Page 1

Instruction Manual

for

Phonograph Evaluation Kit

This Stereo Cartridge Analyzer is for use by Qualified Factory Trained personnel only.

Manufactured by

SHURE BROTHERS INCORPORATED

222 Hartrey Avenue

Evanston, Illinois 60204

Copyright

27A1347

1979,

(SH)

Shure Brothers

Inc.

Printed

in

U.S.A.

Page 2

I

.

Introduction

TABLE OF CONTENTS

PAGE

............................................................

2

II

.

Equipment Checklist

Ill

.

Electronic Equipment Setup and Check

.....................................................

.....................................

TESTING OF CUSTOMER'S SYSTEM

Cleaning and Inspection of the Stylus Tip

Connection of Customer's Equipment

Turntable Speed

Tracking Force and Antiskating Force Adjustment

Channel Orientation. Crosstalk. and Balance Tests

Phase Check

Antiskating Force and Tracking Force Explanation

Antiskating and Tracking Force Optimization using the Trackability Test

Checking Wear of the Shure TTR-103 and TTR-109 11

........................................................

...........................................................

...................................

.......................................

............................

...........................

...........................

.........

............................

2

3

4

5

5

5

6

7

7

8

ADDENDA

Model C/PEK-3/T 12

Guarantee 12

Shipping Instructions 12

Circuit Diagram and Parts List

...............................................................

........................................................

......................................................

...............................................

13

Page 3

I.

INTRODUCTION

The Shure Model C/PEK-3 Phonograph Evaluation Kit is designed for use with

stereo magnetic phonograph cartridges. The

the

stereo

capabilities of discrete quadriphonic phonograph cartridges. Note

C/PEK-3 may also be used to test

that (1) the quadriphonic properties of these cartridges must be evaluated

through listening tests, and

(2)

stylus wear may be more critical in discrete quad-

riphonic cartridges; moderate wear that yields acceptable stereo playback may

seriously affect discrete quadriphonic playback.

II.

EQUIPMENT CHECKLIST

The following equipment is necessary for the C/PEK-3:

A. C/PEK-3 Stereo Cartridge Analyzer.

B.

Good quality microscope (with side or ring illumination).

C.

Reference turntable with tone arm (preferably SME) and high quality Shure

phono cartridge.

D.

Oscilloscope with at least 150 mV/cm sensitivity.

E. Stereo amplifier with magnetic phono inputs and a pair of quality speakers.

F.

At least two copies of the Shure TTR-103 and one of the TTR-109.

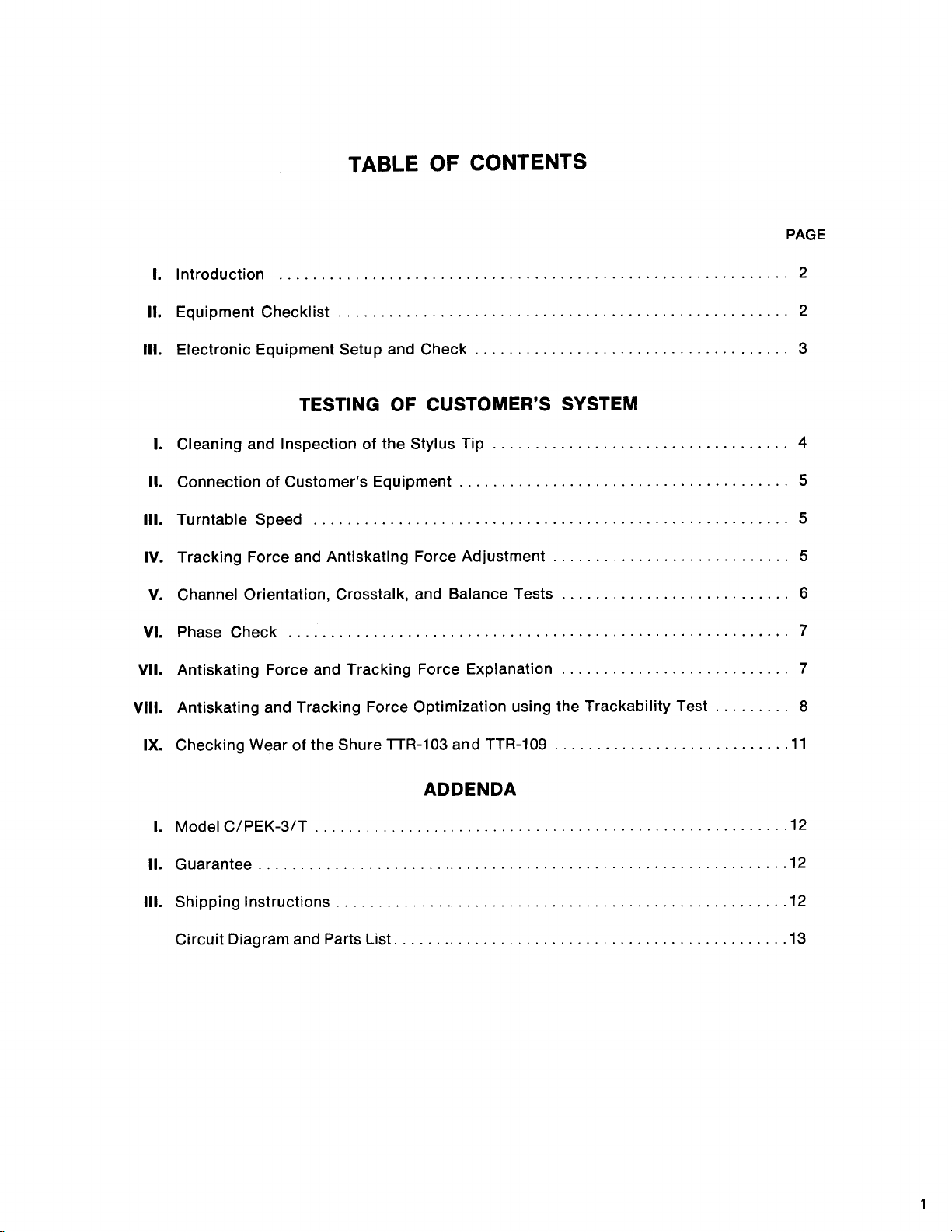

I

TO OSCILLOSCOPE

111

POWER

120

Q

ON

8

OFF

VAC

e

tB

Fig. 1

e

Q

e

LEFT

ull!1

RIGHT

e

d

LO

HIGH

MI0

INPUT

0

0

LEFT RIGHT

METER ZERO LEVEL

OUT A ADD

IN

A

0 -ZODB

GND.

Page 4

,

GROUND

IGHT

LEFT

,

&I

-

-

INTEGRATED

STEREO

AMPLIFIER

---I

7

SPEAKER

u

SPEAKER

I

11

\

dL

REFERENCE

TURNTABLE

I

'B"

INPUTS

TEST PANEL

VERTICAL

i

<:;r

-

---A

HORIZONTAL

I

SCOPE

I

I

I

I

lL

MONITOR

OUTPUTS

Pl

I

/---

I'

I

\

1

\

---/

I

I

L

-

-

-

-

CUSTOMER'S

TURNTABLE

OSCILLOSCOPE

0

0

-:-I

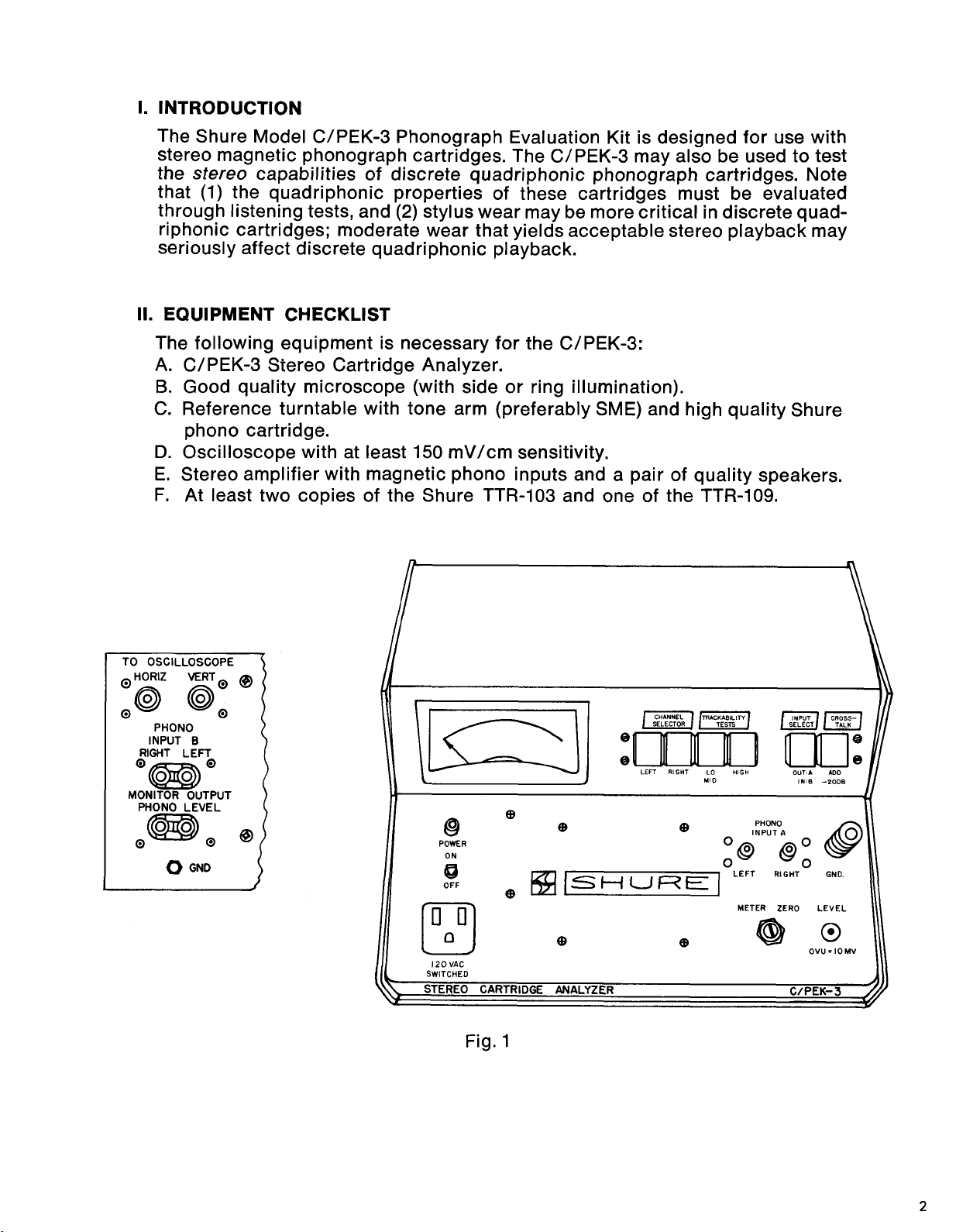

Ill. ELECTRONIC EQUIPMENT SETUP AND CHECK

The following steps (A-H) refer to drawings (Fig. 1 and 2):

A. Connect the ground wire from the reference turntable to the binding post

marked

"GND"

on the back of the Test Panel.

B. Plug the left channel output from the reference turntable into "B Left" on

the back of the Test Panel.

C. Plug the right channel output from the reference turntable into "B Right"

on the back of the test panel.

D.

Plug the C/PEK-3 power cord into a 120 Vac (50-60 Hz) outlet.

E. A listening test may be performed by connecting the monitor outputs on the

rear of the test panel to the magnetic phono inputs on a stereo amplifier. It

is recommended that a pair of good quality speakers be used. The volume

control of the stereo amplifier will control the listening volume only, and

will not affect the tests.

F.

Connect the "Vert" output on the back of the test panel to the vertical input

of the oscilloscope.

G.

Connect the "Horiz" output on the back of the test panel to the horizontal

input of the oscilloscope.

H.

On the oscilloscope:

1.

Set horizontal input to external.

2.

Set vertical and horizontal sensitivity to approximately 150 mV/cm.

To test the reference turntable, depress the turntable selector switch on the test

panel

("ln:B"), follow the test sequence, start by testing the turntable speed.

Page 5

TESTING OF CUSTOMER'S SYSTEM

I.

CLEANING AND INSPECTION OF THE STYLUS TIP

A.

Cleaning the Stylus

For the stylus to trace the groove accurately, it must be clean. To clean the

stylus, use a camel's-hair brush (size No. 2 or smaller), trimmed to a length

lh

no longer than

solution (mixed about 50150) and brush the stylus with a forward motion,

from the rear (terminal end) of the cartridge to the front. Never brush or

wipe the stylus from front to rear or from side to side. The alcohol will

remove any sludge deposits which may have coated the stylus.

Note:

All Shure styli may be cleaned in this way. However, for other makes

of pickups, obtain manufacturer's procedure before using the alco-

hol solution, as permanent damage may result.

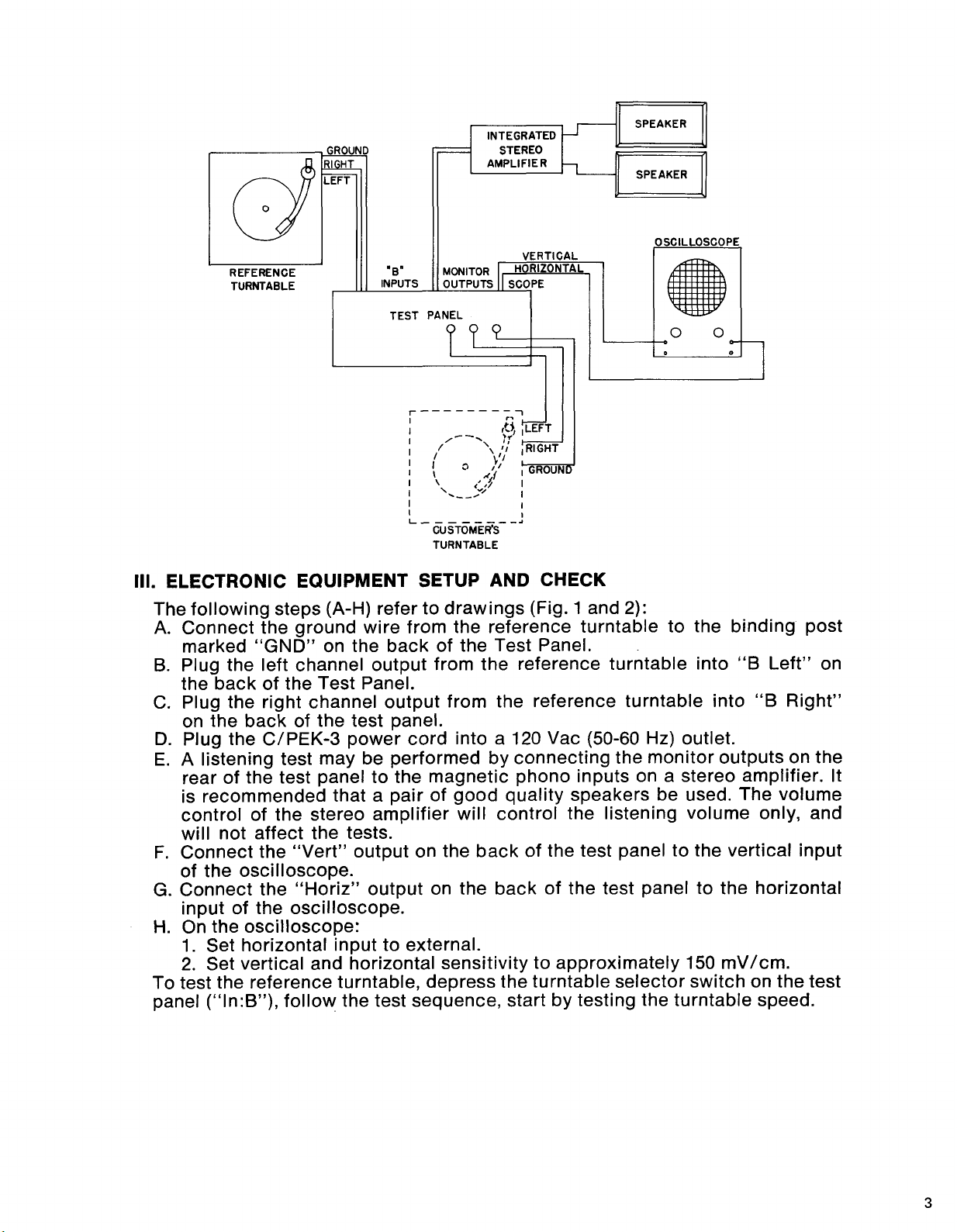

B.

Stylus Tip Inspection

The stylus tip can be checked with a microscope having a minimum of 200X

magnification, such as the Shure Stylus Evaluation Kit. The stylus should be

positioned under the lens so that the bottom or record side of the tip is facing

the lens. The tip must be illuminated on the two sides corresponding to the

record groove walls. After focusing the image, the wear can be determined

by comparing the image of the tip to the photographs (Figures4 through 12).

inch. Dip the brush in an ethyl alcohol and distilled water

Caution:

A badly worn tip will drastically reduce the life of the test record,

and it is not advisable to continue with the remaining tests except

le turntable speed check.

4

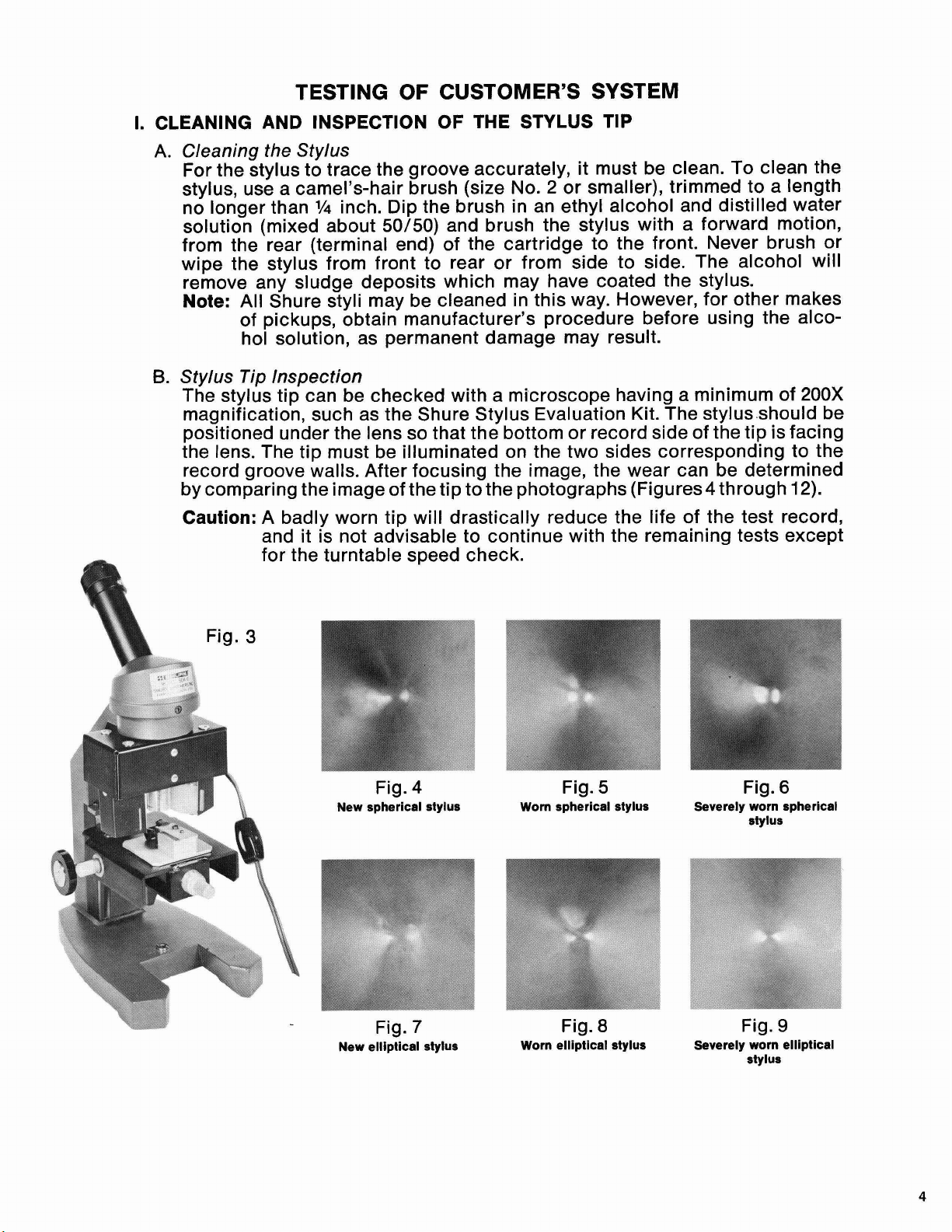

Fig.

New spherical stylus Worn spherical stylus

Fig. 5

Fig.

6

Severely worn spherical

stylus

Fig.

7

New elliptical stylus

Fig.

8

Worn elliptical stylus

Fig.

9

Severely worn elliptical

stylus

Page 6

Fig. 10 Fig. 11 Fig. 12

New hyperbolic stylus Worn hyperbolic stylus Severely worn hyperbolic

Fig. 13 Fig. 14 Fig. 15

New hyperelliptical Worn hyperelliptical Severely worn hyper-

stylus stylus elliptical stylus

II. CONNECTION OF CUSTOMER'S EQUIPMENT

stylus

A. Connect the ground wire to the binding post marked

"GND"

on the front of

the test panel.

B. Plug the left channel output from the customer's turntable into the "left" in-

put on the front of the test panel.

C.

Plug the right channel output from the customer's turntable into the "right"

input on the front of the test panel.

D.

Plug the ac cord from the customer's equipment into the ac outlet on the

front of the test panel.

E.

Push turntable selection switch on test panel to "0ut:A" position.

Ill. TURNTABLE SPEED

Check the turntable connections per Section

place TTR-109 on the turntable, and set the speed to

disc printed on the

TTR-109 label, check the speed of the turntable at

II.

If all connections are correct,

33%

rpm. Using the strobe

331/3

(outer ring). Now set the turntable speed to 45 rpm, and check the speed of the

turntable using the inner strobe. (Attach 50 Hz strobe label for the

when line frequency is

TRACKABILITY TESTS USING THE TTR-103 SHOULD BE PERFORMED

ALL

AT

45

RPM; LEVEL AND CROSSTALK TESTS USING THE TTR-109 SHOULD

BE PERFORMED AT

IV. TRACKING FORCE AND

A.

Set the stylus tracking force adjustment on the tone arm to zero.

50

33%

Hz.)

RPM.

ANTISKATING FORCE ADJUSTMENT

TTR-109

B. Balance the arm in accordance with instructions of the tone arm manufac-

turer.

C.

Set the tracking force at the middle of the tracking force range stated by

the cartridge manufacturer.

Example: If the suggested range is two to four grams, set the tracking force

to three grams.

rpm

Page 7

D.

Check the actual tracking force with the Shure SFG-2 Stylus Force Gauge

by placing the gauge in position on the turntable or, if the turntable is not

suitably flat, on a record on the turntable. Position the stylus tip into the

appropriate groove on the force gauge lever arm for the desired range:

"times

1" or "times 2," then move the rider weight to balance the gauge,

which indicates the actual tracking force at the stylus tip; re-adjust stylus

if

force setting

E.

Set antiskating to the recommended value of the tone arm manufacturer.

necessary.

d

STYLUS

V.

CHANNEL ORIENTATION, CROSSTALK,

AND BALANCE TESTS

A.

Channel Orientation

FORCE

Set up equipment as shown in Section

Place the Shure TTR-109 on the turntable.

THIS IS a

33%

RPM

RECORD.

tridge playing conditions per Section IV.

Press the "Left" button on the test panel and

I,

3

play Band

or 5 for the left channel. You

should observe a vertical line (Fig. 16) on the

4

scope. Play Band 2,

or 6 for the right channel, and press the "Right" button on the test

panel. You should observe a horizontal line

(Fig. 17). If the results are reversed, the

channels have been reversed. If necessarv.

reverse the leads from the changer

proper orientation is obtained.

n

GAUGE

Ill.

Set the car-

Fig. 16

si t6e

Crosstalk

To measure 1 kHz crosstalk, depress the

"Left" button on the test panel and play a

left channel band of the

"Zero

"0."

Adjust" control until the meter reads

Depress the "Crosstalk" button, and the

TTR-109. Adjust the

meter will indicate the left to right crosstalk

relative to a signal 20 dB below the left channel output. For example: a reading of -5 dB

on the meter with the "Crosstalk" button de-

pressed would indicate a crosstalk signal 25

dB down from the left channel output, whereas a reading of

crosstalk signal

+2 dB would indicate a

18

dB down from the main

channel. Meaningful crosstalk measurements

can be made for signals down as much as

30 dB.

The right to left channel crosstalk may be

measured by repeating the above test with the

"Right" button depressed and playing a right

channel band of the TTR-109.

Fig. 17

Page 8

Channel Balance

To check channel balance: Press the "Left"

button on the test panel and place the tone

arm on a left channel band. Use the "Zero

Adjust" control so the meter reads

Switch to the "Right" button on the test panel,

and play a right channel band. The meter

should read

should not be any greater than

which is the difference between left and right

channel outputs. This check may be com-

bined with the above crosstalk test to save

time and facilitate testing.

To measure actual voltage output of the cartridge,

play a left channel band or a right channel band

of the TTR-109. Push the "Level" button on the

panel. The meter will read on a linear scale in

relation to the percentage of modulation (lower

scale).

"0," ideally. The variance (in dB)

2

on the meter,

"0."

Fig. 18

Example:

VI. PHASE CHECK

Place TTR-103, Side 2 on the turntable; the

103

IS

button on the test panel and play Band 5. If you

observe a pattern as shown in Fig. 18, the

nels are out of phase. To correct this problem,

reverse the "hot" and ground leads on one channel at the pickup. Choose a channel which has

no ground tab. If this malfunction is found, the

customer should be advised to check the phasing

of his entire stereo system by means of a test

record such as the Shure "Audio Obstacle

Course." Fig. 19 is the pattern observed, using

Band 5, Side

ment is set correctly and operating normally.

VII.

ANTISKATING FORCE AND TRACKING FORCE

A.

Antiskating Force Explanation

When the stylus contacts the record groove, a certain amount of friction is

present at the stylus tip. As the stylus tracking force increases, this friction

force also increases. This force pulls along a line running through the length

of the body of the pickup. The offset angle (which is used on most tone arms

to reduce the lateral tracking angle error) directs this force in such a relation to the pivot point of the tone arm, as to pull the tone arm in toward the

center of the record. This inward force, called skating force, unbalances

the forces on the groove wall. By adding an outward pulling force, called

antiskating force, to the tone arm, this force can be balanced. The stylus

is then able to exert equal force on both groove walls. Since the skating

force is proportional to the tracking force, any increase in the tracking force

will increase the skating force and will require greater antiskating to balance it. At this time, the antiskating force should still be set to the recommended value of the manufacturer.

100% = 10 mV

50%

35%

A

45

RPM

2

of the TTR-103 when all equip-

=

5

mV

=

3.5 mV

RECORD.

Press the "Low/MidM

chan-

TTR-

~mm~~~~~l

Fig. 19

EX$LANATION

Page 9

B. Tracking Force Explanation

The ability of a cartridge to track properly at low tracking force is very de-

sirable; the wear on the record and the stylus is then kept to a minimum.

However, a stylus tracking at a tracking force too light to maintain contact

with the groove wall (mistracking) can cause permanent damage to the recording. Therefore, the proper adjustment of the tracking force is very important in terms of both reducing mistracking distortion and insuring max-

imum stylus and record life.

Any stereo pickup in good condition should be able to track Band 5, Side 2

of th'e TTR-103 or 15

trackability cartridge should be able to track properly on Band

TTR-103 at the median tracking force recommended by the manufacturer.

cm/sec at the median recommended force. A high

7

or 8 of the

VIII. ANTISKATING AND TRACKING FORCE OPTIMIZATION USING

THE

The trackability test on the Shure TTR-103 is divided into three sections: high

frequency, mid-frequency, and low frequency. The high frequency, 10.8 kHz,

pulse tracking test is recorded on both sides of the TTR-103, Bands 1 through

4; the left channel is on Side 1; the right channel is on Side 2. The mid-frequency tracking test is on Side 1, Bands 5 through

1,500 Hz lateral cut tone. The low frequency tracking test is on Side 2, Bands

5

through

frequency tests have four velocities: 15,

quency test has four velocities: 20, 25, 31.5, and 40

TRACKABILITY TEST

8.

The test is a 1,000

8.

This test is a 400 + 4,000 Hz lateral cut tone. The low and high

19,

24, and 30 cm/sec. The mid-fre-

cm/sec.

+

Note:

A. High Frequency Trackability Test

The high frequency test signal consists of a group of high frequency component

signals, centered at 10.8 kHz and recurring in bursts at

signal could be reproduced without any distortion, only these high frequency

component signals would be detected. However, any alteration of this signal

produces a detectable component signal at 270 Hz.

In a phono reproduction system, distortion results from such system

linearities as tracing distortion, tip indentation, vertical tracking angle error,

stylus dynamics, record wear, electronic signal processing and mistracking.

The contributions to distortion from each of these

tract from one another, yielding a total 270 Hz signal which is unique for a given

set of test conditions. Although mistracking is the dominant contributor to distortion, some confusion may result as it is conceivable that one pickup might

have a larger 270 Hz signal while tracking than another pickup has while

tracking.

However, the mistracking contribution to distortion is not only very large, but

also is typically very unstable, and is, therefore, recognizable.

THE TTR-103 IS

(BANDS

(BANDS

Description and Interpretation of

The Test Signal

1,2,3,

1,2,3,

A

45

RPM RECORD.

&

4.

SIDE 1

&

4.

SIDE 2 RIGHT CHANNEL)

LEFT

CHANNEL)

a

rate of 270 Hz. If this

non-

non-linearities add and sub-

mis-

Record warps also cause instability in the 270

Warps increase and decrease the instantaneous tracking force about the set

tracking force, which can cause intermittent mistracking. This type of insta-

bility is a breakup which occurs at a rate related to turntable speed, whereas

mistracking results in a random instability. In the presence of a warp, the

tracking point has been reached when the breakups are occurring, on a par-

ticular band, most of the time.

Hz

signal, but of a different type.

mis-

Page 10

The modulation of tracking force by a warp

permits the operator to see a particular pickup's distortion both tracking and mistracking,

thus eliminating the confusion due to

nonlinearities other than mistracking. It also suggests the means to separate the contribution

to distortion of mistracking from the other

possible causes, without benefit of a warp.

By

checking the pickup at two different tracking forces on the same band, a large change

in distortion at the lower force would indicate

mistracking at the lower force.

A

small change

in distortion may be expected at the two forces

as a result of indentation, irrespective of

mis-

tracking.

Test Procedure

The C-PEK-3 displays the total 270 Hz com-

ponent signal on

theosci~loscope by depress-

ing the "High" button on the test panel. Begin

the test by playing Band

1, Side 1, of the

TTR-103. The test must begin with the pickup

tracking this band, with appropriate consideration of record warp. The display should

resemble Figure 20. The tracking should be

verified by checking the pickup at two track-

ing forces. Changing the force is easily accomplished by placing a weight on the head

shell and then removing it. The weight should

be about

'/2

gram for pickups in the

3/4

to

11/2

gram range, about 1 gram for pickups in the

11/2

to 3 gram range, and

ups in the 3 to

5

gram range. In some cases,

11/2

grams for pick-

the additional weight will increase the tracking

force beyond the recommended range, but,

for all Shure pickups, no damage will result

during the short observation period.

Fig. 20

Note:

Under no circumstances should the

tracking force be set above the recommended range

for

long

term use.

Page 11

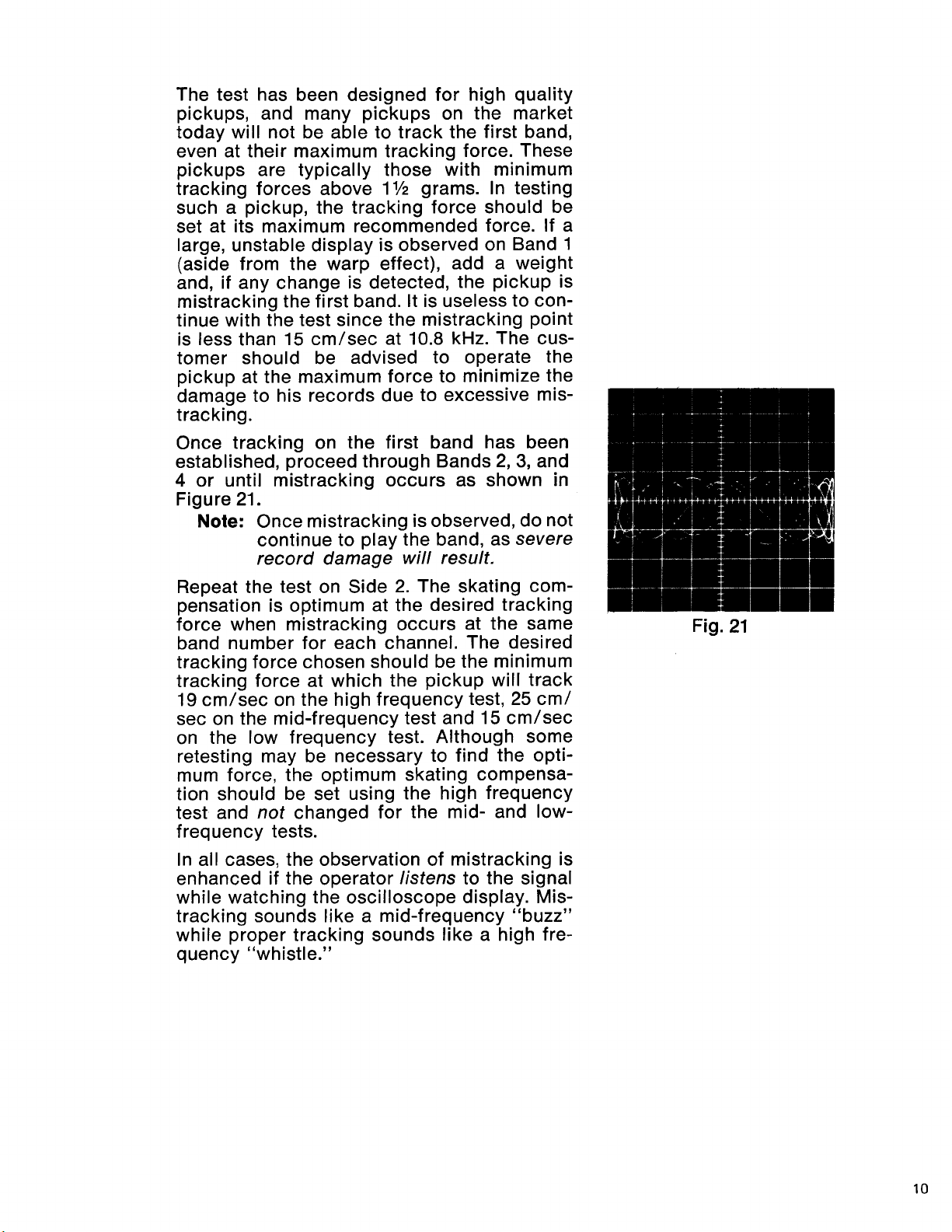

The test has been designed for high quality

pickups, and many pickups on the market

today will not be able to track the first band,

even at their maximum tracking force. These

pickups are typically those with minimum

tracking forces above

such a pickup, the tracking force should be

set at its maximum recommended force. If a

large, unstable display is observed on Band

(aside from the warp effect), add a weight

and, if any change is detected, the pickup is

mistracking the first band. It is useless to continue with the test since the mistracking point

is less than 15

tomer should be advised to operate the

pickup at the maximum force to minimize the

damage to his records due to excessive

tracking.

Once tracking on the first band has been

established, proceed through Bands

4

or until mistracking occurs as shown in

Figure 21.

Note:

Once mistracking is observed, do not

continue to play the band, as severe

record damage will result.

cm/sec at 10.8 kHz. The cus-

11/2 grams. In testing

1

mis-

2,3, and

Repeat the test on Side 2. The skating com-

pensation is optimum at the desired tracking

force when mistracking occurs at the same

band number for each channel. The desired

tracking force chosen should be the minimum

tracking force at which the pickup will track

19

cm/sec on the high frequency test, 25 cm/

sec on the mid-frequency test and 15 cmlsec

on the low frequency test. Although some

retesting may be necessary to find the optimum force, the optimum skating compensa-

tion should be set using the high frequency

test and not changed for the mid- and

frequency tests.

In all cases, the observation of mistracking is

enhanced if the operator listens to the signal

while watching the oscilloscope display. Mistracking sounds like a mid-frequency "buzz"

while proper tracking sounds like a high fre-

quency "whistle."

low-

Fig.

21

Page 12

Mid-Frequency Trackability Test

5,

6,

7,

&

8.

(BANDS

The display for the mid-frequency test is obtained by depressing the

on the test panel. The display will resemble

Figure 22, while the pickup is tracking.

tracking will change the display to resemble

Figure 23.

Low-Frequency Trackability Test

(BANDS 5,

With the

and pickup tracking, the display will resemble

Figure 24. Mistracking will change the display

to resemble Figure 25.

Note:

IX.

CHECKING

TTR-103 AND TTR-109

A log of usage of the TTR-103 and TTR109 should be maintained, since a record

should be used only for a limited period of

time. After about 25 tests, the record

should be checked

known trackability. The TTR-103 should

be compared to another copy of the

103. The TTR-109 is identical on both

sides, so one side should be compared

to the other. In either case, the cartridge

should exhibit the same tracking capabilities, and a similar pattern should be

observed on the oscilloscope for corresponding bands on the new and used

records. When a major difference is

noted, a new TTR-103 should be used, or

the TTR-109 should be turned to the new

side. When substituting a new TTR-103 or

using Side 2 of TTR-109, a new record

should be ordered, so that one new copy

will always be available.

6,

7,

"Low/Mid" button still depressed

The exact display for the low- and

mid-frequency tests will again depend on the particular pickup and

record. Also, in the presence of a

record warp, the operator must judge

when the pickup is mistracking a

band most of the time.

SlDE 1 LATERAL)

"Low/MidM button

&

8.

SlDE 2 LATERAL)

WEAR

OF

THE SHURE

bv using a cartridge of

Mis-

TTR-

22

Fig.

Fig. 23

Fig. 24

Fig. 25

Page 13

ADDENDA

I.

MODEL C/PEK-3/T

The Model C/PEK-3/T consists of a Model C/PEK-3 Stereo Cartridge Analyzer

and a 240 to 120

from a 216 to 264

Vac autotransformer which allows the Analyzer to be operated

Vac, 50-60 Hz, power source.

The autotransformer is supplied with a permanently attached three-conductor

ac power (mains) cord without a connector on the "mains" end. A suitable

connector must be installed by qualified service personnel. To attach a connector, connect the brown conductor of the power cord to the "live" terminal

of the connector, the blue conductor to the "neutral" terminal, and the

green-

yellow conductor to the "earth" terminal.

To operate the Analyzer, plug the

C/PEK-3 power cord into the power receptacle provided on the autotransformer. Connect the power cord from the

autotransformer to the 240

operate as it would if it were directly connected to a 120

120

Vac (80 watts

maximum

Vac (mains) power source. The C/PEK-3 will now

Vac power source and

load)

will be available at the switched power outlet

on the front of the unit.

II. GUARANTEE

This Shure product is guaranteed in normal use to be free from electrical and

mechanical defects for a period of one year from date of purchase. Please

retain proof of purchase date. This guarantee includes all parts and labor.

This guarantee is in lieu of any and all other guarantees or warranties,

express or implied, and there shall be no recovery for any consequential

or incidental damages.

Ill. SHIPPING INSTRUCTIONS

Carefully repack the unit and return it prepaid to:

Shu re Brothers Incorporated

Attention: Service Department

1501 West Shure Drive

Arlington Heights, Illinois 60004

If

outsidethe united States, return the unit to your dealer or Authorized Shure

Service Center for repair. The unit will be returned to you prepaid.

Page 14

222

HARTREY AVE.. EVANSTON. IL.

60204

U.S.A.

AREA CODE

TWX:

910-231-0048

3121866.2200

.

CABLE: SHUREMICRO

TELEX:

72-4381

-

1

IZOYAC

NOTES

:

I.

UL

UP*CllOllS

SHOWN.

ELECTROLmC

L.

ALL RLSISTORS

J

IYL

SWIKYES

"

APvEETd

A.C. VOLTAWLS

'KOlr'S lNPUT,

VOLT-ES

WIM

WWLm-

A.C

VOLTAGE RCADINGS

APP(YlR1412

AND

ME- ZERO

A-C PUDlNGS

MlGM

DCPRSSSED.

CO/Y)*I

IN

MFD

AND

SOY

OR

MORC

SHOWN

IN

OTHLWISE

OR

orF

POSITIMI.

me

SET

ICI~OLRIATLLI~

A.C VOLTAGES IAYKN

A.C

VWMETCR. TD

METER

MPLICIER

BUTTON

MUST

NU

CLOWWlSE.

VnLhL

UNLESS OTdCllWlSt

MLD

i

VOLTS.

~HLMU.

MX

LLCT

OR

RIOllT,

M

URCUIT,

BE

DEPRESED

ALL

MY

OTHER

Y*n

*IS%'

TEST 5UELTOI

WD

DC.

U4CtTm

WA~.

10%

IN

WlTH

INPUT SELECTOR

WITH

IOMR

P-ID

SLULCT-

CONTSOL

TAKEN

WITH

VOLTAOES

UNLESS

mr

OUT

4OOC.L

EDI

TSWUBILlTY

1MV.U.

WVM.

&RE

S~WN

D~%l."h~i~E~-.c5?$Z?~C->Zk'=.GE;L

TALW

WlW

TMU

WNLL

MODEL CIPEK

-

3

STEREO CARTRIDGE ANALYZER

CIRCUIT DIAGRAM

REPLACEMENT PARTS LIST

SHURE PART QTV. IN SHURE PART OTY. IN

ITEM NUMBER RKC KIT DESCRIPTION ITEM NUMBER RKC KIT DESCRIPTION

Dl. D2 RKCZl 4 Diode, Silicon. 100V. R6 46A036 1 Potentiometer, 50k

MCl, MCZ

PL1

0101, 0103,

0105,0107,

0109,0111

0102, 0104.

Q106. Q108,

0110,0112

86A803

RKC45

RKC89

86A348

1/2A (Motorola IN40021

1

Dual Operational Amplifier

(Motorola

or

Signetics N5558V)

1

Pilot Lamp (Leecraft

36N1311-6)

4

Transistor. Silicon, NPN

(Motorola

1

Transistor. Sllicon. PNP

(Motorola

MC1458C-P1

ZN5210)

2N5087)

TI 51AZ53 1 Transformer. Power

-

-

-

-

-

-

95A615

55A110

55A109

55Alll

RKC2

950552

1

Meter Assembly.

instruments 361, A-Scale)

Ac Switch. DPDT

1

(Alco 205N-49)

Push-Button Switch.

1

7-Station

Push-Button Switch, SPDT

1

(Switchcraft 953)

Ac Line Cord with Plug

1

(Eelden 17238)

Ac Receptacle

1

VU

(API

Loading...

Loading...