MODEL RMSOOE

CUSTOM MAGNETIC

CARTRIDGE

HIGH TRACKABILITY

ELLIPTICAL STYLUS

WITH

DATA SHEET

SPECIFICATIONS

RMSOOE CARTRIDGE

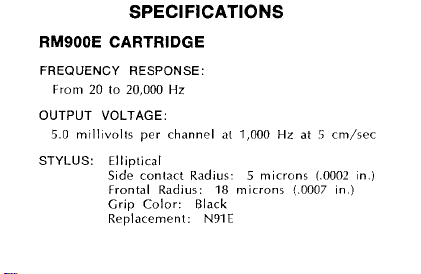

FREQUENCY RESPONSE:

From

20

to

20,000

Hz

OUTPUT VOLTAGE:

5.0

mlll~volts per channel at

STYLUS: Elliptical

S~de contact Radius.

Frontal Radius:

Grip Color: Black

Renlacement:

18

N91E

1,000

5

microns

microns

Hz

at 5 cm/sec

LO007

(.0002

In

)

In.)

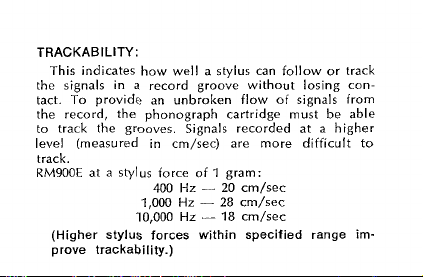

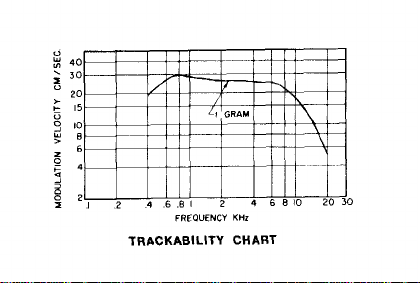

TRACKABILITY:

This indicates how well a stylus can follow or track

the signals in

tact. To provide an unbroken flow of signals

the record, the phonograph cartridge must be able

to

track the gmoves. Signals recorded at a higher

level (measured in

track.

RM900E at a stylus force of 1 gram:

(Higher stylus forces within specified range

prove trackability.)

a

record groove without losing con-

cm/sec) are more difficult

-

Hz

20 cm/sec

-

18

cm/sec

400 Hz

1,000 Hz - 28 cm/sec

10,000

from

im-

to

V

1

'

I,

0

2

Y

z

p

3

40

30

20

15

10

4

FREQUENCY

TRACKABILITY

KHz

CHART

0

TRACKING FORCE RANGE:

3/4 to

1-1/2

Th~s is the amount of force required of the stylus

tip to properly play a record. The lighter the trackfing force, the longer the life of the stylus and

records,

OPTIMUM LOAD:

47,000 ohms resistance in parallel with 400 to 500

picofarads total capacitance per channel. Load

\islance can be up to 70,000 ohms with almost no

audible

tance includes

plif~er input circuit.

grams

prov~ded that tracking is

change in frequency response. Total capaci-

both the tone arm wiring and am-

maintained.

re-

CHANNEL SEPARATION

25

dB

at

1,000

Hz

INDUCTANCE:

720

millihenries

D.C. RESISTANCE:

630

ohms

MOUNTING:

mm

12.7

(standard

1/2

(minimum):

in.) mounting centers

WEIGHT:

6

grams

TERMINALS:

4

terrn~nals

OPERATION:

Thr

RM900E

hern developed for use w~th all h~gh i~delity am-

pl~i~crr havlng magnetic and constant velocity inputs. Recommended

grams for optimum results. Forrrr greater than

1-1/2

Dynet~c phonograph cartr~dge\ have

nerdle force ir

grams should not

be

uscd.

3/4

to

1-1/2

Mounting

The

RM900E

ard

w~th each cartr~dge for mountlng purposes. In some

tone arms and

deep that the stylus cannot he conveniently

plated. For these

Insure adequate clearance for stylus removal.

to

For optimum vertical tracking angle, the cartridge

should be mounted to the top

block is parallel to the record playing

Dynetlc Cartridge has

1/2

in ) mountlng centers. Hardware

plug-ln shells, the carlrldge sit5

applications,

12

7

mm (stand-

18

supplied

spacers are provided

of

the mounting

wrface.

rp-

ro

Connections

4-LEAD

STEREO CONNECTION:

of right channel to terminal

ground lead of right channel to terminal

Connect "hot" lead of left channel to terminal

and shield or ground lead of left channel to

To prevent "ground loops" and hum, no common

connection should

MONOPHONIC OPERATION:

back of recordings, the left and

should be connected in parallel. This is accomplished most conveniently by setting the function

switch on the associated amplifier to

"MONO."

be

Connect "hot" lead

"K"

and shield or

"RG."

"LC."

used at cartridge terminals.

For monophonic play-

right

channels

"A+B"

"L"

or

CAUTION:

tridge terminals. Make all solder connections to

terminal jacks provided before

the terminals.

Do not make solder connections to car-

slipptng them over

RIGHT

CMAMXEL

RIGHT

CSIHNEI

GROUWD CRWNDSD

TO

CASE1

TERMINAL DIAGRAM STYLUS REPLACEMENT

FIGURE

I

FIGURE

2

Recommended

Use a camel's hair brush (No. 2 size or smaller),

trimmed to approximately

in alcohol or an alcohol-distilled water solution.

Commercial cleaning solutions may cause stylus

damage or corrosion. The alcohol will remove any

sludge deposit coating the stylus tip. Always brush

stylus from back to front; never brush or wipe

from front to back or side to side.

Stylus

Cleaning

6

mm

(1/4

in.), dipped

Easy

Stylus

Grasp molded hous~ng oi stylus between thumb

Replacement

forcl~nger. Gently w~thdraw stylus by pulling

and

iorward out of cartridge. Grasp

thumb and loref~nger and ~nsrrl Into stylus

between

socket. Press stylus

housing of the stylus mates with the cartridge

case. Care must be taken not

sl~p off the molded housing of the stylus, re-

to

sult~ng in damage to the stylus t~p or shank.

(see Figure

replaremer~t stylus

Into socket until the molded

ro

allow the finger

2)

SPECIAL

NOTE:

in these cartridges is the most critical component.

To maintain the original performance standards of

your cartridge, be certain that any replacement

stylus you buy bears the following certification on

the package: "This Stereo

sion manufactured by Shure Brothers Inc."

The Dynetic stylus assembly used

Dynetic@ stylus is preci-

retaln proof of purchase dare. This guarantee

includes all parts and labor. Th~s guarantee

doer

no( include stylur wear.

SHIPPING INSTRUCTIONS: Carefully repack

the unit and return

If outs~de the Unitcd States, return the unlt

to your dealer or authorized Shure Service

Center for repair. The

lo

vou nre~aid.

~t prcpa~d io the factory.

un~t will

be

returned

PATENT NOTICE:

under one or

3,055,100, 3,077,521, 1,077,522

Cartridge and stylus manufactured

more of the follow~ng

and

U

1,461,889.

Available exclusively through

ROYAL ELECTRONIC DIST.

Manufactured by Shure Brothers Incorporated

222

Hartrey Avenue, Evanston,

11

60204

S

Patents

COPYRIGHT

27A947

(NE)

1972.

SHURE BROTHERS

PRINTED IN

INC.

U.

S.

A.

Loading...

Loading...