Page 1

Beta 53

User Guide

HEADWORN MICROPHONES

2002, Shure Incorporated

27C3115 (BF)

Printed in U.S.A.

Page 2

ENGLISH

GENERAL

The Shure Beta 5 3 i s a s ubminiature, e lectret c ondenser headworn m icrophone. It is

intended for w ireless u se i n s ound r einforcement a pplications t hat r equire m inimal v isibility and maximum mobility, such as stage performances.

Despite its small size, the microphone element provides full, articulate reproduction

of speech and vocals, and features an omnidirectional pick-up pattern.

The Bet a 5 3 c o n si s ts of an adjustable wireframe a nd boom that allows flexible p lacement of t he m icrophone c artridge. It is a ls o s upplied w ith t wo d ifferent e qualization c aps

that tailor the microphone’s high-frequency response. Acoustic windscreens are supplied to minimize wind noise.

MODEL VARIATIONS

WBH53B: Black microphone with 5’ cable, terminated with a TA4F connector.

WBH53BX: Black microphone with 10’ cable, no connector.

WBH53T: Beige microphone with 5’ cable, terminated with a TA4F connector.

WBH53TX: Beige microphone with 10’ cable, no connector.

FEA TURES

S Interchangeable equalization caps that tailor the microphone’s frequency

response

S Cable clips provide cable management and strain relief

S Offered in black or beige with matching accessories

S Adjustable headband

S Adjustable boom mounts on either side of the head

ACCESSORIES

Windscreens. Acoustic foam windscreens are supplied to help reduce undesirable

wind and breath noise.

Equalization Caps. The Beta 53 is supplied with two types of equalization caps for

high frequency response shaping. The caps differ in response between the frequency range of 5,000 to 20,000 Hz (see Figure 8), and can be distinguished by their

mesh color . The mild boost equalization cap has a silver mesh screen, while the high

boost equalization cap has a gold mesh screen.

Clothing Clip. A clothing clip is supplied with the Beta 53 for cable management

and additional strain relief.

3

Page 3

ENGLISH

USING THE BETA 53 IN HARDWIRED APPLICATIONS

An in-line preamplifier (Shure part no. RPM626) may b e u sed w ith t he B e ta 5 3. T his

device requires phantom power ranging from 11 to 52 Vdc.

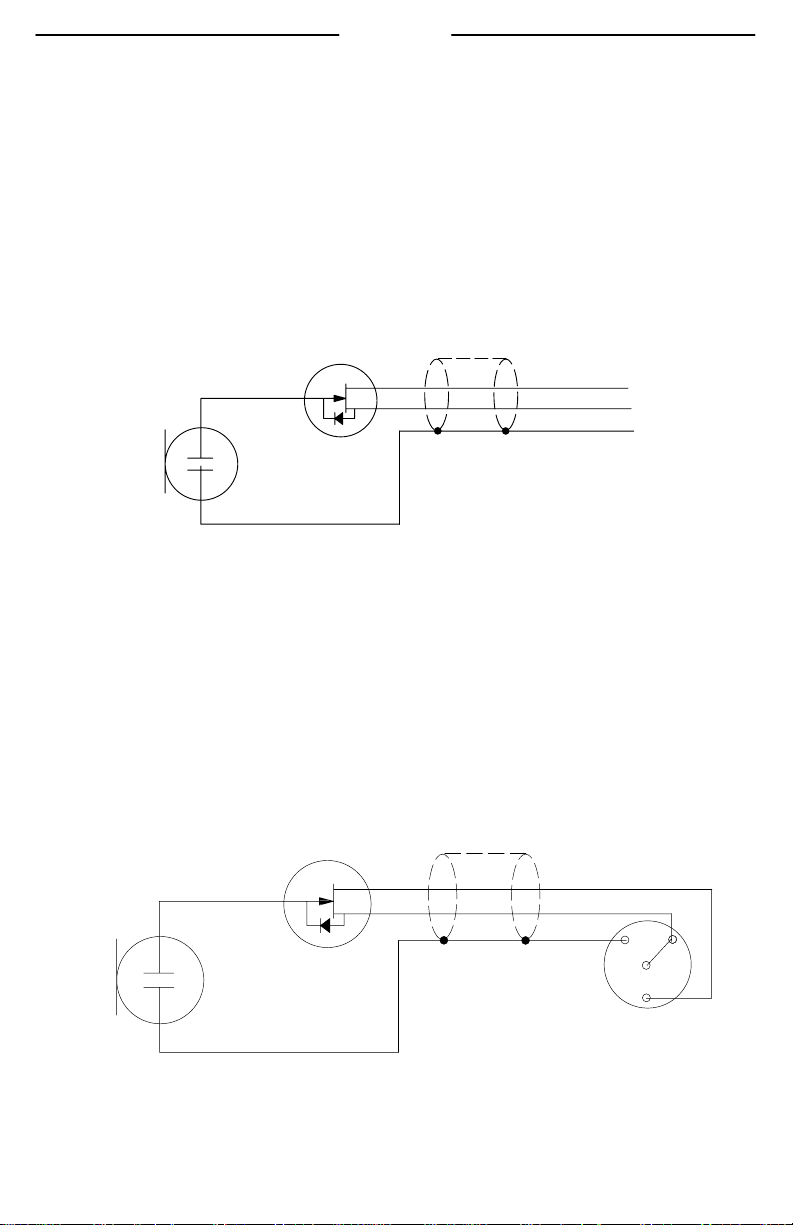

USING THE BETA 53 WITH OTHER BODYPACK TRANSMITTERS

If connecting the microphone to anything OTHER than a Shure wireless bodypack,

make sure it provides a regulated +5 Vdc source (130

mA minimum) to the red con-

ductor, as shown in Figure 1.

CONDENSER

CARTRIDGE

IMPEDANCE

CONVERTER

G

D+

S

RED

BLK

SHIELD

+5 Vdc (130 mA min.)

Audio Out

MICROPHONE WIRING DIAGRAM

FIGURE 1

USING THE BETA 53 WITH THE TA4F CONNECTOR

The following diagram shows how the Beta 53 is wired to the TA4F connector.

IMPEDANCE

CONVERTER

CONDENSER

CARTRIDGE

G

D

S

RED

BLK

SHIELD

+5 Vdc

Audio Out

1

4

2

3

TA4F CONNECTOR WIRING DIAGRAM

FIGURE 2

4

TA4F (solder side view)

Page 4

MICROPHONE PARTS

ENGLISH

Å

Ä

Æ

À Microphone Cartridge

Á Microphone Boom

À

Á

Ã

Â

Boom Clip (rotates as shown)

à Cable

Ä Wireframe

Å Strain relief clips

Æ Earforms

WBH53 HEADWORN MICROPHONE PARTS

FIGURE 3

REVERSIBLE AND ADJUSTABLE BOOM

The Beta 53 boom can be placed on either side of the wireframe. Snap the boom

into the boom clip, which can be rotated as shown in Figure 3. The boom can also

slide forward and backward in the boom clip to adjust the microphone-to-mouth distance. CAUTION! Do not attempt to bend the boom itself. Adjust the boom by rolling

it closer to or further away from the mouth.

WEARING THE WBH53

Place the wireframe around your head so the earforms go over the ears from behind

and the wireframe lays horizontally across the base of the skull (see Figure 4).

WEARING THE BETA 53

FIGURE 4

5

Page 5

ENGLISH

POSITIONING THE MICROPHONE

For best performance, the Beta 53 microphone should be placed at the corner of the

mouth, and as close to the mouth as possible without touching any skin or facial hair

(see Figure 5). If necessary, the boom can be “rolled away” from the mouth to avoid

contact with facial hair (see Figures 6 and 7).

CORRECT POSITIONING OF THE MICROPHONE

FIGURE 5

INCORRECT POSITIONING OF THE MICROPHONE

FIGURE 6

“ROLLING” THE MICROPHONE BOOM

FIGURE 7

6

Page 6

ENGLISH

SPECIFICATIONS

(measured with a standard test circuit, see Figure 9 on page 33).

+20

+10

0

–10

–20

RELATIVE RESPONSE IN dB

–40

500 1,000 2,000 5,000 10,000 20,00050 100 20020

FREQUENCY IN Hz

High Boost Equalization Cap

Mild Boost Equalization Cap

TYPICAL FREQUENCY RESPONSE

FIGURE 8

Type

Condenser (electret bias)

Frequency Response

20 to 20,000 Hz (see Figure 8)

Polar Pattern

Omnidirectional

Recommended Minimum

Input Impedance

20 kW

Output Level

Open Circuit Voltage

-54 dBV/Pa

1 Pascal = 94 dB SPL

Maximum Sound Pressure Level

142 dB at 1% THD/1 kW load

Dynamic Range

103 dB

Output Noise

(equivalent SPL, A-weighted)

39 dB typical; 42 dB maximum

Signal-to-Noise Ratio

55 dB at 94 dB SPL

Current Drain

60–130 mA

Polarity

Positive pressure on the diaphragm

produces a positive voltage at pin 3

relative to pin 1 at the output connector of the microphone.

Power Requirements

+5 Vdc on pin 2, return on pin 1

(ground)

Environmental Conditions

Operating Temperatures:

_

_

-18

to 57

Storage Temperatures:

_

-29

to 74

C (0

_

C (-20

_

to 135

_

to 165

_

F)

_

F)

Humidity: 0 to 95%

Cable

1.5 m (5 ft), small-diameter, shielded, with mini 4–pin connector

(TA4F), or 3 m (10 ft.) small-diameter, shielded, no connector.

Net Weight

35.35 g (1.25 oz.) with cable and

TA4F connector.

7

Page 7

ENGLISH

Certification

Eligible to bear CE marking. Conforms to European EMC directive 89/336/EEC.

Meets applicable tests and performance criteria in European EMC Standard EN

55103 (1996) parts 1 and 2, for residential (E1) and light industrial (E2) environments. Meets applicable test and performance criteria in European wireless microphone EMC standard ETS 300445 (1996) as an “ancilliary device.”

FURNISHED ACCESSORIES

Foam windscreens (2 pcs.), black or beige

High Boost Equalization Caps (2 pcs.), black or beige

Mild Boost Equalization Caps (2 pcs.), black or beige

Swiveling Lapel Clip (1 pc.), black or beige

Plastic Carrying Case, black

OPTIONAL ACCESSORIES

In-line Preamplifier RPM626. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phantom Power Supply (requires the use of an in-line preamplifier) PS1A. . . . . . .

Battery Operated Preamplifier MX1BP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPLACEMENT PARTS

High Boost Equalization Cap (5 pcs.)

Black RPM208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Beige RPM212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mild Boost Equalization Cap (5 pcs.)

Black RPM220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Beige RPM214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Swiveling Lapel Clip (5 pcs.)

Black RPM510. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Beige RPM512. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Boom Holder and Logo Pad (2 pcs.)

Black RPM570. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Beige RPM580. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foam Windscreens (5 pcs.)

Black RPM304. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Beige RPM306. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plastic Carrying Case for Beta 53, black 95A2180. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Headband for Beta 53

Black RPM550. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Beige RPM560. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mini 4–pin Connector (TA4F) WA330. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Microphone and Boom Assembly for Beta 53, Mini 4–pin Connector (TA4F)

Black RPM132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Beige RPM134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Microphone and Boom Assembly for Beta 53, Tinned Leads (No Connector)

Black RPM136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Beige RPM138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

Page 8

20 k

1.0 uf

3

1

4

2

5 Vdc

100 k

STANDARD TEST CIRCUIT S CIRCUIT D’ESSAI S PRUFSCHALTUNG S

CIRCUITO DE PRUEBA S CIRCUITO DI PROVA

FIGURE 9 S FIGURE 9 S ABBILDUNG 9 S FIGURA 9 S FIGURA 9

33

Page 9

Patent Notice: Patent Des. 451,902

SHURE Incorporated Web Address: http://www.shure.com

222 Hartrey Avenue, Evanston, IL 60202–3696, U.S.A.

Phone: 847-866–2200 Fax: 847-866-2279

In Europe, Phone: 49-7131-72140 Fax: 49-7131-721414

In Asia, Phone: 852-2893-4290 Fax: 852-2893-4055

Elsewhere, Phone: 847-866–2200 Fax: 847-866-2585

Loading...

Loading...