Page 1

Microflex)C123 Replacement Kit

User Guide

Disassembly

1. Remove screw in top of the grille, then lift off the grille.

2. Remove screw in bottom of base while holding the microphone

interface in place. Remove the microphone interface.

3. Remove the microphone cartridge and gently screw it into the

new microphone interface.

Attaching the Cable to the Microphone

1. Route the stripped and tinned end of the new cable through the

rear exit hole in the base as shown in Figure 1A. Leave about

six centimeters (2 1/2 inches) of cable between the microphone interface and the strain relief posts.

NOTE: Alternately , for certain t ypes of permanent or “hidden cable”

installations, you may want to run the cable through the exit hole

in the bottom of the base.

2. Seat the microphone interface on the locating stud in the center of the base. Hold the microphone interface in place as you

turn the base over. Insert the screw through the base and

thread it into the microphone interface. Tighten firmly.

3. Route the cable between the posts as shown in Figure 1B. A

visual aid for the path is visible on the die casting between the

posts. Press the cable firmly down between the posts.

4. Gently manipulate the excess cable between the microphone

interface and the base to form a service loop and lay it to the

side of the microphone interface as shown in Figure 1B.

5. Set the grille back into place on the die casting. Thread the

screw through the perforated metal grille and into the microphone interface and tighten.

6 cm (2.5 in. )

Strain Relief

Microphone

Interface

Locating

Stud

Posts

A

Connector Assembly and Attachment

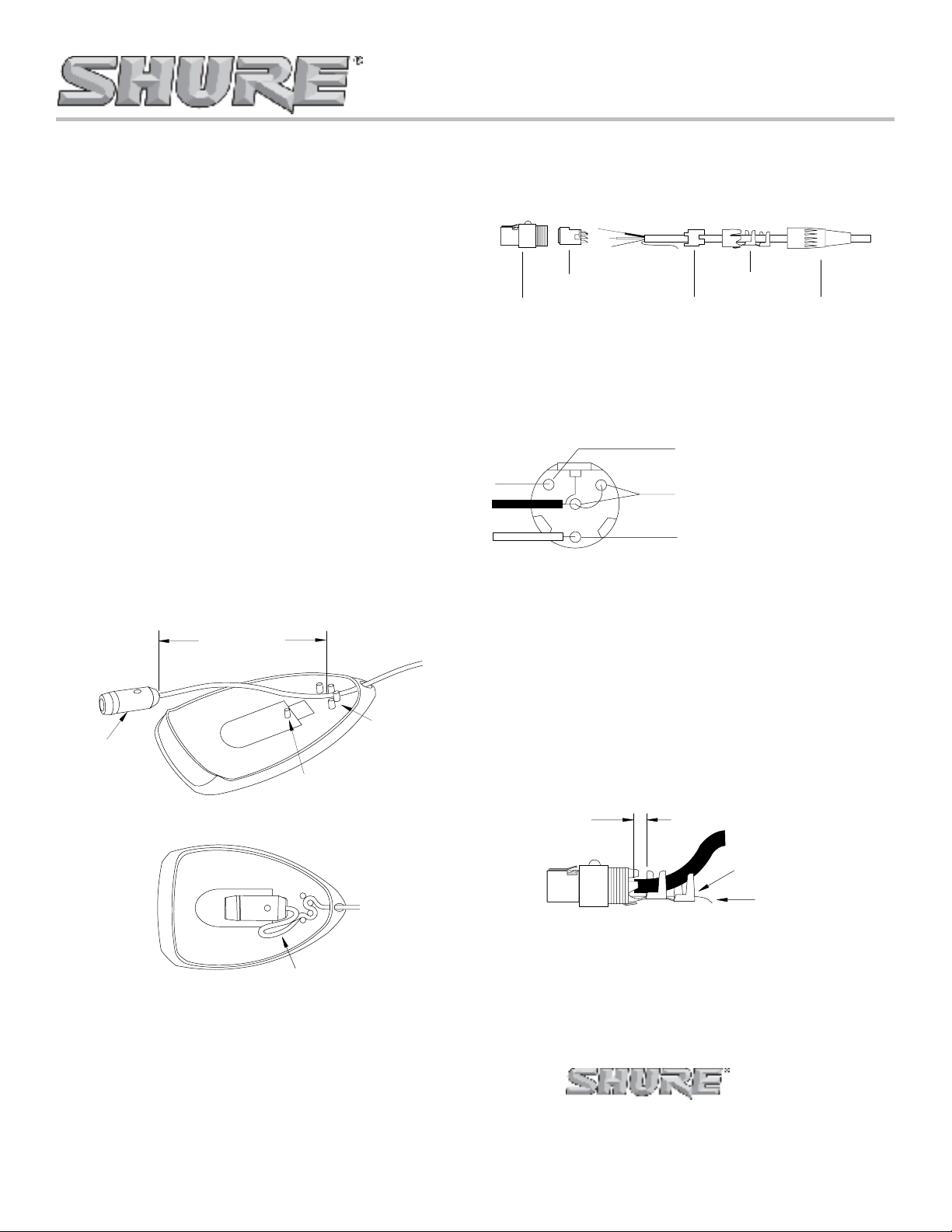

1. Run the cable through the end cap, cable clamp, and insulation

spacer.

Housing

Insert Assembly

Insulation Spacer

Cable Clamp

End Cap

CONNECTOR ASSEMBLY

FIGURE 2

2. Attach wires and ONE of the two shield leads to the insert assembly and solder into place. See the wiring diagram in

Figure 3.

PIN 1 = SHIELD (use only ONE of

3

1

4

2

the shields)

PINS 3 and 4 = BLACK LEAD

(jumped)

PIN 2 = RED LEAD

WIRING DIAGRAM

FIGURE 3

3. Fold the remaining loose shield lead back. Push the circular

end of the cable clamp onto the insulating spacer and slide

them over the loose shield lead until the insert assembly has

been properly mated with the insulating spacer. Slide these interlocking components into the housing (only the cable clamp

and loose shield lead should be exposed).

4. Solder the shield lead onto the interior floor of the cable clamp

(see Figure 4).

IMPORT ANT: Make sure that there is at least 2 mm (1/16 in.) from

the end of the cable jacket to the crim ping fingers on the cable

clamp.

2 mm (1/16 in.)

of insulation before

clamp finger

Solder to cable clamp floor

ROUTING THE CABLE

2001, Shure Incorporated

27B2998 (AK)

Service Loop

FIGURE 1

Shield

B

SOLDERING THE SHIELD TO CABLE CLAMP

FIGURE 4

5. Crimp cable clamp fingers around cable jacket and shield.

Slide the end cap over the cable clamp and thread onto the

housing until snug.

SHURE Incorporated Web Address: http://www.shure.com

222 Hartrey Avenue, Evanston, IL 60202–3696, U.S.A.

Phone: 847-866–2200 Fax: 847-866-2279

In Europe, Phone: 49-7131-72140 Fax: 49-7131-721414

In Asia, Phone: 852-2893-4290 Fax: 852-2893-4055

Elsewhere, Phone: 847-866–2200 Fax: 847-866-2585

Printed in Mexico

1

Loading...

Loading...