Shuangdeng Group Co. GFM, GFM-200, GFM-300, GFM-400, GFM-500 Series Manual

...

Statement

The copyright of this document only belongs to Shuangdeng

Group Co.,Ltd.Any excerpt, copy or translation is prohibited without

the written permission of the writer.

Any pirate must be published.

is our registered trademark. The name and trademark of the

product of Shuangdeng Group is our unique mark. Other products

belongs to their respective owners. Without any prior written

consent of Shuangdeng Group or the third party trademark or the

commodity name owners, this manual gives nobody any right to

use the mark appeared in this manual.

This product complies with the design requirement in

environmental protection and human safety. The storage, usage

and discard of this product should be refer to the manual, contract

or relative laws.

For the update and perfection of the product, please understand

that the information in this manual may differ partially from the real

product.

For the latest information, please dial the market hotline.

Foreword

Manual Description

GFM Series VRLA Battery is the product of Shuangdeng Group. GFM Series VRLA Battery

User s Manual is the manual accompanied with the battery. Please read the manual carefully in

advance.

Introduction

installation dimension and method, and maintenance.

Section 1

Section 2

Section 3

GFM Series VRLA Battery User s Manual introduces the technical parameter, principle,

Safety introduction containing some watchful safety proceedings during batteries s

installation operation and maintance

Summarization containing GFM series battery model product sampling product

conveying and using ambient requirement parts denomination product specification

and main parameters

Usage and maintenance containing maintenance watchful proceedings charge

method relationship of temperature and capacity relationship of temperature and

cycle life capacity checking switch power parameters setting using requirement

under power off condition maintenance periods and requirements

.

.

.

It is promised that:

We apply four eye-catching marks to show the special noticed points in operating.

notice caution warning danger: show the special operation

precautions.

Appendix

Chapter 1 Safety Instruction ....................................................................... 26

1.1 Abstract............................................................................................. 26

1.2 Precautions ....................................................................................... 26

Chapter 2 Summary ..................................................................................... 28

2.1 Model Introduction ............................................................................ 28

2.2 Sampling ........................................................................................... 28

2.3 Conveying ......................................................................................... 28

2.4 Storage ............................................................................................. 29

2.5 Dimension and Weight ...................................................................... 29

2.6 Battery Appearance and Each Part Denomination ........................... 30

2.7 Operation Environment and Precaution. ........................................... 31

2.8 Check After Installation ..................................................................... 31

Chapter 3 Operation and Maintenance ...................................................... 35

3.1 Operations ........................................................................................ 35

3.1.1 Precaution ................................................................................ 35

3.1.2 Battery Charging ...................................................................... 35

3.1.3 Temperature Effects the Battery Capacity ................................ 36

3.1.4 Temperature Impact on the Battery Life .................................... 37

3.1.5 Capacity Determination ............................................................ 38

3.1.6 The Parameter Set of the Switch Power Supply ....................... 38

3.1.7 The Application Requirements for Power Supply Interruption

Time .................................................................................................. 40

3.2 Maintenance Period and Requirements ............................................ 40

Operation Instruction of Battery Recharging 42

Chapter 1 Safety Instruction

1.1 Abstract

This chapter introduces about the safety signs and the precautions. Please carefully

read it before operation to ensure safety.

Safety Signs

The safety signs indicate the safety issues that should be conformed to in installation,

operation and maintenance. The safety signs are shown as following Table1.1-1

Table1.1-1 Safety Signs and Meanings

Safety Signs Meaning

Safety Notice

Electric Shock

1.2 Precautions

Before any operation of the equipment, please carefully read all the safety

instructions in this manual to avoid personal injury or equipment damage.

Shuangdeng Group bears no liability to the consequences incurred by violation of the

general safety operation requirement, or violation of the safety standards for designing,

manufacturing and using the equipment.

1. The battery pack has high voltage, so direct contact or indirect contact through wet

objects with any conducting cable may result in vital injury. The battery pack is

energy-storing equipment, so never short-circuit the battery pack during operation

and maintenance in any way.

2. Do not wear watch, hand chain, bracelet, ring and other conductive objects during

operation.

3. Only qualified and professional personnel are allowed to install, operate and maintain

the equipment.

4. Do use special tools.

Do use special tools, instead of common tools during electrical connections. In

addition, keep the tools in good insulation condition (e.g. wrap insulating tape around

the bare metal parts) before using them to avoid short circuit and personal injury

caused by tool contact with any live objects.

5. Using the batteries of the same model

Use batteries of the same model in the same set. Using different models in the same

set will damage the equipment.

6. Fire hazard

During battery installation, make sure to fix the connecting terminals of the

conducting wire tight, and keep the output terminals of the batteries clean. Otherwise,

it may lead to a high temperature of battery terminals and even to spark/fire.

7. Operation regulation

Before battery operation, read the safety precaution/instruction, and the operation

instructions, especially the battery interconnection instructions.

Substandard operation will cause danger. Prevent battery short circuit and

prevent battery electrolyte from flowing out. Overflowed electrolyte is a latent danger

and it will erode the metal object and circuit board, thus damaging the equipment and

causing short circuit of the circuit board.

8. The Operation Environment

The battery should be kept far away from fire, organic solution; avoid direct sunshine

and the temperature should be the same of the same set.

Chapter 2 Summary

Abstract

product sampling product

conveying and using ambient requirement parts denomination product specification and

main parameters.

2.1 Model Introduction

GFM series valve-regulated lead-acid battery(following called GFM battery for short)

belong to SHUANGDENG

structure rated voltage per cell is 2V. Take GFM-500 for example, its mean as fig.2.1-1

showing.

In the fig.2.1- -regulated lead-acid battery, the figure

presents battery

.

GFM-500

valve-regulated

lead-acid battery

Fig.2.1-1 GFM-500 battery type and description

2.2 Sampling

Choosing batteries should consider use frequency, discharge current, discharge

time and so on. The capacity should be a bit larger to prevent battery from damage

caused by over-discharge or larger current discharge. Discharge current often be

controlled less than 0.1C10A.

2.3 Conveying

Terminal protection is well done, the coping of the battery cannot suffer the pressure,

rated capacity C

unit:Ah

10

safety valve cannot become flexible, and short circuit is prohibited when batteries are

conveyed. Batteries should stand up at the time of transporting and cannot set upside

down, roll, throw, bump, insolate or drench during conveying.

2.4 Storage

1. Batteries can be stored in the environment of 0-35°C before installation. The storage

time is usually 3-6months. Batteries should be charged if the storage time exceeds 6

months.

2. Batteries should be kept in the dry, clean and ventilated environment. They cannot be

kept in the environment of radiation, organic solvent and corrosive gas. They should

be kept away from fire and avoid sun irradiation.

3. Batteries should stand up, safety valve cannot become flexible and batteries without

package box cannot be overlapped.

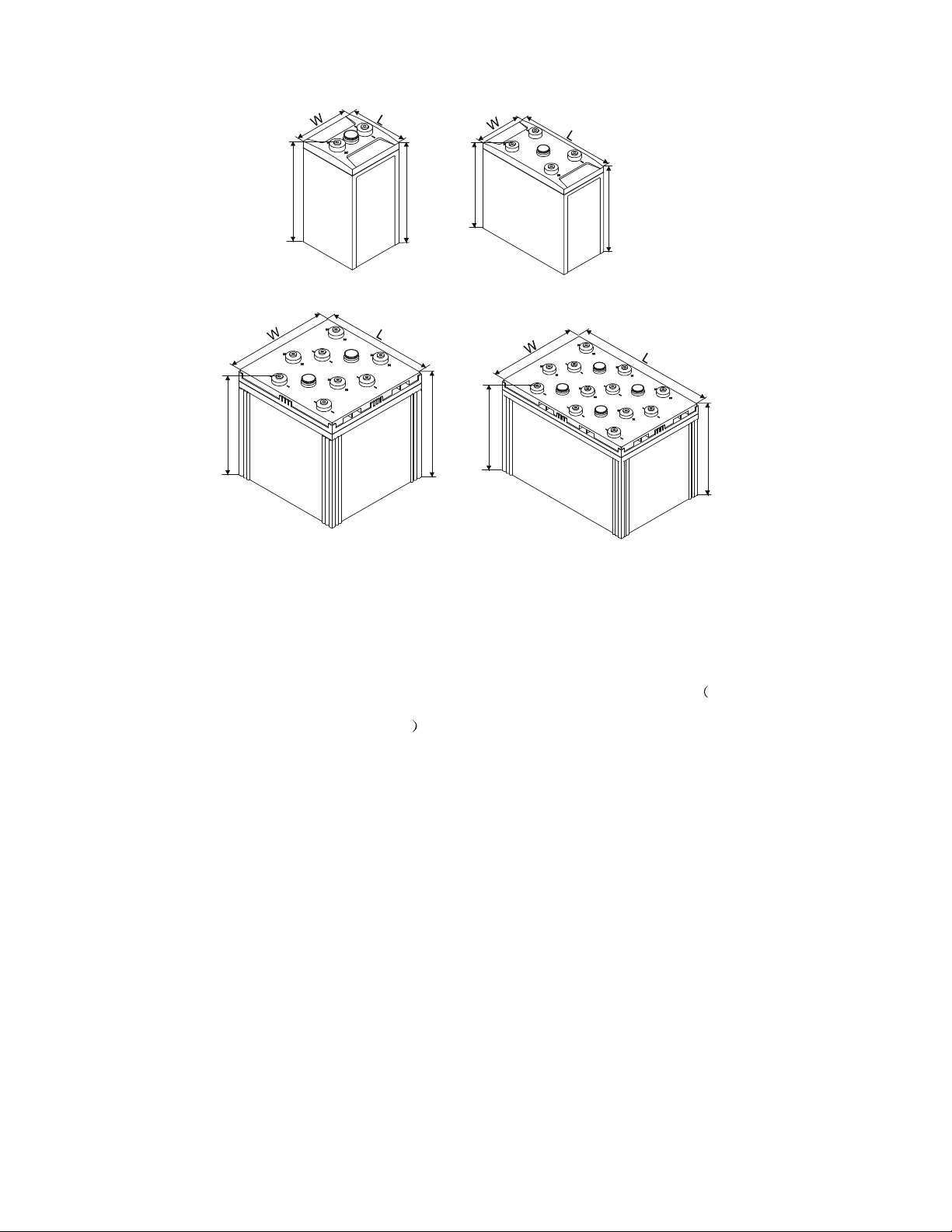

2.5 Dimension and Weight

Table2.5-1 Battery parameters

Dimensions(mm)

Type

L W H TH

Weight

(Kg)

GFM-200 90 181 346 365 12.5 0.90

GFM-300 124 181 346 365 17.6 0.60

GFM-400 158 181 346 365 23.0 0.51

GFM-500 191 181 346 365 28.6 0.41

GFM-600 225 181 346 365 33.2 0.39

GFM-800 303 181 346 365 45.4 0.38

GFM-1000 370 181 346 365 56.5 0.36

Internal

resistance

Terminal

M8

M8

M8

M8

M8

M8

M8

GFM-1600 318 363 369 388 98.0 0.20 M8

GFM-2000 385 363 369 388 117.0 0.18 M8

GFM-3000 568 363 369 388 178.0 0.17 M8

TH

H

TH

H

TH

GFM-200~600

H

GFM-800~1000

TH

GFM-1600~2000

GFM-3000

Fig.2.5-1 Battery figuration

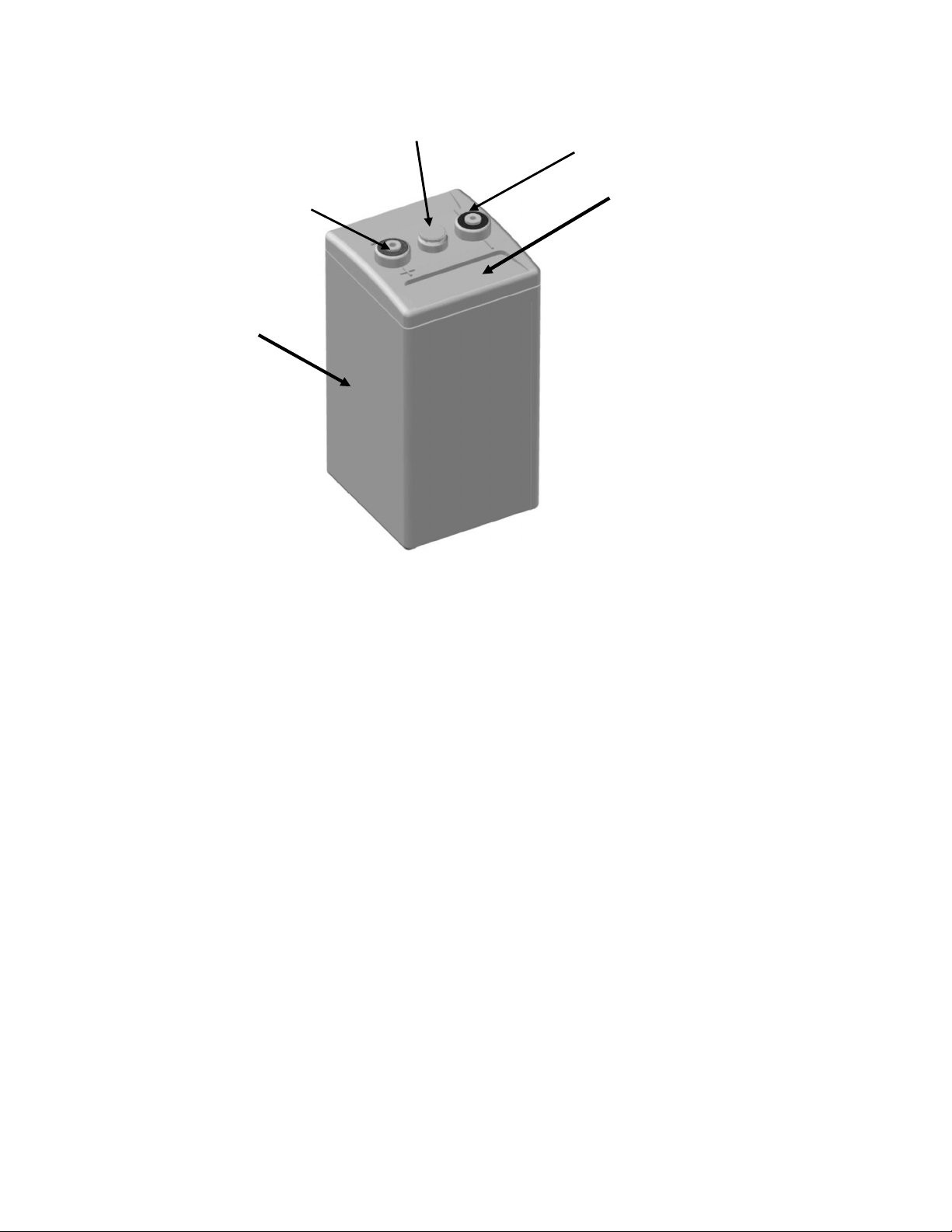

2.6 Battery Appearance and Each Part Denomination

Following is the appearance and each part denomination of GFM battery take

GFM-500 for example, as fig. 2.6-1

H

safety valve

negative terminal

positive terminal

container

cover

Fig.2.6-1 Battery figuration and accessories

2.7 Operation Environment and Precaution.

The battery servicing surroundings should be dry, clean and airy, without large

1.

quantity of irradiation, infrared ray radiation, organic solvents and corrosive gas, and

avoided the direct sun shining. the temperature not exceed 35°C.

2. The ventilation hole of the heater or air-conditioner should not directly face the battery,

and the temperature difference of the each part of the battery should not be higher

than 3°C, and using the infrared ray thermometer to determine the each part

temperature of the battery is suggested.

3. The battery can be installed with the battery cabinet or shelf provided by the

manufacturer. If the battery is installed in the storied buildings, the load requirements

should be inquired from the construction department. The earthquake-preventing

supporting shelf which is fixed with ground foot bolt should be designed in order to

diffuse the stress in the district whose anti-earthquake intensity is more than 7

degree.

Loading...

Loading...