Page 1

Shure Brothers Incorporated

222 Hartrey Avenue

Evanston IL 60202-3696 U.S.A.

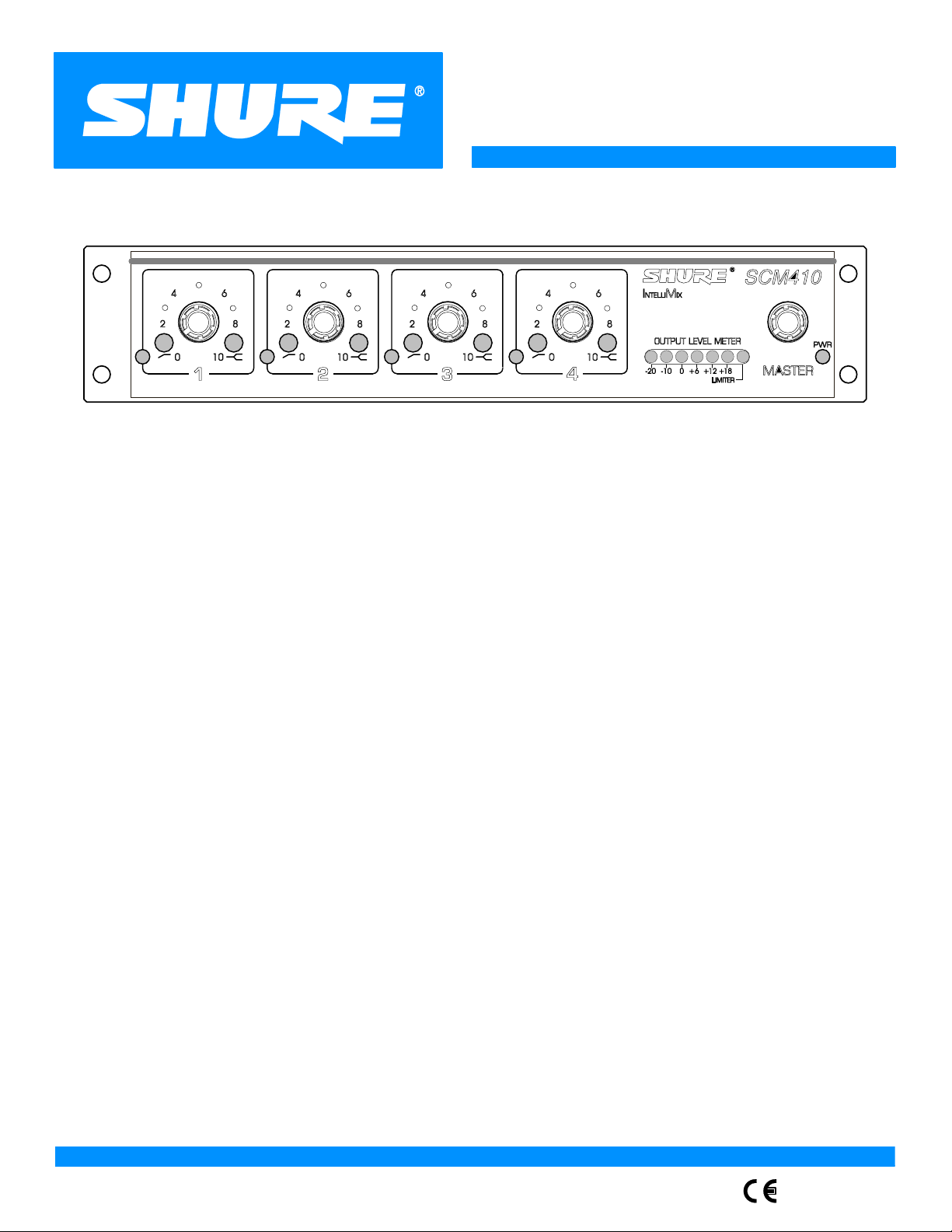

Model SCM410/SCM410E User Guide

SCM410/SCM410E

FOUR CHANNEL AUTOMATIC MICROPHONE MIXER

1999, Shure Brothers Incorporated

27A8690 (SG)

U.S. Patents 4,658,425; 5,297,210

Printed in U.S.A.

Page 2

TABLE OF CONTENTS

DESCRIPTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FEATURES 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATING PRINCIPLES 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT PANEL 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REAR PANEL 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP SWITCH FUNCTIONS 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SUPPLIED HARDWARE 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RACK MOUNTING 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE-TOP MOUNTING 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIXED MOUNTING 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCM410 CONNECTIONS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LINKING MULTIPLE MIXERS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BASIC OPERATION 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIMITER 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EQUALIZER FUNCTIONS 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADVANCED FUNCTIONS 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOGIC CONNECTION SPECIFICATIONS 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SUGGESTED LOGIC APPLICATIONS 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INTERNAL MODIFICATIONS 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARNING: Voltages in this equipment are hazardous to life. No user-serviceable parts inside. Refer all servicing to qualified

service personnel. The safety certifications do not apply when the operating voltage is changed from the factory setting.

This symbol indicates that dangerous voltage constituting a risk of electric shock is present within this unit.

This symbol indicates that there are important operating and maintenance instructions in the literature accompanying this unit.

2

Page 3

DESCRIPTION

The Shure Model SCM410/E is a four-channel automatic microphone mixer designed for use in sound reinforcement, audio recording, and broadcast applications. The SCM410 dramatically improves audio quality in any application where multiple microphones are required. Any low-impedance dynamic

or condenser microphone (including wireless) can be used

with the SCM410. Multiple SCM410 mixers can be linked to

other SCM410 mixers, as well as to Shure Models FP410,

SCM810, SCM800, and AMS8100 mixers.

FEATURES

• Fast, noise-free microphone selection, which automatically

adjusts to changes in background noise

•Automatic gain a djustment a s additional m icrophones a re a c-

tivated–NOMA (Number of Open Microphones Attenuated)

• Last Mic Lock-On circuit maintains ambient sound

• Fits in half-rack space

• Adjustable EQ for each channel

OPERATING PRINCIPLES

The operating concept behind the SCM410 Automatic Mixer is

Shure’s patented*

less automatic mixing by combining three separate functions:

IntelliMix

circuitry.

Intellimix

delivers seam-

• Noise Adaptive Threshold. Distinguishes between constant

background noise (such as air conditioning) and changing

sound (such as speech) for each input channel. It continuously

adjusts the activation threshold so that only speech levels

louder than the background noise activate a channel.

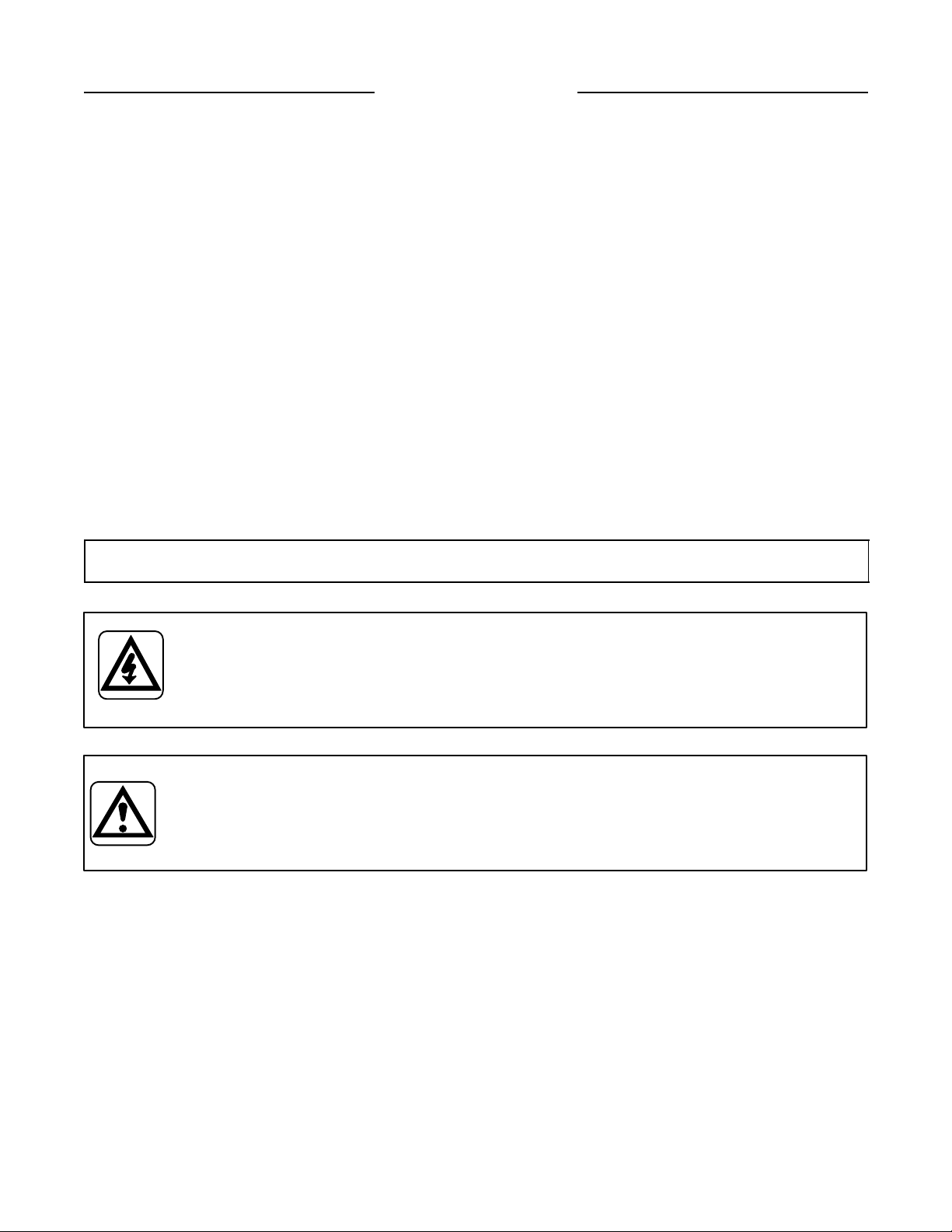

FRONT PANEL

Each input channel has a two-band equalizer and three logic

terminals. The equalizer reduces unwanted low-frequency audio pickup and makes different microphone types—lavaliers,

boundary and handheld—sound similar. The logic terminals

can be used to control external devices.

The SCM410 operates o n 100–120 Vac power and t he S CM410E

operates on 220–240 Vac power. Each mixer is supplied with a

power cord, rack-mounting hardware, and a link cable.

•Active balanced microphone-level XLR inputs and an active

balanced Mic/Line level XLR output

• Unbalanced auxiliary-level phono output

• Bi-color channel activation and clipping LEDs

• Peak-responding output limiter with LED indicator

• Peak-responding output level meter

•MaxBus. Controls the number of channels that may be acti-

vated for a single sound source. One talker activates only

one channel, even if multiple microphones “hear” that talker.

• Last Mic Lock-On. Keeps the most recently activated mi-

crophone open until another microphone is activated. Without Last Mic Lock-On, a long pause in conversation would

cause all microphones to turn off, which would sound as if

the audio signal had been lost. Last Mic Lock-On ensures

that background ambience is always present.

MODEL SCM410 FRONT PANEL

FIGURE 1

1.Microphone Channel Gain Controls 1 - 4: Allows adjustment of microphone gain.

2.Input LED 1 - 4: Lights green when channel is active; lights

red at 6 dB below clipping level.

3.Low-Cut Filter 1 - 4: Provides adjustable low-frequency rol-

loff (high pass), reducing presence of undesirable low-fre-

quency signals.

4.High-Frequency Shelv i n g F ilter 1 - 4: Provides level boost

or cut in mid/high-frequency region for reduced sibilance

from vocal microphones, or to compensate for off-axis col-

oration in lavalier microphones.

5.Output Level Meter: Six-segment LED meter indicates

peak output signal level in dBu (0 dBu = 0.775V). The red

LED illuminates when the output is 6 dB below clipping. The

last LED indicates limiter action.

6. MASTER Level Control: Controls overall output level.

7.POWER LED: Lights green when mixer is plugged into a

power source.

*U.S. Patents 4,658,425 and 5,297,210.

IntelliMix

3

is a registered trademark o f S hure Brothers I ncorporated.

Page 4

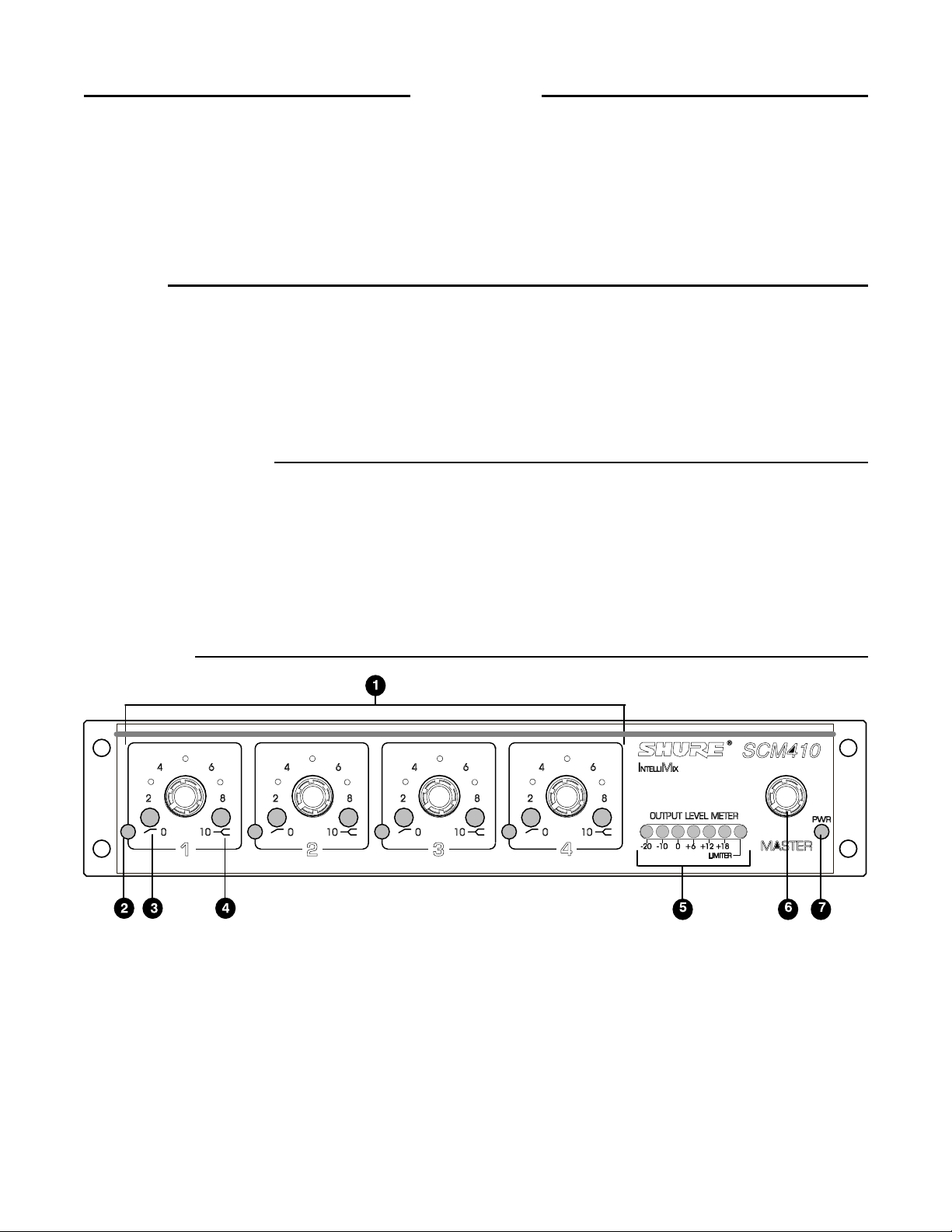

REAR PANEL

MODEL SCM410 REAR PANEL

FIGURE 2

1.Power Connector: Unit is energized when the power cord

is plugged into a 100–120 Vac (SCM410) or 220–240 Vac

(SCM410E) power source. Can be internally modified.Refer

to the “Internal Modification” section. NOTE: There is no

power On/Off switch on this mixer.

2.DIP Switch: The 4-position DIP switch provides additional

functions. Refer to the “DIP Switch Functions”section.

3.Microphone Logic Connector: High density DB-15 male

connector provides connection to GATE OUT, MUTE IN,

and OVERRIDE IN logic terminals on each channel. Refer

to the “Advanced Functions” section. NOTE: THIS IS NOT

A VGA MONITOR PORT.

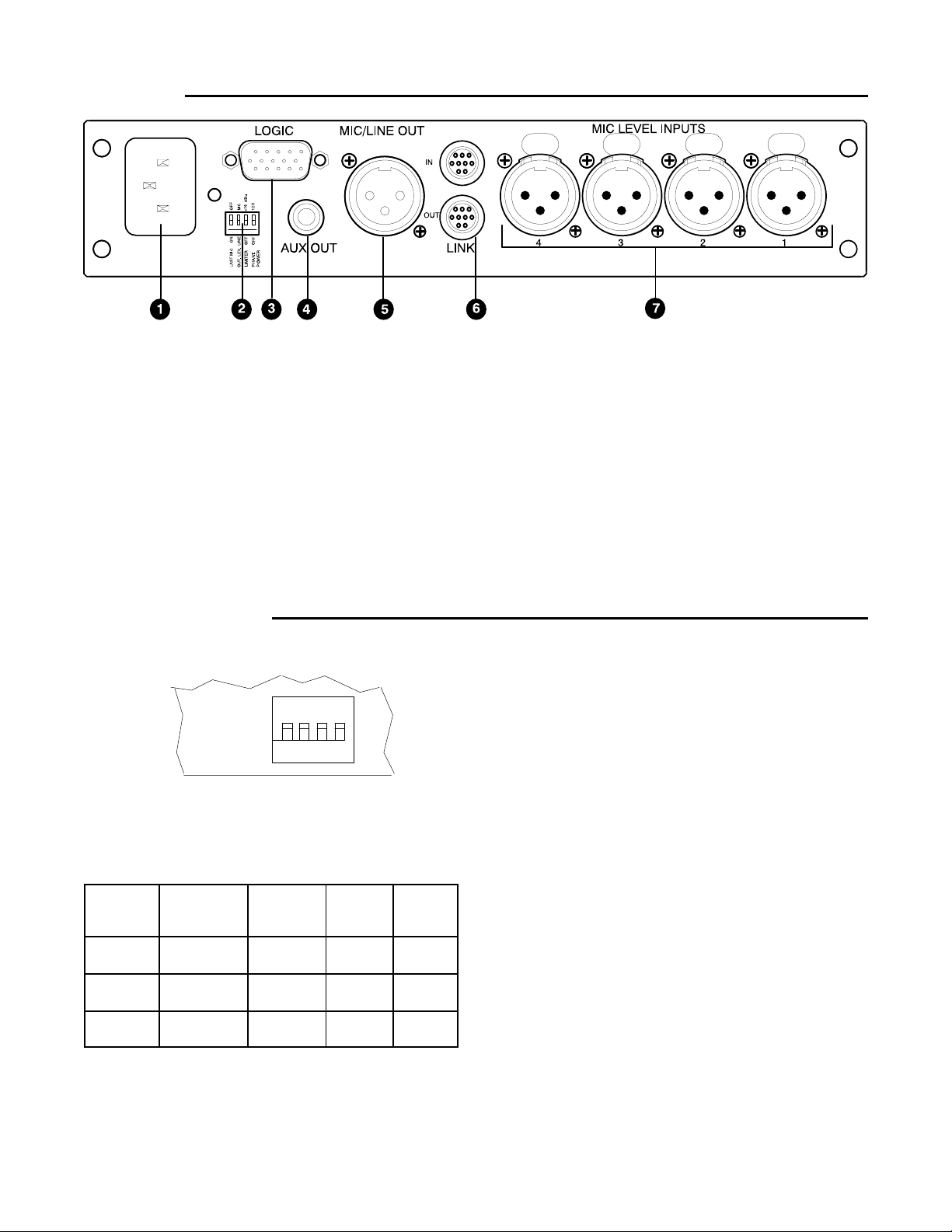

DIP SWITCH FUNCTIONS

The rear panel DIP switches, shown in Figure 3, provide the

functions listed in the table below.

(MIXER

REAR

PANEL)

DIP SWITCH FUNCTIONS

Last Mic

Lock-On

Switch

Number

Switch Up All mics off

Switch

Down

1 2 3 4

after hold time

ON* Line Level* OFF* OFF*

DIP SWITCHES

FIGURE 3

1 2 3 4

XLR

Output

Level

Mic Level ON ON

Limiter 12V

Phantom

Power

4.AUX OUT Phono Connector: Feeds consumer-level audio

equipment, such as a tape recorder, VCR, or video camera.

Not affected by MIC/LINE switch.

5.MIC/LINE XLR OUTPUT Connector: Can be set for micro-

phone or line-level output via a DIP switch.

6.LINK IN/OUT Connector: Permits multiple SCM410/E,

SCM810, SCM800, or AMS8100 mixers to be linked, creat-

ing additional inputs.

7.MIC LEVEL XLR INPUT Connectors: Active balanced microphone-level XLR inputs. For instructions on how to

modify the level of these inputs, refer to the “Internal Modifi-

cations” section.

Last Mic Lock-On: Keeps the most recently activated microphone turned on until another microphone is activated. When

defeated, microphones turn off after their default hold time.

XLR Output Level: Sets the level of the XLR output to line or

microphone level. Make sure the output level matches the input level of the device connected to the SCM410.

NOTE: The output level does not affect the auxiliary output

(AUX OUT) level.

Limiter: Activates the output limiter and sets it to a default

threshold of +16 dBu (see

Internal Modifications

for other

threshold settings).

12V Phantom Power: When this switch is in the ON position,

the SCM410 provides 12Vdc phantom power to each XLR microphone input. This function is particularly useful when using

condenser microphones, since most condenser microphones

require phantom power.

NOTE: Phantom power does not affect the operation of balanced dynamic microphones. They can be connected to the

SCM410 in combination with condenser microphones that use

phantom power. For instructions on how to disable phantom

power by channel, refer to the “Internal Modifications” section.

*Factory setting.

4

Page 5

INSTALLATION

SUPPLIED HARDWARE

4 rubber feet

1 rackmount bracket, long

1 rackmount bracket, short

2 straddle brackets

RACK MOUNTING

The SCM410 is supplied with hardware for mounting one or

two units to a 19-inch audio equipment rack. The hardware can

also be used to rack mount other Shure products, including the

SCM268, SCM262, DFR11EQ, and the DP11EQ.

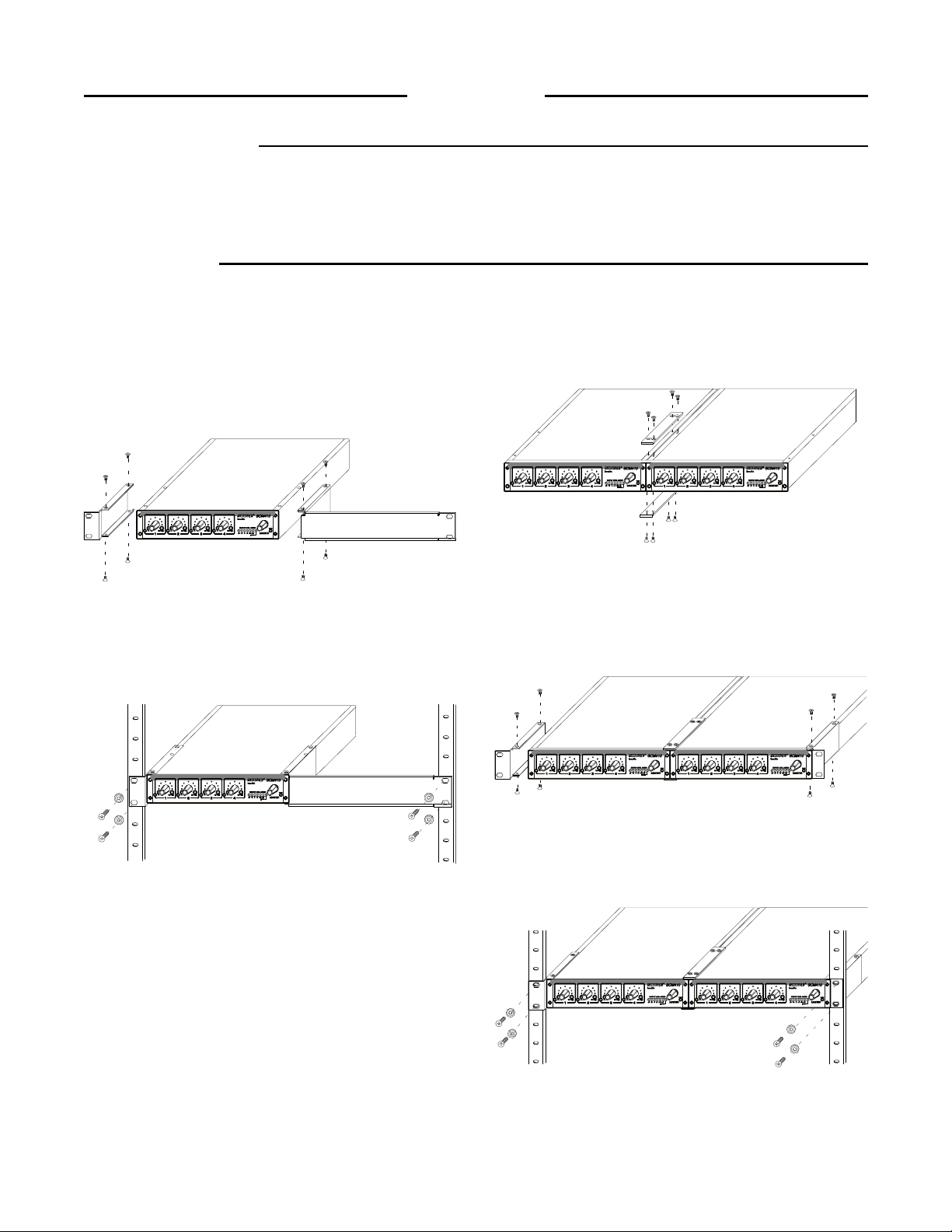

Single Mixer (Half Rack) Installation

1.Attach the short and long rackmount brackets to the

SCM410/E with eight (8) of the supplied bracket screws, as

shown in Figure 4.

10 bracket screws, 6 mm (1/4 in.)

4 rackmount screws, 2.54 cm (1 in.)

4 plastic washers

4 wood screws, 1.25 cm (1/2 in.)

Dual Mixer (Full Rack) Installation

1.Place the two mixers side-by-side and connect them with

two (2) straddle brackets. The brackets should straddle the

recessed edges on the top and bottom of each mixer. See

Figure 6.

INSTALLING HALF–RACK MOUNTING BRACKETS

FIGURE 4

2. Place the mixer in an equipment rack and secure it with

the supplied rackmount screws and plastic washers. See

Figure 5.

RACK MOUNTING A SINGLE SCM410/E MIXER

FIGURE 5

INSTALLING STRADDLE BRACKETS

FIGURE 6

2.Fasten the straddle brackets using eight (8) bracket screws.

3.Attach the

combined mixers with eight (8) of the bracket screws. See

Figure 7.

INSTALLING FULL–RACK MOUNTING BRACKETS

4. Place the mixer in an equipment rack, using the supplied

rackmount screws and plastic washers. See Figure 8.

short

rackmount brackets to the outsides of the

FIGURE 7

RACK MOUNTING DUAL SCM410/E MIXERS

FIGURE 8

5

Page 6

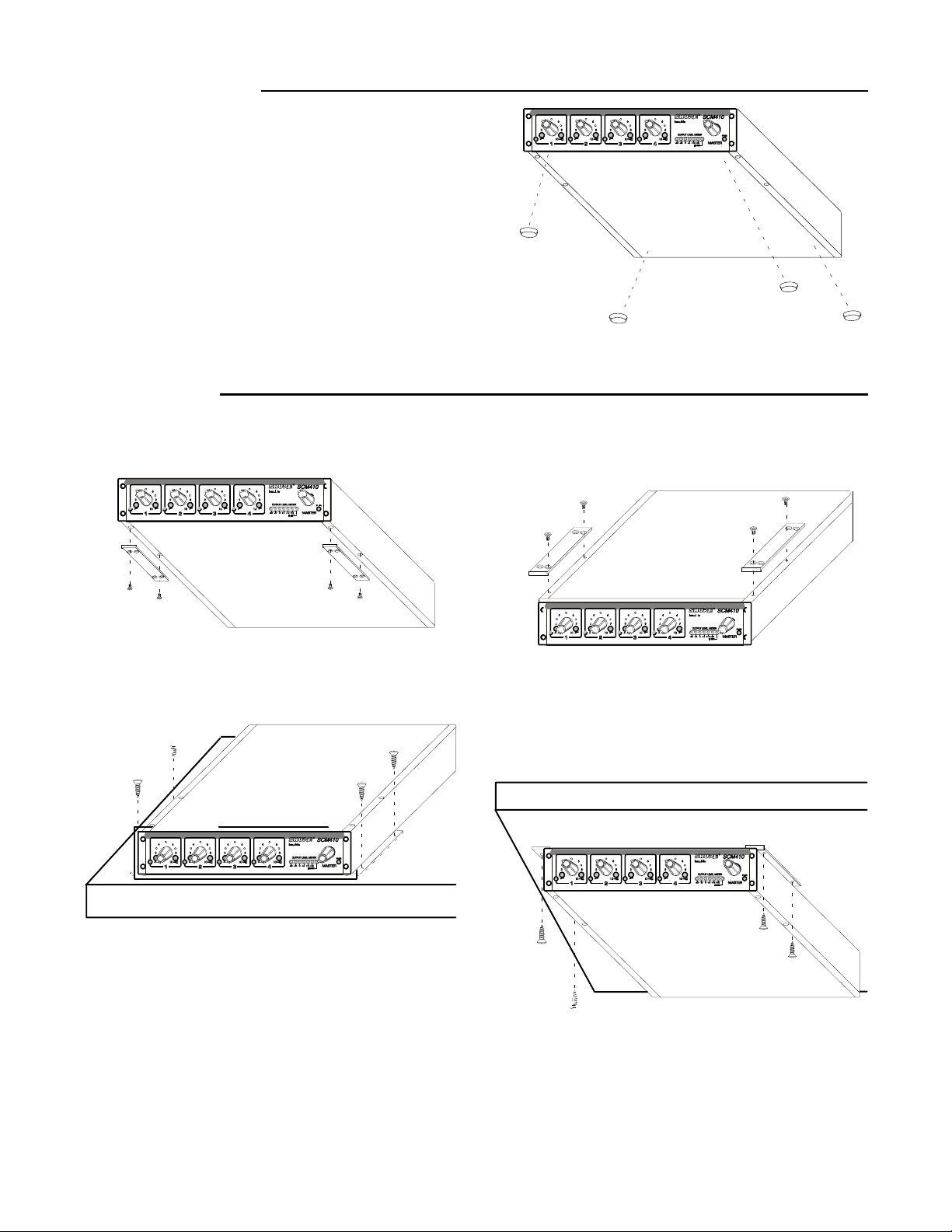

TABLE-TOP MOUNTING

Adhere the four (4) supplied rubber feet to the bottom of the

mixer at each corner, as shown in Figure 9. This will keep it

from sliding and protect the table surface.

FIXED MOUNTING

Top Mount

1. Fasten the straddle brackets to the recessed edges of the

chassis, using four ( 4) b racket s crews, a s shown i n F igure 1 0.

ATTACHING RUBBER FEET FOR TABLE–TOP MOUNTING

FIGURE 9

Hanging Mount

1. Fasten the straddle brackets to the top of the mixer, as

shown in Figure 12.

INSTALLING STRADDLE BRACKETS FOR TOP MOUNTING

FIGURE 10

2.Fasten the straddle brackets to the top of the mounting surface, using the four (4) supplied w ood s crews. S ee F igure 11.

SECURING MIXER TO TOP MOUNTING SURFACE

FIGURE 11

INSTALLING STRADDLE BRACKETS FOR

HANG MOUNTING

FIGURE 12

2. Fasten the s traddle b rackets t o t he b ottom o f t he m ounting s urface, using the four (4) supplied wood screws. See Figure 13.

SECURING MIXER TO BOTTOM MOUNTING SURFACE

FIGURE 13

6

Page 7

SCM410 CONNECTIONS

Ï

1.Connect microphone signal sources to the Channel Input

connectors, as shown in Figure 14. Use conventional 2-con-

ductor shielded audio cables.

2.If any condenser microphones are connected, set the +12V

phantom power DIP switch to ON.

3.Connect the SCM410 Mic/Line Level Output to the input of

mixers, EQs, amplifiers or recorders.

4.Connect the power cord to 100–120 Vac (SCM410) or

220–240 Vac (SCM410E).

SHURE

OR

SCM410 CONNECTIONS

FIGURE 14

LINKING MULTIPLE MIXERS

If more than four inputs are needed, multiple Shure SCM410,

FP410, or SCM810 mixers can be linked by connecting the

LINK OUT of the first mixer to the LINK IN of the next mixer,

and so on. See Figure 15. Leave the LINK IN jack of the

mixer and the LINK OUT jack of the

last

mixer unconnected.

When properly linked, the mixers will operate as a system. Automatic mixing functions will be shared by all units. All input

signals appear at all linked mixer outputs. Each mixer’s Master

level control only controls its own output. However, actual of fattenuation will increase as more mixers are linked. This reduces excessive noise and reverberation contributed by the

increased number of microphones.

IMPORTANT: When using logic terminals on linked mixers,

connect the LOGIC GROUND terminals of each unit together.

NOTE: SCM410 link connections are unbalanced. To minimize hum and noise, avoid using longer link cables. Use high

quality, shielded cable, and keep them away from sources of

magnetic or electrical noise, such as power transformers or

first

light dimmers. To minimize ground currents, make sure linked

mixers are connected to the same AC power mains.

LINKED SCM410 AND SCM810 MIXERS

FIGURE 15

7

Page 8

BASIC MIXER OPERATION

1.Adjust each channel level so that its Overload LED flickers

only during very loud speech or noise.

2.Adjust the Low-Cut and High-Frequency controls adjacent

3.Adjust the Master level control for the required output level,

as indicated by the output peak meter. The SCM410 is now

ready for use.

to each Input Gain control so that the microphones sound

similar.

NOTE: The sensitivity of the

Intellimix

circuitry may allow some channel gating due to static discharge or electrical distur-

bance to the power or signal lines. The unit will not be damaged; normal operation will resume after the disturbance ceases.

LIMITER

Output limiters prevent distortion during loud program peaks

without affecting normal program levels. This keeps the devices connected to the SCM410 output from becoming overloaded. Increasing individual or Master controls on the

SCM410 increases average output and, in turn, the amount of

limiting.

The limiter may be turned on via the rear panel DIP switch. The

default limiter threshold is +16 dBu. As supplied, the limiter is

defeated.

NOTE: Limiter thresholds can be changed from their factory

settings. Refer to the

INTERNAL MODIFICATIONS

section.

EQUALIZER FUNCTIONS

Low Cut Filter (High-Pass)

Low-cut filters are used to reduce unwanted low frequency

sounds such as footsteps, motorized traffic, and to control

proximity effect. The SCM410 has a one-pole, low-cut (highpass) filter of 6 dB per octave. The low-cut filter allows all frequencies above its cutoff point to pass through unchanged.

Frequencies below the cutoff are attenuated (see Figure 16).

The cutoff point is defined as the frequency where the signal

has dropped 3 dB relative to the flat, or bandpass, region. Below the cutoff point, the filter exhibits increasingly more attenuation as the frequency diminishes.

+2

FULL CW

0

-2

-4

-6

AMPLITUDE

(dB)

-8

-10

20 100 1,000

50%

ROTATION

FREQUENCY (Hz)

LOW-CUT FILTER EFFECTS

FIGURE 16

FULL CCW

5,000

High-Frequency Shelving

The fixed-frequency equalizer produces a 6 dB boost or cut at

5 kHz and above (see Figure 17). High-frequency shelving is

extremely useful for boosting flat frequency response and

tempering sibilant vocal microphones or enhancing the sound

of off-axis lavalier microphones.

+10

+8

+6

+4

+2

0

-2

AMPLITUDE

(dB)

-4

-6

-8

-10

200

1,000 10,000

FREQUENCY (Hz)

HIGH-FREQUENCY SHELVING EFFECTS

FIGURE 17

20,000

FULL

CW

50%

ROTATE

FULL

CCW

8

Page 9

SPECIFICATIONS

Measurement Conditions (unless otherwise specified): Line

voltage 120 Vac, 60 Hz (SCM410) or 230 Vac, 50 Hz

(SCM410E); full gain; 1 kHz, one channel activated; source

impedances: Mic 150

Ω

; terminations: Line/Mic Aux 10 k

Ω

Frequency Response (at 1 kHz, channel controls centered)

50 Hz to 20 kHz ±2 dB; -3 dB corner at 25 Hz

Voltage Gain (typical, controls full clockwise)

Output

Input Line Mic Aux

Low-impedance mic (150 Ω) 80 dB 40 dB 68 dB

Inputs

Impedance

Input

Designed for

use with

Mic 19-600 Ω 1.4 kΩ -14 dBV

Actual

(typical)

Input

Clipping Level

Outputs

Impedance

Output

Line ≥5k Ω 300 Ω +24 dBV

Aux ≥10k Ω 1.5 k Ω +14 dBV

Designed for

use with

Mic ≥600 Ω 3 Ω –18 dBV

Actual

(typical)

Output

Clipping Level

Total Harmonic Distortion

<0.1% at +4 dBu output level, 50 Hz to 20 kHz (through 22

Hz to 22 kHz filter; Input at 12 o’ clock and Master at 12 o’

clock, all other controls full counterclockwise)

Hum and Noise (150 Ω source; through 22 Hz to 22 kHz filter)

Equivalent Input Hum and Noise: -123 dBV max., 125 dBV.

typical

Output Hum and Noise (channel controls full counterclockwise):

Master full counterclockwise: -90 dBV

Master full clockwise: -70 dBV

Common Mode Rejection

>70 dB at 1 kHz

Polarity

All inputs to all outputs are non-inverting

Input Channel Activation

Attack Time: 4 ms

Hold Time: 0.4 s

Decay Time: 0.5 s

Off-Attenuation

13 dB

Overload and Shorting Protection

Shorting outputs, even for prolonged periods, causes no

damage. Microphone inputs are not damaged by signals up

to +10 dBV (3V)

Equalization

Low-frequency: 6 dB/octave cut, adjustable corner from 25

to 320 Hz

High-frequency: ±6 dB at 5 kHz, ±8 dB at 10 kHz, shelving

Limiter

Type: Peak

Threshold: +16 dBu (at output)

Attack Time: 2 ms

Recovery Time: 300 ms

Indicator: Lights red when limiting occurs

Input LEDs

Green on channel activation, red at 6 dB below clipping

Phantom Power

12 Vdc open-circuit through 680

Ω resistors

Operating Voltage

SCM410: 100–120 Vac rated nominal, 50/60 Hz,

100 mA (maximum)

SCM410E; 220-240 V ac rated niminal, 50/60 Hz,

50 mA (maximum)

Mains Inrush Current (230 Vac, SCM410E only)

0.7 A peak

Temperature Range

Operating: -7

Storage: -29

Overall Dimensions

44 mm H x 219 mm W x 267 mm D ( 1 -

° to 49° C (20° to 120° F )

° to 74° C (-20° to 165° F)

3

/4 x 8-5/8 x 10-1/2 in.)

Net Weight

1.75 kg (3.86 lbs)

Certifications

SCM410: UL listed to UL 6500 and cUL listed to E65 Canada.

SCM410E: Conforms to applicable European Directives;

eligible to bear CE marking. Low Voltage Directive

73/23/EEC: VDE GS-Certified to EN 60065. EMC Directive

89/336/EEC: Professional Audio Products Standard

EN55103 (1996); Part 1 (Emissions) and Part 2 (Immunity).

Electromagnetic Compatibility (EMC) Statement

The SCM410E mixer is intended for use in E1 (residential)

and E2 (light industrial) environments, as defined in

European EMC standard EN 55103. It meets the applicable

tests and performance criteria found in the standard for

these environments. EMC conformance is based on the

use of recommended and supplied cables.

NOTE: Under certain circumstances, the SCM410E may be

exposed to outside electromagnetic interference levels beyond what is typical in the intended environment. Should

this occur, additional measures may be required to reduce

interference to acceptable levels. The following table identi-

fies possible sources of unwanted interference.

High RF Field (generated by nearby

radio transmitter)

Electrostatic

Discharge

Magnetic Fields

(close proximity to

mains power lines or

CRTs)

Mains Power Line

Interruptions/Dips

(poor power grid

qualtiy/storms)

Mains Surges and

Line Transients

(nearby lightning

strikes/mains arcs)

Decreased

Signal-to-

Noise Ratio

X X X

X X

X X

X X

Erratic LED

and/or

Channel Operation

X X

Signal

Distortion

9

Page 10

Replacement Parts

Knob, Master (white) 95A8238. . . . . . . . . . . . . . . . . . . . . . .

Knob, Channel Gain (blue) 95B8238. . . . . . . . . . . . . . . . .

Line (Power) Cord (SCM410) 95A8762. . . . . . . . . . . . . . .

Line (Power) Cord (SCM410E) 95A8778. . . . . . . . . . . . . .

Link Cable 95A8889. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuse, SCM410

(5 x 20 mm, T 125mA L, 250V, time delay) 80C730. . .

Fuse, SCM410E

(5 x 20 mm, T 50mA L, 250V, time lag) 80C380. . . . . .

Long Rack Mount Bracket 53A8484. . . . . . . . . . . . . . . . . .

Short Rack Mount Bracket 53B8484. . . . . . . . . . . . . . . . . .

Straddle Bracket 53A8443. . . . . . . . . . . . . . . . . . . . . . . . . .

Bagged Hardware Kit 90AA8100. . . . . . . . . . . . . . . . . . . . .

Optional Accessories

Line (Power) Cord, 230–240 V ac (UK) 95A8713. . . . . . . .

External 50 dB Line Pad A15LA. . . . . . . . . . . . . . . . . . . . . .

Service Statement

For additional service or parts information, contact the Shure

Service Department at 1-800-516-2525. Outside the U.S.A.,

contact your authorized Shure Service Center.

10

Page 11

ADVANCED FUNCTIONS

CAUTION: Use of Advanced Functions is recommended only for qualified audio technicians.

LOGIC CONNECTION SPECIFICATIONS

The SCM410 logic functions expand the range of installation

and control options. Logic can be used for everything from simple cough switches to elaborate computer-controlled room

systems. (Shure’s

AMS Update

al applications of advanced logic. This publication is available

by contacting the Shure Applications Department.) The following logic functions are available for each channel:

GATE OUT: Follows channel gating and goes to logic “low”

(sinks current) when microphone is gated on. 500 mA of current sinking ability is provided (see Figure 18A).

MUTE IN: Applying logic “low” (from GATE OUT or a switch

closure to logic ground) gates channel off (see Figure 18B).

Channel output drops to -∞.

AB

+5 V

10K

GATE

OUT

FROM

SCM410

CIRCUIT

LOGIC

GROUND

LOGIC EQUIVALENT CIRCUIT DIAGRAM

OVERRIDE IN: A pplying l ogic “ low” ( from G ATE OUT or a s witch

closure to logic ground) forces channel on (s ee Figure 18B).

When both Mute and Override are activated, Mute takes precedence (see

Internal Modifications

LOGIC GROUND: Logic ground is distinct from audio ground.

Make all logic ground connections to this pin, including power

supply ground o f e xternal l ogic c ircuitry. T o avoid switching clicks,

do not

connect logic ground to audio, chassis or rack grounds.

Logic controls are accessed through the high density DB-15

multi-pin connector on the rear panel (Figure 19). Pin connections are shown in the following table.

publication contains addition-

MUTE IN

OR

OVERRIDE

IN

FIGURE 18

for Override precedence).

+5 V

55K

TO

SCM410

CIRCUIT

LOGIC CONNECTOR

FIGURE 19

LOGIC CONNECTIONS

Pin

No.

1 OVERRIDE IN 1

2 OVERRIDE IN 2 GATE OUT 2 7

3 OVERRIDE IN 3 GATE OUT 3 8

4 GATE OUT 4 GATE OUT 4 4

5 LOGIC GROUND OVERRIDE IN 1 1

6 GATE OUT 1 OVERRIDE IN 2 2

7 GATE OUT 2 OVERRIDE IN 3 3

8 GATE OUT 3 OVERRIDE IN 4 14

9 NO CONNECTION MUTE IN 1 11

10 MUTE IN 4 MUTE IN 2 12

11 MUTE IN 1 MUTE IN 3 13

12 MUTE IN 2 MUTE IN 4 10

13 MUTE IN 3 LOGIC GROUND 5

14 OVERRIDE IN 4 NO CONNECTION 15

15 NO CONNECTION NO CONNECTION 9

Logic

Function

Logic

Function

GATE OUT 1 6

Pin

No.

11

Page 12

SUGGESTED LOGIC APPLICATIONS

This section contains suggestions on the uses of the

SCM410’s logic capabilities. Note that uses of these functions

are not limited to the listed applications. The user is limited only

by imagination and creativity. For additional suggestions and

solutions to installation problems, contact the Shure Applications Department.

Cough Button

The talker can turn off his or her microphone during coughing

or private conversations by installing an SPST pushbutton

switch between the MUTE IN and Logic Ground pins for each

channel to be modified (see Figure 20). When a channel is

muted, no audio is passed. (See

feat

paragraph in the

Internal Modifications

formation on MUTE IN logic.)

M3

M1

M2

Dead Zone on MUTE IN De-

section for more in-

LOGIC

GROUND

Remote Channel-On Indicators

Remote indicators can be used to indicate when a talker’s microphone is on. Connect the LEDs and a 5-volt supply to the

GATE OUT pins (See Figure 22). To avoid switching clicks in

the audio output,

minal in the audio system or rack ground.

IMPORTANT: If a single cable is used for the microphone audio signal

be used. Failure to carry the dc power on a shielded pair may

result in audible clicking due to capacitive coupling between

the dc power lines and microphone lines.

do not

ground the power supply negative ter-

and

the LED dc power, separate shielded pairs must

+

5 V POWER

SUPPLY

470 Ω,

1/4 W

G1 G3

470 Ω,

1/4 W

470 Ω,

1/4 W

LOGIC

GROUND

G2

COUGH BUTTONS

FIGURE 20

Chairperson-Controlled Muting

The chairperson can, by activating a switch, silence all other

microphones and be heard without interruption. For operation

in this mode, connect all the MUTE IN pins together

of the chairperson’s channel

, and wire an SPST pushbutton or

toggle switch between those MUTE IN and Logic Ground pins

(see Figure 21).

An alternative to a switch is to connect the chairperson’s GATE

OUT to the MUTE IN of other channels. When the chairperson’s microphone activates, all other microphones mute.

LOGIC

GROUND

M2 M3

M4

except that

REMOTE CHANNEL-ON INDICATORS

FIGURE 22

Disabling the Gating Function (Bypass)

To keep certain microphones on at all times, wire the desired

microphone channel’s OVERRIDE IN pins together to the Logic Ground pin. The selected channels now function as they

would in a non-automatic mixer (see Figure 23). To perform

this modification internally on the mixer, refer to the

Override In to Logic Ground Internally

nal Modifications

section.

O2O1 O3

paragraph in the

LOGIC

GROUND

GATING BYPASS

FIGURE 23

Shorting

Inter-

CHAIRPERSON-CONTROLLED MUTING

FIGURE 21

12

Page 13

Inhibiting Gating for Unwanted Sounds

MaxBus attempts to activate only one microphone per sound

source. Muting a microphone channel prevents its audio from

appearing at the mixer’s output. However, the muted microphone still communicates with other mic channels via Max-

A sound source picked up by a muted microphone will not

Bus.

activate other microphones.

Sound sources that may cause unwanted microphone channel activation include:

• Heating, ventilation, or air conditioning systems

• A noisy fax machine or printer

• A squeaky door

• A paging system loudspeaker

• An audio teleconferencing return signal loudspeaker

The SCM410 can prevent these and similar sounds from activating microphones as follows:

1. Place one microphone near the unwanted sound source.

Connect that microphone’s signal to a channel input,

—or

—

connect the unwanted sound source directly into a channel

input.

2.Mute that channel using the logic terminal (see Figure 24).

To perform this modification internally on the mixer, refer to

Shorting Mute In to Logic Ground Internally

the

the

Internal Modifications

3.Adjust the channel gain control just past the level where un-

wanted sounds do not activate other microphones in the

system. If the channel gain is set too high, the other microphones may not be activated by the

too low, unwanted sounds will continue to activate other mi-

crophones.

M1

INHIBITING GATING FOR UNWANTED SOUNDS

section.

desired

FIGURE 24

Loudspeaker Muting

Some applications require a loudspeaker to be placed near

each talker to provide audio reinforcement, or to permit telephone conversation or conference monitoring. Each loudspeaker can c ause f eedback u nless i t i s a utomatically s witched

off when t he t alker n ear i t s peaks. To provide this f unction, c onnect the GATE OUT terminal of each channel to a separate

loudspeaker muting relay (See Figure 25). Recommended relays are Radio Shack 275–248, Omron G2R-14-DC12 (DigiKey number Z745-ND), Potter & Brumfield R10-E1Y2-V185

(Newark number 45F106), or equivalent.

NOTE

:

A diode across each relay coil is required to suppress

inductive voltage spikes which may damage the SCM410.

An existing sound system using 24-volt relays can be used

with the SCM410 without modification if the relay coil current

draw is under 500 mA.

paragraph in

sounds. If set

LOGIC

GROUND

D = 1N4148

DD

G3G1

LOUDSPEAKER MUTING

FIGURE 25

+

12 V

POWER

SUPPLY

GROUND

–

LOGIC

FROM

POWER AMP

“Filibuster” Mode

Normally, when several people talk, each microphone gates

on so that no speech is missed. In “filibuster” mode, a microphone remains gated on until the talker pauses long enough

for that microphone to gate off. No other microphone can gate

on until that microphone gates off. This prevents talkers from

being interrupted.

To establish filibuster mode, refer to Figure 26 and proceed as

follows:

1.Perform the

Internal Modifications

2. Connect all the MUTE IN pins together on the modified

channel.

3. Connect all the GATE OUT pins together on the modified

channels.

4.Connect the GATE OUT pin of one modified channel to the

MUTE IN pin of another modified channel .

5. Turn the Last Mic Lock-On switch to OFF.

NOTE: To prevent high-frequency oscillation, do not wire a

GATE OUT pin to a MUTE IN pin on the same channel unless

the

Mute to Inhibit

Mute to Inhibit

modification has been made.

“FILIBUSTER” MODE

modification as presented in the

section.

G1M1G3

G2

M3M2

FIGURE 26

LOGIC

GROUND

13

Page 14

Inhibit Function

For information on the inhibit function, refer to the

Modifications

section.

Internal

Remote Volume Control

The level of the Aux or Master output can be controlled from an

external VCA (Voltage Controlled Amplifier) such as the RUVCA1 from Radio Design Labs (Tel. 1–800–281–2683, or

www.rdlnet.com). To connect a VCA to the SCM410, proceed

as follows:

1. Connect the SCM410 Line output to the VCA line input.

2. Connect the VCA line output to the external device.

3. For remote Master level control, set the SCM410 Master

control to 5.

External Logic Devices

SCM410 logic levels are directly compatible with TTL and 5V

CMOS logic families. Mixer logic may be used with 15V CMOS

logic if a pull-up resistor is used with each GATE output. See

Figure 28.

NOTE: For information on logic gate use, refer to the

and

Cookbook

CMOS Cookbook

, both by D. Lancaster,

TTL

Howard Sams Publishing Co.

+

5.1 K

15 V

POWER

SUPPLY

–

Diode Isolation of Logic Controls

Two or more control functions that use the same logic pins can

be isolated with diodes, as shown in Figure 27. With this modification, a channel can be muted by an overall group mute

switch, or by its own cough button.

GROUP

MUTE

DD

M3

M1

COUGH

BUTTONS

DIODE ISOLATION OF LOGIC TERMINALS

FIGURE 27

D = 1N4148 OR

EQUIVALENT

LOGIC

GROUND

CMOS

GATES

G1M1O1

LOGIC

GROUND

15V CMOS

FIGURE 28

Digital Controls or Microcomputers

The SCM410 logic pins can interface with custom-designed

digital control circuitry or microcomputers for unlimited possibilities of system control functions.

14

Page 15

INTERNAL MODIFICATIONS

WARNING: Voltages in this equipment are hazardous to

life. No user-serviceable parts inside. Refer all servicing

to qualified service personnel.

NOTE:

• Only make changes to jumpers (X) and resistors (R). The

circuit board contains holes where resistors are to be added.

DISASSEMBLING THE SCM410/SCM410E

To access the printed circuit board for internal modifications,

proceed as follows:

1. Remove the power cord from the ac power source.

2. Remove the knobs, retainer nuts, and washers from the

front panel, as shown in Figure 29.

KNOB ASSEMBLY AND DISASSEMBLY

FIGURE 29

• For Channel modifications, the first character of the refer-

ence designator indicates the channel number,(i.e., R1027

refers to a Channel 1 resistor, X2001 refers to a Channel 2

jumper, etc.). Modifications affecting the Master section are

preceded by a “9” (i.e., X9001).

• All Channel modifications in this section use Channel 1 as

an example.

3. Remove the four screws at each corner of the rear panel.

4.Remove the two screws at each bottom corner of the front

panel.

5.Slide the back panel and printed circuit board out from the

rear of the chassis.

CAUTION: When reassembling the SCM410, DO NOT

OVERTIGHTEN the knob retainer nuts.Damage to the internal components will result if too much force is used.

MODIFYING THE SCM410 FOR 220–240 VAC, 50/60 HZ OPERATION

As supplied, the SCM410 uses 100–120 Vac, 50/60 Hz power.

To modify if for use with 220–240 Vac, 50/60 Hz power, proceed as follows:

1. Disassemble the SCM410 according to the procedures in

Disassembling the SCM410/SCM410E

the

2.Locate Voltage Selector switch SW9001 adjacent to power

transformer T9000.

paragraph.

3.Using a screwdriver, turn the center rotor to the 230 position.

4.Locate Fuse F9000 and replace it with a T 50 mA L, 250 V,

time lag fuse for 220–240 Vac operation.

5.Replace the power cord with a cord rated for 220–240Vac

operation.

MODIFYING THE SCM410E FOR 100–120 VAC, 50/60 HZ OPERATION

As supplied, the SCM410E uses 220–240 Vac, 50/60 Hz power. To modify it for use with 100–120 Vac, 50/60 Hz power, proceed as follows:

1.Disassemble the SCM410E according to the procedures in

Disassembling the SCM410/SCM410E

the

2.Locate Voltage Selector switch SW9001 adjacent to power

transformer T9000.

paragraph.

3.Using a s crewdriver, turn the center rotor to the 115 position.

4.Locate Fuse F9000 and replace it with a T 125 mA L, 250

Vac, time delay fuse for 100–120 Vac operation.

5.Replace the power cord with a cord rated for 100–120 Vac

operation.

INSERTING A 12 DB MIC PREAMPLIFIER PAD

A microphone preamplifier channel gain can be reduced by 12

dB. This may be desirable with high-output microphones.

Procedure:

1. Short jumper X1000.

2. Remove resistor R1006.

DISABLING PHANTOM POWER BY CHANNEL

To disable phantom power for a given microphone input channel, remove the resistor specified in the following table.

Channel Remove Resistor

1 R1005

2 R2005

3 R3005

4 R4005

15

Page 16

INSERTING AN INPUT LINE PAD

T o insert a 40 dB line pad for a given microphone input, remove

the resistors specified in the following table.

Channel Remove Resistor

1 R1005, R1006

2 R2005, R2006

3 R3005, R3006

4 R4005, R4006

DISABLING THE MASTER LEVEL CONTROL

The Master gain control can be disabled to prevent tampering.

Refer to the following table for gain levels and resistor values.

Master Section Gain Resistance

-6 dB 5.1 kΩ

0 10 kΩ

6 dB 20 kΩ

CHANGING THE LIMITER THRESHOLD

To change the limiter threshold from the preset value of +16

dBu, modify the circuitry according to the following table.

CHANGE LIMITER THRESHOLD

Limiter Threshold

(dBu)

0 On –– Remove 20k

+4 On Short –– ––

+8 Off Short –– ––

+12 On –– Remove 110k

+16

(default)

+20 On –– Remove 300k

+24 On –– Remove 400k

Limiter

DIP switch

Οn –– –– ––

X9003 R9149 R9142

Procedure:

1. Remove resistor R9203.

2. Install new resistor at jumper R9173.

CHANGING HOLD TIME

To change the hold time from the preset value of 0.4 seconds,

modify the circuitry according to the following table.

CHANGE HOLD TIME

Hold Time

(seconds)

0.3 –– –– 2M

0.4 (default) –– –– ––

1.0 Short –– ––

1.5 Short 470k ––

X9000 R9073 R9079

LOCAL AUX OPERATION

This modification removes the auxilliary audio from the

SCM410 outputs. Auxilliary audio originates from the aux inputs of the Shure SCM810, SCM800, and AMS8100 mixers

when linked to the SCM410.

MUTE IN

PRECEDENCE TO

OVERRIDE IN

PRECEDENCE

Procedure:

Remove resistor R9187.

16

Page 17

When both MUTE IN and OVERRIDE IN logic are grounded,

the Override mode will take precedence (as supplied, the

MUTE IN takes precedence over OVERRIDE IN).

DEAD ZONE ON

As supplied, MUTE IN is intended for use as a momentary

cough button or privacy function (mute when necessary).

However, i f the MUTE IN is intended to be used so that the talker must unmute microphones to enable speech pickup (unmute when needed), this modification is needed. This removes the muted channel from the MaxBus which eliminates

“dead zones.” A dead zone is an area in which a microphone

picks up a talker through a muted microphone and other microphones do not activate for that talker.

MUTE IN

DEFEAT

Procedure:

1. Short jumper X1005.

2. Remove resistor R1087.

Procedure:

Short jumper X1002.

CHANGING

As supplied, a channel will mute when its MUTE IN terminal is

grounded. The mute function for each channel can be modified

so that a logic “low” at the MUTE IN terminal prevents that

channel from gating on if it is off, but allows it to remain on if it is

already on. Use this modification to enable Filibuster Mode.

IMPORTANT: To prevent high-frequency oscillation, never

connect the GA TE OUT to the MUTE IN of the same channel

unless the “Inhibit” modification has been made.

CHANGING

This modification should only be performed with the

MUTE IN to Inhibit

necessary if the Mute function is desired along with Filibuster

Mode.

MUTE IN

OVERRIDE IN

TO

INHIBIT

TO

MUTE IN

modification described above. This is only

(FILIBUSTER MODE)

Change

CHANGING THE OFF-ATTENUATION LEVEL

This procedure changes the off-attenuation level from -13 dB

(as supplied). Refer to the following table for attenuation levels

and resistor values.

Off-Attenuation Level Resistor Value

10 dB 18 kΩ

13 dB

(default)

20 dB 75 kΩ

30 dB 250 kΩ

dB open circuit

NOTE: As more Input channels are added to the system, the

off-attenuation increases slightly.

30 kΩ

Procedure:

Short jumper X1007.

Procedure:

1. Short jumper X1006.

2. Remove resistors R1087 and R1082.

Procedure:

1. Remove resistor R9178.

2. Install new resistor

at jumper points R9177.

GROUP GATING

With this modification, several channels can be grouped together so that all of them activate whenever one of them activates. This is useful for miking choirs.

Procedure:

1. Locate pad PD1000.

2. Solder a wire from PD1000 to the other channels in the

group. For example, to gate channels 1–3 as a group, solder

a wire connecting PD1000, PD2000, and PD3000.

SHORTING OVERRIDE IN TO LOGIC GROUND INTERNALLY

17

Page 18

This modification is equivalent to shorting one of the channel

OVERRIDE IN t o the LOGIC GROUND pin via the high density

DB-15 logic connector. With this modification, a channel is always on.

Procedure:

Short jumper X1003.

SHORTING MUTE IN TO LOGIC GROUND INTERNALLY

This modification is equivalent to shorting a channel MUTE IN

to the LOGIC GROUND pin via the high density DB-15 logic

connector. With this modification, a channel is always muted.

Procedure:

Short jumper X1004.

DISABLING AUTOMATIC MIXING FUNCTION BY CHANNEL

This modification removes a given channel from the

automatic mixing circuitry, so that a source such as music can

be played through a channel of the SCM410 without affecting

the automatic mixing of the unmodified channels.

IntelliMix

Procedure:

1. If necessary, modify the channel input to accept line level

signals. Refer to the

2.Modify the channel’s Override In to On. Refer to the

3.Short j umper X 1001 t o r emove t he c hannel f rom t he M axBus.

4.Remove R1064 to remove the channel from the Last Mic

MANUAL MODE ENABLE

This modification defeats the automatic mixing functionality of

the SCM410, so that it operates as a standard 4 x 1 mixer.

Procedure:

Short jumper X9001.

Inserting an Input Line Pad

Override In to Logic Ground Internally

Lock-On Bus.

paragraph.

Shorting

paragraph.

18

Loading...

Loading...