Page 1

222 HARTREY AVE.. EVANSTON,

AREA

CODE

TWX: 910- 231-0048 TELEX: 72-4381

31z/866-2~00

.

CABLE:

IL.

UNIDIRECTIONAL DYNAMIC MICROPHONE

GENERAL

The Shure Model 515BG UNIDYNEB B Microphone

is a low-impedance unit designed specifically for

mounting on

microphone is a moving coil unit providing good

reproduction of music and voice.

This microphone is particularly suitable for use in

language lab systems, paging applications, and base

station communications. It is highly recommended for

talk-back and cuing from professional control rooms

TV,

in

film, and recording studios, and other uses demanding a customized installation with concealed

cables.

Microphone Features:

True cardioid pickup pattern: symmetrical about

axis and uniform at all frequencies

Response especially effective for announcing,

narration, paging and music

Cartridge shock mounted for quiet operation

Dependability and ruggedness under all operating conditions

A %"-27 thread for mounting to a gooseneck

%"-27 thread arm or gooseneck. The

60204 U.S.A.

SHUREMICRO

MODEL 515BG

UNIDYNE@ B

I

MODEL 515BG

MOUNTED ON

GOOSENECK

SPECIFICATIONS

TY pe

Dynamic

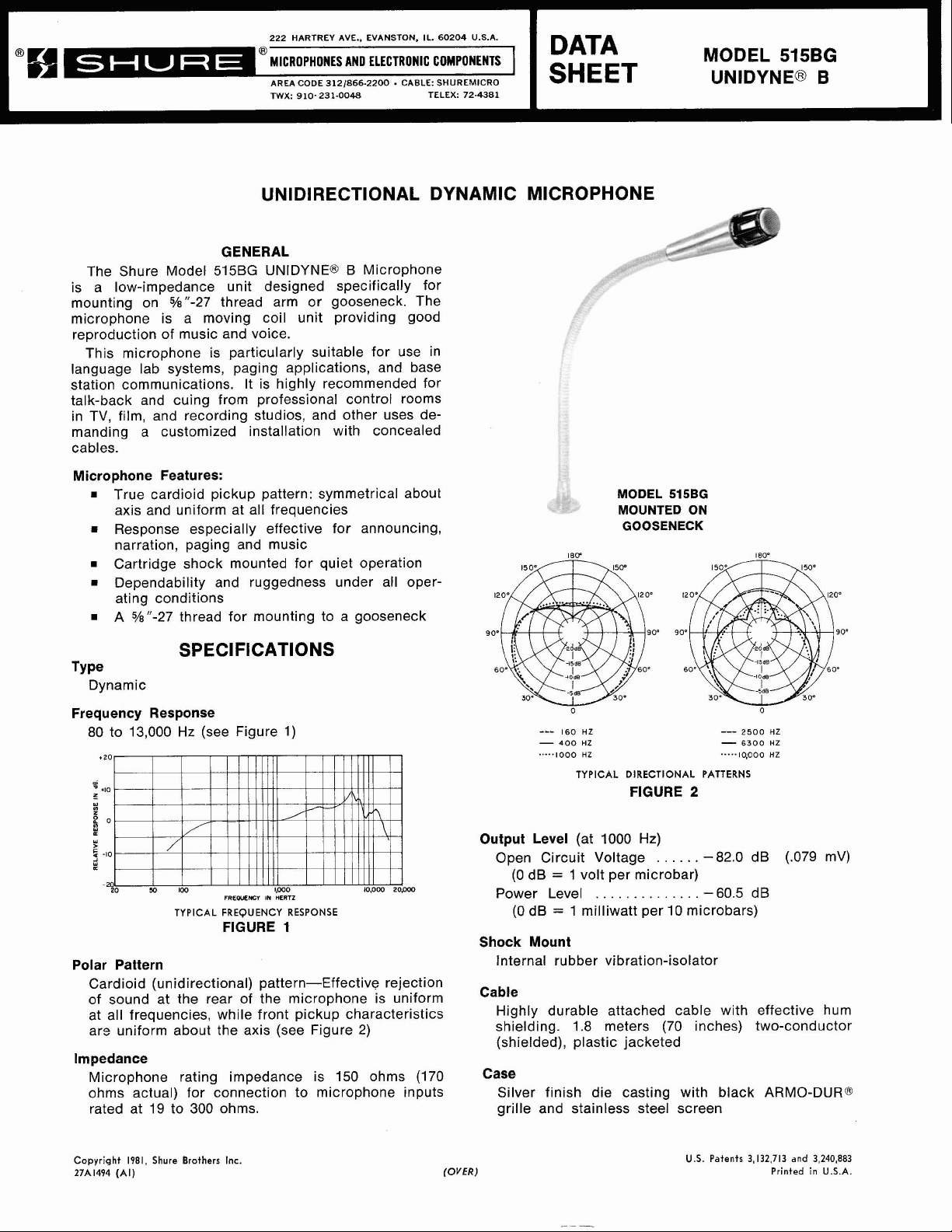

Frequency Response

80 to 13,000 Hz (see Figure

20

m

IM)

FREwENcY

TYPICAL

FREQUENCY

FIGURE

Polar Pattern

Cardioid (unidirectional) pattern-Effective rejection

of sound at the rear of the microphone is uniform

at all frequencies, while front pickup characteristics

are uniform about the axis (see Figure

Impedance

Microphone rating impedance is 150 ohms (170

ohms actual) for connection to microphone inputs

rated at 19 to 300 ohms.

1)

1.000 10.000 20m

IN

HERTZ

RESPONSE

1

2)

o o

---

160

HZ

-

400

HZ

.....

1000

HZ

TYPICAL

Output Level

(at 1000 Hz)

Open Circuit Voltage

DIRECTIONAL

FIGURE

. . .

2

.

.

.

---

2500

-

6300

.....

10.000

PATTERNS

-

82.0 dB

HZ

HZ

HZ

(.079 mV)

(0 dB = 1 volt per microbar)

. . . . .

.

.

. . .

. . . .

-

Power Level

60.5 dB

(0 dB = 1 milliwatt per 10 microbars)

Shock Mount

Internal rubber vibration-isolator

Cable

Highly durable attached cable with effective hum

shielding. 1.8 meters (70 inches) two-conductor

(shielded), plastic jacketed

Case

Silver finish die casting with black ARMO-DUR@

grille and stainless steel screen

Copyright

27A1494

1981,

(Al)

Shure

Brothers

Inc.

(OVER)

U.S.

Patents

3,132,713

Printed

and

3,240,883

in

U.S.A.

Page 2

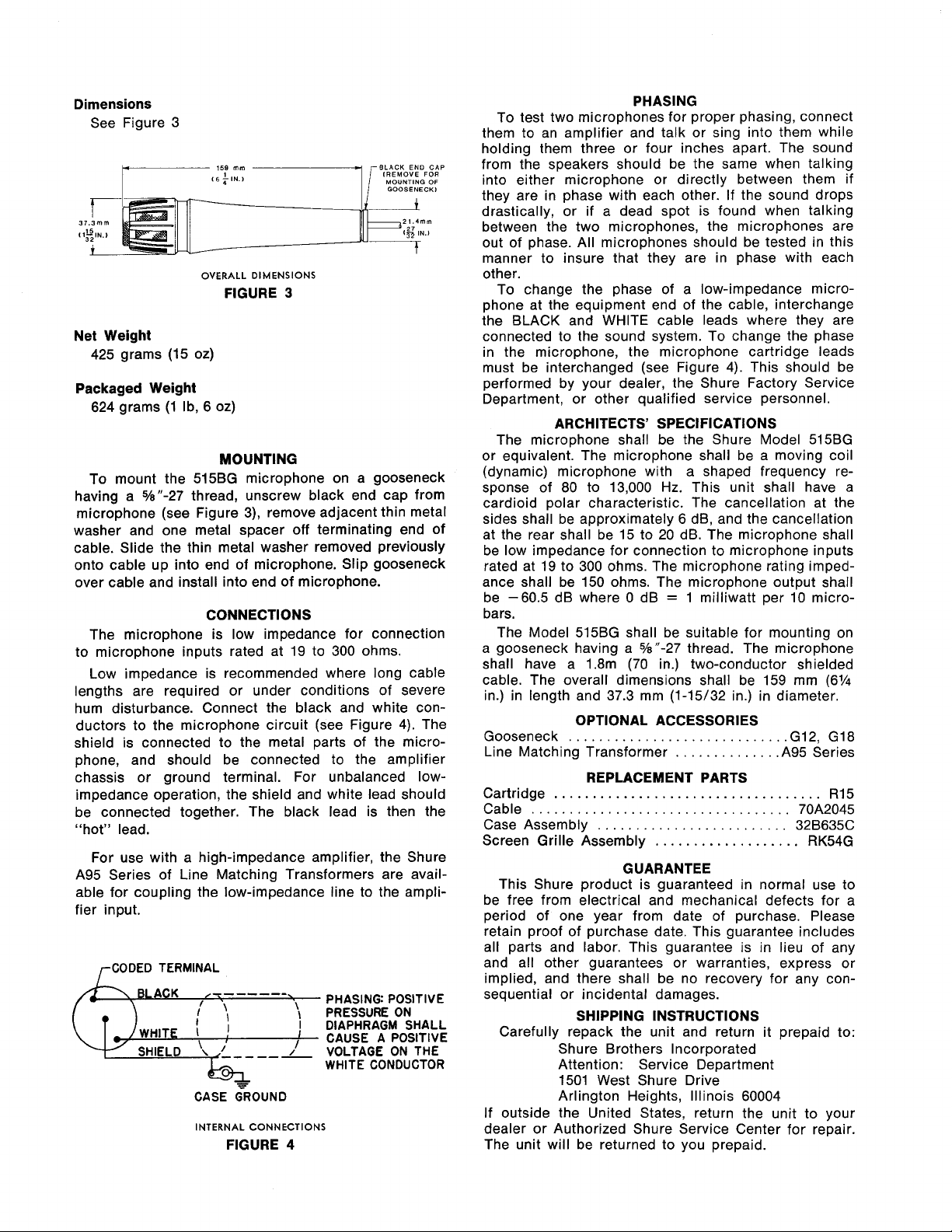

Dimensions

See Figure 3

-

OVERALL

FIGURE

DIMENSIONS

3

BLACK END CAP

IREMOVE

FOR

MOUNTING OF

GOOSENECK1

Net Weight

425 grams (15 oz)

Packaged Weight

624 grams (1 Ib, 6 oz)

MOUNTING

To mount the 515BG microphone on a gooseneck

having a

microphone (see Figure

Y8"-27 thread, unscrew black end cap from

3),

remove adjacent thin metal

washer and one metal spacer off terminating end of

cable. Slide the thin metal washer removed previously

onto cable up into end of microphone. Slip gooseneck

over cable and install into end of microphone.

CONNECTIONS

The microphone is low impedance for connection

to microphone inputs rated at 19 to 300 ohms.

Low impedance is recommended where long cable

lengths are required or under conditions of severe

hum disturbance. Connect the black and white con-

ductors to the microphone circuit (see Figure 4). The

shield is connected to the metal parts of the micro-

phone, and should be connected to the amplifier

chassis or ground terminal. For unbalanced

lowimpedance operation, the shield and white lead should

be connected together. The black lead is then the

"hot" lead.

For use with a high-impedance amplifier, the Shure

A95 Series of Line Matching Transformers are available for coupling the low-impedance line to the amplifier input.

CODED TERMINAL

r

------

INTERNAL

FIGURE

-

-

CONNECTIONS

4

PHASING: POSITIVE

PRESSURE ON

DIAPHRAGM SHALL

CAUSE A POSITIVE

VOLTAGE ON THE

WHITE

CONDUCTOR

PHASING

To test two microphones for proper phasing, connect

them to an amplifier and talk or sing into them while

holding them three or four inches apart. The sound

from the speakers should be the same when talking

into either microphone or directly between them if

they are in phase with each other. If the sound drops

drastically, or if a dead spot is found when talking

between the two microphones, the microphones are

out of phase. All microphones should be tested in this

manner to insure that they are in phase with each

other.

To change the phase of a low-impedance microphone at the equipment end of the cable, interchange

the BLACK and WHITE cable leads where they are

connected to the sound system. To change the phase

in the microphone, the microphone cartridge leads

must be interchanged (see Figure 4). This should be

performed by your dealer, the Shure Factory Service

Department, or other qualified service personnel.

ARCHITECTS' SPECIFICATIONS

The microphone shall be the Shure Model 515BG

or equivalent. The microphone shall be a moving coil

(dynamic) microphone with a shaped frequency response of 80 to 13,000 Hz. This unit shall have a

cardioid polar characteristic. The cancellation at the

6

sides shall be approximately

dB, and the cancellation

at the rear shall be 15 to 20 dB. The microphone shall

be low impedance for connection to microphone inputs

rated at 19 to 300 ohms. The microphone rating imped-

ance shall be 150 ohms. The microphone output shall

be -60.5 dB where

0 dB = 1 milliwatt per 10 micro-

bars.

The Model

a gooseneck having a

shall have a

cable. The overall dimensions shall be 159 mm

515BG shall be suitable for mounting on

%"-27

thread. The microphone

1.8m (70 in.) two-conductor shielded

(6%

in.) in length and 37.3 mm (1-15132 in.) in diameter.

OPTIONAL ACCESSORIES

Gooseneck

Line Matching Transformer

.............................

.............

.A95 Series

G12, GI8

REPLACEMENT PARTS

Cartridge

Cable

Case Assembly

Screen Grille Assembly

...................................

..................................

.........................

32B635C

...................

R15

70A2045

RK54G

GUARANTEE

This Shure product is guaranteed in normal use to

be free from electrical and mechanical defects for a

period of one year from date of purchase. Please

retain proof of purchase date. This guarantee includes

all

parts and labor. This guarantee is in lieu of any

and all other guarantees or warranties, express or

implied, and there shall be no recovery for any consequential or incidental damages.

SHIPPING INSTRUCTIONS

Carefully repack the unit and return it prepaid to:

Shure Brothers Incorporated

Attention: Service Department

1501 West Shure Drive

Arlington Heights, Illinois 60004

If outside the United States, return the unit to your

dealer or Authorized Shure Service Center for repair.

The unit will be returned to you prepaid.

Loading...

Loading...