Page 1

Model 1200 Powermixer

Price $7.50

SERVICE MANUAL

ISSUE NO. 1

Manufactured by

SHURE BROTHERS INC.

222 Hartrey Avenue

Evanston, Illinois 60202-3696

Copyright 1988, Shure Brothers Inc.

AL954 (HE) 27A8187

Printed in U.S.A.

Page 2

SPECIFICATIONS

Type

Mono Powermixer

Frequency Response

Flat +1, -3 dB, 40 Hz to 20 kHz (any input to any output)

Inputs

Six input channels: six unbalanced high- and/or balanced low-impedance inputs; channels 1 and 2 highimpedance inputs switchable to Aux level; available

expansion modules* each contain 2 high- and 2 lowimpedance microphone inputs; two modules (4 channels) can be added to each 1200

Power Output (1 kHz, 120 Vac, 1% THD)

200 watts minimum with 4 ohm speaker

120 watts minimum with 8 ohm speaker

Distortion

THD typically less than 0.15% at 1 kHz, 0.35% at 70 Hz

and 20 kHz (180 watts to 4 ohms, measured from low-

impedance input, Input Attenuation, individual channel

and Master Volume controls at typical user settings)

IM distortion typically less than 0.4% (116 watts to 4

ohms, Input Attenuation, individual channel and Master

Volume controls at typical user settings)

Low- and High-Frequency Equalization (Individual channel

and Monitor)

±10 dB at 100 Hz and 10 kHz

Input OVERLOAD Indicators

Illuminate 3 dB before clipping of input preamplifier or

equalizer stage

Power Amp Limiter

Threshold: 1.5 dB below speaker output clipping level

Input signal range: 15 dB beyond limiting threshold

Output PEAK/LIMIT Indicator

With Limiter Out: Lights 2 dB before clipping at speaker

outputs

With Limiter In: Lights 0.5 dB before onset of Limiter

action

Output NORMAL Indicator

Lights when speaker output level is greater than 1.4

Vrms (0.5 W into 4 ohms)

Input Sensitivity (full power output)

BAL LO Z: -66 dBV (0.5 mV)

HI Z: -44 dBV (6.3 mV)

AUX: -26 dBV (50 mV)

PA INPUT: 0 dBV (1.0 V)

Input Clipping Level

INPUT

CLIPPING LEVEL

ATTENUATION

BAL LO Z -33 to -3 dBV 0 to -30

(22 to 707 mV)

HI Z

-11 to +18 dBV 0 to -30

(281 mV to 8.41 V)

AUX +6 to +36 dBV 0 to -30

PA INPUT -1 dBV

2 to 63 V

--

(891 mV)

Voltage Gain (at 1 kHz)

INPUT OUTPUT

SPEAKERPGM MIXMONITORPHONES

LO Z

HI Z 73 dB

95 dB 65 dB

43 dB 49 dB

AUX 55 dB 25 dB

PA

29 dB - - 16 dB -

71 dB

31 dB

82 dB51 dB

60 dB29 dB

42 dB11 dB

TAPE

Output Clipping Level

OUTPUT

SPEAKER

MONITOR

PROGRAM MIX

PHONES

TAPE

MINIMUM CLIPPING LEVEL

+29 dBV (28 V)

+18 dBV (7.9 V)

+18 dBV (7.9 V)

+16 dBV (6.3 V)

+18 dBV (7.9 V)

Impedance

INPUTS

LO Z MIC

HI Z MIC

AUX

PA

ACTUAL

1 kΩ

130 kΩ

50 kΩ

50 kΩ

FOR USE WITH

75 to 600 Ω

100 kΩ or less

10 kΩ or less

10 kΩ or less

OUTPUTS

MONITOR

PROGRAM MIX

TAPE

PHONES

SPEAKER

2.4 kΩ 2 kΩ or more

2.4 kΩ 2 kΩ or more

2.4 kΩ

430 Ω 4 Ω or more

-

2 kΩ or more

4 Ω or more

Hum and Noise

Less than -126 dBV equivalent input hum and noise

(20 Hz to 20 kHz, LO Z input to SPEAKER output)

Noise

Less than -127 dBV equivalent input noise (300 Hz to

20 kHz, LO Z input to SPEAKER output)

Signal-to-Noise Ratio

Greater than 80 dB (below full output) at typical control

settings

Phantom Power

24 Vdc ± 10% open circuit, 1.8 k series resistance

Power Requirements

120 Vac ± 10%, 50/60 Hz, 420 watts typical with no ac

receptacle load

AC Convenience Receptacle

120 Vac, 100 watts maximum

Certifications

Listed by Underwriters Laboratories Inc. and by

Canadian Standards Association as certified

Environmental Conditions

Operating Temperature: -7 to 43°C (20 to 110°F)

Storage Temperature: -40 to 74°C (-40 to 165°F)

Relative Humidity (Operating and Storage): 0 to 95%

Overall Dimensions

191 mm H x 483 mm W x 343 mm D (7-½ x 19 x 13-½ in.)

Weight

12.3 kg (27 lb)

18.2 kg (40 lb) in A1200C Carrying Case

RECOMMENDED LOUDSPEAKERS

AUDIOMASTER Model 3200, 100 W, 8 Ω, vented two-way

speakers

OPTIONAL ACCESSORIES

Carrying Case. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1200C

Input Expansion Module*

(2 channels, 2 each HI Z and LO Z inputs). . A1200MX

Speaker Cable, 15 m (50 ft) with phone plugs

Line Matching Transformer (LO Z to HI Z)

. . . . . .

. . . . . . . . .

A50SC

A95UF

240-V Conversion Kit* . . . . . . . . . . . . . . . . . . . . . . . . RKC209

Phono Preamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M64A

*For installation by qualified service personnel only.

Page 3

MODEL 1200 SERVICE MANUAL

TABLE OF CONTENTS

Description

For Years of Dependable Service

Troubleshooting ..................................

Service Instructions

External Parts

Diagnosis .....................................

External Fuse Replacement

Service Access

General Service Procedure

AC Voltage Measurements

DC Voltage Measurements

Resistance Measurements

Chassis-Mounted Boards and Components

A1 Reverb Pan

SHR-11 (and SHR12) Power Amplifier

SHR-12 Temperature Sensor Board

SHR-14 Main Board

Rear-Panel Boards and Components

SHR-10 Input-Output Board

SHR-03 Aux/Mic Board

SHR-02 Hi-Z Input Board

SHR-01 Lo-Z Input Board.......................

SHR-13 Speaker Output Board

B1 Fan

S3 Phantom Power Switch

Front-Panel Boards and Components

SHR-04 Channel Board (6)......................

Front Mounting Panel

SHR-05 Master Control Board

SHR-09 Limiter Board

SHR-06 Headphones Output Board and

SHR-08 Indicators Board

S2 On/Off Switch

A1200MX Input Expansion Module

Checking Active Components

Ferrite Beads

Service Illustrations

Optional Accessories

.....................................

....................

...............................

..................................

.......................

.................................

...............................

Board Assembly

SHR-11 Potentiometer Adjust

VR1101 Output Voltage Offset

VR1102 Driver Balance

VR1103 Idle Current

VR1201 Temperature Sensor Threshold

VR1401 Power Amplifier Limiter Threshold

......................................

SHR-07 Headphones Control Board

..................................

.......................

........................

........................

........................

.............................

..................

................

.....................

.......................

...............

...........................

...............

.....................

........................

.......................

..................

......................

...............

..........................

...................

.........................

.............

.......................

.............................

.................

.....................

.............................

............................

..........

..........

........

1

2

2

3

3

3

3

3

4

5

5

5

5

5

5

5

6

6

6

6

6

6

7

7

7

7

7

7

7

7

8

8

8

8

8

8

8

8

8

9

9

9

9

9

Page 4

Page 5

DESCRIPTION

The Shure Model 1200 AUDIOMASTER® Powermixer is a

compact, flexible microphone mixer with six inputs for high- or

low-impedance sources and a 200-watt power amplifier. The

1200 is human-engineered for ease of setup and operation.

Connection of microphones, speakers and other equipment

(tape recorder, equalizer, effects device, remote amp, etc.) is

fast and convenient.

The 1200 is rack-mountable or portable. Its 6 inputs are

expandable to 8 or 10 inputs through the use of A1200MX

Expansion Kits. Inputs accept both high- and low-impedance

microphones (dynamic, ribbon or condenser), as well as ampli-

fied instruments or other high-level sources. Individual channel

input attenuators with overload indicators permit precise gain

control to prevent input overload. The 1200 has built-in rever-

beration with individual channel and overall level adjustments.

Other effects devices or an equalizer can be connected through

a post-master control program loop. An integral power amp

limiter prevents overload distortion over a wide signal input

range. Pre-volume monitor send controls and pre-master volume tape output provide maximum versatility in stage or recording applications. The control panel has color-coded knobs for

ease of adjustments, while LED indicators give instant notice of

operating status.

In addition to the A1200MX Expansion Module, the following

accessories are available for the 1200: A1200C Carrying Case,

A95UF Line Matching Transformer, RKC209 240 V Conversion

Kit, and M64A Phono Preamplifier.

The 1200 is Listed by Underwriters Laboratories, Inc., and

listed by Canadian Standards Association as certified.

1

Page 6

FOR YEARS OF DEPENDABLE OPERATION...

The AUDIOMASTER® System is exceptionally well designed,

with all components of the highest quality, operating well within

their respective ratings to assure long life. The following list of

Do’s and Don’ts describes minimal operating precautions and

maintenance to provide years of dependable service.

DO

use a 16 AWG or larger, heavy-duty, 3-conductor extension

cord when additional line cord length is needed.

DON’T replace the rear-panel fuse with a different size or type.

Use only 5 A, 250 V, Type 3AG.

DON’T operate the Powermixer with its air vents blocked; don’t

place it on a radiator or heat-producing equipment. Avoid operation in direct, hot sunlight.

DO unplug the Powermixer before cleaning. Use only mild

detergent and a damp (never wet) cloth to clean the outer

SYMPTOM

Powermixer is “dead” (no output, POWER LED off)

OVERLOAD LED illuminates, either

A.

Flickering with program material, indicating abnormal

speaker load

B.

Continuously to indicate power amplifier shutdown

No signal at speaker (all other functions appear normal), either

A. NORMAL LED illuminated, or

B. NORMAL LED not illuminated

Fuse blown

One of two inputs on same channel not working properly (both

1/4-inch and 3-pin jacks in use)

surfaces; Don’t use strong solvents or cleaning fluids.

DON't use unbalanced low-impedance microphones with the

PHANTOM 24V switch on; turn off the switch if not required for

powering condenser microphones. If phantom power is in use,

connect unbalanced low-impedance microphones through a

line matching transformer (Shure A95UF) to a HI Z input. Phantom power will not affect balanced low-impedance dynamic

microphones.

DON’T risk fire or shock hazard by operating the Model 1200

in the rain.

TROUBLESHOOTlNG

Should any difficulty be encountered in operation of your AUDIOMASTER System, the trouble can often be traced to some

simple source. The following is offered as a basic guide to

solving this kind of problem.

PROBABLE CAUSE AND CORRECTION

1.

Check that ac power source is “live” and Model 1200 is

plugged in.

2. Check that POWER switch is on.

3.

Check that rear panel fuse (5 A, 250 V) is good.

4.

If the 1200 has turned off due to excessive internal temperatures, allow at least an hour for cooling, and reactivate unit.

If difficulty persists, refer to General Service Procedure in

this manual.

1.

Check total speaker load (must be no lower than 4 ohms)

and for possible shorted speaker cable.

1.

Check air vents for blockage.

2.

Check that internal fan is operating (fan located on rear

panel).

3.

Turn MASTER volume control down for several minutes to

allow proper cooling. If difficulty persists, refer to General

Service Procedure.

1.

Check for defective or improperly connected speaker cables.

1. Check settings of channel VOLUME and MASTER VOLUME

controls.

2. Check connections to EXTERNAL DEVICE LOOP

1. Replace with identical fuse (5 A, 250 V, 3AG).

2.

If second fuse blows, refer to General Service Procedure.

1.

Make sure similar microphones are used on both inputs,

and microphone impedances match the inputs used.

2.

Make sure a low-impedance microphone is not used with

aux level equipment on other input.

3.

Make sure MIC/AUX switch is in MIC position (Ch. 1 and 2

only).

4.

Make sure microphone switches are on; check microphone

cables.

2

Page 7

SYMPTOM

INPUT OVERLOAD LED flashing

NOTE: Occasional flashing is acceptable

Loud clicks when certain microphones or cables are used

No MONITOR output (program output normal)

Sound quality poor (weak or thin)

SERVICE INSTRUCTIONS

PROBABLE CAUSE AND CORRECTION

1.

Adjust INPUT ATTENUATION counterclockwise to reduce

channel input level.

2.

Reduce input signal level at source.

1. Make sure PHANTOM 24V switch is not on (when not needed).

2. Make sure unbalanced low-impedance microphone or cable

is not used when PHANTOM switch is on.

3.

Check for defective microphone cables.

1.

Make sure channel MONITOR and MONITOR MASTER

controls are turned up.

2.

Make sure controls on external equipment connected to

Monitor output jack are turned up.

3.

Check for defective cable from MONITOR output jack.

1.

Check for excessive treble boost or bass cut on equalization

controls.

2.

Check PROGRAM and MONITOR output jacks for signal

quality (if acceptable, problem is in power amplifier section).

3.

Check for defective cables.

4.

Check impedance match (high- or low-impedance mics)

at input.

EXTERNAL PARTS

The knobs and feet can be replaced without disassembling

the 1200. All knobs are of the pull-off type, and are color-coded

by function. The Equalization knobs are dual concentric types;

all other knobs are single.

DIAGNOSIS

A simple method of localizing problems without opening the

1200 is as follows. Turn off the Power switch. Do not connect a

speaker or headphone load. Set all controls of the channel

under test only to full clockwise (other channel volume and

monitor controls full counterclockwise), except: Reverb Return

full counterclockwise, and Eq controls centered. Turn the unit

on and apply a 0.5 mV, 1 kHz test signal across pins 2 and 3 of

one of the Bal Lo Z input connectors. Normal voltmeter readings

taken at each output connector are given in Table 1. Similarly, a

5 mV signal inserted in a HI Z input, 50 mV in an AUX input, or

891 mV in the Power Amp and Monitor Inputs will yield similar

output voltages. This method is useful for saving time in localizing problem areas. Internal servicing should be performed only

by qualified service personnel.

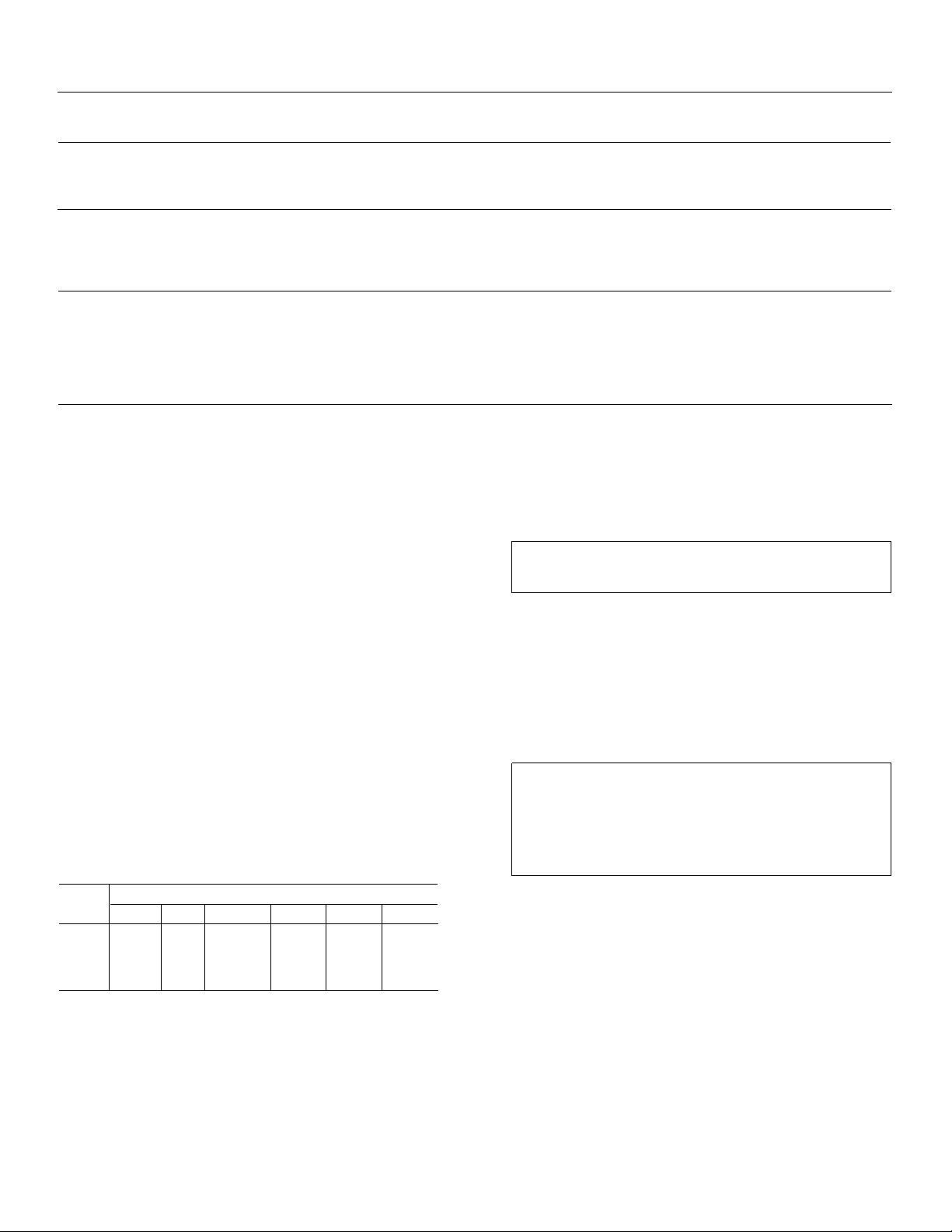

TABLE 1. NOMINAL TEST VOLTAGES

OUTPUTS

INPUT

LO z 0.5 mV 28 V

HI Z

AUX

PA

Input

50 mV

891 mV 25 V

Spkr Prgm Mix

890 mV

5 mV 22 V 708 mV

28 V 890 mV 1.78 V 6.31 V

Mon Phones

1.78 V

1.41 V

--- ---

Tape

6.31 V

5.01 V 141 mV

5.62 V

178 mV

178 mV

---

WARNING

Voltages in this equipment are hazardous to life. Refer

servicing to qualified service personnel.

EXTERNAL FUSE REPLACEMENT

To replace line fuse F1 (with no apparent problems in the

Powermixer), disconnect the line cord from the ac source and

remove the rear panel fuseholder cap by pushing it in and

turning it counterclockwise (either a screwdriver or fingertip

may be used.) Replace the defective fuse only with a 5A 250V

Normal Blow type.

CAUTION

If trouble symptoms (overheating, erratic operation, etc.)

were apparent before the fuse blew, or if the replacement

fuse blows, a qualified service person should trouble-

shoot the Powermixer carefully to find the source of the

problem. Do not continue to replace fuses; have the

trouble corrected.

SERVICE ACCESS

Disconnect the 1200 from its power source. To open the unit

for servicing, remove ten screws and lockwashers from the top

and five from each side of the cover. The cover can then be

lifted off exposing the internal parts (see Figure 1).

3

Page 8

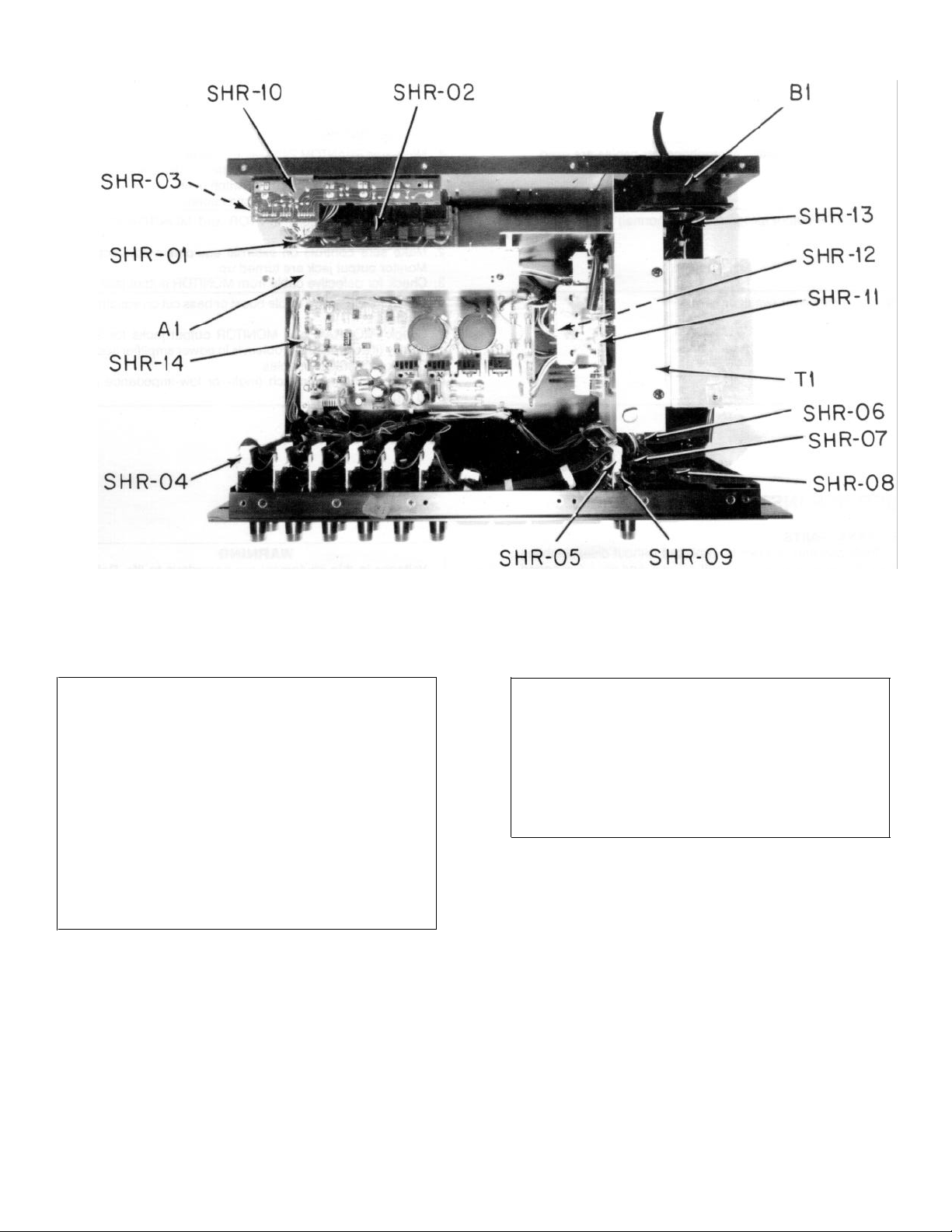

PRINTED CIRCUIT BOARD AND PARTS LOCATION

FIGURE 1

After replacing high-voltage parts such as the fan, power

WARNING

cord, rear panel convenience receptacle, or printed wiring assemblies SHR-11, SHR-12, or SHR-14 (or their

components), make certain that a dielectric voltage

breakdown test is performed before connecting the unit

to a power supply. With the unit disconnected from the ac

source, turn the unit on and measure the resistance

between the ground contact of the power plug and each

of the other two prongs. This resistance should measure

infinite. Then measure the resistance between the plug

ground and exposed metal parts of the chassis, screws,

connectors, fan grille, etc. This resistance should be zero

ohms. If any measurements are recorded outside the

specified limits, a shock hazard exists. The unit must be

repaired and rechecked before it is returned to operation.

IMPORTANT: When removing any printed wiring board, be sure

the wires and connectors detached from the board are identified

for proper reconnection. This may be done by affixing a piece

of masking tape marked with the reference designation

(connectors) or terminal letter or color (wires).

NOTE: Any cable ties that were loosened or removed must be

tightened or replaced after servicing.

Similar wire colors and connectors with the same number

CAUTION

of pins are used in different circuits; make sure proper

reconnections are made. Push-on connectors must be

removed by pulling straight out. The side of a small screwdriver blade inserted between the free and fixed connector

can sometimes be helpful in separating the connector.

Do not apply side force when removing or reconnecting

terminals, or damage may result. Reference to the service

illustrations will be helpful in case of difficulty.

GENERAL SERVICE PROCEDURE

To isolate a problem area, a general procedure is as follows. If

the Powermixer is completely dead, check the ac power source,

line cord, and fuses (external and internal). If the unit turns on

but operation is abnormal, check the chassis power supply

output (-56 Vdc between test point SHR-11-AB and ground,

and +56 Vdc between test point SHR-11-AA and ground; -15

Vdc across C1421, +15 Vdc across C1420, and +24 Vdc

between P1404-A and ground). If the measured dc voltages are

correct, perform additional AC and DC Voltage Measurements

as described below to isolate the problem.

4

Page 9

AC VOLTAGE MEASUREMENTS

Numbers within rectangular symbols on the circuit diagrams

denote ac voltages at that point under the following test

conditions:

1.

Voltages measured with respect to chassis unless otherwise indicated.

2. Line voltage: 120 V, 60 Hz.

3.

Test signal of 0.5 mV across pins 2 and 3 of connector

J101.

4. AC voltage measurements may vary ±20% from values

shown.

5.

Measurements made with ac voltmeter of 1 megohm or

greater input impedance.

6.

No load on Speaker Outputs.

7.

All controls (of channel under test only) full clockwise

except Equalization controls centered.

8. Reverb Return full counterclockwise.

9. Limiter switch and Phantom switch in Off position.

10.

Monitor Master control clockwise.

DC VOLTAGE MEASUREMENTS

Numbers within elliptical symbols on the circuit diagrams

denote dc voltages at that point under the following test

conditions:

1.

Voltages measured with respect to chassis unless other-

wise indicated.

2. Line voltage: 120 V, 60 Hz.

3.

No input signal applied.

4.

Dc voltage measurements may vary ±20% from values

shown.

5.

Measurements made with dc voltmeter of 11 megohms or

greater input impedance.

6.

Phantom switch in On position.

RESISTANCE MEASUREMENTS

With the ac line cord disconnected from the ac source and

the Power On/Off switch off, the following ohmmeter measure-

ments may be made.

1.

Reverb pan output coil: approximately 360 ohms; input

coils approximately 40 ohms.

2.

Transformers may be checked for continuity of each winding.

3. To test transistors, ICs and diodes, refer to the section on

CHECKING ACTIVE COMPONENTS.

To replace the reverb pan, connect the white lead connector

to the reverb Input and the orange lead connector to the reverb

Output. Use the previously removed screws to secure the reverb

pan to the reverb shield, and to secure the shield to the chassis

bottom and the parallel vertical interior shield. Be sure to replace

any cable ties that were removed or loosened.

SHR-11 AND SHR-12 POWER AMP BOARD ASSEMBLY

The Power Amplifier Board Assembly consists of SHR-11

and SHR-12 mounted on the large aluminum heat sink. To

separate the heat sink and its associated boards from the 1200,

remove the screws holding the sink to the power transformer

shield bracket, and those holding the sink to the metal shield

that divides the fan from the input and output connectors and

boards. Disconnect the connectors from P1101, P1102 and

P1201, and unsolder the red, green, and white leads from AA,

AB and AC, respectively, on SHR-11. (The opposite ends of

leads AA and AB are connected to SHR-14, Main Board; the

opposite end of lead AC is connected to SHR-13, Speaker

Output Board.) The Power Amp Board is now free of the 1200.

To replace parts on SHR-11, it is then necessary to remove

SHR-11 from the large heat sink. Do this by removing the four

Phillips screws holding the power transistors at the corners of

the board, and the two Phillips screws holding the board on the

brass standoffs.

NOTES:

1.

Removal of SHR-11 from the heat sink may damage the

insulators below the power transistors. Therefore, when

servicing SHR-11, be prepared to replace all four 802639FK

insulators. If either predriver transistor Q1103 or Q1104

(mounted on the vertical heat sink fastened to SHR-11)

is replaced, be prepared to replace insulator 802681FK

beneath it.

2.

If transistor Q1105, mounted on the solder side of board

SHR-11, is replaced or if the board has been removed from

the heat sink, make certain that Q1105 physically contacts

the large heat sink after reassembly of the board to the heat

sink is completed. Apply a small amount of Wakefield Type

120 Thermal Joint Compound to the top surface of the

transistor in order to ensure proper heat transfer.

CHASSIS-MOUNTED BOARDS AND COMPONENTS

The following printed wiring boards and components are

chassis-mounted.

SHR-11

SHR-12

SHR-14

A1

T1

POWER BOARD

SENSOR BOARD

MAIN BOARD

REVERB PAN

POWER TRANSFORMER

REVERB PAN

To remove the reverb pan assembly, turn the 1200 on its side

(power transformer down) and remove the three screws holding

the reverb shield to the chassis bottom. Turn the 1200 upright

and remove the screw holding the reverb shield to the standoff

attached to the parallel vertical interior shield. Disconnect the

phono connectors at the bottom of the reverb pan assembly.

Remove the four screws holding the reverb pan to the vertical

metal interior shield, and lift the reverb shield and pan assembly

out of the chassis holding the pan to the shield. (If necessary to

free the reverb shield, remove the cable tie(s) holding the

orange and white leads to the metal shield.)

To replace SHR-11 in the 1200, solder the red, green and

white leads to AA, AB and AC. Connect the cable assembly with

three leads from P1405, SHR-14, to P1101 ; and connect the

cable with a single lead from P1407, SHR-14, to P1102.

SHR-11 POTENTIOMETER ADJUSTMENT

If any components are replaced on SHR-11, trimpots VR1101,

VR1102 and VR1103 may require readjustment. Measure the

SHR-11 voltages described in the following paragraphs. If

measured voltages are not correct, make adjustments as follows.

With power off, no input signal applied, and no load on the

1200’s speaker output, turn VR1103 completely clockwise. Turn

power on and allow unit to warm up or thermally stabilize for ten

minutes prior to making the adjustments. See Figure 2 for

trimpot locations.

5

Page 10

VR1101 OUTPUT VOLTAGE OFFSET ADJUSTMENT

1.

Connect a dc voltmeter between SHR-11 terminal AC and

ground (see Figure 2).

2.

Adjust VR1101 so that V1 equals 0 V ±15 mV

VR1102 DRIVER BALANCE ADJUSTMENT

1.

Connect a dc voltmeter between CP1101 and ground (see

Figure 2).

2. Adjust VR1102 so that V2 equals 1.2 V.

VR1103 IDLE CURRENT ADJUSTMENT

1.

After the unit has been turned on for at least five minutes,

connect a dc voltmeter between R1126 and R1127 as shown

(see Figure 2) and check the idle current. If the value of V3

does not equal 6.6 mV ±3.3 mV, use a razor blade to carefully

remove from the top and side of VR1103 the old cement that

prevented its adjustment from changing.

2. Adjust VR1103 so that V3 equals 6.6 mV ±3.3 mV.

3. Apply a drop of cement (white glue, hot melt glue, caulk, etc.)

to VR1103 to eliminate movement due to vibration.

VR1201 TEMPERATURE SENSOR THRESHOLD ADJUSTMENT

If U1201 or other SHR-12 parts are replaced, VR1201 will

probably require recalibration as follows.

1.

Turn off the unit long enough for the heat sink to reach

ambient temperature. Remove all input signal sources and

speaker loads.

2.

Measure the heat sink temperature or ambient temperature

around the heat sink. Consult the graph in Figure 3 to

determine the proper voltage at test point CP1402.

3.

Attach a dc voltmeter between CP1402 (+) and ground (-).

4.

Apply power to the unit and quickly adjust potentiometer

VR1201 on SHR-12 until the proper voltage is reached.

SHR-11 POTENTIOMETER ADJUSTMENTS

FIGURE 2

SHR-12 TEMPERATURE SENSOR BOARD

To remove SHR-12 from the large heat sink, remove the

Power Amplifier Board Assembly from the 1200 as described

above. Then remove the two Phillips screws that hold SHR-12 to

the small vertical heat sink. When replacing SHR-12, U1201

(mounted on the solder side of the board) must physically

contact the vertical heat sink in order to ensure correct operation of the power amplifier over-temperature protection circuitry.

In addition, apply a small amount of Wakefield Type 120 Thermal

Joint Compound to the top surface of the IC to allow good heat

transfer.

TEMPERATURE SHUTDOWN SENSOR CALIBRATION

FIGURE 3

SHR-14 MAIN BOARD

The 1200 contains four internal fuses mounted on the Main

Board (SHR-14). If replacement becomes necessary, replace

only with identical Normal Blow fuses: two 0.75 A 250 V, and two

8 A 250 V. Do not continue to replace fuses if a fuse continues to

blow; have the trouble corrected.

To remove SHR-14 from the chassis, remove the three Phillips

screws on each of the long sides of the board and the single

screw next to the two 8 A fuses on the short side of the board.

This will allow the board to be lifted free of the chassis. If it is

necessary to completely separate SHR-14 from the 1200,

remove all seven connectors (be sure to label the four 4-pin

connectors and their receptacles to ensure proper reattachment).

Unsolder the six transformer and two fan leads from pins AA

through AH, and the two ground leads connected to Al and AJ.

Be sure to label leads also so they can be resoldered to the

proper pins. Unsolder from connection pins AA and AB of

SHR-11 the red and green wires attached to the solder side of

SHR-14. (Remove cable ties as necessary.) The SHR-14 board

can now be completely detached from the 1200.

6

Page 11

If any of the heat-sink-mounted parts (voltage regulators

U1408, U1409 and U1410, or silicon rectifiers D1423 and D1424)

is replaced, be sure to apply a small amount of Wakefield Type

120 Thermal Joint Compound between the component and the

heat sink to allow maximum heat transfer.

A number of components on SHR-14 are mounted on spacing

insulators to keep them a measured distance from the board,

e.g., R1460, D1422. If any of these parts is replaced, be sure to

remount them the required distance above the board on spacing

insulators as originally supplied.

VR1401 POWER AMPLIFIER LIMITER THRESHOLD ADJUSTMENT

This adjustment is made under the following conditions.

1.

Terminate the Speaker Output in a 4-ohm resistive load.

2.

Set the Master control and trimpot VR1401 on SHR-14 fully

clockwise.

3.

Set the Limiter switch to Out.

4.

Connect the unit to a 120 Vac, 60 Hz power source and

switch the unit on.

5.

Drive one low-impedance input channel at 1 kHz with its

channel control fully clockwise. (Turn all the other input

channel Volume Controls fully counterclockwise.) Increase

the input signal until the signal at the Speaker Output just

visibly clips.

6.

Reduce the input signal level such that the output voltage

drops 1.5 dB.

7.

Switch the Limiter In. Slowly turn trimpot VR1401 counterclockwise until the output voltage drops an additional 0.2 dB.

REAR-PANEL BOARDS AND COMPONENTS

The following printed circuit boards and components are

mounted on the rear panel.

SHR-10

INPUT-OUTPUT BOARD

SHR-03 AUX/MIC BOARD

SHR-02

SHR-01

SHR-13

B1

S3

W1

J1

XF1

HI-Z INPUT BOARD

LO-Z INPUT BOARD

SPEAKER OUTPUT BOARD

FAN

+24 VDC PHANTOM POWER SWITCH

POWER CORD

AC CONVENIENCE RECEPTACLE

EXTERNAL FUSEHOLDER

SHR-02 HI-Z INPUT BOARD

To remove SHR-02, remove the six 1/2-inch nuts on the input

jacks. Disconnect the four 3-pin connectors from the SHR-01

LO-Z INPUT BOARD and the two 3-pin connectors from the

SHR-03 AUX/MIC BOARD. Pull the board straight back to

disengage the jacks from the rear panel: SHR-02 can then be

completely separated from the 1200.

SHR-01 LO-Z INPUT BOARD

Remove the twelve screws (two per input) connecting the

XLR-type connectors to the rear panel. To remove SHR-01 without

first removing SHR-02 HI-Z INPUT BOARD, remove the four

Phillips screws that hold the rear panel to the chassis bottom.

Rest the unit on its side while performing this operation. Then

swivel the rear panel away from the chassis (it is still held by the

power cord). This allows SHR-01 to be pulled straight back and

away from the rear panel without being stopped by the interior

vertical metal shield. Disconnect the four 3-pin connectors (two

from SHR-03 and two from SHR-04 CHANNEL BOARDS) and

the four 4-pin connectors (from SHR-02 and SHR-04). (Be sure

to label all removed lead-connector assemblies.) Unsolder from

point AA the yellow lead from SHR-10 REAR PANEL INPUTOUTPUT BOARD: SHR-01 is now completely free of the 1200.

SHR-13 SPEAKER OUTPUT BOARD

To remove SHR-13 SPEAKER OUTPUT BOARD:

1.

Disconnect the 3-pin connector from P1301.

2. With a 1/2-inch nutdriver or wrench, remove the nuts holding

the speaker output jacks to the rear panel.

3.

Unsolder the leads from AA and AB.

4.

The SHR-13 board is now free of the 1200.

B1 FAN

To remove the fan:

1.

Remove the four screws, nuts, and starwashers at the four

corners of the fan grille. This frees the fan from the rear

panel.

2. Unsolder the black fan leads from pins AE and AG on SHR-14.

3.

If necessary to remove the fan from the 1200, slide the fan

leads out of the insulating tubing and separate the fan from

the unit.

For access to or replacement of any of these parts, turn

the 1200 on its side (power transformer down) and remove the

four Phillips screws that hold the rear panel to the chassis

bottom. The rear panel then can be separated sufficiently from

the chassis bottom to permit access to these boards and

components.

SHR-10 INPUT-OUTPUT BOARD

To remove SHR-10, use a 1/2-in. nutdriver to remove the nuts

on the five phone jacks. Carefully pull the board straight back

until the connectors are free of the rear panel. To separate the

board completely from the rear panel, remove the 6-pin and

4-pin connectors from P1001 and P1002. Unsolder the green

and red leads from the Phantom Power switch, and unsolder

from SHR-10 the yellow lead that connects AC on SHR-10 to

AA on SHR-01. SHR-10 can now be completely separated from

the 1200.

SHR-03 AUX/MIC BOARD

To remove SHR-03, disconnect the four connectors from AA,

AB, BA, and BB to P201 and P202 of SHR-02 and from AC, AD,

BC, and BD to P102 and P104 of SHR-01. Remove the four

Phillips screws that hold the switches to the rear panel; SHR-03

can be completely separated from the 1200.

CAUTION

When replacing the fan, be sure to slide the leads through

the insulating tubing before soldering them to the pins on

SHR-14.

S3 PHANTOM POWER SWITCH

Remove the two screws that fasten the Phantom Power Switch

to the rear panel. This will free the switch from the panel. to

separate the switch completely from the 1200, unsolder the red

and green leads from the switch terminals.

FRONT-PANEL BOARDS AND COMPONENTS

The following printed wiring boards and components are

mounted on the front panel.

SHR-04 CHANNEL BOARD (6)

SHR-05

MASTER CONTROL BOARD

SHR-07 HEADPHONES CONTROL BOARD

SHR-06

SHR-09

SHR-08

S2

HEADPHONES OUTPUT BOARD

LIMITER BOARD

INDICATORS BOARD

POWER ON/OFF SWITCH

7

Page 12

SHR-04 CHANNEL BOARD

The SHR-04 Channel Boards are assembled and installed in

pairs. Therefore, SHR-04s for Channel 1 and Channel 2 constitute

one pair, those for Channel 3 and Channel 4 constitute another

pair, etc. To remove any pair of Channel Boards:

SHR-09 LIMITER BOARD

To free SHR-09 LIMITER BOARD from the Mounting Panel,

remove from the front of the panel the two Phillips screws that

attach the Limiter Switch to the panel. This frees the board from

the panel.

1.

Remove the control knobs by pulling them off the shafts.

2.

Remove the two flat-head Phillips screws that hold the Channel

Board Assembly in place. One screw is attached to the top of

the front panel ledge, the other to the chassis bottom.

3.

Disconnect the Channel Bus Connector from the top of each

of the two Channel Boards.

4.

Disconnect the 3-pin connector (coming from SHR-01 Input

Board) from the bottom of each of the two SHR-04 Channel

Boards.

5.

Pull the Channel Board Assembly horizontally backward to

free the control shafts from the front panel; the Assembly is

now free of the 1200.

FRONT MOUNTING PANEL

The Front Mounting Panel must be freed from the Front Panel

in order to work on or remove SHR-05 MASTER CONTROL

BOARD, SHR-06 HEADPHONES INPUT BOARD, SHR-07

HEADPHONES CONTROL BOARD, SHR-09 LIMITER BOARD,

SHR-08 INDICATORS BOARD and the Power On/Off Switch

from the 1200. To remove the Mounting Panel:

1.

Remove the two flat-head Phillips screws from the front

panel ledge above the Mounting Panel.

2.

Rest the 1200 on its side with the fan and mounting panel

upwards.

3.

Remove the top three Phillips screws holding the front panel

to the chassis bottom. Leave the bottom screw (below Channel

1) in place. (This will permit swiveling the front panel far

enough away from the chassis to allow the Mounting Panel

to be freed from the 1200 after other required disconnections

have been made.)

4.

Remove the knobs from the control shafts of the Master and

Headphones Controls.

5.

Disconnect the 3-pin connector from P701 on the HEAD-

PHONES CONTROL BOARD.

6.

Disconnect the 3-pin connector from P601 on the HEADPHONES OUTPUT BOARD.

7.

Disconnect the CHANNEL BUS connector from P501 at the

top of the MASTER CONTROL BOARD and disconnect 8-,

4-, and 5-pin connectors from P502, P503, and P504 at the

bottom of the MASTER CONTROL BOARD.

IMPORTANT:

Mark all connectors before removing them so

that they can be reconnected correctly.

8.

Loosen the cable tie that holds the cable harness to the hole

in the outside bottom of SHR-05.

9.

Swivel the front panel away from the chassis bottom enough

to permit pulling the control shafts out of the front panel and

partially freeing the Mounting Panel from the 1200. (The

panel is still connected to the 1200 by the transformer leads

connected to the On/Off switch.) From this position it is

possible to remove or work on boards SHR-05, -06, -07,

-08, and -09.

SHR-05 MASTER CONTROL BOARD

To remove SHR-05 MASTER CONTROL BOARD from the

Mounting Panel:

1.

Remove the control knobs.

2.

Use a nutdriver or wrench to remove the nuts holding the

control shafts to the Mounting Panel.

3. To free the board, pull the shafts back out of the panel.

SHR-06 HEADPHONES OUTPUT BOARD AND SHR-07 HEAD-

PHONES CONTROL BOARD

SHR-06 and SHR-07 are connected together by a solderedin-place 4-conductor ribbon cable. If it is not necessary to

replace the cable, either remove both boards (if desired to free

one of them completely from the 1200), or only remove one (if

freeing the assembly from the 1200 is not essential).

To remove SHR-07 HEADPHONES CONTROL BOARD, remove

the 7/16-inch nut that holds the control shaft to the Mounting

Panel. This permits the board to be freed from the panel (although

it is still connected via the ribbon cable to SHR-06 HEADPHONES

OUTPUT BOARD).

To remove SHR-06 HEADPHONES OUTPUT BOARD, remove

the 1/2-inch nut that holds the phone jack to the Mounting

Panel. This permits the board to be freed from the Panel.

SHR-08 INDICATORS BOARD

Remove the two Phillips screws holding SHR-08 to the back

of the Mounting Panel. Pull the board back from the panel to

remove the LEDs from their holes and to free the board.

S2 ON/OFF SWITCH

To remove the On/Off Switch from the Mounting Panel:

1.

Pull the switch button off the switch control shaft.

2.

Remove the two Phillips screws that hold the switch to the

panel.

3.

Unsolder the red and black transformer leads from the switch.

A1200MX INPUT EXPANSION MODULE

The A1200MX is an optional input expansion module kit that

provides two additional input channels to the 1200. A maximum

of two A1200MXs can be added to the 1200 for a total of 10

inputs. The A1200MX consists of an input connector module

(SHR-15 and SHR-16), an input transformer module (SHR-17),

a channel control module (two SHR-04s), control knobs, and

hardware.

The A1200MX circuitry is identical to the input circuitry of the

other six input channels. Servicing can be accomplished in the

same manner. Printed wiring board drawings are provided with

the service drawings.

CHECKING ACTIVE COMPONENTS

Integrated circuits can be checked without removing them

from their circuit board. Measure the input, output and power

supply voltages as shown on the applicable circuit diagram.

Defective transistors and diodes can be located by use of a

standard ohmmeter such as a Simpson 260. Polarity of the

ohmmeter must be verified before these checks are made; all

resistance measurements are made with the power off in the

circuit under test.

With a known diode orientation, measure the diode resistance

in the forward and reverse directions. The lowest meter reading

will establish the probe at the cathode end (schematic symbol

arrow points to cathode) as the “minus” probe while the other

probe will be “plus.” (Some ohmmeters are not polarized in this

manner with relation to “volts plus probe” and “volts minus

probe.“) With the ohmmeter “plus” probe on the anode end of a

diode, and the “minus” probe on the cathode end, the ohmmeter

should be read approximately 2000 ohms or less. With the

meter probes reversed, a reading of about 10,000 ohms or

more should be obtained. If either of these conditions is not

met, one lead should be unsoldered from the circuit and the test

repeated. If the results are identical, the diode should be replaced.

8

Page 13

To check LEDs, connect the cathode (notch or flat on flange,

tab on lead or short lead) of the LED to the negative terminal of a

standard 9 V transistor battery. Connect the positive battery

terminal through a 4.7 k resistor to the LED anode. Replace any

LED that does not light.

CAUTION

Do not check LEDs with an ohmmeter. The LEDs may be

damaged or erroneous readings may be obtained.

To check transistors, the ohmmeter should be set to the 100or 1,000-ohm scale. Transistors must be removed from the

circuit before testing. If all conditions in the following table are

met, the transistor may be considered free of any major defect;

if any of the following conditions are not met, the transistor

should be replaced. See Figure 3 for active component lead

codes.

OHMMETER CONNECTlON

“Plus” Lead

Collector

Emitter

Collector

Emitter Base

Base

Base

“Minus” Lead Transistor

Emitter

Collector

Base High Low

Collector

Emitter Low High

OHMMETER READING

NPN PNP

High High

High High

High Low

Low

Transistor

High

FERRITE BEADS

All low-impedance microphone connectors contain ferrite

beads (L101-L112, SHR-01). Be sure to replace any ferrite

beads removed during servicing.

SERVICE ILLUSTRATIONS

Immediately following the parts list on the pages that follow

are printed wiring board foil and legend drawings, and circuit

diagrams. Once a board has been located through the parts

location photo (Figure 1), the components on that board can be

located from the board drawing. The function of the part is

shown on the relevant circuit diagram.

OPTIONAL ACCESSORIES

The following optional accessories are designed for use with

the Shure 1200 AUDIOMASTER Powermixer.

Carrying Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1200C

Input Expansion Module (2 channels,

2 each HI Z and LO Z inputs . . . . . . . . . . . . . . . . A1200MX*

Speaker Cable, 15 m (50 ft), with phone plugs . . . . . . A50SC

240 V Conversion Kit . . . . . . . . . . . . . . . . . . . . . . . . . RKC209*

Line Matching Transformer (LO Z to HI Z) . . . . . . . . . . . A95UF

Phono Preamplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M64A

*For installation by qualified service personnel only.

9

Page 14

REPLACEMENT PARTS LIST

The following list provides information on replacement parts for the Shure Model 1200 AUDIOMASTER Powermixer. Shure part numbers

are given for all parts and, where available, manufacturer’s name and part number for acceptable equivalents in parentheses following the

part description (note that for optimum performance, only direct replacement parts should be used).

NOTE: Carbon film resistors shown in this parts list are rated at 0.2 watts. Standard 1/8-watt resistors should only be used as

replacements if circuit power requirements are not exceeded. Standard 1/4-watt resistors can only be used if they are physically mounted

in a vertical position.

NOTE: In early production, PC Board Assembly SHR-14 contains the following legend error: Capacitor C1423 is marked “+” on the

wrong lead. Note the position of C1423 and replace (if necessary) according to the part, not the legend.

REFERENCE DESIGNATION

A1

B1

C401, C702, C1405, C1408

C402, C410-C411, C413, C508, C509

C404

C407, C503

C408-C409, C501-C502, C1410

C412, C1411, C1415

C506, C510-C511, C1414

C701

C1006

C1101

C1103

C1104, C1113

C1105, C1107

C1106

C1108

C1109, C1112

C1110-C1111

C1201

C1301

C1401

C1403

C1406, C1412-C1414

C1407

C1417-C1418

C1419

C1420-C1421

C1422-C1423

C1424-C1425

C1426-C1428

D401-D404, D701-D702, D1401-D1418

D405

D801-D802

D803

D804

D1101

D1102-D1105

D1106-D1107, D1419-D1421

D1422

D1423

D1424

F1

F1401-F1402

F1403-F1404

J1

J101-J106

J201-J206, J1001-J1005

J601, J1301-J1302

L101-L112

L1101

MP1

MP2

MP3

MP4

MP5

SHURE

PART NO.

803039FK

802641FK

707471FK

707416FK

707425FK

707707FK

707725FK

707439FK

707424FK

800660FK

707351FK

707344FK

707328FK

707358FK

802602FK

707316FK

707350FK

708009FK

707629FK

707315FK

802600FK

707714FK

707571FK

707416FK

707705FK

707438FK

707329FK

707322FK

707354FK

802599FK

802605FK

800625FK

802594FK

800633FK

802596FK

802597FK

706541FK

802593FK

706306FK

706319FK

706323FK

706322FK

713642FK

802634FK

784129FK

802633FK

802629FK

713373FK

784104FK

784108FK

802625FK

788427FK

802579FK

802580FK

802581FK

802582FK

DESCRIPTION

Reverb Pan

Fan

Capacitor, Electrolytic, 0.22 µF, 50 V (Nichicon UKB1HR22KAA)

Capacitor, Electrolytic, 22 µF, 16 V (Nichicon UKB1C100KAA)

Capacitor, Electrolytic, 10 µF, 25 V (Nichicon UKB1E100KAA)

Capacitor, Mylar, 0.0015 µF (Panasonic ECQ-B1H152JZ)

Capacitor, Mylar, .047 µF (Panasonic ECQ-V1H473JZ)

Capacitor, Electrolytic, 1 µF, 50 V (Nichicon ULB1H010MAA)

Capacitor, Electrolytic, 4.7 µF, 25 V (Nichicon ULB1H4R7MAA)

Capacitor, Electrolytic, 10 µF, 50 V (Nichicon ULB1H100MAA)

Capacitor, Electrolytic, 100 µF, 50 V (Nichicon ULB1H101MPA)

Capacitor, Electrolytic, 1 µF, 50 V (Nichicon ULB1H010MAA)

Capacitor, Electrolytic, 47 µF, 25 V (Nichicon ULB1E470MAA)

Capacitor, Electrolytic, 10 µF, 63 V (Nichicon ULB1J100MAA)

Capacitor, Ceramic, 10 pF, 500 V

Capacitor, Electrolytic, 22 µF, 16 V (Nichicon UKB1C100KAA)

Capacitor, Electrolytic, 47 µF, 50 V (Nichicon ULB1H470MAA)

Capacitor, Ceramic, 100 pF, 100 V

Capacitor, Mylar, .1 µF (Panasonic ECQ-V1104JZ)

Capacitor, Electrolytic, 10 µF, 16 V (Nichicon UKB1C100KAA)

Capacitor, Mylar, .047 µF, 100 V (Sprague 225P47391WD3)

Capacitor, Mylar, 0.0056 µF (Panasonic ECQ-B1H562JZ)

Capacitor, Bipolar Electrolytic, 10 µF, 16 V (Panasonic ECE-A1CN100S)

Capacitor, Electrolytic, 10 µF, 16 V (Nichicon UKB1C100KAA)

Capacitor, Mylar, .001 µF (Panasonic ECQ-B1H102JZ)

Capacitor, Electrolytic, 0.47 µF, 50 V (Nichicon UKB1HR47KAA)

Capacitor, Electrolytic, 100 µF, 25 V (Nichicon ULB1E101MAA)

Capacitor, Electrolytic, 1000 µF, 16 V (Nichicon ULB1C102MRA)

Capacitor, Electrolytic, 470 µF, 50 V (Nichicon ULB1H471MRA)

Capacitor, Electrolytic, 10,000 µF, 63 V

Capacitor, Ceramic, .01 µF, 500 V

Diode (RCA SK3100)

LED, Red (RCA SK2022/3022)

LED, Red (RCA SK2022/3022)

LED, Yellow (RCA SK2021/3021)

LED, Green (RCA SK2024/3024)

Diode, Zener (RCA SK24A)

Diode (RCA SK3100)

Diode (RCA SK3311)

Silicon Rectifier (RCA SK3647)

Silicon Rectifier

Silicon Rectifier

Fuse, 5 A, 250 V (Littelfuse 312005)

Fuse, 0.75 A, 250 V (Littelfuse 312.750)

Fuse, 8 A, 250 V (Littelfuse 312008)

Outlet, Unswitched AC

Connector, XLR-type Receptacle, 3-pin (Cannon XLB-3-31PC)

Phone Jack, 2-Circuit

Headphone Jack, 3-Circuit

Ferrite Bead

Coil, 4.6 µH

Rubber Foot

Knob, Green, Bass

Knob, Green, Treble

Knob, Black

Knob, Gold

10

Page 15

REFERENCE DESIGNATON

MP6

MP7

MP8

MP9

MP10

P1003-P1004

P1401

Q501, Q1110, Q1403

Q1101, Q1114

Q1102

Q1103-Q1104

Q1105,Q1109

Q1106

Q1107-Q1108

Q1111

Q1112-Q1113

Q1401-Q1402, Q1404

Q1405

Q1406

R101-R106

R201-R206, R405, R520, R522,

R1404, R1415, R1445, R1452

R301, R304, R514

R302, R305

R303, R306, R407, R414, R416, R503,

R513, R1401, R1412, R1423,

R1426-R1427, R1430

R401, R518

R402

R403

R404, R409-R410, R502, R504,

R512, R519, R602

R406, R408, R505-R506

R411, R1410, R1422, R1424, R1448-R1449

R412, R1006, R1409, R1420-R1421,

R1433, R1435-R1438, R1443, R1446,

R1451, R1458

R413, R1419, R1453

R415, R523, R601, R704, R1414,

R1417-R1418, R1425, R1429, R1442,

R1444, R1447

R501, R511

R507

R508, R515, R1428

R509, R516-R517

R510

R521, R1001-R1005, R1413,

R1431-R1432, R1459

R603-R605

R701, R703

R702

R1101

R1102, R1104

R1103, R1112, R1201

R1105

R1106-R1108

R1109

R1110

R1111

R1113

R1114

R1115

R1116

R1117

R1118-R1119

R1120, R1122

R1121, R1123

R1124-R1125

SHURE

PART NO.

802583FK

802584FK

802585FK

802587FK

802642FK

802628FK

711080FK

706102FK

706146FK

800412FK

802590FK

801798FK

706156FK

802591FK

706155FK

802592FK

706537FK

706139FK

706147FK

802610FK

801057FK Resistor, 4.7 K

801059FK Resistor, 6.8 K

801068FK Resistor, 39 K

801065FK

802607FK

801075FK

801076FK

801061FK

801058FK

801081FK

801073FK

801072FK Resistor, 82 K

801069FK

801062FK

801055FK

801077FK

801041FK

803041FK

801053FK

802614FK

802815FK

803042FK

708857FK

708842FK

708845FK

708835FK

708850FK

708906FK

708934FK

802617FK

803043FK

708838FK

708836FK

802616FK

802610FK

708849FK

708854FK

708840FK

802613FK

Knob, Red

Knob, Blue

Knob, White

Fan Grille, Front Panel

Fan Grille, Rear Panel

Connector, Receptacle, 2-pin

Connector, Receptacle, 8-pin

Transistor, PNP (RCA SK3932)

Transistor, Dual, NPN (RCA SK9427)

Transistor, Dual, FET

Transistor, Power, PNP (RCA SK9042) (requires 802681FK insulator)

Transistor, NPN

Transistor, NPN (RCA SK9118)

Transistor, Power, NPN (requires 802639FK insulator)

Transistor, PNP (RCA SK9363)

Transistor, Power, PNP (requires 802639FK insulator)

Transistor, FET

Transistor, NPN (RCA SK9137)

Transistor, PNP (RCA SK9138)

Resistor, 1.8 K

Resistor, 22 K

Resistor, 2 K, 2%

Resistor, 150 K

Resistor, 180 K

Resistor, 10 K

Resistor, 5.6 K

Resistor, 470 K

Resistor, 100 K

Resistor, 47 K

Resistor, 12 K

Resistor, 3.3 K

Resistor, 220 K

Resistor, 220

Resistor, 43 K (Early Production); 30 K (Later Production)

Resistor, 2.2 K

Resistor, Metal Oxide Film, 220, 1 W

Resistor, 13 K, 1%

Resistor, 680, 2%

Resistor, 47 K

Resistor, 2.7 K

Resistor, 4.7 K

Resistor, 680

Resistor, 12 K

Resistor, 1.8 K, 2%

Resistor, 47 K, 2%

Resistor, Metal Oxide Film, 5.6 K, 2 W

Resistor, Metal Oxide Film, 68, 1/2 W

Resistor, 1.2 K

Resistor, 820

Resistor, Metal Oxide Film, 3.9 K, 2 W

Resistor, Metal Oxide Film, 1.8 K, 1/2 W

Resistor, 10 K

Resistor, 27 K

Resistor, 1.8 K

Resistor, Metal Oxide Film, 100, 1 W

11

DESCRIPTION

Page 16

SHURE

REFERENCE DESIGNATION

R1126-R1127

R1128

R1301

R1402

R1403, R1454

R1406-R1407

R1408

R1411

R1416

R1434

R1439

R1440, R1455

R1441

R1450

R1456

R1457

R1460

R1461-R1462

S1

S2

S3

S301-S302

S901

SHR-01

SHR-02

SHR-03

SHR-04

SHR-05

SHR-06

SHR-07

SHR-08

SHR-09

SHR-10

SHR-11

SHR-12

SHR-13

SHR-14

T1

T101-T106

U401-U402, U501-U504, U701,

PART NO.

802612FK

708853FK

710041FK

801064FK

801080FK

800190FK

801033FK

801085FK

801089FK

801063FK

802609FK

801070FK

801051FK

801045FK

800749FK

802611FK

709314FK

802615FK

802630FK

802631FK

802632FK

801599FK

784110FK

235901FK

235902FK

235903FK

235904FK

235905FK

235906FK

235907FK

235908FK

235909FK

235910FK

235911FK

235912FK

235913FK

235914FK

803474FK

802626FK

706077FK

U1401-U1407

U1201

U1408

U1409

U1410

V1401

VR401

VR402, VR502

VR403, VR405, VR701

VR404

VR501, VR504

VR503

VR1101-VR1102

VR1103

VR1201

VR1401

W1

W2

W3

W4

XF1

+ May not exhibit the low-noise characteristics of the original part.

802588FK

802589FK

706097FK

706098FK

802598FK

802620FK

802622FK

802619FK

802621FK

802623FK

802624FK

802618FK

802681FK

800030FK

710138FK

802638FK

908575FK

908580FK

800618FK

802636FK

DESCRIPTION

Resistor, Ceramic, Dual, .22, 5 W

Resistor, 22 K

Resistor, Ceramic, 10, 5 W

Resistor, 18 K

Resistor, 390 K

Resistor, 22, 1/2 W

Resistor, 47

Resistor, 1 M

Resistor, 2.2 M

Resistor, 15 K

Resistor, 51 K, 2%

Resistor, 56 K

Resistor, 1.5 K

Resistor, 470

Resistor, Metal Film, 100 K, 1%

Resistor, Metal Film, 36 K, 1%

Resistor, Metal Oxide Film, 39, 1/2 W

Resistor, Metal Oxide Film, 47, 2 W

Switch, Voltage Selector, DPDT

Switch, On/Off, SPST

Switch, Phantom Power, SPST

Switch, Slide, DPDT

Switch, Slide, DPDT

Printed Wiring Assembly, Lo-Z Input

Printed Wiring Assembly, Hi-Z Input

Printed Wiring Assembly, Aux/Mic

Printed Wiring Assembly, Channel

Printed Wiring Assembly, Master Control

Printed Wiring Assembly, Headphones Out

Printed Wiring Assembly, Headphones Control

Printed Wiring Assembly, Indicator

Printed Wiring Assembly, Limiter

Printed Wiring Assembly, Input/Output

Printed Wiring Assembly, Power

Printed Wiring Assembly, Sensor

Printed Wiring Assembly, Speaker Output

Printed Wiring Assembly, Main

Transformer, Power

Transformer, Mic Input

IC, Quad Op Amp (RCA SK3465+)

IC, Thermal Sensor

IC, Voltage Regulator (Motorola MC7824)

IC, Voltage Regulator, Positive (Motorola MC7815)

IC, Voltage Regulator, Negative (Motorola MC7915)

Opto-Isolator

Potentiometer, Log, 100 K

Potentiometer, Dual, Linear, 50 K

Potentiometer, Log, 10 K

Potentiometer, Linear, 20 K

Potentiometer, Log, 100 K

Potentiometer, Linear, 10 K

Potentiometer, Linear, 100

Potentiometer, Linear, 1 K

Potentiometer, Linear, 47 K

Potentiometer, Linear, 5 K

Power Cable and Plug, 3 m (10 ft), 3-Conductor

Channel Bus Cable, Ribbon, 8-Conductor, with Connectors

Cable, Ribbon, 5-Conductor

Cable, Ribbon, 4-Conductor

Rear Panel Fuseholder

12

Page 17

BLOCK DIAGRAM

Page 18

LEAD CODES

Page 19

15

Page 20

16

Page 21

17

Page 22

18

Page 23

19

Page 24

20

Page 25

21

CIRCUIT DIAGRAM-1

(SHR-01, SHR-02, SHR-03, SHR-04)

Page 26

22

CIRCUIT DIAGRAM-2

(SHR-05, SHR-07, SHR-08, SHR-10)

Page 27

23

CIRCUIT DIAGRAM-3

(SHR-09, SHR-12, SHR-14)

Page 28

24

CIRCUIT DIAGRAM-4

(SHR-06, SHR-11, SHR-13, SHR-14)

Page 29

Page 30

Loading...

Loading...