Page 1

222 HARTREY AVE., EVANSTON.

IL.

60204

U.S.A

DATA

MODEL

~~45

i

@

AREA

CODE~https://manualmachine.com/~~S-~OOO .

CABLE,

SHUREMICRO

SHEET

CONTROLLED MAGNETICB NOISE-CANCELING CITIZENS BAND MICROPHONE

NOISE CANCELLATION

The important characteristics contributing to noise

cancellation and clear speech transmission in the

Model CB45 are shaped frequency response,

tionality, and distance discrimination.

Shaped Frequency Response:

ments are arranged to optimize performance in the

critical voice frequency range of 200 to 5,000 Hz. The

result is the reduction in pickup of sounds outside the

desired frequency range and proper control of those

sounds within the desired range.

Directionality: Through its inherent directional prop-

erties, Model CB45 rejects sounds that do not orig-

inate from the front of the microphone. This reduces

pickup of off-axis sounds extraneous to the user's

voice.

Distance Discrimination:

inates against sounds arriving from a distance in favor

GENERAL

The Shure Model CB45 LONG RANGER CONTROLLED MAGNETIC noise-canceling microphone is

designed especially for use with Citizens Band transceivers, either mobile or base station. The microphone

provides clear, crisp, natural voice response in even

the noisiest surroundings. A small, rugged, hand-held

CONTROLLED MAGNETIC unit, this dual-impedance

microphone can be used to replace ceramic or dynamic microphones supplied as original equipment.

The Model CB45 noise-canceling microphone represents a significant improvement over most microphones with anti-noise features. Noise cancellation

in Model CB45 is provided through the combination of

highly directional operation and superior discrimination against noise from distant sources over an unusually wide frequency range. The CB45 is particularly

suited for mobile use where wind, traffic, or engine

noise may otherwise interfere with voice transmission.

With greater clarity and improved reliability and

durability, Model CB45 also offers easy impedance

selection at the end of the cable. The microphone is

suitable for connection to either high-impedance or

low-impedance (ceramic or dynamic) inputs.

of sounds from a near source. The microphone op-

erates on the pressure gradient principle. Two sound

entry ports spaced a small distance apart produce, by

means of phase cancellation, reduction of sensitivity

to all distant sounds.

OPERATION

In order to obtain the best noise-canceling perform-

ance with Model

CB45, "close-talking" is required.

The lips must be as close as possible to the microphone grille (directly facing the grille and pressed

against the rubber lip guard). For greatest discrimination between voice sounds and background noise, do

not hold the microphone more than 25 mm

the mouth.

No special precautions beyond ordinary care are

necessary in operating the Model CB45 microphone.

It will function very satisfactorily under most conditions of humidity and temperature. Severe mechanical

shocks, such as dropping the microphone, should be

avoided.

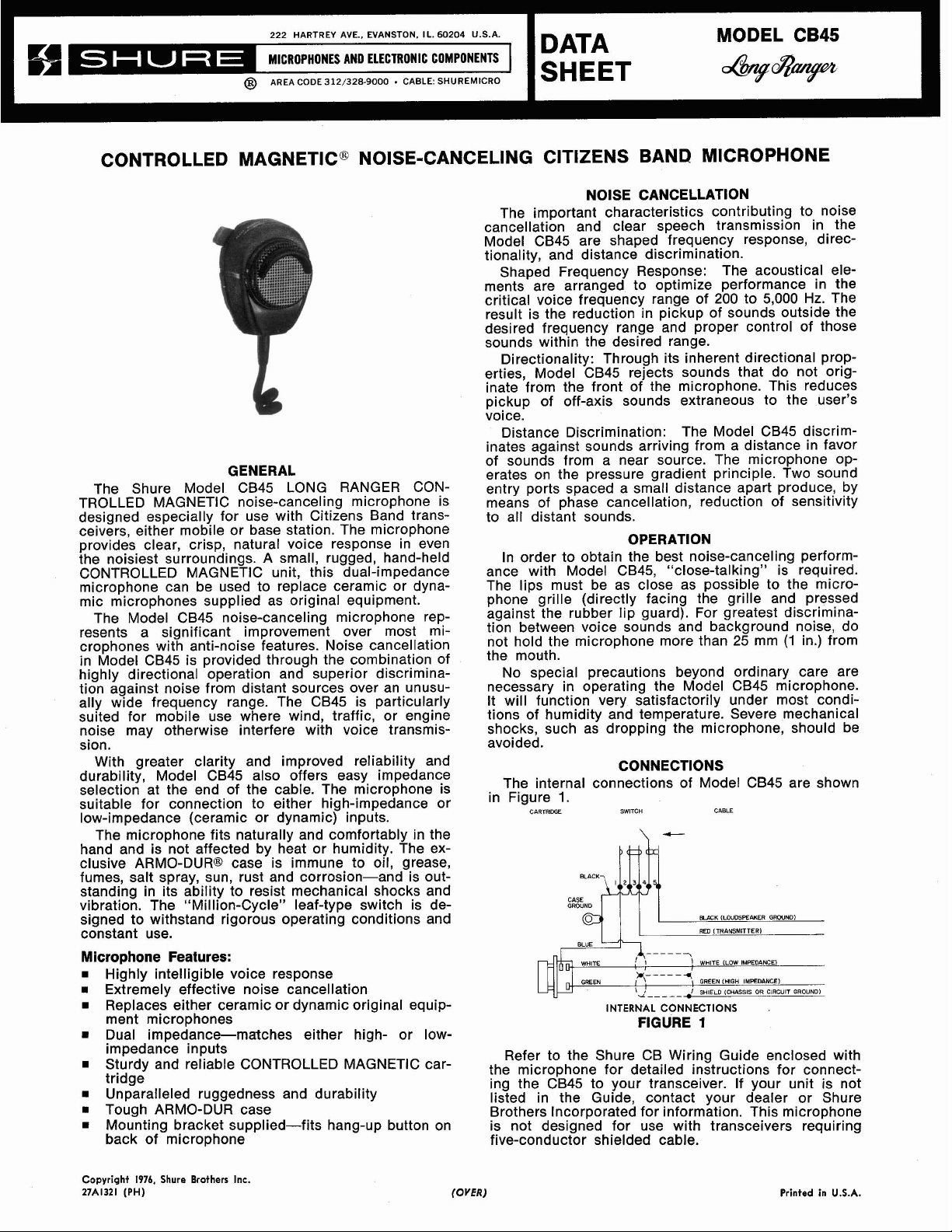

CONNECTIONS

The internal connections of Model CB45 are shown

in Figure

1.

CARTMCGE SWITCH CABLE

The microphone fits naturally and comfortably in the

hand and is not affected by heat or humidity. The exclusive

ARMO-DUR@ case is immune to oil, grease,

fumes, salt spray, sun, rust and corrosion-and is outstanding in its ability to resist mechanical shocks and

vibration. The "Million-Cycle" leaf-type switch is de-

CASE GROUND

signed to withstand rigorous operating conditions and

constant use.

Microphone Features:

Highly intelligible voice response

Extremely effective noise cancellation

&WHITE

GREEN

Replaces either ceramic or dynamic original equipment microphones

=

Dual impedance-matches either high- or lowimpedance inputs

Sturdy

tridge

and

car-

Unparalleled ruggedness and durability

Tough ARMO-DUR case Brothers lncor~orated for information. This micro~hone

~ounting bracket supplied-fits hang-up button on

back of microphone

Refer to the Shure CB Wiring Guide enclosed with

the microphone for detailed instructions for connect-

ing the CB45 to your transceiver. If your unit is not

listed in the Guide, contact your dealer or Shure

is not designed for use with transceivers requiring

five-conductor shielded cable.

------

[-'I

y-----*

I

\,

1

_

:

-----

INTERNAL

FIGURE

CONNECTIONS

The acoustical ele-

The Model CB45 discrim-

(1

in.) from

WK

(LOUDSPEOKER GRWND)

Rm

ITRANSMITTERI

!

WHITE (LOW IMPEDANCE)

\

GREEN (HIGH IMRDANCEI

-1

SHIELD (CHASSIS OR CIRCUIT GROUND)

1

direc-

Copyright

27A1321

1976,

Shure Brothers Inc.

(PHI

(OVER)

Printed

in

U.S.A.

Page 2

The general wiring procedure for transceiver con-

nections is as follows.

Relay or Switching Circuit:

GROUNDED SWITCHING

Most transceivers employ a grounded circuit to

switch from the receive to the transmit position. To

connect the microphone to such a circuit, proceed as

follows.

1. Connect the RED lead to the terminal used to

complete the transmitter circuit.

2. Connect the BLACK lead to the terminal used to

complete the receiver circuit. This will usually be

a ground return from the loudspeaker. If a microphone switching contact is not required for the

loudspeaker ground, insulate (wrap with tape)

the BLACK cable lead.

3. Connect the shield to chassis or circuit ground

of the transceiver (see Guide)

ISOLATED SWITCHING

In some transceivers, an isolated circuit is required

to switch power supply voltages rather than grounds.

If an isolated switching circuit is required, proceed as

follows.

1. Remove the three No. 4-40 pan head screws from

the back of the microphone case; separate the

case front and back. CAUTION: Microphone case

is spring-loaded; care must be taken to hold the

two halves of the microphone case together while

removing screws.

2. Clip and remove the bare lead connecting switch

terminals 2 and

4

(see Figure 1).

3. Unsolder the BLACK cable lead from switch ter-

minal 5; solder the BLACK cable lead to switch

terminal

4.

4. Locate springs in cutouts of cartridge shield and

take care not to pinch leads when closing case.

Fasten the two case halves together with the

previously removed screws.

5. At the end of the cable, connect the RED lead

to the isolated switch contact terminal used to

complete the transmitter circuit.

6. Connect the BLACK lead to the other isolated

switch contact terminal used for power supply

voltage.

7.

Connect the shield to chassis or circuit ground

(see Guide).

CAUTION

Make certain that the shield is not connected to

chassis ground for those models where the Guide

specifies the shield should be connected to circuit

ground.

Microphone Audio Input Circuit:

LOW IMPEDANCE

Connect the WHITE cable lead to the low-impedance

microphone audio input terminal. Insulate (wrap with

tape) the GREEN lead.

HIGH IMPEDANCE (ceramic microphone replace-

ment)

Connect the GREEN cable lead to the

high-impedance microphone audio input terminal. Insulate (wrap

with tape) the WHITE lead.

NOTE

The high-impedance connection will generally be

used when replacing a ceramic microphone supplied

with original equipment. If you do not know whether

your transceiver requires a high-impedance or a

low-

impedance microphone, follow the wiring instructions

for the low-impedance connection. Check whether

there is sufficient output from your transceiver. If the

modulation output is too low, reconnect the micro-

phone for high impedance.

SPECIFICATIONS

TY pe

CONTROLLED MAGNETIC@, Noise-Canceling

Frequency Response

Optimized response in the critical 200 to 5,000 Hz

range

lmpedance

Dual. Microphone rating impedance is 150 ohms

(190 ohms actual) and "High". For impedance selection, see section on Connections.

Load lmpedance Range

Low lmpedance

High lmpedance

Output Level

Open Circuit Voltage*

Power Level**

*O dB = 1 volt per 100 microbars

**0 dB

=

Switch

Push-to-talk leaf-type switch to actuate microphone

circuit and an external relay or switching circuit.

Microphone circuit normally open in either high- or

low impedance.

Cable

1.5m (5 ft) four-conductor, two conductors individually shielded, coiled cable

Case

Light gray ARMO-DUR@

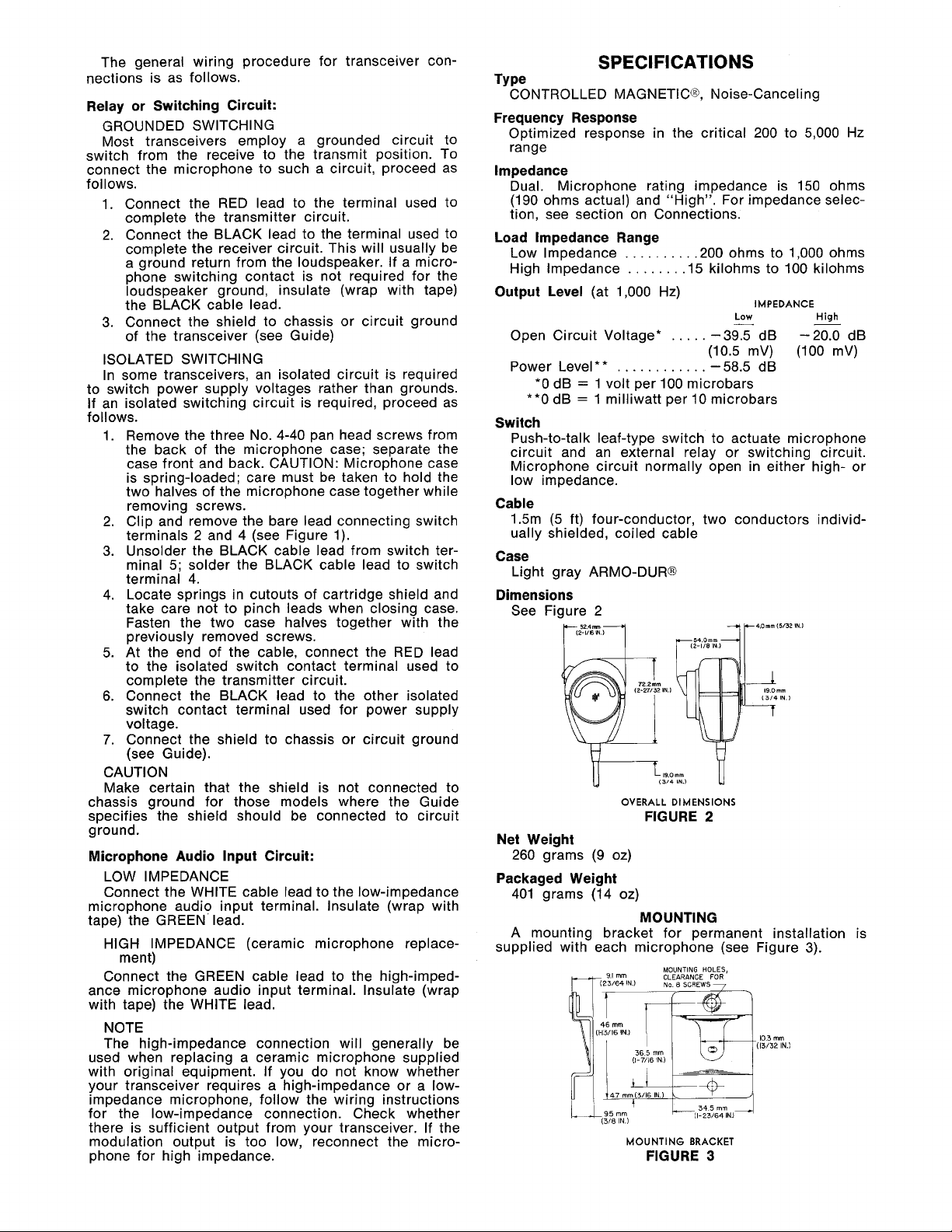

Dimensions

See Figure 2

Net Weight

260 grams

Packaged Weight

401 grams (14 oz)

A

mounting bracket for permanent installation is

supplied with each microphone (see Figure 3).

m2%6"4"lN

. . . .

. . . . .

.

. . . . . .

(at 1,000

.

.

. .

,200 ohms to 1,000 ohms

.15 kilohms to 100 kilohms

Hz)

. . .

.

. . . . . . . .

.

IMPEDANCE

Low

-

-39.5 dB

(10.5

mV) (100 mV)

-58.5 dB

1 milliwatt per 10 microbars

4.0nm

OVERALL

DIMENSIONS

FIGURE 2

(9

oz)

MOUNTING

MOUNTING HOLES,

CLEARANCE FOR

I

No.

8

SCREWS

7

MOUNTING

BRACKET

FIGURE

3

-20.0 dB

(5/32

IN.]

High

-

Page 3

FURNISHED ACCESSORY

Mounting Bracket RK6MB

Cartridge .90C1756

Switch Assembly .90F1008

Switch Button .65A240A

Cable

Case Front 90D1084

Case Back

..............................

...................................

..............................

.........................

REPLACEMENT PARTS

........................

..........................

70A4137

..............................

90M1047

FULL ONE YEAR WARRANTY

Shure Brothers Incorporated ("Shure"), 222 Hartrey

Avenue, Evanston, Illinois 60204, warrants to the owner

of this product that it will be free, in

any defects in workmanship and materials for a period

of one year from date of purchase. You should retain

proof of date of purchase. Shure is not liable for any

consequential damages. If this Shure product has any

defects as described above, carefully repack the unit

and return it prepaid to the above address. If you are

not in the United States, return the unit to your dealer

or authorized Service Center for repair. The unit will

be repaired or replaced and returned to you promptly,

and if it cannot be repaired or replaced, you may elect

to receive

a

refund.

normal use, of

Loading...

Loading...