Page 1

222 HARTREY AVE.. EVANSTON. IL. 60204 U.S.A.

D

I

@r

MICROPHONES

AREA

CODE 312/866-2200 CABLE:

TWX: 910-231-0048 TELEX: 72-4381

AND ELECTRONIC

COMPONENTS

SHUREMICRO

1

DATA

SHEET

1

MODEL

711

LOUDSPEAKER SYSTEM

VARADTM AND SIT EQUIPPED

I

OPERATION AND SERVICE INSTRUCTIONS

DESCRIPTION

The Model 71 1 Professional Loudspeaker System

consists of an all-new Shure-designed and

-manufactured 15-inch

a Shure-designed and -manufactured high-power highfrequency driver, and a unique

dispersion horn with sliding vanes to set 60°, 90° Left,

90° Right, or 120° coverage angles. The Model 711

Speakers can be used individually or in combination to

provide high-SPL sound reinforcement of wide frequen-

cy range program material in any shape or size of

room-from the most intimate club to the largest

auditorium.

The 711 system has a frequency response of 56 to

14,000 Hz and an impedance of 8 ohms. The system is

designed to operate with amplifiers capable of deliver-

ing up to 150 watts continuous to an

range operation and up to 200 watts low-frequency

when biamplified. The 711

that automatically converts to biamplif ied operation. In

addition, two low-frequency

parallel-wired to permit cascading speakers as well as

connecting each speaker to a separate amplifier output.

The 711 has built-in passive low-frequency and highfrequency crossover networks for optimum acoustic

matching and speaker protection.

overload protection circuit safeguards the highfrequency driver against damage from unusually high-

level signals.

The speaker system is housed in a front-vented

Thiele-Small aligned bass reflex cabinet constructed of

(5/s

15.9 mm

resistant black vinyl, with steel corner protectors and

durable plastic feet. A handsome metal grille that protects the woofer can be easily removed or permanently

attached (see page 2). The 71 1 weighs 30 kg (66 Ib) and

can be carried by grasping it at the top and sides of the

cabinet corners. Proper lifting techniques should be

observed when handling equipment of this size and

weight.

A heavy-duty 15m (50 ft), 18-gauge, rubber-jacketed

connecting cable with phone plugs is supplied with the

speaker. A rugged vinyl slip-on protective cover with a

Copyright

27A8006(AH)

1981,

in.) plywood, covered in strong, scuff-

Shure Brothers

Shure Music Transducer

VARADTM variable-

&ohm load for full-

features a switching jack

andlor full-range jacks are

In

Inc.

woofer,

addition, an

cable pocket is available as Model A711C.

SPECIFICATIONS

Power Rating

Maximum recommended amplifier output to 8 ohms:

Full Range: 150 watts continuous, 34.6 Vrms, 55V

peak;

Biamplified-Low Frequency: 200 watts continuous,

40 Vrms,

continuous, 34.6 Vrms, 55V peak.

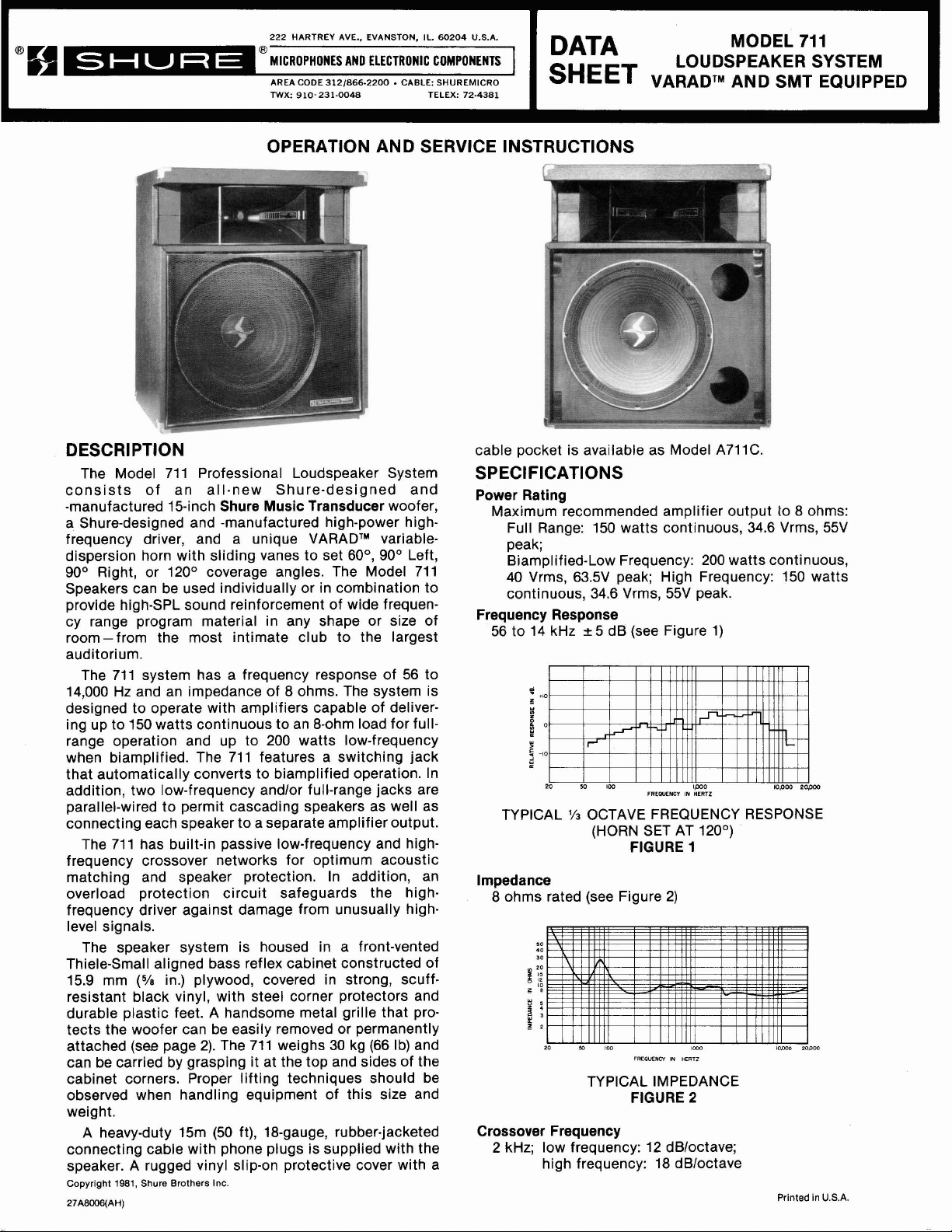

Frequency Response

56 to 14 kHz k5 dB (see Figure 1)

TYPICAL

Impedance

8 ohms rated (see Figure 2)

Crossover Frequency

2 kHz; low frequency: 12 dBloctave;

63.5V peak; High Frequency: 150 watts

'/3

OCTAVE FREQUENCY RESPONSE

(HORN SET AT

FIGURE

FREOUENN

TYPICAL IMPEDANCE

FIGURE

high frequency: 18 dBloctave

120')

1

IN

HERTZ

2

Printed

in

U.S.A.

Page 2

Sound Pressure Level

101 dB at

1m with 1W input (2.83V)

Phasing (polarity)

Positive voltage on phone jack tip produces positive

sound pressure (woofer cone moves out)

High Frequency Section

120°, 90°L, 90°R, or 60° (selectable) radial horn;

High-power driver,

1 %-inch voice coil

Low Frequency Section

15-inch SMT woofer,

2lh-inch voice coil

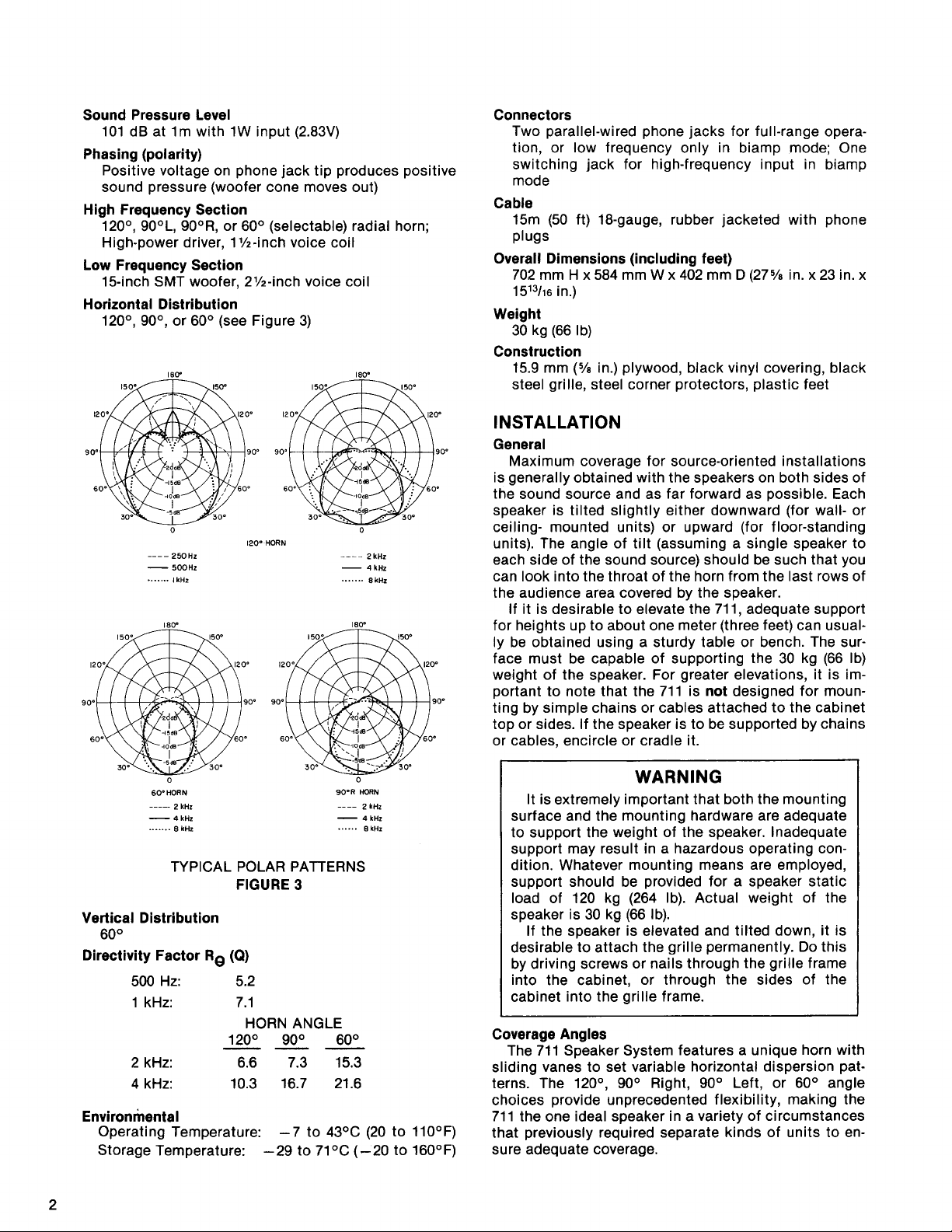

Horizontal Distribution

120°, 90°, or 60° (see Figure 3)

HORN

----

-

.......

0

2 kHz

4

kHz

8

kHz

Connectors

Two parallel-wired phone jacks for full-range operation, or low frequency only in biamp mode; One

switching jack for high-frequency input in biamp

mode

Cable

15m (50 ft) 18-gauge, rubber jacketed with phone

plugs

Overall Dimensions (including feet)

702

mm H x584 mm W x 402 mm D(27% in. x23 in. x

1513/16 in.)

Weight

30 kg (66 Ib)

Construction

mm

(%

15.9

in.) plywood, black vinyl covering, black

steel grille, steel corner protectors, plastic feet

INSTALLATION

General

Maximum coverage for source-oriented installations

is generally obtained with the speakers on both sides of

the sound source and as far forward as possible. Each

speaker is tilted slightly either downward (for wall- or

ceiling- mounted units) or upward (for floor-standing

units). The angle of tilt (assuming a single speaker to

each side of the sound source) should be such that you

can look into the throat of the horn from the last rows of

the audience area covered by the speaker.

If it is desirable to elevate the 711, adequate support

for heights up to about one meter (three feet) can usually be obtained using a sturdy table or bench. The surface must be capable of supporting the 30 kg (66 Ib)

weight of the speaker. For greater elevations, it is im-

portant to note that the 711 is not designed for moun-

ting by simple chains or cables attached to the cabinet

top or sides. If the speaker is to be supported by chains

or cables, encircle or cradle it.

90DR

6O'HORN

.....

-

.......

2

kHz

4

kHz

8

kHz

..--

-

......

HORN

2

4

8

kHz

kHz

kHz

TYPICAL POLAR PATTERNS

FIGURE

3

Vertical Distribution

60°

Directivity Factor Re

(Q)

500 Hz: 5.2

1 kHz: 7.1

HORN ANGLE

120° 90° 60°

---

2 kHz: 6.6 7.3 15.3

4 kHz:

10.3 16.7

21.6

Environmental

Operating Temperature: -7 to

43OC (20 to llO°F)

Storage Temperature: -29 to 71°C (-20 to 160°F)

WARNING

It is extremely important that both the mounting

surface and the mounting hardware are adequate

to support the weight of the speaker.

support may result in a hazardous operating condition. Whatever mounting means are employed,

support should be provided for a speaker static

load of 120 kg (264 Ib). Actual weight of the

speaker is 30 kg (66 Ib).

If the speaker is elevated and tilted down, it is

desirable to attach the grille permanently. Do this

by driving screws or nails through the grille frame

into the cabinet, or through the sides of the

cabinet into the grille frame.

Coverage Angles

The 71 1 Speaker System features a unique horn with

sliding vanes to set variable horizontal dispersion patterns. The

120°, 90° Right, 90° Left, or 60° angle

choices provide unprecedented flexibility, making the

711 the one ideal speaker in a variety of circumstances

that previously required separate kinds of units to ensure adequate coverage.

Inadequate

Page 3

Adjust the angle by sliding the vane all the way out or

all the way in. With both vanes out, the speaker is set for

120°; with both vanes in, for 60°; with the right vane in,

90° left; and with the left vane in, for 90° right. (To

for

narrow the angle, slide the vane in; to widen it, slide the

vane out.)

Setting the horn at

60° concentrates the high-

frequency energy in an area one half that of a 120° horn.

3

This concentration produces an approximately

dB increase in the high-end response for "long throw" applications. The extra high-end energy is extremely

useful in providing maximum intelligibility for speech

and singing voices, or in penetrating where acoustics

are "dead" or where singers' voices must compete with

loud amplified instruments on stage.

Use the

in "short throw" applications. Use the

"off center" or

120° angle for coverage of short, broad areas,

90° angles for

'I"-shaped applications. The 60° and 90°

positions are also extremely useful when several

speakers are employed to cover individual sectors of a

very large hall or outdoor stadium.

Figure 4 illustrates the coverage angles, areas, and

sound pressure levels of the

VARADTM horn in the 711

Speaker System.

HORN 120'

1'01$,"'1

HOOKUP

Amplifiers

The 71 1 is designed for use with the Shure Models

700 or 706 Power Consoles and similar amplifiers having the following maximum power output capabilities.

Speaker Wiring

Fifteen meters (50 ft) of cable is supplied with each

711 Speaker System. For convenient attachment, a

straight phone plug and a right-angle phone plug are

provided. Connect either end to the back of the speaker

and to the Power Console amplifier. The supplied cable

is 18 gauge (No. 18 AWG) and can be used for cable runs

of up to 15m (50 ft) between the speaker and the

amplifier. If cable runs longer than

use the following table to determine the correct wire

gauge.

Maximum

Distance From

Power Console

Amplifier Wire Gauge Recommended Cables

15m are required,

HIGH-FREQUENCY COVERAGE: ON-AXIS SPL

INCREASES AS ANGLE DECREASES

COVERAGE ANGLES

FIGURE

4

If two speakers are stacked for source-oriented installations, horn-to-horn mounting with horns angled

apart to cover separate areas will provide the best

sound dispersion pattern. For stacked and splayed

speakers, the

Judicious speakerlmicrophone placement

60° horn angle is recommended.

andlor the

use of equalization or feedback filters in the sound

system will often relieve acoustic feedback. In addition,

narrowing the horizontal dispersion angle from

120° to

90° or 60° can be effective in remedying high-frequency

feedback conditions, when, for instance, speakers on

stage have dispersion patterns that overlap the pickup

areas of open microphones.

15m (50 ft) AWG 18 Belden

#8460, #8461,

#9470, #8542

30m (1 00 ft) AWG 16 Belden #8470, #8471,

#8472

60m (200 ft) AWG 14 Belden #8473

Preferably, each speaker should be connected to a

separate amplifier output jack to minimize power losses

in the cable. Two parallel-wired Low

FrequencylFull

Range jacks are provided on the back of each 711

Speaker System. This allows connecting two speakers

by connecting the first speaker to the amplifier and the

second speaker to the first. This may be helpful in certain room shapes. However, when speakers are connected in this manner, the next heavier wire gauge is

recommended between the amplifier and the first

speaker. Therefore, for two speakers connected

together where the first is at a distance of 30m (100 ft)

from the amplifier, use No. 14 AWG cable between the

amplifier and the first speaker; for two speakers where

the first is at 15m (50 ft), use No. 16 AWG cable between

the amplifier and the first speaker. When positioning

the speaker cables, place them where the audience, performers, or passers-by will not trip over them.

To avoid frequency response aberrations, poor

coverage, and dead zones caused by improper speaker

phasing in multiple speaker installations, all speakers

must be wired with the same polarity. The cables listed

in the chart above are color-coded to ensure that identical connections are used. Note that even common

18-gauge lamp cord ("zip" cord) is phase-coded with ribs

along the outer jacket of one conductor.

Page 4

The cable can be stored in the convenient snap-

pocket of the optional slip-on cover for the 711 speaker.

25-Volt Line Operation

The 711 can be operated from a 25-volt line without

the need for an accessory transformer. Note that the

speaker will draw 78 watts when connected to a

constant-voltage, 25-volt line.

70-Volt Line Operation

For operation from a 70-volt line, a transformer such

as the Shure Model

A102A, providing power taps of 50,

25, 12, and 6 watts, should be used.

CHECKING SOUND COVERAGE

After the 711 speakers, Power Console amplifiers,

and other equipment have been installed and connected, sound coverage can be checked as follows.

1. Apply a fairly constant-level signal to the system

(preferably low-level pink noise* or program material)

and walk around the audience area. Listen for a

smooth, even output from the speakers, with minimal

differences in volume and tone, and no "dead" spots

or phase distortion.

-

A. A dead spot

sound is heard, or where the sound level is appreciably

not covering that area, or that the speaker wires

are connected out-of-phase. Proper phasing can

be readily determined by checking the connections on each speaker, but inadequate coverage

generally requires repositioning the speakers.

The dead area should be examined carefully to

determine that the problem can be corrected

without resorting to auxiliary speakers.

B.

Phase distortion - a type of distortion distinguishable by being heard only in parts of the audience area-can be due to overlapping areas of

speaker coverage or sound reflecting off hard surfaces. Re-aim the speakers or change the horn

angle to

kind of distortion.

2. Use an Equaiization Analyzer System such as the

for audio purposes, where no direct

lower- may mean that the speakers are

60° or

90°

from 120° to eliminate this

Shure Model

M615AS to supply and analyze a pink

noise signal. An octave equalizer like the ones found

on the Shure Models 700 or 706 PRO

MASTERTM

Power Consoles (or separate equalizers like the

Shure Models

SR107 or M610) can be used to adjust

the sound system for optimum equalization and maximum gain before feedback.

General

The 711 is designed for automatic biamplification

when an amplifier is connected to the high-frequency in-

put switching jack. Using this jack disconnects the

high-frequency driver and crossover from the

lowfrequency woofer and crossover. Separate power

amplifiers are then required for individual connection to

the high- and low-frequency speaker sections.

The advantage of biamplification is the elimination of

high-frequency and intermodulation distortion caused

by high-level low-frequency signals. The separate power

amplifiers used in biamplifying reduce these distortions

and increase the acoustic output.

Biamp Connections

When the 711 is biamplified, the low-frequency sec-

tion is designed to operate with an amplifier capable of

delivering up to 200 watts continuous (40 Vrms,

63.5V

peak) to an &ohm load; and the high-frequency section

is designed to operate with an amplifier capable of

delivering up to 150 watts continuous (34.6 Vrms,

55V

peak) to an &ohm load. To biamplify, an active

crossover is required to separate the high and low frequencies. Set the crossover frequency at 2 kHz, and

connect the crossover high- and low-frequency outputs

B

to separate amplifiers, such as the A and

Power Amps

of the Shure Model 700 Power Console. Connect the

speaker output from the low-frequency amplifier to one

of the jacks marked "Low

FrequencylFull Range", and

connect the speaker output from the high-frequency

amplifier to the jack marked "High Frequency".

GUARANTEE

See enclosed sheet for your Shure Guarantee.

*sine-wave signals delivering

because they present a much greater average power than does pink noise

or program material. Consequently, when setting up or adjusting a sound

system with the

test signals.

711

150

watts to a speaker should be avoided

speaker, avoid the use of high-level, continuous-type

Page 5

REPLACEMENT PARTS LIST

DESIGNATION

A1

A2

A3

A4

Cl

C2

C3

J1, J2

J3

L1

L2

LS1

LS2

M

PI

M P2

M P3

M P4

M

P5

M P6

M P7

PL1, PL2

R1, R2

W1

KIT NO.'

RKC166

RKC157

RKC168

R KC4

QTY.

1

1

1

1

PART NO.

90A8037

90A8053

9083033

90A2636

50H71

50J71

50K71

95Y446

952446

95A8006

95A8021

90A8042

9082650

90A8047

65A999A

53A1563D

53A 1 656C

65A8012A

90A8036

9088036

95A932A

45EC508G

90C1373

DESCRIPTION

High-Frequency Crossover Network (includes L1)

Low-Frequency Crossover Network (less L2)

&

Coil

PL1, PL2)

Overload Protection Kit (includes

High-Frequency Diaphragm

Capacitor, Mylar, 8.0

pF, lo%, 250 WVdc*"

Capacitor, Mylar, 25.0 pF, lo%, 200 WVdc**

Capacitor, Mylar, 15.0 pF, lo%, 200 WVdc"

Connector, Phone Jack, 2-Conductor, Open Circuit

Connector, Phone Jack, Switching Type, 2-Conductor, Closed Circuit

Inductor, 0.4

Inductor, 1.2

mH, 0.40

mH, 0.20

15-inch SMT Woofer

High-Frequency Driver (includes A3, A4)

Grille

Foot, Plastic

Corner Protector, Front

Corner Protector, Rear

Molded Horn, Top or Bottom Section (Order 2 for complete

molded horn)

Slider Vane, Left

Slider Vane, Right

Lamp, Automotive 1156

Resistor, 54

Cable,

22W, 10%

15.2m (50 ft) with Phone Plugs

Parts listed as RKC Kits should be ordered by that kit number. Any orders received for piece parts where RKC Kit number is

shown will be shipped in RKC quantities.

"

Selected for low dissipation factor.

CROSSOVER NETWORKS

BLACK

LOW

FREWENCY/

FULL

RANGE

H16H

FREQUENCY

BLACK

-...

BLUE

\

\

- - - - - -

RED

GRAY

-

I

LS

1

CIRCUIT

FIGURE

DIAGRAM

5

Page 6

SERVICE

Diagnosing the Problem

1.

Disconnect the speaker cables.

2.

Using an ohmmeter, measu.re the resistance between

the tip and sleeve of either Low

Range phone jack. The dc resistance should be 5 to

ohms. A clicking sound will usually be made by a

"good" woofer when an ohmmeter is connected or

disconnected (although a digital multimeter may not

produce a click).

NOTE: This test checks only the woofer and the

series inductor in the low-frequency crossover network.

3.

For access to the high-frequency driver, crossover

network, and protection circuit, proceed as follows.

NOTE: This is most easily done by supporting the

cabinet on its back with the head of the large bolt in

the upper center of the cabinet back hanging over the

edge of the bench.

A. Unscrew and remove the

B. Pull the horn and driver out of the cabinet. Free it

4.

Using an ohmmeter, measure the resistance between

the driver terminals and across the terminals of each

lamp in the protection circuit. The dc resistance of

the driver should be

may be made by a "good" driver as described in step

2

above. The dc resistance of a cold lamp should be

approximately 0.4 ohms.

5. If the above tests do not locate the problem, apply a

small ac voltage from an oscillator and amplifier to

each speaker individually. Use approximately

Hz to

Hz to 15 kHz for the high-frequency driver. As the test

signal frequency is varied, any erratic buzzes or rattles indicate possible problems.

INSTRUCTIONS

FrequencylFull

8/,,

in. hexhead bolt from

the upper center of the cabinet back.

from the cabinet by disconnecting from the

crossover the red and gray leads that go to the

jack panel.

5

to 7 ohms; a clicking sound

4V,

50

3

kHz for the woofer, and approximately

2V,

500

WARNING

Sound pressure levels generated by this test may

be damaging to your hearing. Aim speakers away

from listeners and toward sound-absorbent

material (curtains, blanket, etc.) Carefully adjust

test signal amplitude to avoid unnecessarily high

sound pressure levels for prolonged periods.

6. To reassemble the horn and driver, connect the jack

panel leads (see Figure 5): red lead to the crossover

terminal with a red lead on it (center terminal of three

in a row); gray lead to the terminal with a gray lead on

it (outside terminal [toward the mouth of the horn] of

three

in

a row).

7

7.

With the crossover facing the top of the cabinet,

replace the driver and horn by inserting it in the

cabinet and firmly tightening the bolt.

Replacing the 1Binch Woofer or Gaining Access to the

Jack Panel and Low-Frequency Crossover

1.

Remove the grille by pulling the tabs.

2.

Supporting the cabinet on its back, remove the eight

screws that hold the woofer in place.

3.

Pull the woofer upward out of the cabinet and disconnect the red and black leads from the woofer terminals. The woofer is now free from the cabinet and

can be lifted out and removed. Take care not to

damage the cone nor to break the leads when doing

this.

4.

Before replacing the woofer, connect the leads: red

lead to the red coded terminal.

5. Insert the woofer in the cabinet and tighten the eight

previously removed screws.

6. Press the grille back in place.

Replacing the High-Frequency Driver

1. Remove the horn and driver as described in step 3 of

the section

2.

At the crossover, disconnect the white and gray

leads that come from the driver, and the red leads

that come from the overload protection lamps.

3.

Unscrew the driver from the back of the horn.

NOTE: The diaphragm and coil

overload protection lamps

Instructions for replacement are enclosed with the

replacement part kit.

4. When reassembling, screw the driver to the back of

the horn. Tighten the driver by hand. Do not use a

wrench or other tools.

5.

Connect the white and gray driver leads to the

crossover (see Figure 5): white lead to the inner terminal of three in a row (toward the throat of the horn);

gray lead to the outside terminal of three in a row

(toward the mouth of the horn). Connect one red lamp

lead to the empty terminal and the other red lamp

lead to the single terminal closest to the throat of the

horn.

6. Replace in the cabinet as described in steps 6 and 7

of

Diagnosing the Problem.

Diagnosing the Problem.

(RKC157) and the

(RKC166) can be replaced.

SOUND OF

THE

PROFESSIONALS@

Loading...

Loading...