Page 1

222

HARTREY

AVE

.

EV:NSTON.

ILL

-

CABLE

SHUREMICRO

-

I-

MICROPHONES AND

EVANSTON PHONE

DA

ELECTRONIC

8.9000

CHICAGO

COMPONENTS

PHONE

SH

3.1600

DATA

I

SHEET

Model

81

5

and

Model

816

I

Magnetic Tape Recordinq Heads

General:

ing Heads are high quality recording units designed for use with

paper and

places Shure Manufacturers Model Numbers TR5,

TR5H. Model 816 replaces Shure Manufacturers Model Numbers

TR6C and TRbE.

Model 815 Recording Head comjines the functions of recording, playback and signal erasure

Recording Head is a record and playback unit only.

Applications:

able for use in all types of tape recording and playback applica-

tions-the professional,

The recording heads are of rugged construction and immune to

practically all effects of moisture, tenperature and mechanical vibrations. The carefully contoured and highly polished surfaces give

uniform response, long operating life, and (in case of the Model

8

15) high erase efficiency.

The outer metal cases are

excellent hum shielding, which minimizes the

Ins*alla+ion:

mounted by clamping the recording head at the center top of the

metal case or at the flanged edges. Positioning pins through the

center of the eyelets may be used to accurately locate

ing head on the mechanism. Care

ing or distorting of the

of hum shielding effectiveness. Dimensional data is given in

Figure

Care must also be taken to position the heads so that the re-

cording-playback gap is perpendicular to the length of the tape.

This is especially important in using pre-recorded tapes. The Model

815 is assembled in such a manner as to insure that the recording

gap is perpendicular within

bosses. When properly installed, tho mounting bosses of the recording head should seat on a mounting surface parallel to the

direction of travel of the tape. To insure perpendicularity, the

mounting bosses on some heads are shimmed with a thin tab of

metal held by the eyelets on one side of the head. Deforming or

removing this tab destroys the alignment between gap and mounting bosses.

The Model 815

of positioning and

Some external

user in adjusting the tape

ing surface. Also, by proper location of the tape guide, the tape

will enter and leave the recording surface at the correct angle.

See Figure C for information on tape guides and tape angles.

To insure proper contact of the tape against the recording surface of the head, pressure pads may be used. The pressure pads

are made of felt

on small metal arms, which are held against the recording head

b

springs adjusted to the force indicated in Figure

a%o, shows a suggested layout for pressure pad arrangement.

The Model 816 Tape Recording Head does have a means of

positioning and guiding the tape across the recording

a groove to properly locate the recording tape has been machined

and polished into the recording surface. In this case, the unit is

assembled in such a manner as to insure that the recording gap

is perpendicular within,

TAPE GUIDE GROOVE. Proper contact of the tape against the

recording surface may be insured by use of a pressure pad. Figure

C,

also, shows tape angle and pressure pad arrangement for the

Model 816.

Model 815 and Model 816 Magnetic Tape Record-

plastic base magnetic recording tapes. Model 815 re-

In

a single unit. Model 816

Both the Model 815 and Model 816 are suit-

semi-professional and home-recording types.

high permeability shields and afford

of hum producing components.

The Model 815 and the Model 816 may be

metal shield, which wouid result in loss

mtist be taken to prevent bend-

TRBA, TR5D and

~roblem of mechanical

the record-

B.

&

Y20

to the surface of the mounting

Tape Recording Head does not have a means

guiding the tape across the recording surface.

guides will be required. These guides assist the

1

/

parallel to the recording head mount-

16"

thick by

1/4"

square. The pads are mounted

C.

2

Y2"

to the BOTTOM EDGE OF THE

Figure

surface-

C,

L-

-

b

-

I,,;d

Model

815

Model 816

A

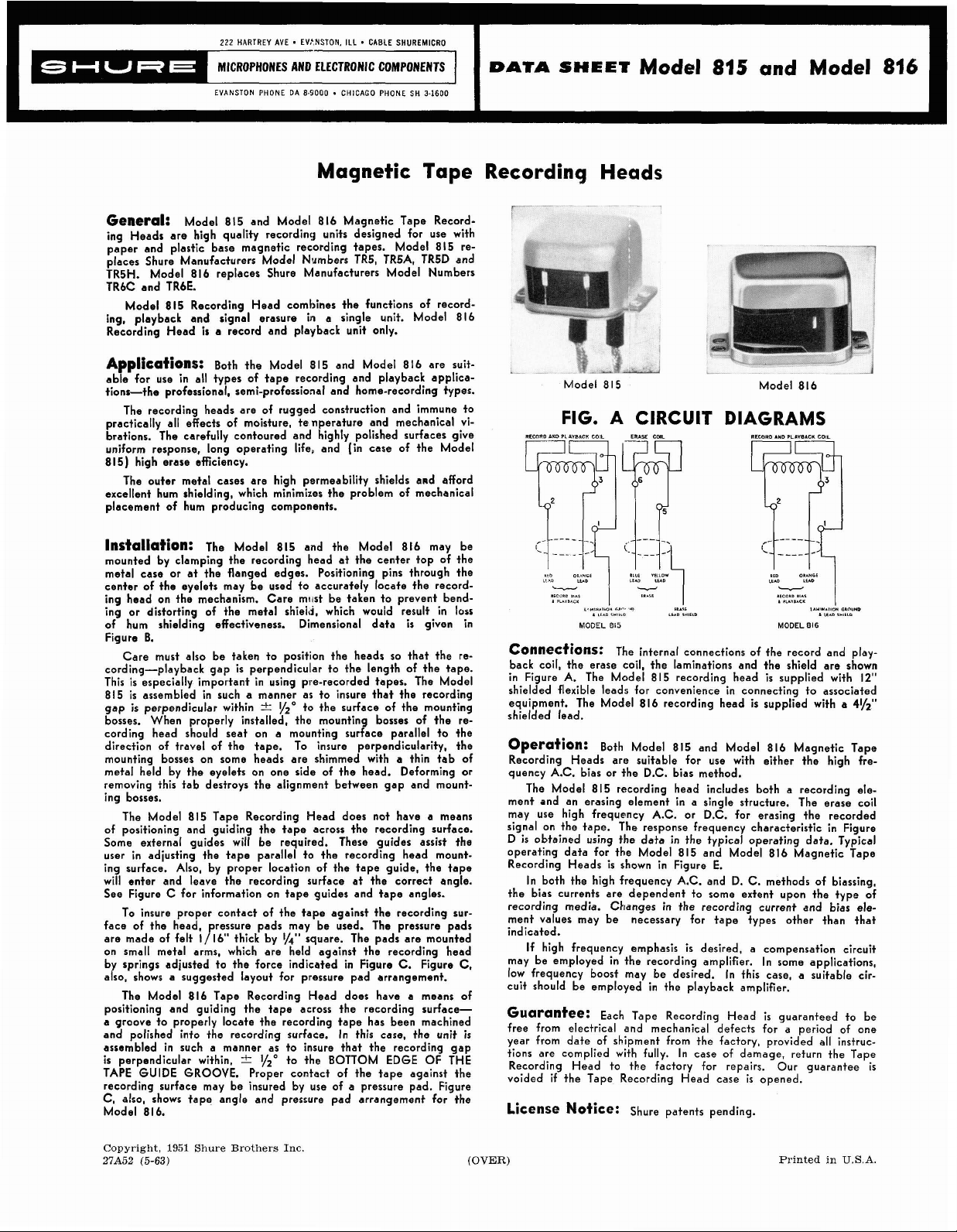

FIG. A CIRCUIT DIAGRAMS

RECORD

AND

PLIIBLCK

COlL

1LYL

ItD

011*61

L5\0

,MD

,."X,.,,O"

'

,SAD

MODEL

C~nne~ti~nS:

back coil, the erase coil, the laminations and the shield are shown

in Figure

shielded flexible leads for convenience in connecting to associated

equipment. The Model 816 recording head is supplied with a

shielded lead.

Operation:

Recording Heads arc suitable for use with either the high fre-

quency A.C. bias or the D.C. bias method.

ment and an erasing element in a single structure. The erase coil

may use

signal on the tape. The response frequency characteristic in Figure

D is obtained using the data in the typical operating data. Typical

operating data for the Model 815 and Model 816 Magnetic Tape

Recording Heads is shown in Figure E.

the bias currents are dependent to some extent upon the type of

recording media.

ment values may be necessary for tape types other than that

indicated.

may be employed in the recording amplifier. In some applications,

low frequency boost may be desired. In fhis case, a suitable circuit should be employed in the playback amplifier.

Guarantee:

free from electrical and mechanical defects for a period of one

year from date of shipment from the factory, provided all instructions are complied with fully. In case of damage, return the Tape

Recording Head

voided if the Tape Recording Head case is opened.

A.

The Made1 815 recording head is supplied with 12"

Both Model 815 and Model 816 Magnetic Tape

The Model 815 recording head includes both a recording ele-

high frequency A.C. or D.C. for erasing the recorded

In both the high frequency A.C. and D. C. methods of biassing,

If

high frequency emphasis is desired, a compensation circuit

Each Tape Recording Head is guaranteed to be

License Notice:

"11101

e"

."

,"<k,O

815

The internal connections of the record and play-

S..,&

LEAD

,",eLD

RID

LEAD

MODEL

O.*NLT

-0

l."I*.110*

TIOUND

1

LEAD

,*,EL0

816

4%"

Changes in the recording current and bias ele-

to the factory for repairs. Our guarantee is

Shure patents pending.

1

Copyright,

27A52

(5-63)

1951

Shure Brothers

Inc.

(OVER)

Printed in

U.S.A.

Page 2

MODEL

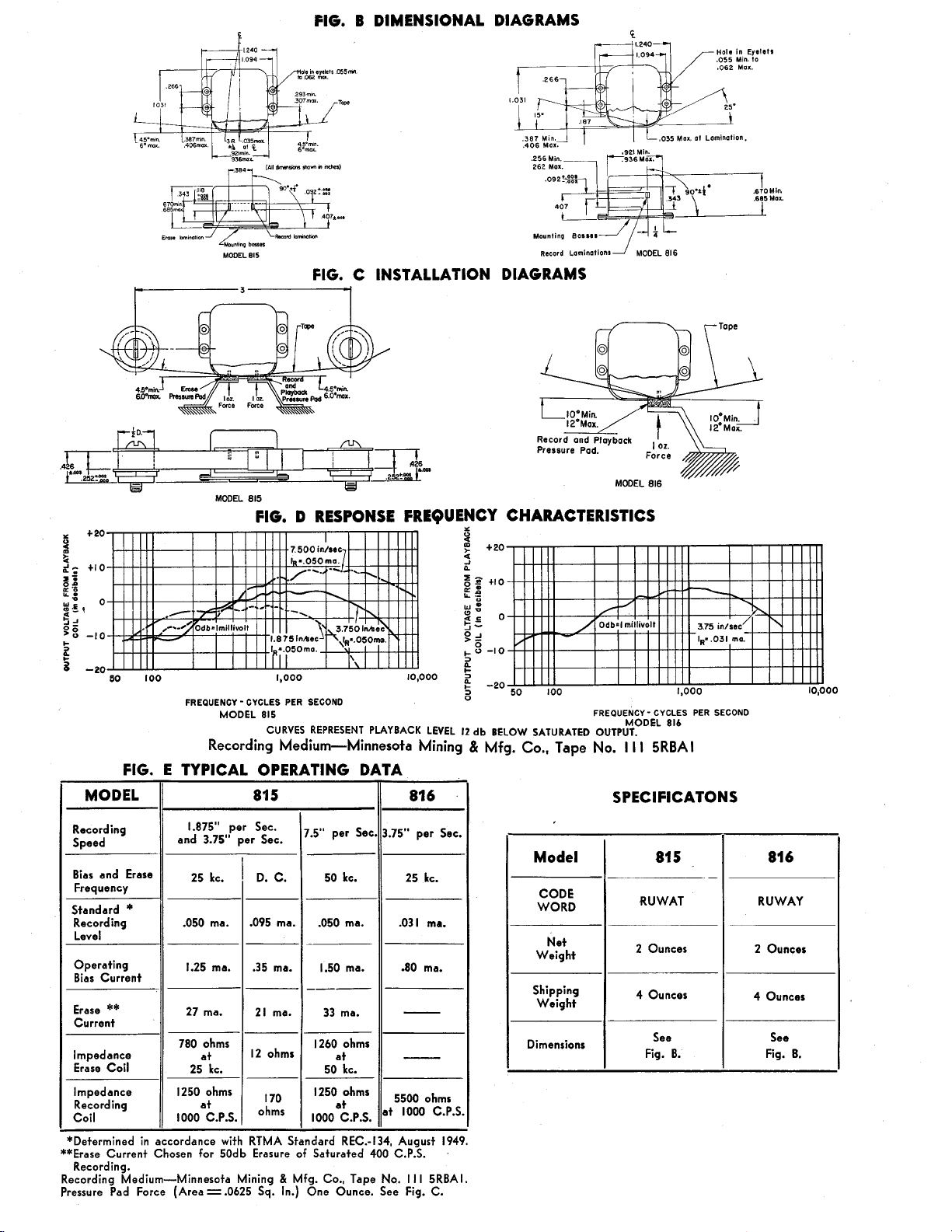

FIG. B DIMENSIONAL DIAGRAMS

815

C INSTALLATION DIAGRAMS

FIG.

D

RESPONSE FREQUENCY CHARACTERISTICS

I

t

2;

s

z

e

B

g5t

4

-1

g

a

0

I-

s

8

t

20

+I0

-10

-20

FREQUENCY - CYCLES PER SECOND

MODEL 815

CURVES REPRESENT PLAYBACK LEVEL

Recording Medium-Minnesota Mining & Mfg. Co., Tape

FIG. E TYPICAL OPERATING DATA

MODEL

Recording

Speed

Bias and Erase

Frequency

Standard

Recording

Level

Operating

Bias Current

Erase

Current

Impedance

Erase Coil

Impedance

Recording

Coil

*Determined in accordance with RTMA Standard REC.-134, August 1949.

**Erase Current Chosen for 50db Erasure of Saturated 400 C.P.S.

Recording.

Recording Medium-Minnesota Mining

Pressure Pad Force (Area = .0625

*

**

and

1.875"

3.75,,

25

.050 ma.

1.25 ma.

27 ma.

780 ohms

25 kc.

1250 ohms

at

1000 C.P.S.

kc.

per

per

/

81

5

Sec.

D.

.095 ma.

.35 ma.

-

21 ma.

I2

7.5" per Sec.

Set.

C.

50 kc.

.050 ma.

1.50 ma.

---

33 ma.

ohms

Sq.

1260 ohms

at

50 kc.

1250

at

1000 C.P.S.

&

Mfg. Co., Tape No.

In.) One Ounce. See Fig.

ohms

816

3.75" per Sec.

25 kc.

.031 ma.

.80 ma.

-

-

5500 ohms

at

I0O0

C.P.S.

I I

I

5RBAI.

C.

12

db

BELOW SATURATED OUTPUT.

Model

CODE

WORD

Net

Weight

Shipring

We~ght

Dimensions

1,000

FREQUENCY - CYCLES PER SECOND

MODEL 816

No.

I I

I

5RBAI

SPECIFICATONS

81

5

-

RUWAT

2 Ounces

4 Ounces

See

Fig. B.

10,o

81 6

RUWAY

2 Ounces

4 Ounces

See

Fig. B.

Loading...

Loading...