Page 1

222 HARTREY AVE., EVANSTON.

MICROPHONES AND ELECTRONIC COMPONENTS

AREA CODE 3121866-2200 CABLE: SHUREMICRO

TWX:

910-231-0048 TELEX: 72.4381

IL.

60204 U.S.A.

MODEL

HF52

MOBILE VOICE PICKUP SYSTEM

GENERAL

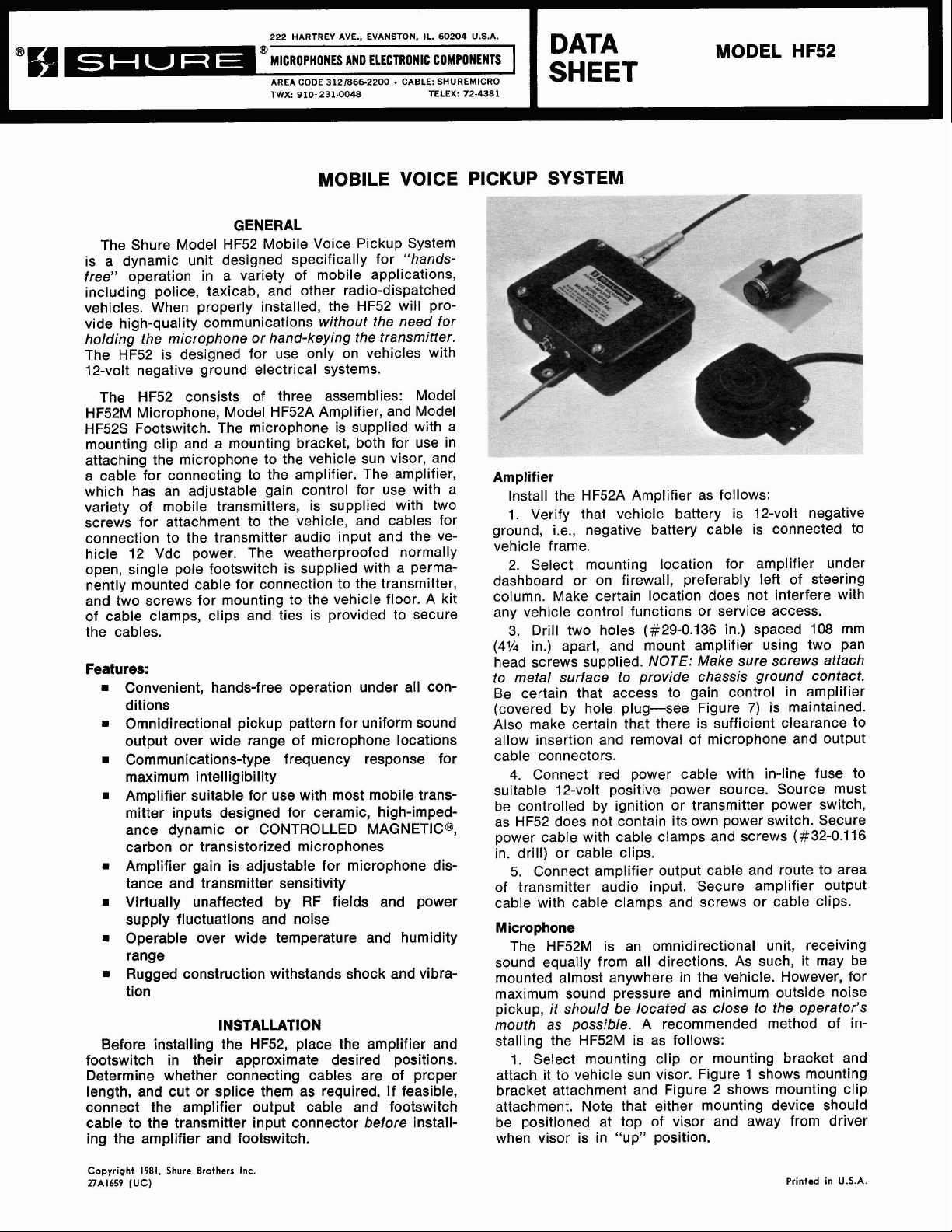

The Shure Model HF52 Mobile Voice Pickup System

is a dynamic unit designed specifically for

free" operation in a variety of mobile applications,

including police, taxicab, and other radio-dispatched

vehicles. When properly installed, the HF52 will provide high-quality communications without the need for

holding the microphone or hand-keying the transmitter.

The HF52 is designed for use only on vehicles with

12-volt negative ground electrical systems.

The HF52 consists of three assemblies: Model

HF52M Microphone, Model HF52A Amplifier, and Model

HF52S Footswitch. The microphone is supplied with a

mounting clip and a mounting bracket, both for use in

attaching the microphone to the vehicle sun visor, and

a cable for connecting to the amplifier. The amplifier,

which has an adjustable gain control for use with a

variety of mobile transmitters, is supplied with two

screws for attachment to the vehicle, and cables for

connection to the transmitter audio input and the vehicle 12 Vdc power. The weatherproofed normally

open, single pole footswitch is supplied with a perma-

nently mounted cable for connection to the transmitter,

and two screws for mounting to the vehicle floor. A kit

of cable clamps, clips and ties is provided to secure

the cables.

Features:

Convenient, hands-free operation under all conditions

=

Omnidirectional pickup pattern for uniform sound

output over wide range of microphone locations

.

Communications-type frequency response for cable C~~-~nectors.

maximum intelligibility 4. Connect red power cable with in-line fuse to

.

Amplifier suitable for use with most mobile trans-

mitter

carbon or transistorized microphones

=

Amplifier gain is adjustable for microphone distance and transmitter sensitivity

Virtually unaffected by

supply fluctuations and noise

Operable over wide temperature and humidity

range

.

tion

Before installing the HF52, place the amplifier and

footswitch in their approximate desired positions.

Determine whether connecting cables are of proper attach it to vehicle sun visor. Figure 1 shows mounting

length, and cut or splice them as required. If feasible,

connect the amplifier output cable and footswitch attachment. Note that either mounting device should

cable to the transmitter input connector before installing the amplifier and footswitch. when visor is in "up" position.

inputs designed

dynamic

Rugged withstands shock and vibra- mounted almost anywhere in the vehicle. However, for

Or

INSTALLATION

for

ceramic,

'ONTROLLED

RF

fields and power cable with cable clamps and screws or cable clips.

"hands-

high-imped-

Amplifier

Install the

1. Verify that vehicle battery is 12-volt negative

ground! i.e., negative battery cable is connected to

vehicle

2. Select mounting location for amplifier under

dashboard or on firewall, preferably left of steering

column. Make certain location does not interfere with

any vehicle control functions Or service access.

3. Drill two holes

(4Y4 in.) apart, and mount amplifier using two pan

head screws supplied.

to metal surface to provide chassis ground contact.

Be

certain

(covered by hole plug-see Figure

Also make certain that there is sufficient clearance to

allow insertion and removal of microphone and output

suitable 12-volt positive power SOUrCe. Source must

be controlled by ignition or transmitter power switch,

as HF52 does not contain its own power switch. Secure

power cable with cable clamps and screws (#32-0.116

in. drill) or cable clips.

5. Connect amplifier output cable and route to area

of transmitter audio input. Secure amplifier output

Microphone

The

sound equally from all directions. As such, it may be

maximum sound pressure and minimum outside noise

pickup, it should be located as close to the operator's

mouth as possible. A recommended method of installing the HF52M is as follows:

1. Select mounting clip or mounting bracket and

bracket attachment and Figure

be positioned at top of visor and away from driver

HF52A Amplifier as follows:

frame.

(#29-0.136 in.) spaced 108 mm

NOTE:

that

access

HF52M is an omnidirectional unit, receiving

Make sure screws attach

to

gain

control

2

shows mounting clip

in

7)

is maintained.

amplifier

I

Copyright

27A1659

1981,

(UC)

Shure Brothers

Inc.

Printed

in

U.S.A.

Page 2

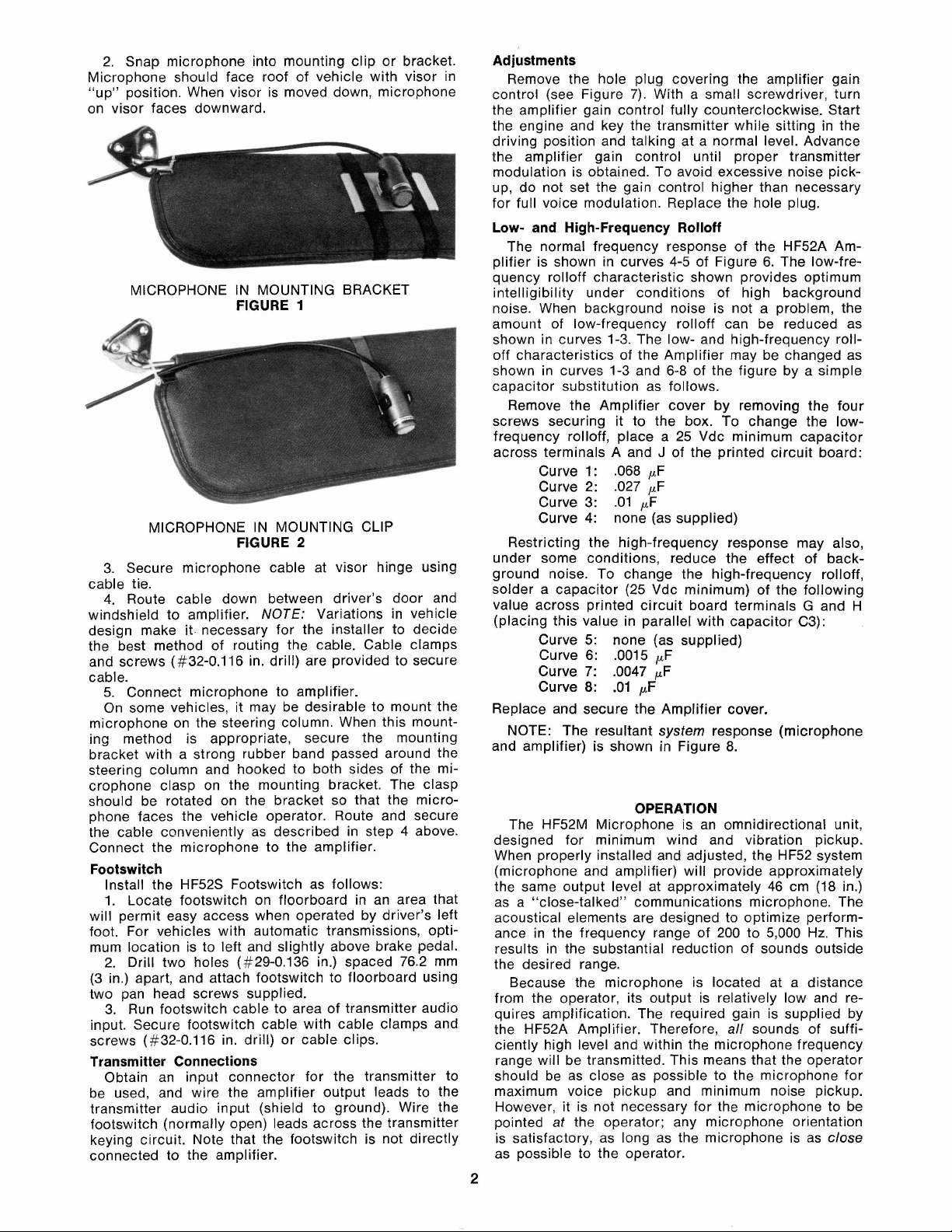

2. Snap microphone into mounting clip or bracket.

Microphone should face roof of vehicle with visor in

"up" position. When visor is moved down, microphone

on visor faces downward.

MICROPHONE IN MOUNTING BRACKET

FIGURE

MICROPHONE IN MOUNTING CLIP

FIGURE

3. Secure microphone cable at visor hinge using

cable tie.

4. Route cable down between driver's door and

windshield to amplifier.

design make it. necessary for the installer to decide

the best method of routing the cable. Cable clamps

and screws

cable.

5. Connect microphone to amplifier.

On some vehicles, it may be desirable to mount the

microphone on the steering column. When this mounting method is appropriate, secure the mounting

bracket with a strong rubber band passed around the

steering column and hooked to both sides of the microphone clasp on the mounting bracket. The clasp

should be rotated on the bracket so that the micro-

phone faces the vehicle operator. Route and secure

the cable conveniently as described in step 4 above.

Connect the microphone to the amplifier.

(#32-0.116 in. drill) are provided to secure

1

2

NOTE: Variations in vehicle

Footswitch

Install the HF52S Footswitch as follows:

1. Locate footswitch on floorboard in an area that

will permit easy access when operated by driver's left

foot. For vehicles with automatic transmissions, optimum location is to left and slightly above brake pedal.

2. Drill two holes

(3 in.) apart, and attach footswitch to floorboard using

two pan head screws supplied.

3. Run footswitch cable to area of transmitter audio

input. Secure footswitch cable with cable clamps and

screws

(#32-0.116 in. drill) or cable clips.

(#29-0.136 in.) spaced 76.2 mm

Transmitter Connections

Obtain an input connector for the transmitter to

be used, and wire the amplifier output leads to the

transmitter audio input (shield to ground). Wire the

footswitch (normally open) leads across the transmitter

keying circuit. Note that the footswitch is not directly

connected to the amplifier.

Adjustments

Remove the hole

control (see Figure 7). With a small screwdriver, turn

the amplifier gain control fully counterclockwise. Start

the engine and key the transmitter while sitting in the

driving position and talking at a normal level. Advance

the amplifier gain control until proper transmitter

modulation is obtained. To avoid excessive noise pickup, do not set the gain control higher than necessary

for full voice modulation. Replace the hole plug.

plug covering the amplifier gain

Low- and High-Frequency Rolloff

The normal frequency response of the HF52A Amplifier is shown in curves 4-5 of Figure 6. The

quency rolloff characteristic shown provides optimum

intelligibility under conditions of high background

noise. When background noise is not a problem, the

amount of low-frequency

shown in curves 1-3. The low- and high-frequency

off characteristics of the Amplifier may be changed as

shown in curves 1-3 and 6-8 of the figure by a simple

capacitor substitution as follows.

Remove the Amplifier cover by removing the four

screws securing it to the box. To change the

frequency rolloff, place a 25 Vdc minimum capacitor

across terminals A and

Curve 1:

Curve

Curve

Curve

Restricting the high-frequency response may also,

under some conditions, reduce the effect of background noise. To change the high-frequency

solder a capacitor (25 Vdc minimum) of the following

value across printed circuit board terminals G and H

(placing this value in parallel with capacitor C3):

Curve

Curve 6:

Curve 7: .0047

Curve 8: .O1

Replace and secure the Amplifier cover.

NOTE: The resultant system response (microphone

and amplifier) is shown in Figure 8.

,068 pF

2:

.027 pF

3:

.O1 pF

4:

none (as supplied)

5:

none (as supplied)

.0015 pF

rolloff can be reduced as

J

of the printed circuit board:

pF

pF

low-fre-

roll-

low-

rolloff,

OPERATION

The HF52M Microphone is an omnidirectional unit,

designed for minimum wind and vibration pickup.

When properly installed and adjusted, the HF52 system

(microphone and amplifier) will provide approximately

the same output level at approximately 46 cm (18 in.)

as a "close-talked" communications microphone. The

acoustical elements are designed to optimize performance in the frequency range of 200 to 5,000 Hz. This

results in the substantial reduction of sounds outside

the desired range.

Because the microphone is located at a distance

from the operator, its output is relatively low and requires amplification. The required gain is supplied by

the

HF52A Amplifier. Therefore,

ciently high level and within the microphone frequency

range will be transmitted. This means that the operator

should be as close as possible to the microphone for

maximum voice pickup and minimum noise pickup.

However, it is not necessary for the microphone to be

pointed

is satisfactory, as long as the microphone is as close

as possible to the operator.

at

the operator; any microphone orientation

all

sounds of suffi-

Page 3

The operator can help provide good commun~cations

by remembering these factors:

1. Keep vehicle windows closed to minimize out-

side noise while transmitting.

2. Bear in mind that passenger conversation or

other in-vehicle noise (radio, air conditioner, etc.) will

be transmitted.

3. Remember that higher vehicle speeds mean

higher background vehicle noise.

4. As with any communications system, care in

speaking clearly will promote intelligible communication.

SPECIFICATIONS

MICROPHONE

Type:

Frequency Response: 200 to 5,000 Hz (see Figure

Dynamic

3)

Dimensions: See Figure 5

....

(72

IN.)

MICROPHONE OVERALL DIMENSIONS

FIGURE 5

Net Weight: 98 grams (3% oz)

AMPLIFIER

Voltage Gain

(at 1,000 Hz): Adjustable,

38

to 59 dB

d

-

+I0

W

$

O

W

5

-10

L

20 lpO0 lO.000

TYPICAL FREQUENCY RESPONSE

Microphone Impedance:

Output Level (at 1,000 Hz):

Open circuit voltage

(without amplifier)

(0 dB

Power Level

(0 dB = 1 milliwatt per 10 microbars)

Phasing: Positive pressure on diaphragm produces

positive voltage on pin 2 of connector (see Figure

/

FREQUENCY

FIGURE

190 ohms at 1 kHz

.......... -79.0 dB

=

1

volt per microbar)

................

CODED

TERMINAL

IN

HERTZ

3

-

58.0 dB

24000

4)

Frequency Response: 200 to 10,000 Hz as shown in

curve 4-5 of Figure 6

AMPLIFIER FREQUENCY RESPONSE

FIGURE

Output Clipping Level:

mination)

Recommended Load Impedance: 100 ohms min.

(superimposed dc voltage up to

operation)

Output Impedance: Less than 10 ohms

Phasing:

Noise (300 Hz

(equivalent input noise at full gain)

Output is out of phase with input

-

20 kHz): - 11 8 dBV

6

1V min. (100-ohm output ter-

16V will not affect

&

Operating Conditions:

Temperature

Relative

Cable: Non-detachable 1.8m (70 in.) two-conductor

shielded plastic-jacketed cable

Connector: Two-pin male miniature audio*

Finish: Dark gray

*

Designed to mate with Switchcraft

alent connector.

MICROPHONE WIRING DIAGRAM

FIGURE

...

-40" to +74"C (-40" to +165"F)

Humidity .................... .5 to 95%

4

"Slim

Line

"I

II"

or equiv-

Total Harmonic Distortion (at 1,000 Hz):

mV output

500

Current Drain:

15 mA max. (no signal)

mA max. (100-ohm load, 750 mV output)

25

Operating Voltage:

ground

Fuse: 5A, 32V, 3AG

Operating Temperature Range:

-29" to +74"C (-20" to 165°F)

Dimensions: See Figure

+

10.0 to +I59 Vdc, negative

7

3

3%

max. at

Page 4

AMPLIFIER OVERALL DIMENSIONS

Net Weight:

Finish:

323 grams (111/2 oz)

Dark gray

SYSTEM

Frequency Response:

FIGURE

7

200 to 5,000 Hz (see Figure 8)

MICROPHONE CARTRIDGE AND CABLE

REPLACEMENT

To remove and replace the HF52M Microphone car-

tridge or cable and plug assembly, proceed as follows:

1. Using pliers or wrench, remove bushing at rear

of microphone.

2. Without allowing cable to turn, unscrew end cap

of microphone, exposing

3. Using spanner wrench or similar tool, unscrew

brass retainer bushing from inside case.

4. Carefully slide cartridge and attached cable out

of case.

5. Unsolder cartridge from cable.

6. Replace cartridge by soldering cable to new

cartridge (see Figure 4).

7. Replace cable by slipping bushing, end cap and

retainer bushing over new cable, and soldering new

cable to cartridge (see Figure 4).

8.

Reassemble microphone by performing steps 1

4

through

in reverse.

cablelcartridge connections.

REPLACEMENT PARTS

The following replacement parts may be ordered

from your dealer or from Shure Brothers Inc.

SYSTEM FREQUENCY RESPONSE

FIGURE

Output Level

Open Circuit Voltage

(0 dB

(at 1,000 Hz):

=

1

volt per microbar)

Combined Net Weight:

835 grams (1 Ib, 13 oz)

Packaged Weight:

1.13 kg (2 Ib, 71/2 oz)

8

...

.Variable, -43 to -21 dB

DESCRIPTION PART NO.

Microphone 97A297 (HF52M)

Microphone Cartridge .99A367

Microphone Cable & Connector

Amplifier .90A2707 (HF52A)

Gain Control Hole Plug .80A289A

Amplifier Cover .................. .95A833

Amplifier Output Cable .95C453

Footswitch ................ .90A2240 (H F52S)

A Parts List for the HF52A Amplifier is given on a

following page. The commercial alternates shown in

the list are not necessarily equivalent parts, but are

electrically and mechanically similar, and may be used

if direct factory replacements are not immediately

available. To maintain highest possible performance

and reliability, Shure Factory Replacement Parts

should be used.

.................

............

..................

..........

...........

...

.90A2573

GUARANTEE

This Shure product is guaranteed in normal use to

be free from electrical and mechanical defects for a

period of one year from date of purchase. Please

retain proof of purchase date. This guarantee includes

all parts and labor. This guarantee is in lieu of any

and all other guarantees or warranties, express or

implied, and there shall be no recovery for any consequential or incidental damages.

LI

I

FOOTSWITCH DIMENSIONS

FIGURE

9

SHIPPING INSTRUCTIONS

Carefully repack the unit and return it prepaid to:

Shure Brothers Incorporated

Attention: Service Department

1501 West Shure Drive

Arlington Heights, Illinois 60004

If outside the United States, return the unit to your

dealer or Authorized Shure Service Center for repair.

The unit will be returned to you prepaid.

Page 5

MODEL HF52A AMPLIFIER PRINTED CIRCUIT BOARD ASSEMBLY

MODEL

Reference

Designation

A1

Dl, D2

D3, D4

D5

D6

F1

J1

J

2

L1 - L4

Q1

Q2, Q3

Q4

Q5

Q6, Q7

Q8

R20

'Parts listed as

RKC Kit number is shown will be shipped in RKC quantities.

Replacement

Kit No.*

Qty.

-

-

RKC21

-

RKC22

-

-

-

-

RKC9

-

RKC66

RKC65

-

-

RKC Kits should be ordered by that kit number. Any orders received for piece parts where

HF52A AMPLIFIER PARTS LIST

Replacement Kit Consists

Part No.

-

-

4

-

1

90A8048

86A415

86A404

86A421

86A408

-

-

-

-

-

4

-

1

1

-

90AZ2600

90AR2600

80A250

86C349

86A349

86A348

86A335

86A334

86A8303

46D033

Of:

Description

Printed Circuit Board

Assem bly

Diode, Silicon,

Computer, 75V

Silicon Rectifier,

100V, 112A

Zener Diode, Silicon,

8.7V +5%, 1/2W

Zener Diode, Silicon,

*5%, 1W

-

22v

Fuse, 3AG, 5A, 32V

Connector, Two-Socket

Connector, Phono Pin Jack

Ferrite Bead Ring

Transistor, Silicon, NPN

Transistor, Silicon, NPN

Transistor, Silicon, NPN

Transistor, Silicon, PNP

Transistor, Silicon, NPN

Transistor, Silicon, NPN

Potentiometer,

100k

Commercial

Alternate

None

TI or GE

Motorola 1 N4002

Motorola 1 N5238B

Motorola 1 N4748A

Littelfuse 31 1005

Switchcraft SL-17-2F

Switchcraft 3501 FP

Stackpole 57-01 81

Motorola

Motorola 2N5088

Motorola 2N5087

TI TIS93

TI TIS92

Motorola 2N6121

CTS X201 R104B

IN4148

2N5210

5

Page 6

'E

.B

~t,

aNW

2

LCaNI

ZMHl

OU

SWHO

'

WHL

lMNl

051

=mwA

3m

SWHO

Cl31S0MW

QI

9NW

7t331d~

ICdh-0

33naobld

aNw

COS

AVW

Au

A~WA

I

NI aUWNIWW

IflcUNj

-%GI

'

nw

'3'0

13A3

WULNcn

135

aL

HllM 03tlnSW3W S39WllOA

WnWlNlW

01

TN)

SWHO93W

WAJA

(351~~?073~lNm

SUOISI=U

.AS

'

.M*/I

HllM 03BIEWOW S33WllOA '3.W

01

SS~-IN~

SWH033W

3SlMU3U.O

3W

39Wl70A AlddS AO'ZI HllM 03tlflSd3W 533WllOA 7lW

'

.WAJ.A

~EIUI-s

NMOHS

3SIMMtu.O

NI

X

C13UIZBdS

S170A

'

3UlCUl33l3

9jQLladW3

'I

(U

nv

5310

-.

stco~lswdv5

NI

ajw

aNv

cs

SITX

w

3aw

smn

01

llfl3M13 9NIA3X

tl3111WSNVMl

Loading...

Loading...