Page 1

Price

$7.50

HOME

THEATER

SOUND

HTS5000

SURROUND

AUDIO

PROCESSOR

SERVICE

INFORMATION

MODELS: HTS5000, HTS5000E, HTS5000J

Home

Theater

Sound

Division

SHURE

BROTHERS INCORPORATED

222

Hartrey

Avenue

Evanston,

Illinois

60202-3696

Copyright

1W.

Shurm

Bmlhn

Inc

nrsra

(GO

UlO

Prlnfed

In

U.S.A.

Palent PIndlnp

Page 2

DESCRIPTION

-

OUTPUTS

TAPE

1

--m

-tg

0

0 0

,

&-go

-

The HTSW Surround Audio Processor provides a

theater-sound environment in the home. This Home

Theater Sound (HTS) system decodes Dolby1 stereo

sound encoded

In video discs, video tape, and broad-

cast television. The

HTS5000 provides up to six chan-

nels of audio output: left, center, right, two surround

channels, and a subwoofer. Acra-Vector* decoder

clrcuitry replicates the directional accuracy of the finest

theater sound equipment. True digital time delays pro-

'de the same performance, free of distortion and noise.

s

in the theater. The Acoustic Space Generator creates

the same Immersion in sound as

In the theater, but us-

ing a minimum number of speakers. All these features

help to re-create the sound field of an original theater

showing. The

HTS5000 can also produce simulated surround sound from ordinary stereo, and even from mono

sources.

Three models of the

HTS5000 are presently

available:

the

HTS5000, for 120 Vac,

60

Hz operation;

the

HTS5000E, for 220.240 Vac, 50160 Hz operation; and

the

HTS5000J, for

100

Vac, 50160

Hz

operation.

All

three

models are described

In this document.

A

basic HTS Surround Sound Installation employs

four loudspeakers and two stereo amplifiers; a complete system uses

six loudspeakers and three stereo

amplifiers to reproduce the theater experience. The

system operates as follows: Exclusive Acra-Vector

clrcuits enhance the directional accuracy of the reproduced sound field.

In the front, this creates a spaclous

stereo panorama with realistic "motion" effects from

moving sources. In the basic system, dialogue

originates from a phantom center channel. However, to

keep the acoustic image properly located regardless of

where the listener sits in the room, the addition of a

center front loudspeaker is recommended.

The surround channel signals are delayed according

to a user-selected digital display setting chosen for the

particular room envlronrnent. Then an Acoustic Space

Generator processes the delayed

slgnal to further

nhance the perception of spaciousness.

The

finishing touch to complete the system is an add-

ed subwoofer. Because the film industry uses very

low-

frequency audio as an Integral part of the creation

of

mood and place. uslna a subwoofer reinforces the

theater illusion and

lrrt~nslfies the versimilitude of the

performance. To conveniently add a subwoofer, the

HTS5000 has a subwoofer output containing only lowfrequency information (below 80 Hz). The subwoofer will

smoothly extend the response of typical bookshelf or

satellite speakers, or

It can be used to augment the

bass output of larger speakers.

(The left, center, and

'

right outputs are full-frequency-range and also contain

'

this low-frequency informatlon.)

:

The HTS5000 front-panel controls and displays ln-

clude push-button operating mode selectors: Dolby

Surround, synthesized-surround stereo or mono, and, by

means of a defeat button, pure stereo or mono. There

Is

'

also push-button choke of the audio source from either

Left and Right inputs or Tape Monitor Return inputs.

Rotary knobs on the front adjust the following:

Input

level, with a five-LED display; input balance, with an

LED for visual determination of correct balance; digital

delay time to best suit the particular listening room; and

volume and surround levels. An overriding wired remote

control lets the listener adjust surround and overall

volume levels from the listening position. The remote

also permits muting of the audio outputs.

A

four-

channel graphic display provides visual demonstration

of the surround characteristics of the input signal.

The

HTS5000 rear panel includes left and right audio

inputs; outputs for front left and right and surround left

and right channels;

a

separately switched front-center

output jack; and a subwoofer output jack. Tape Monitor

Send outputs and Left and Right Return inputs are also

Included. These audio input and output jacks are all

phono types. In addition, front- and rear-panel

eighthInch-diameter phone jacks accommodate the wired

remote control.

The

HTS5000 lnstallationlOperator's Manual contalns

,

specifications, troubleshooting and safetylmaintenance Information.

7.

Manufactured under llcennr from Dolby Laboratories Llcenslnp

Cor

poratlon. Additionally licensed under one or more of the following

'

patents:

U.S.

numbers

3,632,886, 3,746,792,

and

3,959,590;

Canada

numbers

1,004,803

and

1,037,Bn.

'Dolby* and the double-D symbol

are

trademarks

of

Dolby Laboratories Llcenslnp Corporation

'Patent

pendln~.

Page 3

SERVICE

This section contains lnformatlon on replacement

parts, servlce access, fuse replacement, and complete

equipment checkout. If difficulties in

HTS5000 installation or operatlon are experienced, the Troubleshooting

Guide

In the installationlOperator's Manual should

be

consulted. If that information fails to correct the problem, the checkout procedure given here can

be

per-

formed.

Note that

circuitry

lnformatlon is only given where It can

be of use in field servlce; most internal adjustments

cannot be made and some circuit blocks cannot

be

ser-

viced without factory test equipment.

Voltages in this equipment are hazardous to life.

No user-serviceable parts inside. Refer all servicing to qualified servlce personnel.

Replacement Parts

Parts that are readily available through local electronic parts distributors are not shown on the accompanying Parts List. Their values are shown on the Circuit

Diagram. Commercial parts not readily available and

unique parts are shown on the Parts List and may be

m-dered directly from the factory.

'he commercial alternates shown on the Parts

Llst

are not necessarily equivalents, but may be used In the

event that direct factory replacements are not immediately available. To maintain the highest possible

performance and reliability, Shure fgctory replacement

parts should be used. When ordering replacement parts,

specify the Shure replacement part number,

descrip

tion, product model number, and serial number.

External

Parts

The following paris can be removed and replaced

without disassembling the

HTS5000:

Remote Control

(A13)

Rotary Knob

(MP1-Me)

Foot

(MFS-MP9)

.

All five front-panel knobs are either pull-off or setscrewretained types and are interchangeable. Setscrew-type

knobs must be unscrewed from

inside

the front panel

before removing the knobs.

Service Access

Disconnect the

HTS5000

from Its ac power source.

Remove two cover-securing screws from each side

panel. Slide the cover back toward the rear of the unit

and upward to remove.

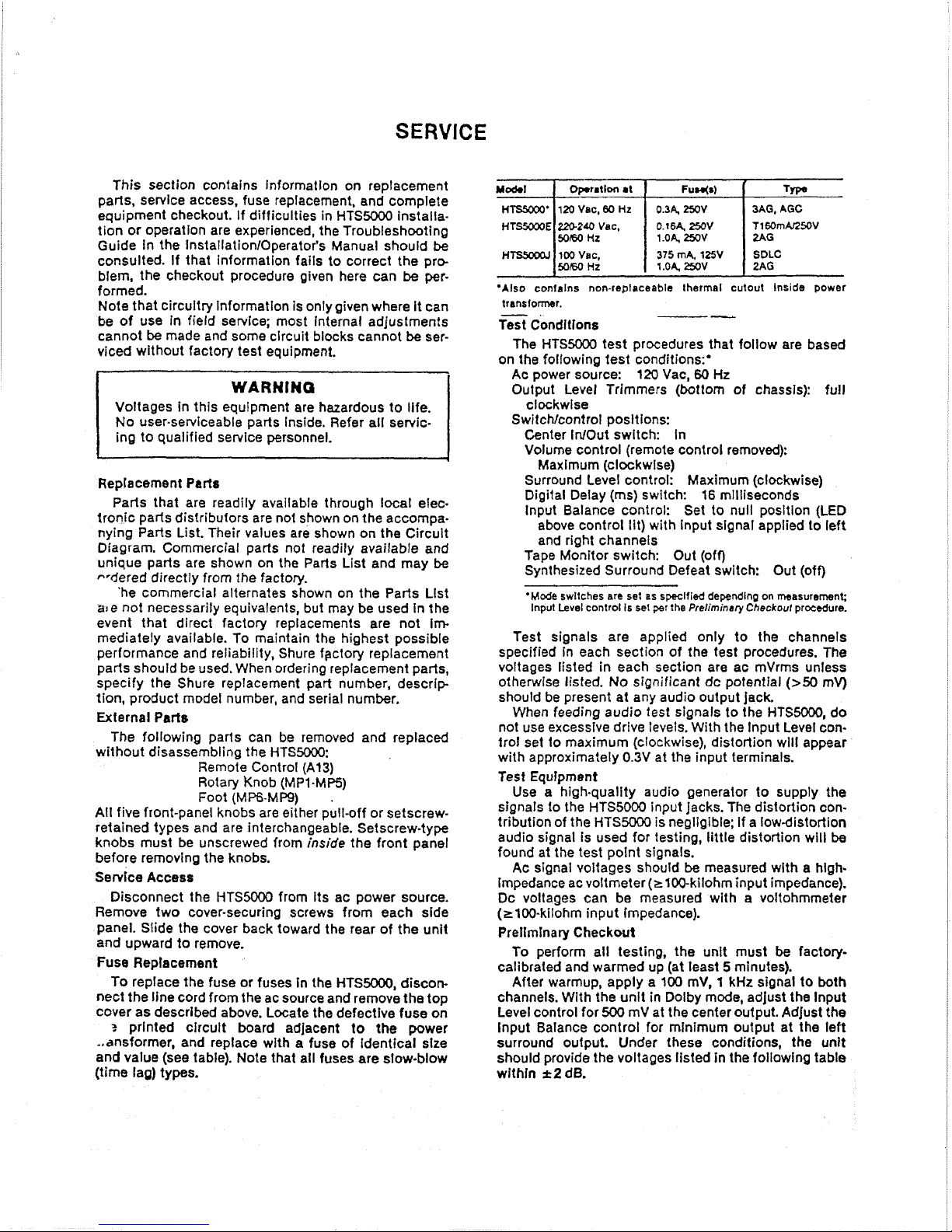

Fuse Replacement

To replace the fuse or fuses in the

HTS5000, disconnect the line cord from the ac source and remove the top

cover as described above. Locate the defective fuse on

?

printed circult board adjacent to the power

-.ansformer, and replace with a fuse of ldentlcal slze

and value (see table). Note that all fuses are slow-blow

(time lag) types.

opt~tlon at

Fuw(r)

HTSSOOO*

120

Vac,

60

Hz

0.34

250V

3AG,

AGC

HTWE

2MZa0

Vac.

0.164

2WV

T160mAnWV

1

.OA,

250V

HTSSoOQl

100

Vac,

375

mA.

125V

50m0

HZ

1.04

2SV

'Also conlalns non-replaceable thermal cutout Inside power

trmsfomr.

--

T%

Conditions

The

HTS5000 test procedures that follow are based

on the following test conditions:'

Ac power source:

120 Vac,

60

Hz

Output Level Trimmers (bottom of chassis): full

clockwise

SwitcNcontroi posltions:

Center

Inlout switch: In

Volume control (remote control removed):

Maximum (clockwise)

Surround Level control: Maximum (clockwise)

Digital Delay (ms) switch:

16

milliseconds

lnput Balance control: Set to null position (LED

above control lit) with input

slgnal applied to left

and right channels

Tape Monitor switch: Out

(off)

Synthesized Surround Defeat switch: Out (off)

'Mode swltches are set as

specified

depending on measurrmenr;

lnput Level control Is

set

par

the Preliminary

Checkout

procedure.

Test signals are applied only to the channels

specified in each section of the test procedures. The

voltages listed in each section are ac

mVrms unless

otherwise listed.

No

significant dc potential

(>50

mV)

should be present at any audio output jack.

When feeding audio test signals to the

HTS5000, do

not use excessive drive

levets. With the lnput Level con-

trol set to maximum (ctockwise), distortion

wlll

appear

with approximately

0.3V at the input terminals.

Test Equfpment

Use a high-quality audio generator to supply the

signals to the

HTS5000

input jacks. The distortion con-

tribution of the

HTS5000

is negligible; if a lowdistortion

audio signal is used for testing, little distortion

will

be

found at the test polnt signals.

Ac signal voltages should

be

measured with a hlghImpedance ac voltmeter (2100-kilohm input impedance).

Dc voltages can be measured with a voltohmmeter

(~100-kilohm input impedance).

Prellmlnary Checkout

To perform all testing, the unit must

be

factory-

calibrated and warmed up (at least 5 minutes).

After

warmup, apply a

100

mV, 1 kHz signal to both

channels. With the

unit in Dolby mode, adjust the lnput

Level control for

500

mV at the center output. Adjust the

lnput Balance control for

minimum output at the left

surround

output. Under these conditions, the unit

should provide the voltages listed in the following table

withln

&2

dB.

Page 4

Mode Switch: Dolby Surround

1

kHz,

100

rnV

Input

to:

--

<M

rn~ <ZO rn~

X)O

rn~

Center

Right

<5

rnV

380

rnV

en

Sunound

c20 rnv cX) rnV

cro

rnV

Ri~ht Surround

<a

mV

c20

rnV

c10mV

Mode Switch: Stereo

lJsHr,lol,mVkprlto:

Center

Right

<5

rnV

270

rnV

Lett Surround

XY)

rnV

533

rnV

el0

mV

533

mV

clO

rnv

Mode Switch: Mono

Before Preliminary Checkout In the mono mode, adjust

the Mono Enhance Adjust control (located on the

chassis bottom). With the unit In the mono mode and a

100

mV, 1 kHz signal applied to both channels, adjust

the Mono Enhance Adjust control for

300

mV at the left

output.

Output

1

kHr,

100

rnV

Input

lo

both chrnnols

Center

Right

I

eft Surrwnd

ht

Sunound

280

rnV

Subwoofer Output

Proper operation of the subwoofer output can

be

veri-

fied by measuring the following voltages.

If the above voltages are measured, the

HTS5000

is

operating correctly. If any voltages are outside the

specified limits, the following procedure

will aid In

isolating the major circuit block that is causing the pro-

blem. Any circuit block (visible on the printed circuit as

an outlined block of components), with the exception of

the Directional Enhancement

(A6),

Direction Sensing

(A7)

and Digital Delay (A12) Blocks, can be serviced

using conventional circuit troubleshooting techniques.

Mode Swltth

Mono

Dolby

Checkout Procedure (cover

removed)

Power Supply Block

(A 1 1)

1

kHz, 1W mV

lnpul

io

both channels

190

rnV

270

mV

lnpul Block

(A2)

Component mersud

(to

ground)

Cathode of dlode

Dl105

Anode of diode

Dl100

Cathode of diode

Dl110

Mode

switch:

Dolby.

Proper operation of the lnput

Block .is verified by the following test point TP2.A and

TP2B

voltages.

Msrrunnwnt

+

15

Vdc

-15

Vdc

+5

Vdc

Use extreme care when measuring voltages

near

the 120 Vac power supply fuses (Fl100, F1101.

F1102).

Directional Enhancement

(A6)

and Direction Sensing

(A7)

Blocks

Tost Pdnt

Proper operation of the Directional Enhancement and

Direction

Senslng-Blocks was verified in the Preliminary

Checkout procedure

In the Dolby mode.

IMPORTANT: If Incorrect voltages were obtained in

the Preliminary Checkout, the

unit must be returned to

Shure Brothers Service Department. The Directional

Enhancement

(A6) and Direction Sensing (A7) Blocks

are not field-serviceable.

Digital Delay Block

(A12)

Proper operation of the Dfgital Defay Block was

verified in the Preliminary Checkout procedure.

IMPOR.

TANT: If incorrect voltages were obtained in the

Preliminary Checkout, the unit must be returned to

Shure Brothers Service Department. The Digital Delay

(A12) Block is not fleld.serviceable.

Dolby Noise Reduction Block

(A3)

Proper operation of the Dolby Noise Reduction Block

is verified by the following voltages at Test Point

TP3A.

Mode switch: Dolby Surround

Input to: Left Channel

1

kH&

100

mV

impul to:

Output

Level Control and Remote Block

(A9, AID)

Proper operation of the Output Level Control and

Remote Blocks was verified in the Preliminary Checkout

procedure in all

mcdes.

LOR Chrnnel

TP2A

I

4W

rnv

TF2B

4W

rnv

Input Ftvqurncy

LOO

Hz

4

kHz

Remofe Control Voltage

The Volume

(R1016) and Surround Level (R1014) con-

trols can be checked

by

turning them both to their

minimum (counterclockwise) positions and measuring

the following voltages with the wired remote control

disconnected from the

HTS5000.

Test Point TPlOA

.

. . . . . .

. .

. . . . .

. . . . . . . . . . .

4

Vdc

Potentiometer

R1014 (ungrounded side)

.

. . . .

.

4

Vdc

Wired Remote Control

Unlt

~eslstance. readings made at the miniature stereo

phone plug of the

HTS5000

remote control unit will ln-

dicate proper operation.

Both Chrnnols

m

rnv

<a

rnv

Input hre1

100

mV

730

rnv

703

rnV

10

mV

m

rnv

35

mV

Mersuternont

Slctevs

lo

rlng

Sleeve to tlp

(Mula

on)

Sleeve lo tlp

(Mule

off)

SwltcWontrd

Mute

Surround Level

Surround lewl

Volume Level

Surround

Lsvel

Volume

hl

Surround Lml

Volume

Level

Volume Level

5.fflng

OnorOH

Mlnlmum

.

Maxlmurn

Mu-Mln

MaxMIn

Mu-Mln

Mu-Min

Mlnlmum

Maxlmum

Rbadlng

BW120

80012000

>25Q

No chmw

No cbnw

16OBl000

No chrnps

850200

cm

Page 5

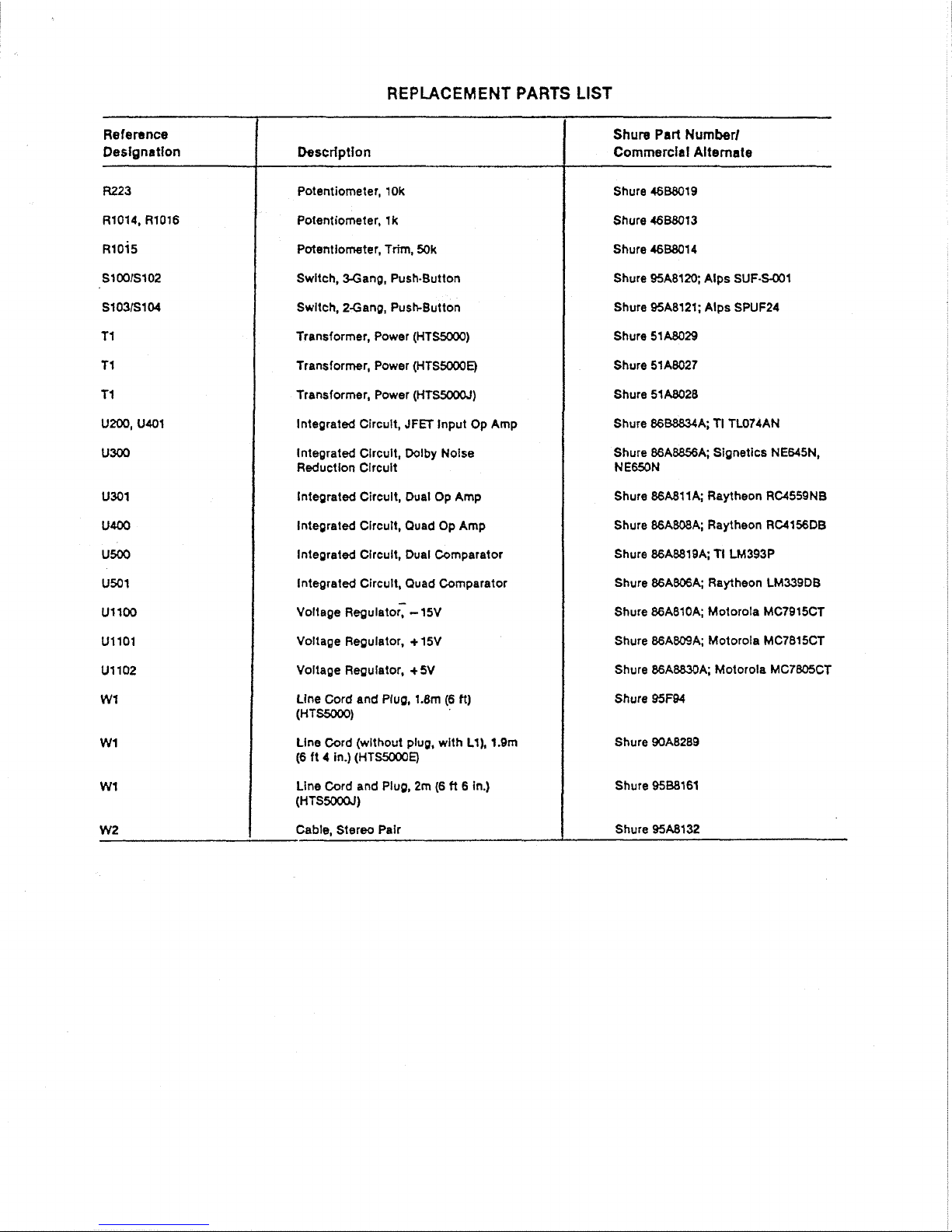

PARTS

LIST

The following pages contain a replacement parts list

for the

HTS5000. Part numbers not shown on the parts

list (except for Directional Enhancement, Direction Sensing, and Digital Delay Block parts which are also not

listed) are readily available through local electronics

parts suppliers. In these Instances, the circuit diagram

shows only the reference designation and value of the

standard parts.

SERVICE

ILLUSTRATIONS

Following the parts llst are an HTS5000 block

diagram, and clrcult diagrams and printed circuit board

layouts, including the basic

HTS5000, HTS5000E, and

HTS5000J power supplies.

Note that circuit

Information on the non-fieldserviceable Directional Enhancement, Direction Sensing, and Digital Delay Blocks

(A6,

A7

and

A12)

is not in-

cluded.

Power Supply

(All)

parts shown on the circuit

diagram

with

a

A

are critical and must be re

placed

only

with identical parts as specified by

Shure Brothers.

Page 6

REPLACEMENT

PARTS

LIST

Reference

Deslgnatlon

A1 3

C202,CXH

C301,W05-W06

C303,d312

C309

C400-C407

CllOO,C1106,

CllfO

'

C1102,C1107,

C1111

D416D420

050005(33

D50a

0890

D912.D914

D1100-Dl110

FllW

FllOO

F1101

FllOl

J200

J201

J202

J9W,J1000

L1

MPI-MPS

MP6-MP9

QB00-QB01

R107,

R309

R211

Description

Remote Control Assembly

Capacitor, Electrolytic,

2ZrF, 6.3V

Capacitor,

Electrolytic,

1 pF. 50V

Capacitor,

Electrolytlc, 10 rF, 16V

Shura

Part

Number1

Commerklal Alternate

Shure

90A8248

Shure 86V628; Mallory TAC226KOlOP05

Shure 86S628; Cornell-Dubilier NLWl.50

Shure 86Y628; Cornell-Dubilier

Capacitor, Electrolytic,

220

pF, 25V

Capacitor, Electrolytic, 2.2

rF, 25V

Capacitor,

Electrolytic, 10 pF, 35V

Capacitor,

Electrolytic, 1000 pF,

35V

Light-Emlttinp Diode, Clear

Light-Emittlng Diode, Green

Light-Emitting Diode, Red

Llght-Emitting Diode, Yellow

Zener Diode,

5.6V

Diode, Silicon Rectifier, 100V, II2A

Fuse, SIO-Blo, 3AG, 0.34 250V

(HTS5000)

Fuse, Time Delay, 375

mA,

125V

(HTS5OW.l)

Fuse, Time

Lag,

0.16A, 250V

(HTS5000E)

Fuse, SIo.Blo, Pigtall, 2AG, 1 A,

250V

(HTSWE, HTS5000J)

Phono Jack, Dual

Phono Jack,

4-Posltion

Phono Jack, &Position

Phone Jack, Miniature, Stereo

Ferrlte Balun

Core

(HTS5000,

HTW)

Knob,

Front

Panel

Feet

Transistor, NPN

Potentiometer, Trim,

1Ok

Potentiometer, Dual, lOOk

NLWIO-16

Shure 86x629; Nichlcon 1 E220MP.A

Shure 86AB628; Mallory

TAC225K025P02

Shure 86AA628; Mallory CTL-

lNM050PlA

Shure

86J629;

Sprague 503DlWF050SJ

Shure &A841 1

Shure B6A8410

Shure 8668410

Shure 86C8410

Shure 86A8409; Motorola lN5232A

Shure 86A404; Motorola IN4002

Shure 805159; Littelfuse Ser. 313000

Shure

86A6059; San-0 SDLC

Shure

80D380; Schurter

034.3109

Shure 80AgD52; Llttelfuse Ser. 230001

Shure

95A8127

Shure 95A8128

Shure 95A8129

Shure 95A8130

Shure 80AB051

Shure

31AB010

Shure 66AB002

Shure 86A350; Motorola 2N5210

Shure

468084

Shure 46A8019

Page 7

REPLACEMENT

PARTS

LIST

Reference

Designation

R223

R1014, R1016

~1015

S1001S102

S103/S104

TI

TI

TI

Urn,

U401

U300

U301

U400

USCK)

U501

UllOO

UllOl

U1102

W1

W1

W1

W2

Description

Potentiometer,

10k

Potentiometer, 1 k

Potentlometer, Trim, 50k

Swltch, 3Gang, Push-Button

Swltch, Z-Gang, PushButton

Transformer, Power (HTS5000)

Transformer, Power (HTS5000E)

Transformer, Power (HTS5000J)

Integrated Circult,

JFET

Input Op Amp

Integrated Clrcult, Dolby Nolse

Reduction

Circuit

Integrated

Circult, Dual

Op

Amp

lnteprated

Clrcult, Ouad Op Amp

Integrated Circuit, Dual Comparator

Integrated

Circult, Quad Comparator

Voltage

~e~ulato< - 15V

Voltage Regulator, + 15V

Voltage Regulator,

+SV

Line Cord and Plug, 1.8m

(6

ft)

(Hf

S5ow

Llne Cord (wlthout plug, with Ll),

1.9m

(6

ft

4

in.) (HTS5000E)

Line Cord and Plug, 2m

(6

ft

6

In.)

(HTSsoOar)

Cable, Stereo Pair

Shure

Part

Number1

Commercial

Alternate

Shure 4688019

Shure

46BB013

Shure 4688014

Shure 95A8120; Alps SUF-S001

Shure 95A8121; Alps SPUF24

Shure 51AB029

Shure 51AB027

Shure 51AB028

Shure 86-A; TI TL074AN

Shure 86A8856A; Sipnetics NE645N,

NE650N

Shure BGA811A; Raytheon RC4559NB

Shure 86ABOBA; Raytheon RC4156DB

Shure 86A881BA; TI

LM393P

Shure 86A806A; Raytheon LM339DB

Shure 86A810A; Motorola MC7915CT

Shure 86A809A; Motorola MC7815CT

Shure 86A8830A; Motorola MC7B05CT

Shure WFW

Shure 90A8289

Shure 95B8161

Shure 95A8132

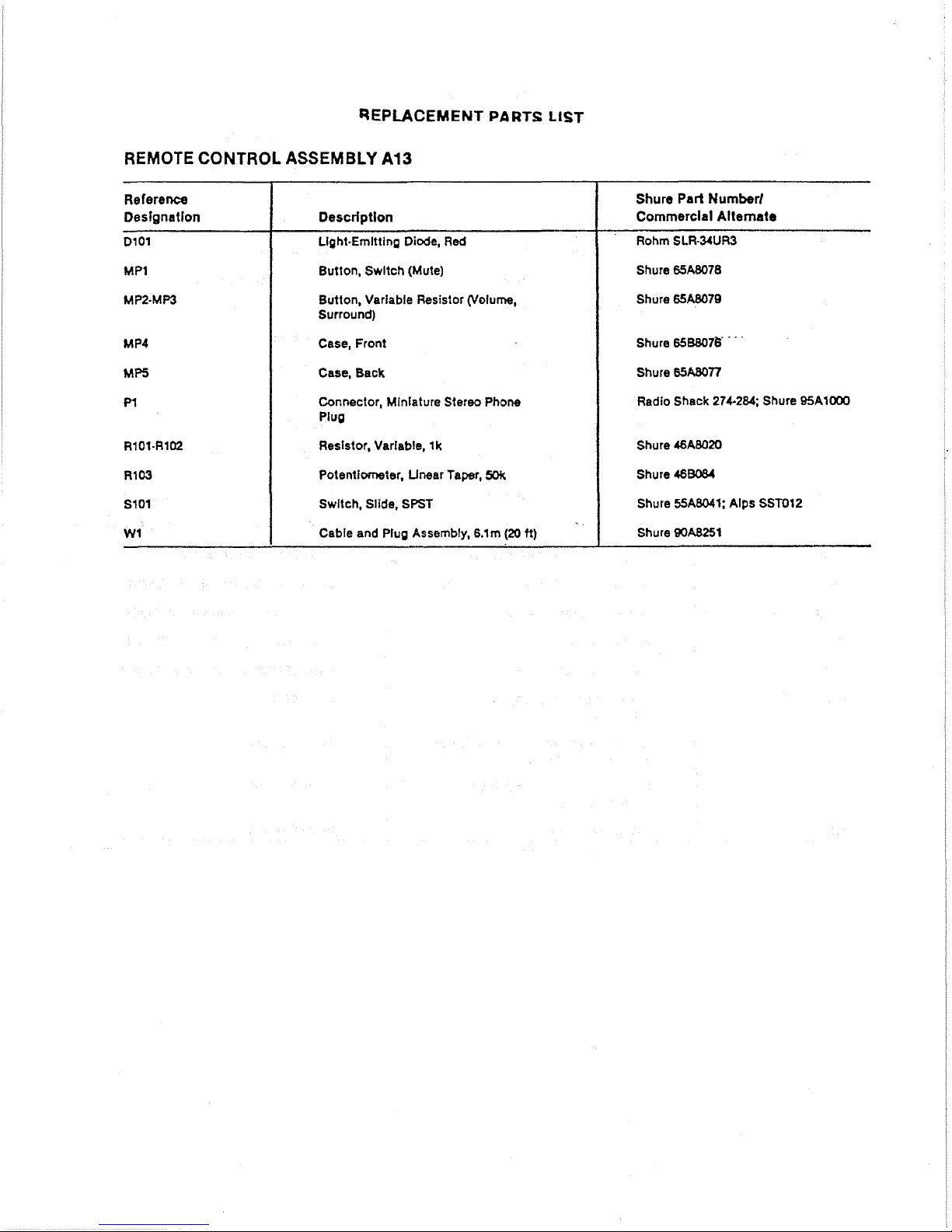

Page 8

REPUCEMENT

PARTS

LIST

REMOTE CONTROL ASSEMBLY

A13

Shure

Part

Number1

Commercial

Allemate

Rohm SLR-34UR3

Shure

65A8078

Shore

65A8078

Shure

658807E

'

Shure

65-n

Radio Shack

274-284;

Shure 95A1000

Shure

46A8020

Shure

46B084

Shure 55AW1; Alps

SST012

Shure

@JAB251

Reference

Designation

Dl01

MP1

MP2-MP3

MP4

MP5

Pl

R101-RIM

R103

SlOl

W1

Description

Light-Emltting Diode,

Red

Button, Swltch (Mute)

Button, Variable Resistor (Volume,

Surround)

Case, Front

Case, Back

Connector, Miniature Stereo Phone

Plug

Resistor, Variable,

lk

Potentimeter, Unear Taper,

5Qk

Swltch, Slide, SPST

Cable and Plug Assembly,

6.1m

(20

ti)

Page 9

L

--

LEFT

R

-

RICH1

c

-

crxrrr

s

-

runnowno

-~oolc

www

--msGML8YIDUlYOOamm%MLTYIL*

------

%I.

L

C

n

11

MODEL HTS5000

SURROUND AUDIO PROCESSOR

BLOCK

DIAGRAM

Page 10

NOTES

TO

SERVICE

ILLUSTRATIONS

The notes below apply to the partial circuit diagrams

and printed

clrcult board layouts shown on the follow-

ing pages. As previously stated, information is

not

in-

cluded on the Directional Enhancement Block

(A@,

Direction Sensing Block (A7). and Digital Delay Block

(A12).

In addition, only partial information is given on

the Output Level Control

&

Remote Block (A9,

A10).

This

is done because the equlpment required for

troubleshooting, adjusting and repairing these circuits

is not available

outside Shure's factory.

Remember that

all

Internal adjustments are con-

sidered factory-serviceable only. Field repair should

be

limited to replacing known defective parts, repairing

defective connections, etc. Attempting to calibrate the

HTS5000

in

the field without proper equipment (including computer setup) can result in serious performance problems.

1.

All resistors are 114W,

5%

unless otherwise

specified.

2.

All capacitors in microfarads and

50

volts or more

unless otherwise specified. Electrolytic capacitors

shown in microfarads

X

volts.

3.

The following symbols denote:

PC

Board

A

Chassis

Ground

"

Ground

4.

The printed clrcult board is subdivided into sections

where the first two digits of the part number

describe Its "block."

A1

-

Mode Switching Block

A2

-

lnput Block

A3 - Dolby Noise Reduction Block

A4

-

Directional Display Block

A5

lnput Level Display Block

A6

-

Directional Enhancement Block

(drawings not supplied)

A7

Direction Sensing Block (drawings not supplied)

A8

-

lnput Balance Display Block

A9,10 - Output Level Control & Remote Block

(parfial drawings supplied)

All

-

Power Supply Block*

A12

-

Digital Delay Block (drawings not supplied)

A13

-

Remote Control Assembly

'Separate

drawings

provlded

for

the

HTSXK)O,

HTSWE

and

HTSXKXU.

5.

To eliminate risk

of

fire or electrical shock, all cornponents In the power supply indicated

wlthA

are critical components and must

be

replaced only with identical parts as specified by

Shure Brothers lnc.

Page 11

MODE

SWITCHING

BLOCK

A1

(snow

11

(SJ+OW

I#

I-----

gsmm

-------A

-1~.

POSITIOW~

-YOR)UL-

PD~I~ID*)

.

~a

oo~er

OURROUHD-

~OS~TIMO

Page 12

Page 13

INPUT

BLOCK

A2

Page 14

INPUT

BLOCK

A2

Page 15

DOLBY

NOISE

REDUCTION

BLOCK

A3

Page 16

DOLBY

NOISE

REDUCTION

BLOCK

A3

Page 17

DIRECTIONAL

DISPLAY

BLOCK

A4

Page 18

DIRECTIONAL

DISPLAY

BLOCK

A4

Page 19

INPUT

LEVEL

DISPLAY

BLOCK

A5

Page 20

INPUT LEVEL DISPLAY.BLOCK

A5

Page 21

INPUT

BALANCE DISPLAY

BLOCK

A8

Page 22

INPUT

BALANCE

DISPLAY

BLOCK

A8

Page 23

OUTPUT LEVEL CONTROL

&

REMOTE BLOCK A9,

A10

(PARTIAL DRAWINGS SUPPLIED)

Page 24

OUTPUT LEVEL

CONTROL

&

REMOTE

BLOCK

A9,

A10

(PARTIAL DRAWINGS

SUPPLIED)

Page 25

POWER

SUPPLY

BLOCK

All

(HTS5000)

TO

ELIllIHATE RISK OF FIRE

OR

ELECTRICAL

SHOCK,

ALL

COWONEHTS IN THE POWER SUPPLY

INDICATED

VITH

A

ARE

CRITICAL

COnPOHEHfS

AND

MUST

BE

REPLACED ONLY UITH lDEWTICM

PARTS AS SPECI~ICD BY SHURE BROTHERS INC.

Page 26

POWER

SUPPLY BLOCK

All

Page 27

POWER

SUPPLY

BLOCK

All

(HTS5000E)

Page 28

POWER

SUPt

,Y

BLOCK

All

(HTS5000J)

Tl

A

I

1

01 104

I

Dl 10s

U.

TO ELIMINATE RISK

OF

FIRE.OR ELECTRICAL

SHOCK* ALL COMPONENTS

IN

THE POWER

SUPPLY

INDICATED WITH ARE CRITICAL COMPONENTS

AND MUST

BE REPLACED

ONLY

WITH IDENTICAL

I

'RED

ELK

l

OOV

BLK/REO

A

I

4-

*ISV

+

REDIYEL

RED

D'

n

86A404

UI 101

86A

009

fL

JWL

PARTS AS SPECIFIED

BY

SHURE BROTHERS INC.

..

--

+

I

t

BLU/YEL

--

-----

1

I

/

i

86A404

86A404

z,'

+

C.

FllO2

I

A.

250V

El

/I

SLOW-BLOW

9

01 108 01

l

lo

4b--+-

n

PI 100

861404 B6A404

J

1

n

86A404

CllO4 CIIO3 ~1102

Ll

--C11OS

--.

33

--c1101

-.

33

i

I

I

"1

A

t

OOV

AC

Pe°

125~~~

50/60

Hz

36W

-

86A404

-----

........................

-

C1107

1000

X35V

C1102

I000

--

x3sv

"

Dl

103

U

..

86A404

DllOl

-CI

106

IOX35Y

+

--Cl I00

1

OX35Y

Jv

-

n

86A404

.01

SOOV

I

I

'

A

U.

a-

.01

SOOV

t~ll~~

86A

BIO

Dl 100

I'L

-

-1C)-15V

i

-

------

n

Page 29

Page 30

Loading...

Loading...