-

rating voltage (108-132 V or 216-264 V, 50/60 Hz).

Battery Operation: Unit will automatically operate on bat-

teries installed in Battery Compartment (24) if unit is not

supplied with ac power. Condition of the 9-volt batteries

should be checked periodically with the Batt. Check Switch

(9) and batteries should be replaced as the meter indication approaches 0 VU with the unit in operation. Standby

battery condition may be checked even during ac line

operation, but an indication of +½ VU should be considered as the replacement point, since the battery voltage

will drop somewhat under load. The auxiliary light D cell

may be checked by operating the Aux. Light switch (10).

If the light becomes extremely dim, promptly replace or

remove the D cell to avoid damage due to leakage.

The unit will remain operative, except for the light, regard-

less of the condition of this cell.

Automatic Switchover: If batteries are installed in Battery

Compartment (24). operating power will be supplied by

these batteries in the event that the ac line voltage drops

too low or is removed. The switchover is automatic and

noiseless.

External DC Operation: An external source of dc may be

connected to the 30 Volts DC jacks (26) to operate the

unit if ac power is not used. The SE30 will draw approximately 12 ma. at 30 volts and must be operated at 30 volts

± 20%.

INPUT CONNECTIONS:

Microphones: Inputs (13) with switches (14) set to MIC.

are designed to accept signals from low impedance (25 to

600 ohms) dynamic, ribbon, or condenser microphones,

or microphone level signals such as the low impedance

microphone level output of a mixer. Inputs are balanced

(transformer coupled, mumetal shielded) and connections

are pins 2 and 3 “hot,” pin 1 ground. For unbalanced

sources, connect either pin 2 or pin 3 to ground at the

input cable connector.

High Level Signals: With switches (14) set to LINE the

(See Figure 2)

inputs (13) will accept balanced 600-ohm line signals.

Inputs are bridging (with 66 K ohm impedance) so that

higher impedance sources such as Aux. signals (up to

33 K ohms) may also be used. For such unbalanced inputs, the signal may be applied to pin 3, with pins 1 and

2 ground. Input 1 can accept two high-level signals simultaneously through the three-pin Input connector (13a), and

through the Aux. Line Input jack (15), which are electrically

isolated but identical in gain and impedance.

OUTPUT CONNECTIONS:

Microphone: The microphone level output is available at

the Output connector (16) when the switch (17) set to MIC.

It is used for feeding a low-impedance microphone line

or the low impedance microphone input of an associated

piece of equipment. This is a balanced output with pin 1

ground and pins 2 and 3 “hot” and in phase with the corresponding input pins. This output is isolated and may be

used simultaneously with all other outputs appearing on

other connectors.

Line: The line output is available at the Output connector

(16) when the switch (17) is set to LINE, and at all times

at the Line Output terminals (20). These two connectors

are then wired in parallel and are provided for interconnection convenience for either standard three-pin audio

connectors or for wires such as a telephone twisted pair.

This is a balanced output, transformer coupled with pin 1

ground and pins 2 and 3 “hot” and in phase with the corresponding input pins. The Line Output terminals (20) are

similarly numbered for phase indication. This output may

be used to drive impedances above 150 ohms but the VU

meter is properly calibrated for use with a 600-ohm termi-

nated line. The line output transformer will operate properly with up to 100 ma. flowing through the line, permitting

the use of ordinary “dialed-up” telephone lines with dc

across them. Operation at +4 dBm output is recommended

for this use to avoid any significant increase in distortion

due to overdriving the phone line. This output is isolated

and may be used simultaneously with all other outputs except that the Output connector (16) and Line Output terminals (20) are wired in parallel when the switch (17) is set to

LINE.

Aux. Output: An unbalanced output 20 dB below line level

is available at the Aux. Output jack (18) for a Separate,

isolated lower level feed. The impedance is 4.3 K ohms,

suitable for driving high impedance (10 K ohms or greater)

loads, such as reel to reel or cassette tape recorders or

power amplifiers. Tip of jack is in phase with tip of Aux.

Line Input jack (15).

Headphones: The headphone output appears on the rear

panel and is designated “Headphones.” A three-conductor

phone jack is used to provide a choice of level for different

sensitivity or impedance headphones. Normally, a two-conductor phone plug should be used. If inserted only partially (to the first detent), the available voltage is approximately .18 volts into 1,000 ohms with +4 dBm out of the

Line Output. With the same output conditions (+4 dBm),

the second position will provide approximately .38 volts.

These voltages are selected for normal operation with

600-ohm to 2,000-ohm headphones. Other headphone impedances may be used, but with a variation in the headphone monitor level. The headphone jack is isolated from

the line output and with the headphone output shorted the

maximum change in line level output is .5 dB. If stereo

phones are used, the three-conductor plug may be inserted

completely (to second position) and output will appear in

both phones.

7

Page 8

GENERAL OPERATION (Cont’d)

The “Tip” connection of the headphone plug will be in

phase with Pin 3 of all Input (13) and Output (16) connectors, and with the tip of the Mix Bus jack (12).

TYPICAL SET-UP AND OPERATION

A typical set-up and operation procedure is described

for remote amplifier applications, with a single input source

(microphone).

1. Connect microphone to Input 1 connector (13a) and

set Input switches (14) to MIC. Set Output Switch (17)

to LINE and connect phone line either to Output jack

(16) or Line Output terminals (20). Insert ac line cord

into ac receptacle (25) and plug cord into ac source,

unless battery operation is desired. Monitor headphones may be connected to Headphone jack (19).

2.

Set Compressor (22) and Gated Memory (21) switches

to ON, Meter switch (8) to DB COMP, Lo-Cut switches

(2) and VU Range switch (4) as appropriate.

3. Rotate Input Control (1) and Output Control (3) full

counterclockwise to 0, and set Response Rate Control

(6) to 3, assuming a typical speech input.

4. Turn Power switch (11) ON and wait approximately 1

minute for the circuitry to stabilize. DB Comp. meter (7)

should read full scale left (line below zero on lower

scale) and Gated Memory indicator (5) should be red.

5.

Set Input 1 switch (2a) to TONE OSC. and rotate Input

1 Control (la) clockwise for a DB Compression meter

(7) reading of 10 (lower scale). Gated Memory indicator (5) will change to white.

6. Set Meter switch (8) to VU and rotate Output Control

(3) for a VU meter (7) reading of 0 VU (upper scale).

Tone will be heard in headphones. The signal thus ap-

plied to the line may be used for calibration of the

equipment receiving the signal.

7. Reduce setting of the Output control (3) for a meter

reading of -2 VU, and return Input 1 switch (2a) to

IN. Note setting of Output Control (3) for future use.

(This reduction in sine-wave output is made to account

for the moderate short-term output dynamic range encountered for speech with the suggested Response

Rate control setting. A faster setting would eliminate

the need for this, but the compression would then become more audible.)

8. Set Meter switch (8) to DB COMP.

9. Now, with the expected average sound level entering

the microphone, set the Input 1 control (la) for an

average DB Compression meter (7) reading of ap-

proximately 10 (lower scale). This is the recommended

operating level for the SE30, since the unit will now

be able to maintain a substantially constant output

level for input reductions of 10 dB and increases of

as much as 30 dB.

10. Observe the operation of the Gated Memory indicator

(5). It should be white during speech input and change

to red during pauses between sentences and words,

indicating that the DB compression level is being

“remembered” during program lapses.

If the indicator remains white or “jitters” with no

spoken input to the microphone, it is an indication

that the acoustic background noise level at the micro-

phone is near or above the Gated Memory threshold.

The solution to this is to reduce the setting of the

Input 1 Control (1a) until the Gated Memory Indicator

(5) is consistently red without speaking into the microphone. The DB Compression level will then be determined by the loudness of the speaker and his proximity

to the microphone. This adjustment is very important

to insure proper operation in situations having very

high background noise levels, such as sporting events

or parades.

OPERATING CONSIDERATIONS

LARGE CHANGES IN INPUT LEVEL

If the overall sound and noise levels entering the microphone do not significantly change from those encountered

during set-up, as indicated by a DB Compression meter

(7) reading of 0 to 20 dB, and if proper operation of the

Gated Memory indicator (15) continues, it will not be necessary to adjust any controls further.

If, however, large changes in the signal going into the

microphone and/or in background noise do occur, some

Input 1 control (1A) readjustment may be advisable, as

indicated by the DB Compression meter and Gated Memory indicator. For example, a significant increase in background noise and signal may occur during an exciting portion of a sporting event, such that the Gated Memory no

longer “holds” during pauses and the DB Compression

reads higher than previously indicated. A gradual reduction of the Input 1 control (1a) setting will not be noticeable

to the listener, due to the automatic effect of the compressor, but proper action will be restored.

During a later, more subdued portion of the program, it

may become apparent that the DB Compression meter (7)

is reading near zero, and the Gated Memory indicator does

not always change to white during speaking. A gradual

increase of the Input 1 control (la) setting will then allow

operation at the proper level. Thus, during operation, after

setting the proper output level with the master gain control,

it is generally necessary only to monitor compression level

on the DB Compression meter (7) and to observe proper

action of the Gated Memory indicator (5).

Control setting changes need only be made for longterm, large changes in signal or noise levels. It is not necessary to “ride gain” to maintain a constant line output

level as measured by the VU meter, since that is the compressor’s function.

RESPONSE RATE ADJUSTMENT

The proper setting of the Response Rate control (6)

is determined by subjective factors, according to the type

of program material. Generally, a slower setting will result

in less audible compression, but a wider short-term out-

put dynamic range, that is, a less consistent output level.

Faster settings will result in a more nearly constant output

level but will make the effect of compression more audible.

The Response Rate control (6) setting may be changed

during operation for more satisfactory results if desired. A

guideline for an initial setting according to program material is: Speech-3; Popular Music-5; Symphonic Music-

7. The output leveling effect may be observed for various

settings by observing the VU meter (Meter switch (8) set to

VU), while the subjective effect is best ascertained by

listening on monitor headphones.

MULTIPLE INPUTS

Up to three microphones or input sources may be used

simultaneously with the SE30. In this case, the overall

“mixed” signal and background noise levels determine

DB Compression and Gated Memory action. For the best

results when several inputs are to be used one at a time,

only the used Input controls should be turned up. For a

8

Page 9

OPERATING CONSIDERATIONS (Cont’d)

conference or conversation situation, with several microphones “live” but only one speaker talking at a time, each

Input control should be set so that each speaker results in

approximately the same amount of compression, observing

that the overall level is correct for proper Gated Memory

action.

SIMULTANEOUS MIXED INPUTS

With simultaneous (mixed) inputs, the compressor will

automatically maintain a constant overall output level, so

that the balance among the sources may be adjusted easily

by monitoring with headphones. Simply observe that the

DB Compression meter (7) is reading in the normal operating range and that Gated Memory action is proper.

AUTOMATIC “DUCKING”

The balance between two sources may be adjusted to

produce automatic “ducking,” for example, for an announcer’s voice over musical programming. In this case,

set the Input control for the music source for a low amount

of compression, such as 5 dB. Then set the announcer’s

microphone Input control for 15 dB compression when he

is speaking. When the announcer talks during music, the

SE30’s gain will be reduced by 10 dB, “ducking” the music

level below the voice level by that amount. When he stops

speaking, the music will return to full output.

ADDITIONAL INPUTS

To accommodate more inputs than three, a Mix Bus

jack (12) is provided which may be connected to a similar

jack on another SE30 or M67 Mixer. When a Mixer

with a mix bus is used in conjunction with the SE30, a

compressed output may be obtained from the SE30, and

an uncompressed output of the same mixed material will

be available from the Mixer.

Inputs may also be added by connecting the line level

or microphone level output of another mixer to one of the

SE30 inputs.

EXCESSIVE AMBIENT NOISE

Under certain conditions, such as high noise levels,

it may be impossible to adjust the Input control (1) so that

the Gated Memory can consistently discriminate between

background and program. In such a case, the Gated Memory switch (21) should be set to Disable and the amount of

compression should be reduced to minimize the audible

effects of “pumping.”

In extremely severe cases, compression should not be

used at all, since the increase in background noise during

pauses will be quite unpleasant. The SE30 may then be

used as a high-quality linear mixer by setting the Comp.

switch (22) to DISABLE and setting the Meter switch (8)

to VU to monitor output level. As with any mixer it will then

be desirable to set the Input control (1) as high as possible without clipping, and set the output VU level with

the Output control (7), to provide best signal-to-noise ratio.

FADING TECHNIQUE WITH COMPRESSION

Fading of inputs with a compressor must be accomplished somewhat differently than with a linear mixer.

Since a slow reduction of input level within the compression region will be compensated for by an increase in

gain, no audible fading will occur. Consequently, fading

an input down should be done rapidly, at least to the point

at which the Gated Memory changes to the “hold” state.

For overall program fades, it is desirable to use the

Output control (3), since it does not affect the amount of

compression but only the output level.

SPECIAL APPLICATION

CONSIDERATIONS

SOUND REINFORCEMENT

The SE30 may be used in sound reinforcement installations, but some care must be exercised in such applications. Since this compressor can only reduce its gain when

a signal exceeds its compression threshold, maximum gain

occurs with low signal levels, and the sound-reinforcement

system’s gain must be adjusted to be stable (no ringing or

howling) with no compressor gain reduction. This may be

accomplished by adjusting system gain with the SE30’s

Comp. switch (22) set to DISABLE. With proper system

adjustment, the SE30 may be used to level the sound of

a “wavering” speaker, or to prevent power amplifier over-

drive with extremely strong signals.

STEREO OPERATION

Two SE30’s may be synchronized to operate together for

stereo applications by interconnecting their Stereo Parallel

jacks (23) and performing the adjustment procedure out-

lined in the Service Section of the manual.

One unit will compress the left channel signal and the

other will compress the right channel signal, but both will

respond equally to the sum (left and right) signal to minimize apparent stereo image shift.

Because of the necessity of providing the two units

with a properly balanced stereo signal, it is recommended

that stereo applications be restricted to single inputs for

each channel, with mixing and balancing being accomplished in another mixer prior to the SE30’s.

SINGLE INPUT PROGRAM COMPRESSOR

When the SE30 is used as a single line input, perma-

nently installed program compressor, it is possible to improve the signal-to-noise ratio by disabling two of the

inputs and thus reducing the electrical noise of the mixing

system. This modification is outlined in the Service Section.

RESPONSE RATE KNOB REMOVAL

To prevent inadvertent misadjustment of the Response

Rate control (6) the knob may be removed and the hole

filled with the plastic plug included with the SE30. This

procedure is described in the Service Section.

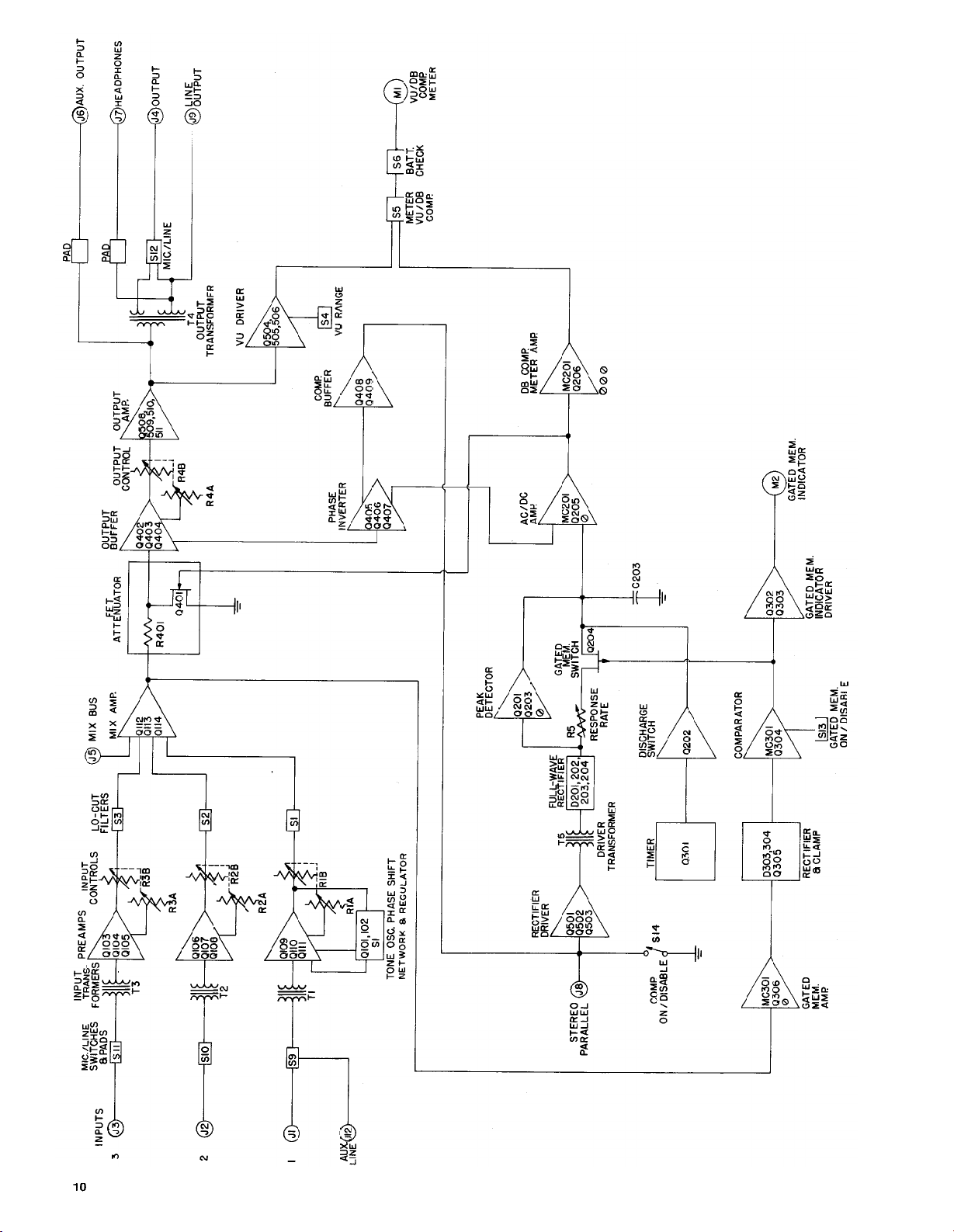

THEORY OF OPERATION

(See Figure 3)

Operation of the SE30 Gated Compressor/Mixer may be

explained by referring to the Functional Block Diagram,

Figure 3. The active devices in each stage, as well as other

important components, are identified by their reference

numbers, for ease of location on the Schematic Diagram

(Figure 4) and the Chassis Parts and Printed Circuit Board

Parts Placement diagrams (Figures 5 and 6). The first digit

of three-digit references indicates the printed circuit board

upon which the part is located.

INPUT-OUTPUT SIGNAL PATH

Balanced input signals entering through J1, J2, and J3

are amplified by the three transformer-coupled, variablegain input preamplifiers. Low-level signals are applied directly to the transformer primaries, and high-level (line)

signals are attenuated by balanced -48 dB resistive pads.

The Input controls are ganged, dual-section potentiometers

arranged such that a reduced control setting increases the

negative feedback around the stage, thus reducing gain

and increasing the input clipping level. Since the pream-

plifier stage gain cannot be reduced below 6 dB from its

9

Page 10

FUNCTIONAL BLOCK DIAGRAM - FIGURE 3

Page 11

THEORY OF OPERATION (Cont’d)

maximum of 30 dB, the second potentiometer section acts

as a conventional voltage divider output attenuator for low

control settings. The input transformers increase the signal

voltage by 21 dB.

Input 1 has a second line input, phone jack J12, which

operates only in the LINE position of S9. Additionally, this

stage (Q109, 110, 111) may be converted to a level-stabil-

ized, low distortion, 1 kHz Wien bridge tone oscillator.

A feedback-type, virtual-ground, low gain (3 dB) mixing

amplifier (Q112, 113, 114) assures nearly zero interaction

among input level control settings. Each input to the mixing

stage has a resistance-capacitance low frequency rolloff

filter providing a 6 dB per octave slope, 3 dB down at about

150 Hz. The mix bus jack (J5) contains a switch so that

when a phono plug is inserted, the mix bus impedance is

increased from near zero to 3.9 K ohms, for compatibility

with conventional mixing systems.

Automatic gain reduction is accomplished by the voltage

variable FET attenuator, R401 and Q401. With signal levels

below compression threshold, or when compression is disabled, the FET gate-to-source voltage is sufficiently negative to prevent FET conduction. Increased signal levels,

however, are sensed and the dc control voltage is increased until the FET drain-to-source resistance is reduced

enough to maintain a nearly constant signal voltage across

Q401.

This compressed signal is applied to the Output Buffer

stage (Q402, 403, 404), which has variable feedback sim-

ilar to the input preamplifiers, via the dual-section Output

potentiometer. This assures optimum output-stage clipping

and noise characteristics, either with a constant, compressed signal to the Output Buffer stage, or with compression disabled. The output amplifier (Q508, 509, 510,

511) is a class -AB, fixed gain line driver stage transformercoupled to the output load. A tertiary winding on T4 provides a microphone level balanced output, and headphone

and unbalanced auxiliary outputs are also derived from

the output amplifier stage through appropriate pads.

A three-transistor circuit (Q504, 505, 506) provides

full-wave rectification and power amplification to drive the

meter (Ml) with proper damping characteristics for the

VU output level function. The gain of the VU driver circuit

is changed by S4 for the two VU ranges.

D.C. CONTROL GENERATION

The signal voltage appearing across the attenuator FET

(Q401) travels through a portion of the Output Buffer

(Q402, 403, 404) and a unity-gain Phase lnverter (Q405,

406, 407) to the Compression Buffer (Q408, 409), a 30-dB

gain stage. The output of this stage may be shorted to

ground by switch S14 to disable compression, or it may be

connected in parallel with a similar stage in a second SE30

via its Stereo Parallel jack (J8) so that stereo difference

signals will be canceled out and thus not compressed, and

the stereo sum will be the controlling signal.

The signal at this point enters a small class-B power

amplifier, the Rectifier Driver (Q501, 502, 503). A full-wave

diode bridge rectifier (D201, 202, 203, 204) is driven from

this amplifier through Driver Transformer T5, thus generating full-wave rectified, unfiltered pulses whose am-

plitude is proportional to the absolute value of the signal

across the attenuator FET (Q401).

The Response Rate control (R5) and capacitor C203

form a resistance-capacitance integration or averaging

network with an adjustable time constant so that a smooth

dc voltage is generated, equal to the average value of the

full-wave rectified pulses. This dc voltage is amplified

(X2) by the AC/DC Amplifier (MC201, Q105) and applied

to the gate of the attenuator FET (Q401). The AC/DC Amplifier has low input bias current to minimize its discharging effect upon the integrating capacitor (C203). An adjustment associated with this amplifier applies an offset voltage

to the FET, setting the compression threshold.

The integrating R-C network assures an equal charge

and discharge time constant to provide a true average-

responding compression system. However, such a system

will exhibit a large overshoot in output when the input level

is suddenly increased. A Peak Detector (Q201, 203) is

therefore provided which monitors the instantaneous am-

plitude of the rectified pulses. If a pulse exceeds the average value by a preset amount, this detector will very

rapidly charge C203 enough to maintain the peak signal

amplitude within a reasonable upper limit. The Peak Detector threshold is set such that normal program material

at a constant level will not activate the circuit, but it will

reduce compressor gain rapidly for significant increases in

input level.

The AC/DC *Amplifier also has an input terminal for

signal voltage, fed via the Output Buffer and Phase Inverter. This serves to apply one-half of the signal voltage

across FET Q401 to its gate, along with the dc control

voltage, thus reducing distortion due to the FET’s non-

linear resistance characteristic.

The dc control voltage applied to the gate of Q401 is

used to drive meter Ml through the dB Compression Meter

Amplifier (MC201, Q206). This amplifier has gain, offset, and

gain reduction adjustments to allow calibration of the

meter reading to correspond at three points to actual levels

of compression, despite the nonlinear relationship between

compression and dc control voltage.

GATED MEMORY

The Gated Memory Switch FET Q204 allows the integrating capacitor (C203) to be charged and discharged

as described under normal signal conditions. However,

when the input signal drops below compression threshold,

Q204 becomes an open circuit, preventing discharge of

C203 and maintaining the amount of gain reduction just

prior to the opening of the FET switch.

The Gated Memory Amplifier (MC301, Q306) receives

the uncompressed signal, proportional to input level, from

the Mixing Amplifier. A fast-acting voltage doubler rectifier (D303, 304) converts this signal to a dc level which is

applied to the Comparator (MC301, Q304) after being

clamped by Q305 to assure fast recovery. The Comparator

output is a two-level dc signal applied to the gate of FET

Q204, and to the Gated Memory Indicator Driver (Q302,

303) to indicate the state of the Gated Memory circuit. The

gain of the Gated Memory Amplifier is adjustable to allow

setting the comparison threshold, and the switching FET

may be prevented from opening by switches S13 or S14.

When power is first applied to the SE30, approximately

30 seconds is required for the dc power supply voltages

to become properly established. During this interval, Timer

Q301 and Discharge Switch Q202 partially discharge integrating capacitor C203, preventing a possible “latch-up”

condition due to a turn-on transient combined with Gated

Memory Switch Q204 being open.

11

Page 12

SCHEMATIC DIAGRAM - FIGURE 4A

Page 13

SCHEMATIC DIAGRAM - FIGURE 4B

Page 14

SCHEMATIC DIAGRAM - FIGURE 4C

Page 15

SCHEMATIC DIAGRAM - FIGURE 4D

Page 16

SCHEMATIC DIAGRAM

PIN CONNECTIONS-

TOP VIEW

INTEGRATED CIRCUIT MC201 AND MC301

FIGURE 4E

REPLACEMENT PARTS FOR SE30-TABLE 1

16

NOTE:

THE COMMECIAL ALTERNATES SHOWN ABOVE ARE NOT NECESSARILY EQUIVALENTS, BUT MAY BE USED IN THE EVENT THAT DIRECT FACTORY REPLACEMENTS ARE NOT

IMMEDIATELY AVAILABLE. TO MAINTAIN SPECIFICATIONS AND RELIABILITY, SHURE FACTORY REPLACEMENT PARTS SHOULD BE USED.

FOR REPLACEMENT, PURCHASE Q502-Q503 AND Q510-Q511 AS MATCHED PAIRS TIS92M-TIS93M.

ORDER REPLACEMENT PARTS UNDER THlS NUMBER WHEN APPLICABLE. IF NO NUMBER IS SHOWN IN THlS COLUMN, ORDER UNDER SHURE PART NUMBER.

REPLACEMENT OF THESE PARTS NECESSITATES RECALIBRATION OF UNIT. SEE SERVICE SECTION.

(TABLE 1 cont’d on next page)

Page 17

TABLE 1 (Cont’d)

THE COMMERCIAL ALTERNATES SHOWN ABOVE ARE NOT NECESSARILY EQUIVALENTS BUT MAY BE USED IN THE EVENT THAT DIRECT FACTORY REPLACEMENTS ARE NOT

NOTE:

IMMEDIATELY AVAILABLE. TO MAINTAIN SPECIFICATIONS AND RELIABILITY, SHURE FACTORY REPLACMENT PARTS SHOULD BE USED.

FOR REPLACEMENT, PURCHASE Q502-Q503 AND Q510-Q511 AS MATCHED PAIRS TIS92M-TIS93M.

ORDER REPLACEMENT PARTS UNDER THIS NUMBER WHEN APPLICABLE. IF NO NUMBER IS SHOWN IN THlS COLUMN, ORDER UNDER SHURE PART NUMBER.

REPLACEMENT OF THESE PARTS NECESSITATES RECALIBRATION OF UNIT. SEE SERVICE SECTION.

17

Page 18

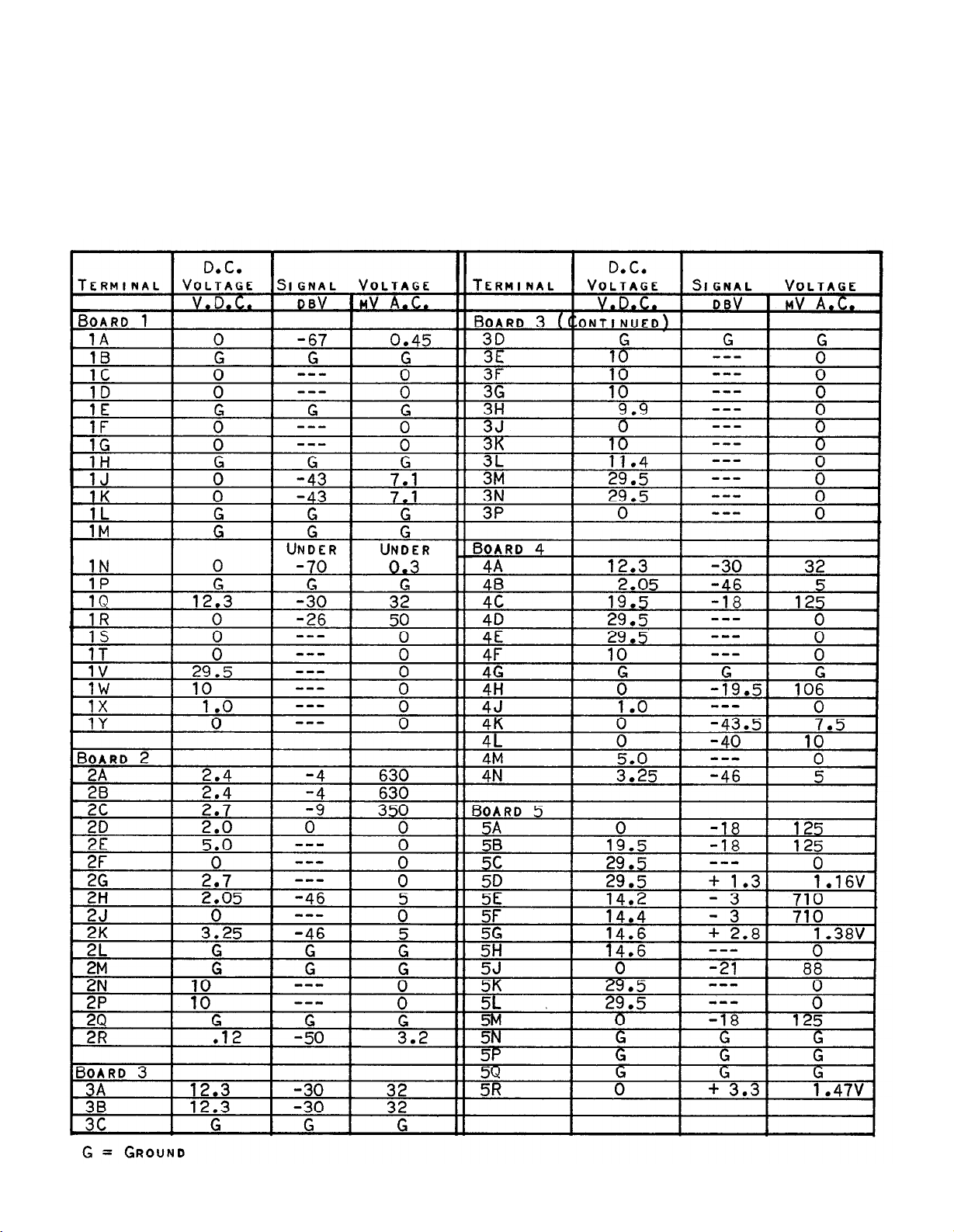

TEST VOLTAGES, P. C. BOARD TERMINALS

TABLE 2A

18

Page 19

TEST VOLTAGES, TRANSISTORS - TABLE 2B

19

Page 20

TEST VOLTAGES, INTEGRATED CIRCUITS

TABLE 1C

NOTES TO SCHEMATIC DIAGRAM AND

TEST VOLTAGES (Figure 4, Table 2)

1. All capacitors shown in microfarads and 50 volts or

more unless otherwise indicated. Electrolytic capacitors shown in mF X volts. pF = picofarad.

2. All fixed resistors ±10%, ¼ watt unless otherwise

shown. K = 1,000

M = 1,OOO,OOO

3. Components and wiring enclosed within dashed lines

are parts of printed circuit board assemblies.

4. The following symbols denote:

Direct chassis ground

Wired circuit ground

Printed circuit board ground

5. Arrows on potentiometers denote clockwise rotation.

6. Wire color designations with asterisks refer to

stranded No. 20 AWG wiring, and those in parentheses

refer to integral component leads. All other wires are

stranded No. 24 AWG.

20

7.

P. C. board terminals and wire destinations are shown

as board number-pin letter.

8. First digit of three-digit component references (for

example, R101) denotes number of printed circuit

board upon which part is mounted. One and two-digit

component references denote chassis-mounted parts.

9. AC and DC voltages given in Tables 2A, 2B and 2C

are measured with a 2.2 megohm or greater AC voltmeter and a 10 megohm or greater DC voltmeter. All

switches set as shown in schematic diagram. AC line

= 120 V, 60 Hz. Input 3 control set to 5, Input 1 and 2

controls set to zero, and Response Rate control set

to 3. Input signal 1 kHz applied to Input 3, level ad-

justed for 10 dB compression (signal at Pin A, board

3 equal to -30 dBV or 32 mV). Output control adjusted for + 4 dBm (+ 1.8 dBV or 1.23 V) line output

into a 600-ohm load.

Page 21

CHASSIS PARTS PLACEMENT

FIGURE 5

21

Page 22

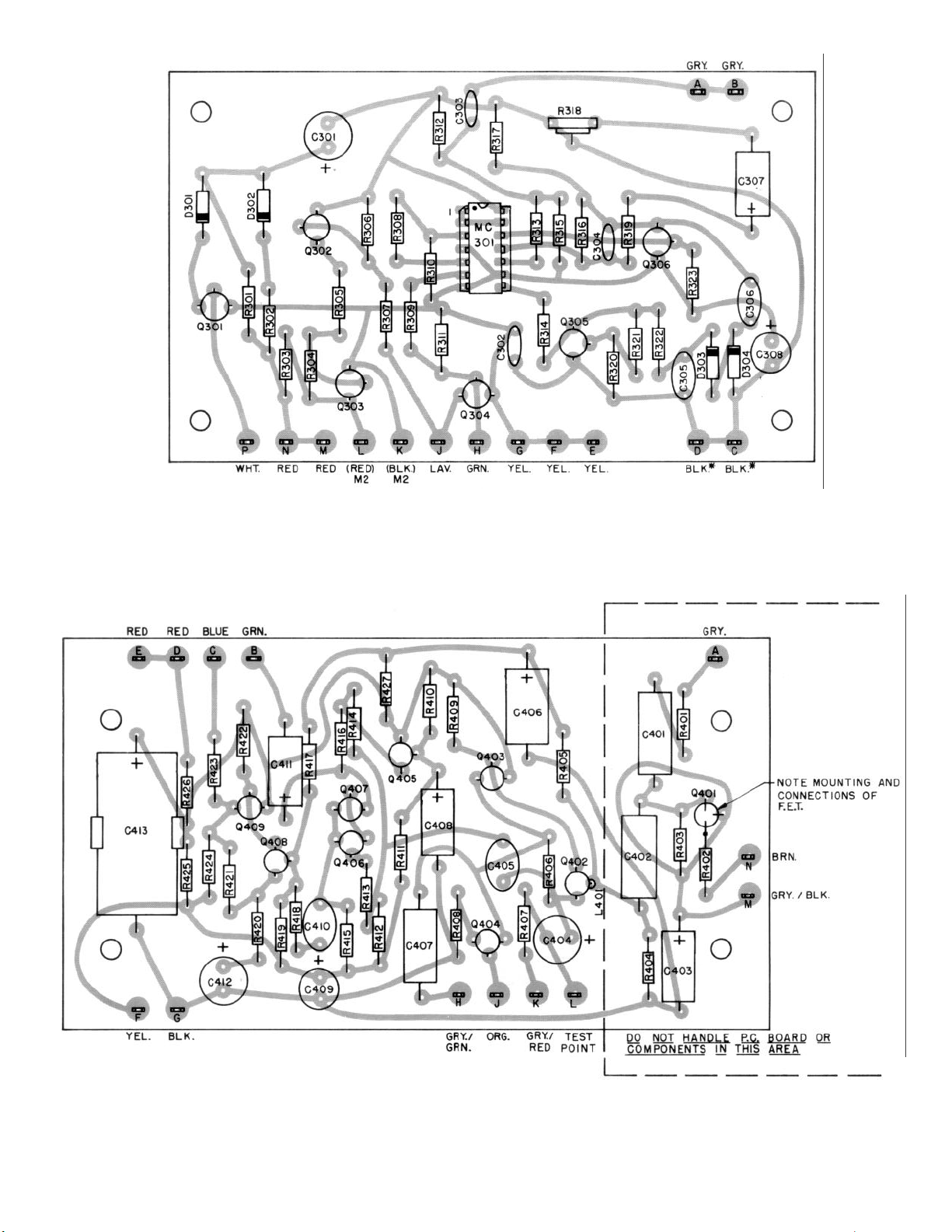

PRINTED CIRCUIT BOARD 1

22

PRINTED CIRCUIT BOARD 2

PARTS PLACEMENT

FIGURE 6A

Page 23

PRINTED CIRCUIT BOARD 3

PRINTED CIRCUIT BOARD 4

PARTS PLACEMENT

FIGURE 6B

23

Page 24

PRINTED CIRCUIT BOARD 5

PARTS PLACEMENT

FIGURE 6C

24

Page 25

SERVICE INSTRUCTIONS

The SE30 Gated Compressor/Mixer uses components

of the highest quality, operating well within their ratings

to assure long life and excellent stability. No routine maintenance is necessary with the exception of battery re-

placement.

CAUTION:

BATTERY REPLACEMENT:

No special tools are required.

1.

Turn knob on back of Battery Compartment (24) ¼

turn counterclockwise to OPEN position.

2.

Slide compartment rearward out of chassis.

3.

Release cover by unscrewing thumbscrew on top of

cover.

4.

Tilt cover upwards, pivoting at connector end of compartment, thus exposing batteries.

5.

Unsnap the six 9-volt batteries and replace. Remove

the 1.5-volt D cell and replace.

Note: The SE30 may be operated in an emergency

6.

Pivot cover down, align thumbscrew with speednut,

and tighten fully. Batteries are now held firmly by pads

in cover.

7.

Align metal bottom plate of compartment with plastic

guides in SE30 chassis and gently slide compartment

fully into chassis.

8.

Rotate knob clockwise to LOCK position.

COVER REMOVAL AND REPLACEMENT

Most servicing and calibration can be performed with

only the top cover removed. The only tool required is a

No. 1 or No. 2 Phillips screwdriver.

1.

Turn Power switch (11) OFF and remove ac line cord

from AC Power Receptacle (25).

2.

Remove the upper of the two Phillips screws on each

side of the SE30.

3.

Remove the top cover by grasping the upper half of

each side and pulling straight up. This exposes the

components shown in the top view of Figure 5.

4.

End plates may be removed for easier access to sidemounted components by removing the remaining Phillips screws on each side of the SE30. The end plates

may then be removed by pulling straight up.

5.

The bottom cover may be removed either with or without removing the end plates as above. Invert the SE30

and unscrew the four bumpers (feet). The bottom cover

may then be pulled straight up from the central

chassis. The SE30 will operate properly, except for

possible increased hum pickup, with both the top and

bottom covers removed.

6.

Replace the bottom cover by placing the chassis upside-down and sliding the cover over the chassis,

securing it in place with the four bumpers and screws.

If the end plates are attached to the cover, position it

so that the large holes in the end plates are near the

front of the chassis.

7.

Replace each end plate, if necessary, by sliding it

between the end of the chassis and the inside of the

bottom cover, securing it with a Phillips screw. Posi-

There are no user serviceable parts within the

case of the SE30. Refer servicing to qualified

service personnel.

with only three 9-volt batteries, installed in

either the right or left row of battery connectors.

The 1.5-volt D cell operates only the auxiliary

light, and may be omitted if this feature is not

required.

tion the large hole near the front of the chassis. The

right and left end plates are interchangeable.

8. Replace the top cover by sliding the ends downward,

guided by the recesses in the end plates. Secure with

the two remaining Phillips screws.

CHASSIS PARTS

Figure 5 illustrates the location of each chassis-mounted

component by reference number, corresponding with those

in the Schematic Diagrams (Figure 4) and Replacement

Parts List (Table 1). Note that all one and two-digit reference numbers denote ‘chassis-mounted components.

The five printed circuit boards are numbered 1 through

5 from left to right, and are easily removable as outlined

below. Trimmer potentiometers used during calibration

are located on P.C. Boards 2 and 3 and are shown in Figure

5. Complete replacement P.C. Board Assemblies are available. See Replacement Parts List (Table 1), and note that

the replacement of certain components and P.C. Boards

will necessitate recalibration of the unit.

The color-coded chassis wiring is indicated both in the

Schematic Diagrams (Figure 4) and in the P.C. Board Parts

Placement Diagrams (Figure 6). Connections associated

with each printed circuit board are shown in the Schematic

Diagram as follows:

PC. Board 1, Figure 4A; P.C. Board 2 and P.C. Board 3,

Figure 4B; P.C. Board 4, Figure 4C; and P.C. Board 5,

Figures 4C and 4D. Power supply wiring is shown in

Figure 4D.

LAMP REPLACEMENT

The tools required are a No. 1 or No. 2 Phillips screw-

driver, and ¼" and 5/16" open-end wrenches.

1.

Remove the topcover as described above.

To replace the ac operated pilot lamps (PL1 and

2.

PL2), remove the hexagonal-head screws mounting

the lampholders to their vertical brackets, using the

¼" open-end wrench.

The sockets may now be pulled rearward and rotated

3.

up so that the #47 bulbs may be replaced. It is advisable to replace both of these lamps when one burns

out.

Replace the sockets in position and secure with the

4.

hexagonal head screws. Note that there are two holes

in each bracket, the rear hole for the socket tab and

the front hole for the screw.

To replace the battery operated Aux. Light (PL3), note

5.

the position of the socket between the Gated Memory

indicator (M2) and the meter (M1). Remove the hex

nut and lockwasher holding the socket to the left

meter stud, using the 5/16" open-end wrench.

6.

Unscrew the bulb and replace with a #223 lamp,

tightening it firmly in the socket.

7.

Position the socket bracket over the meter stud, fol-

lowed by the lockwasher and the nut, and tighten

while holding the socket in proper position.

8.

Replace the top cover.

PRINTED CIRCUIT BOARD REMOVAL AND SERVICE

A standard blade screwdriver or similar prying tool and

long-nose pliers are the only tools needed, unless soldered components are to be replaced. To avoid component

and printed circuit board damage, a soldering iron of 40

watts or less is recommended

1. Remove AC line cord and remove top cover as described above.

2. Each printed circuit board is mounted by four plastic

25

Page 26

SERVICE INSTRUCTIONS (Cont’d)

push-on retainers so that it may be raised above the

chassis for service without complete removal. With all

power turned off, depress retainer locking tab, if any,

and pry each corner of the board from its retainers. Lift

the board straight up assuring that all wires clear any

obstructions, and position the two lower board mounting holes over the two upper plastic retainers. Snap the

board over the retainers, thus exposing the component

side and most of the conductor side of the board.

After positioning one or more boards in this manner,

the SE30 may be operated and measurements made.

3.

All connections to printed circuit boards are made by

push-on terminals crimped to color-coded wires. To

remove a printed circuit board, first turn off all power

and remove ac line cord, then grasp each brass terminal with long-nose pliers and pull away from board.

The board may then be pried from its retainers and

lifted out of the chassis.

4.

Figure 6 illustrates the location and position of each

printed circuit board component. Note that all such

components have three-digit reference numbers, the

first digit of which denotes the printed circuit board

number. The colors of wires connected to each ter-

minal are also shown to aid in reconnecting boards.

Color abbreviations with asterisks refer to stranded

No. 20 AWG wiring, and those in parenthesis refer to

integral component leads. All other wires are smaller,

stranded No. 24 AWG.

5.

Printed Circuit Board 4 requires special handling, as

noted in Figure 6B. To avoid possible erratic operation

under high humidity conditions, the area of the board

which includes Q401, R401-404, and C401-403 must

be kept free of contamination from perspiration, skin

oils, and the like on both sides. This area should not

be touched with the fingers, and if any of these components must be replaced, soldering flux must be removed by brushing with a solvent such as clean wood

alcohol (methanol) or denatured alcohol. (Do not use

rubbing alcohol.) After flux removal, rinse with distilled water to remove electrolyte contaminants.

CAUTION: Alcohol is flammable. Do not use near fire.

Note that FET Q401 is mounted inverted to the board

with a direct soldered connection between R402 and

the gate lead.

6.

Integrated circuits MC201 and MC301 are mounted in

14-pin sockets to facilitate removal and replacement.

The notch on one end and a dot or mark identify pin 1,

which must be positioned as shown in Figures 6A and

6B and as indicated on the printed circuit board.

Typical voltage measurements are given for Various

7.

points in the circuitry in Tables 2A, 2B, and 2C. The

notes to Schematic Diagram and Test Voltages Outline

the test conditions for these measurements. Voltages at

all printed circuit board terminals are given in Table

2A, and board-mounted transistor and integrated circuit terminals voltages are given in Tables 2B and 2C.

All voltages are measured with respect to chassis

ground.

8.

Replacement of Printed Circuit Boards 2, 4, or 5, or

of MC201 will necessitate recalibration of the compression system as outlined below. In addition, Printed

Circuit Board 3 replacement requires Gated Memory

recalibration, and Printed Circuit Board 5, or meter

Ml replacement require VU Meter calibration. Compression system calibration should also be checked

if meter M1 is replaced.

26

CALIBRATION

Each SE30 Gated Compressor/Mixer is individually cali-

brated at the factory with six internal trimming potentiom-

eters and a selected fixed resistor, to compensate for

individual component variations and to assure uniform and

accurate performance. The complete calibration procedure

is given here for qualified service personnel with access

to laboratory quality instruments, in the event that component replacement or changes in internal control settings

necessitate recalibration.

For those without adequate facilities, the complete unit

may be returned to the factory for calibration. Carefully

repack the unit and return it to the factory Service Department. The unit will be returned to you prepaid.

EQUIPMENT NEEDED:

A high-impedance (2 megohm or greater), high-sensitivity (10 mV full scale or better) ac voltmeter, such as a

Hewlett-Packard 400 GL or Ballantine 861, is necessary for

accurate results. The meter should be equipped with a

clip-on shielded test cable.

In addition, a sine-wave audio generator, capable of

producing 1 volt at 1 kHz with less than 1% total harmonic

distortion, is desirable. A generator with an accurate 10

dB stepped output attenuator, such as the Hewlett-Packard

204D, will greatly simplify changes in input level necessary

during the procedure. A shielded cable to connect the out-

put of the generator to the professional three-pin female

Input 1 receptacle will be needed. Unbalance the generator

output (low side connected to chassis), if generator output

is balanced, and wire the cable so that input connector

pins 1 and 3 are to the low side of the generator and pin 2

is to the high side.

There are three different portions of circuitry which re-

quire calibration: the Gated Memory, the compression system, and the VU meter. A standard blade screwdriver may

be used to adjust the trimmer potentiometers during the

Gated Memory and compression system calibration. VU

meter calibration requires the selection of a fixed resistor

and soldering it in place on P.C. Board 5.

During the Gated Memory and compression system Cali-

bration, the internal signal level at terminal A of P.C. Board

3 is monitored and adjusted. The signal voltage at this

point will be referred to as E3A. The test signal is provided

by an external sine-wave generator, or the internal Tone

Oscillator may be used. If an external generator is used,

connect its mating cable to the Input 1 connector (13A) with

the Input switch (14A) set to LINE, and the Input 1 Filter

switch (2A) set to IN. Adjust the generator for 1 volt output

at 1 kHz. If the Tone Oscillator is used, set the front-panel

Input 1 Filter switch (2A) to TONE OSC.

If the Tone Oscillator or an external generator without a

stepped attenuator is used, the voltage at terminal A of

P.C. Board 3 (E3A) should be adjusted to the required

values by the Input 1 control (1A). If the external generator

does have a stepped attenuator, the Input 1 control (1A)

should be adjusted so that a l-volt generator output results

in 1 volt at terminal A of P.C. Board 3. Lower levels are then

obtained by using the generator’s attenuator.

Calibration must be performed with the top cover removed to permit access to the trimmer potentiometers and

test points, and during compression system calibration,

removal of the bottom cover is also suggested. For complete safety from hazardous powerline voltages, the SE30

should be battery-operated during calibration, using fresh

batteries which indicate +1½ VU or better on the meter,

with the Batt. Check switch (9) actuated and the Power

switch (11) ON.

Page 27

SERVICE INSTRUCTIONS (Cont’d)

PROCEDURE:

First, the meter (7) must be mechanically set to zero.

Turn the Power switch (11) OFF and wait one minute. The

meter pointer should rest over the mark at the left-hand

end of the scale, left of the -20 VU and 0 dB Compression

line. Using a small blade screwdriver, rotate the black

plastic screw below the meter face to set the pointer, if

necessary. The electrical calibrations may now be performed as outlined below.

Unless otherwise specified, set all Lo-cut Filter switches

(2) to IN, the Meter switch (8) to DB COMP., the Power (11),

Gated Memory (21), and Comp. (22) switches to ON, the

Input (14) and Output (17) switches to LINE, and the VU

Range switch (4) to +4. Set Output (3) and Input (1) con-

trols to 0, except for Input 1 (1A), adjusted as above. Set

Response Rate control (6) to 3. Measure all voltages with

respect to chassis ground.

GATED MEMORY CALIBRATION:

The Gated Memory calibration should be checked and

adjusted before proceeding to the compression system

calibration.

Connect meter probe to P.C. Board 3, terminal A,

leaving existing gray wire connected, to measure E3A.

Adjust input such that E3A is -43.5 dBV (6.6 mV).

Red portion of Gated Memory indicator (5) should be

exposed.

Adjust input such that E3A is -41.5 dBV (8.4 mV).

Red portion of Gated Memory indicator (5) should be

covered by white vane.

If steps 2 and 3 are not correct, adjust input such that

E3A is -42.5 dBV (7.5 mV) and rotate R318 fully

counterclockwise. Gated Memory indicator (5) will be

white. Slowly rotate R318 clockwise just until red

portion of Gated Memory indicator is exposed. Recheck steps 2 and 3.

COMPRESSION SYSTEM CALIBRATION:

Because of the interdependence of trimmer settings, the

following procedure must be followed in the order listed.

The Gated Memory must first be properly calibrated as

outlined above.

The voltage at terminal L, P.C. Board 4, referred to as

E4L, must also be measured. This terminal is a test point

with no wire connected to it, and access may most easily

be obtained by setting the chassis on its right or left end

and inserting the meter probe from the chassis bottom

through the rectangular hole near transformers T4 and T5.

The temporary wiring change in step 2 may also most

easily be done from the bottom of the unit.

Average Level Adjustment (R212).

Set input such that E3A is -30 dBV (31.6 mV). Voltage

E4L must be -40 ± 0.2 dBV (10± 0.2 mV). If necessary, adjust R212 for the proper E4L reading, but allow

15 seconds of settling time after moving R212 setting

to read E4L. If this setting is changed, all subsequent

calibration steps must be checked.

Peak Level Adjustment (R211).

Move blue wire from terminal C of P.C. Board 2 to

terminal D. Set input such that E3A is -20 dBV (100

mV). Voltage E4L must be -27.5 ± 0.3 dbV (44 ± 3

mV). If necessary, adjust R211 for proper E4L reading.

Return blue wire from terminal D of P.C. Board 2 to

terminal C.

DB Compression Meter Calibration Check.

A. Set input such that E3A is -40 dBV (10 mV).

Meter pointer should lie over 0 on the DB Compression scale.

B.

Set input such that E3A is -20 dBV (100 mV).

Meter pointer should lie in region occupied by

20 on the DB Compression scale. If either of these

checks is not correct, proceed to step 4.

C.

Set input such that E3A is 0 dBV (1.0 V). Meter

pointer should lie in region occupied by 40 on the

DB Compression scale. If checks A and B are

correct, but if this check is not, proceed to step 5.

4. DB Compression Meter Calibration, 0 and 20 Points

(R213, R214).

The settings of R213 and R214 interact to calibrate the

meter to read 0 when E3A is -40 dBV (10 mV) and to

read 20 when E3A is -20 dBV (100 mV).

A. Rotate R215 fully clockwise.

B. Set input such that E3A is -40 dBV (10 mV). Ro-

tate R213 for a meter reading of 0.

C. Set input such that E3A is -20 dBV (100 mV). If

meter reading is less than 20, rotate R214 slightly

clockwise. If meter reading is more than 20, rotate

R214 slightly counterclockwise. The effect upon

the meter reading at this point is unimportant.

D. Set input such that E3A is -40 dBV (10 mV) and

again rotate R213 for a meter reading of 0.

E. Again set input such that E3A is -20 dBV (100 mV)

and observe meter for a reading of 20.

F. Repeat steps B through E until meter reads 0 when

E3A is -40 dBV (10 mV) and 20 when E3A is -20

dBV (100 mV).

G. Proceed to step 5.

5. DB Compression Meter Calibration, 40 Point (R215).

Set input such that E3A is 0 dBV (1.0 V). Rotate R215

until meter reads 40 on the DB Compression scale.

VU METER CALIBRATION:

Proper VU meter calibration is determined by a VU

CAL trimmer potentiometer (R529) on P.C. Board 5. The

check outlined in step 1 may be performed if P.C. Board 5

has not been replaced, but the procedure of step 2 must

be followed if it has been changed.

First, connect a 600-ohm ± 5%, ½ watt resistor (two

1200-ohm, 5%, ¼ watt resistors in parallel may be used)

between terminals 3 and 2 of the Line Output connector

(20).

1. Calibration check.

A.

Set input so that meter reads approximately 20 on

the DB Compression scale, with the Meter switch

(8) set to DB COMP.

Set the Meter switch (8) to VU and rotate the Out-

B.

put control (3) until the meter reads 0 on the VU

scale.

The voltage measured across the 600 ohm resistor

C.

should be 1.8 ± 0.3 dBV (1.23 ± 0.04 V). This is

4.0 ± 0.3 dBm.

2. Calibration procedure.

If meter Ml has been replaced, first check calibration

in step 1. If check fails, follow procedure below.

A. Set input such that meter reads approximately 20

on the DB Compression scale, with the Meter

switch (8) set to DB COMP.

B. Set the Output control (3) such that the voltage

measured across the 600-ohm resistor connected

to the Output terminals (20) is 1.8 dBV (1.23 V or

4.0 dBm).

27

Page 28

SERVICE INSTRUCTIONS (Cont’d)

C. Set the Meter switch (8) to VU and the VU Range

switch (4) to +4. Adjust VU CAL trimmer potentiometer (R529) for a 0 VU meter reading. Cali-

bration is complete.

STEREO SYNCHRONIZATION

Two SE30’s may be synchronized to operate together

for two-channel stereo applications. With the Stereo Parallel jacks (23) connected together and the adjustment

below performed, the two units will respond equally to the

sum (left and right) signal to minimize apparent stereo

image shift. After synchronization, the two units will track

together over at least a 20 dB compression range. It is intended that the two units be supplied with a properly balanced and mixed stereo signal from a separate mixer or

other source.

The synchronizing adjustment procedure may be per-

formed upon two properly calibrated SE30’s as outlined

below. The same equipment needed for calibration is

used for this procedure, except that an external audio

generator is a necessity. A second cable for connecting

the generator to the input connector also is required.

ADJUSTMENT:

1.

Connect the Input 1 connectors (13A) of both units

simultaneously to the audio generator, observing

proper phasing. Cables should be wired such that

input connector pins 1 and 3 are to the low side of

the generator and pin 2 is to the high side. Set the

Mic/Line input Switches (14A) appropriately.

2.

Set the output of the audio generator for the expected

signal level to be applied to the units. This will be ad-

justed as follows to correspond with 10 dB of com-

pression.

3.

Set Output (3) and Input (1) controls to zero, and Re-

sponse Rate controls (6) to the same setting on both

units, preferably between 2 and 5. Set VU Range

switches (4) and Input 1 Lo-Cut Filter switches (1A)

the same on both units, as required. Set Comp.

switches (22) to ON and Gated Memory switches (21)

to DISABLE. Set Meter switches (8) to VU.

4.

Remove the top covers of both units and apply power.

5.

Measure the signal voltage at terminal A of P.C. Board

3 (referred to as E3A) of one unit. Rotate the Input 1

control (1A) of this unit until E3A is -30 dBv (31.6 mv).

Measure E3A of the second unit and set its input 1

control (1A) for the same reading. Do not readjust

either input 1 control after this step.

6.

Set the Output control (3) of the first unit for a meter

reading of 0 VU. Repeat for the second unit.

7.

Connect the Stereo Parallel jacks (23) of the two units

together, using a phono pin plug shielded jumper

cable.

8.

After 30 seconds, observe the VU meter readings of

the two units and note which unit’s meter reading has

increased above 0 VU. Slowly rotate R212 of this unit

clockwise until its VU meter reads 0 VU. Allow 30

seconds for meter reading to stabilize.

9.

Reduce generator output until E3A of this unit is -40

dBv (10mv) and set Meter switch (8) to DB COMP.

Adjust R213 for a reading of 0 on the dB Compression

scale of the meter. Do not disturb any adjustments on

the other unit.

10.

Increase generator output until E3A of this unit is -20

dBv (100 mv). Set both Meter switches (8) to DB

COMP. and observe readings of both meters.

11.

Short circuit the output of the audio generator and

note the time required for the meter readings of each

unit to fall to 0 DB Compression. Remove the generator

short circuit and allow the meter readings to rise and

stabilize.

12.

Adjust the Response Rate control (6) of one of the

units in the appropriate direction to make the two

meter fall times equal and repeat Step 11 to check the

results.

13.

Repeat Steps 11 and 12 until meter fall times are equal.

The settings of the two Response Rate controls may be

somewhat different because of individual component

variations between units.

14.

Replace the top covers of both units.

OPERATION:

After performing the above adjustments, do not disturb

any of the Input, Output, or Response Rate control settings

thus established. If the Gated Memory feature is desired,

set the Gated Memory switches (21) on both units to ON.

The units may now be fed from a balanced, mixed, stereo

source whose level will determine the amount of compres-

sion as indicated on the DB Compression meters of the

SE30’s. Because of individual component variations be-

tween units, the two meters may indicate somewhat dif-

ferently, but both units will operate similarly if adjusted as

outlined above.

Since stereo operation is recommended for only a single

pair of inputs, it may be desirable to improve the operating

signal-to-noise ratio by disabling the two unused input

channels on each unit. This procedure is described in the

Modifications section below.

If it is necessary to change the Response Rate control

settings to compensate for different types of program

material, the timing of the two units should be adjusted to

be equal. This may be done without removing the covers

by applying a signal from an external audio generator to

the inputs of both units simultaneously. Set the Gated

Memory switches (21) of both units to DISABLE and ad-

just the generator output for a DB Compression reading of

approximately 20 on either unit’s meter. Set the Response

Rate control (6) of one unit to the number desired, then

adjust the Response Rate control of the other unit as described in Steps 11, 12, and 13 above.

28

Page 29

MODIFICATIONS

Noise Improvement for Single Inputs:

The overall signal-to-noise ratio of the SE30 may be improved for single-input applications by disabling the two

unused input channels. This automatically reduces the

noise level of the mixing circuitry without changing the

gain or other characteristics of the remaining input. It is

recommended that Input 1 be used and Inputs 2 and 3 disabled to retain the Tone Oscillator and Aux. Line Input

features associated with Input 1. To disable Inputs 2 and 3,

follow the procedure below.

1. Remove AC line cord and turn off all power. Remove

the top cover.

2.

Locate resistors R12 and R13 (33K ohms), between Input 2 and 3 controls and their associated Lo-cut Filter

switches. Disconnect resistors R12 and R13 from

switches S2 and S3. Bend removed lead of resistor

away from all terminals, wires, and chassis.

3. Replace top cover. During operation, set Input 2 and

Input 3 controls to zero.

Response Rate Knob Removal:

To prevent inadvertent misadjustment of the Response

Rate Control for applications in which a fixed setting may

be established, the knob may be removed.

1. Experimentally determine the proper Response Rate

Control setting for the intended application and rotate

the knob to this position.

2. Remove AC line cord and turn off all power. Remove

the top cover.

3.

Note that the plastic Response Rate knob (K5) extends

through the front panel, over the shaft of potentiom-

eter R5. Insert the blade of a standard screwdriver

between the rear of the knob and the shaft bushing of

R5, and twist the screwdriver ¼ turn. This will slide

the knob forward on the shaft partially out of the front

panel.

4.

Grasp the knob and pull it completely out of the front

panel.

5.

Push the black plastic plug supplied with the SE30 into

the hole thus exposed.

6. To permit subsequent control adjustment or replacement of the knob, the plug may be released by remov-

ing the top cover and using long-nose pliers to pinch

together the locking devices on either side of the plug

body.

Telephone Line Surge Protection:

When using the SE30 to feed a telephone line subject

to lightning induced voltage surges, the following part

(commercially available) can be installed across the Line

Output terminals to provide additional protection for output circuit components:

Metal Oxide Varistor

General Electric Co.

Type No. V22ZA1

29

Page 30

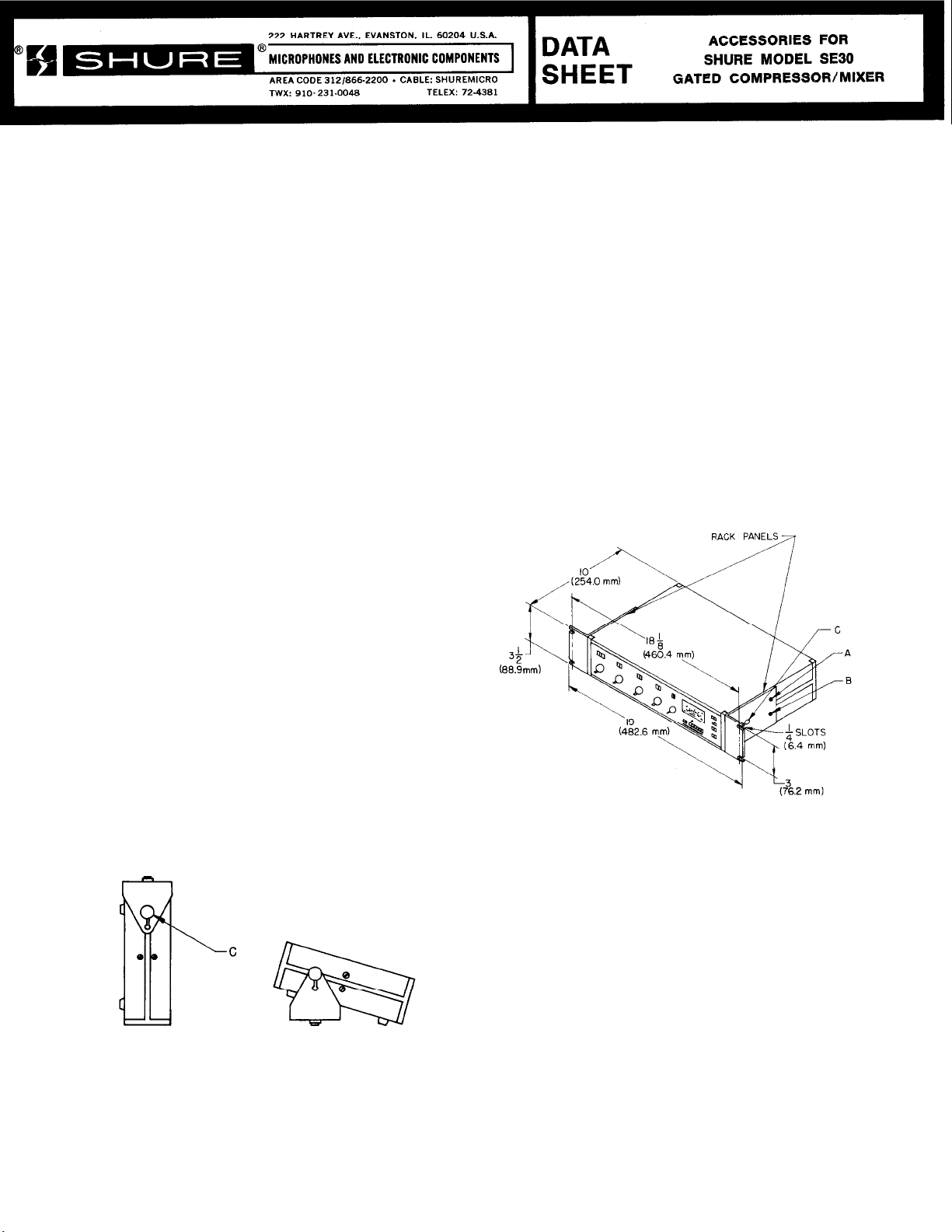

MODEL A100A CARRYING HANDLE ASSEMBLY

The Shure Model A100A Carrying Handle Assembly

provides a means for conveniently carrying the Shure

Model SE30 Gated Compressor/Mixer. The Model

A100A serves as a handle for carrying the SE30, as a

cover for the front panel, and as a tilt stand for position-

ing the SE30 at an angle for easy reading of the controls and meters. The A100A is easily switched from

carrying handle use to tilt stand use simply by readjusting two knurled bolts which secure the Model

A100A to the SE30. When in the tilt stand position,

the SE30 rests on rubber feet mounted on the Model

A100A. When in a carrying position, the SE30 may be

rested on any flat surface and is then protected by the

die cast corners on the rear of the case.

to mount the Model A100A on the Model SE30,

proceed as follows:

1. Place the back (bottom) of the SE30 on a flat

surface with the front controls facing up.

2. Position the Model A100A over the front of the

SE30. The top of the screw slots on the sides

of the Model A100A should align with the two

tapped holes (C) on the sides of the SE30. See

Figure 1, Carrying Position.

3. Screw the two knurled bolts supplied with the

Model A100A fully clockwise into the two tapped

holes (C) on each side of the SE30.

To position the Model A100A in tilt stand position,

proceed as follows:

1.

Loosen the knurled bolts at sides of Model A100A

by turning them partially counterclockwise.

2. Lift the Model A100A away from the SE30 so

that the knurled bolts pass through the bottom

of screw slots.

3. Swing the Model A100A handle beneath the SE30

and tighten the knurled nuts (screw clockwise).

See Figure 1 Position in Use.

MODEL A100B RACK PANEL

The Model A100B Rack Panel provides the Model

SE30 with supports for rack mounting. To mount the

Model A100B to the Model SE30, proceed as follows:

1.

Unscrew the four rubber feet from the bottom

of the SE30 to eliminate the obstruction of the

rubber feet when sliding the SE30 into a rack

panel.

2.