Installation Instruction

Heatshrink Termination For 3 Core

Pilc Belted Cables 12kV

! PLEASE READ INSTRUCTIONS THOROUGHLY BEFORE PROCEEDING

! INSTALLATION SHOULD BE CARRIED OUT BY A TRAINED COMPETENT

FITTER

INDOOR

OUTDOOR

UNITS P1-P3 GROVEMERE COURT BICTON INDUSTRIAL PARK KIMBOLTON CAMBS PE28 OEY

TEL: +44 (1480) 861001 FAX: +44 (1480) 861002 E-MAIL: info@shrinkpolymersystems.co.uk

WEBSITE: www.shrinkpolymersystems.co.uk

©

General Fitting Instructions

CONNECTION

TYPE

LENGTH INDOOR

L

LENGTH OUTDOOR

L

X

STRAIGHT

CONNECTION

650mm 650mm

LENGTH OF

BARREL

CROSSED

CONNECTION

700mm

NOT

APPLICABLE

+ 10%

! It is highly recommended that suitable tools are utilised for the

correct preparation on Paper Cables

! Use a propane gas torch with a soft flame

! Avoid a pencil like blue flame which is caused by unregulated supply

! Keep the flame on the move to ensure even shrinkage of all the

materials and also helps to reduce scorching

! Ensure that all components are kept clean and grease free during

installation

! Allow to cool before applying any mechanical strain

Remove Outer Cable Sheath:

Table 1

Alternative tail lengths available upon request.

Note:- If T erminations are being applied to Armoured Cable, User may wish to use the ‘Bolt

On’ Heatshrink type cylinder Gland kit. See Instructions supplied with Gland.

Glands Available

SPS 318 16-70mm Pilc Cable SPS 452 35-185mm Picas Cable

SPS 319 95-150mm Pilc Cable SPS 453 240-400mm Picas Cable

SPS 320 185-300mm Pilc Cable

22

22

2

Improved Clearance/Cross Core Kit

A kit is available which converts Paper Belted Cable into a Screened Cable which enables

greater clearances between Cores and allows a Core Cross if required.

SPS 946 70-400mm

IMPORTANT NOTICE TO PURCHASER:- Sellers and Manufacturere’s only obligation shall be to replace such quantity of the product proved to be defective. Neither the Seller nor

Manufacturer shall be liable for any injury, loss or damage, direct or consequential, arising out of the use or inability to use the product. Before using, User shall determine the

suitability of the product for his or her intended use and User assumes all risk and liability whatsoever in connection therewith.

2

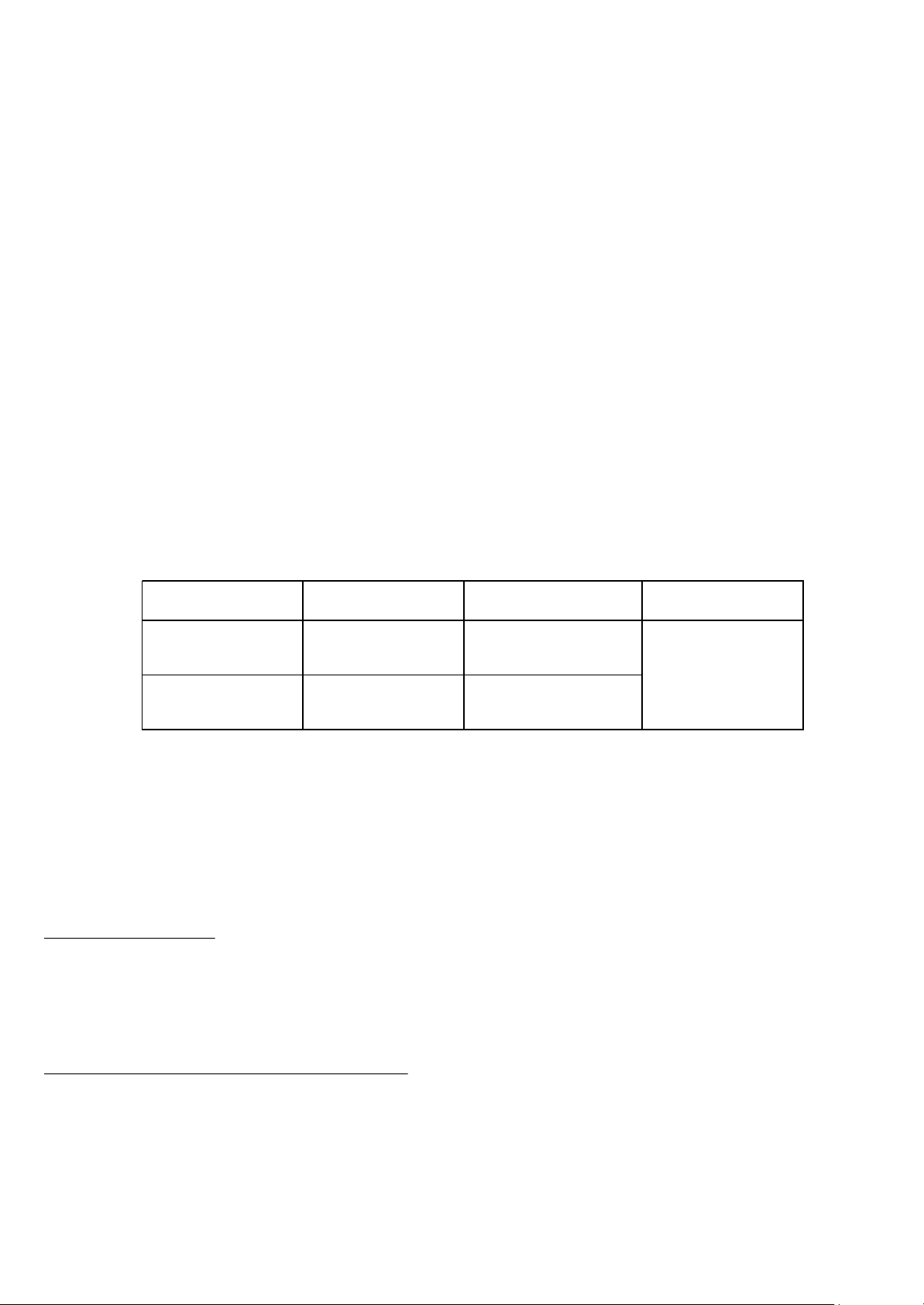

CORES

LEAD OR

ALUMINIUM

SHEATH

ARMOUR

WIRES

1. Installation

Prepare the Cable to the dimensions

shown in Fig 1 (For dimension L see

Table 1).

Expose the armour wires to 50mm for

plumbed connections. De-grease and

clean the Lead or Corrugated Aluminium

sheath and armour wires.

SHRINK

TUBE

L

100mm

150mm

EARTH BRAID

BREAKOUT

BOOT

ROLL

SPRINGS

ARMOUR

WIRES

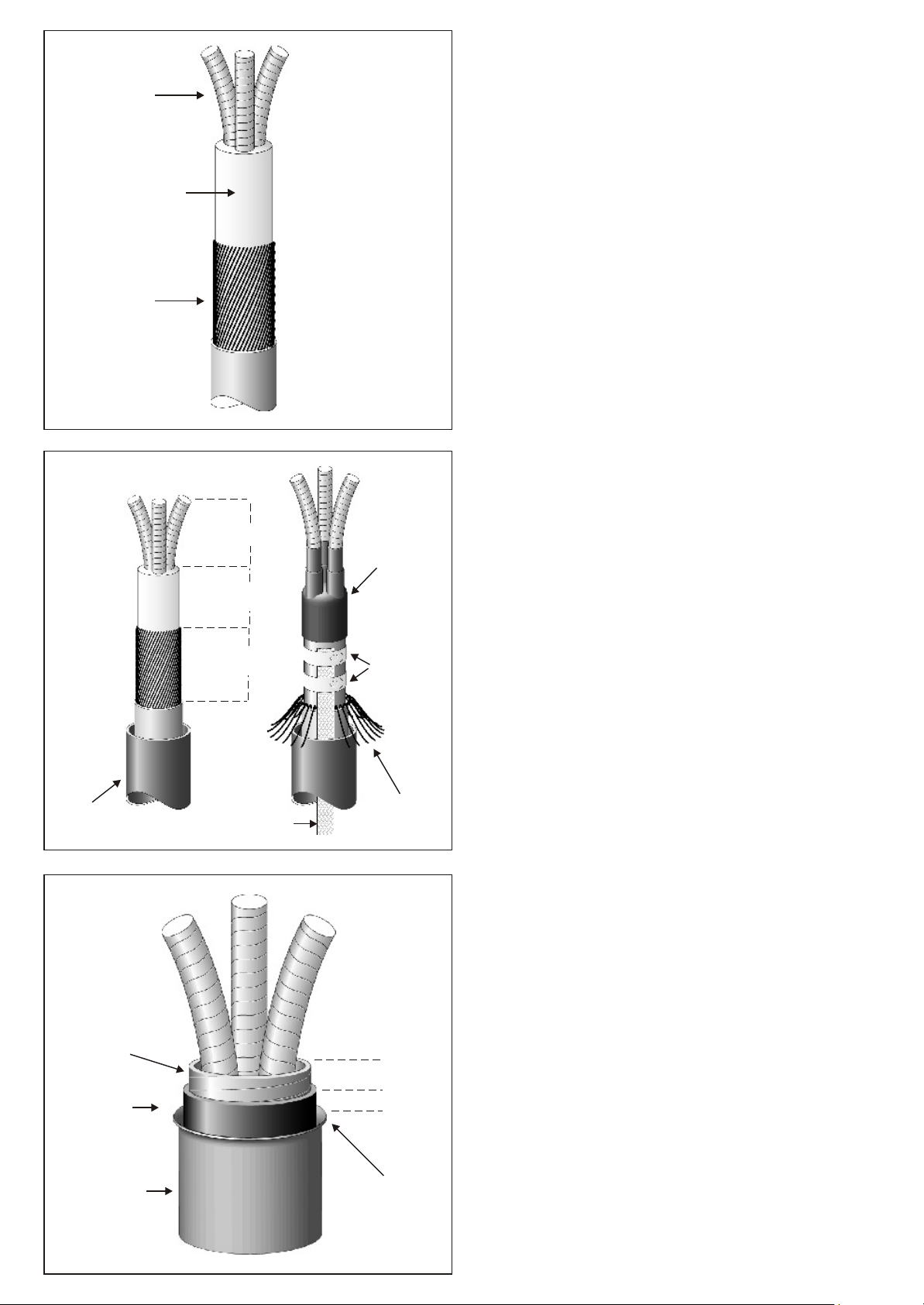

Mechanical Earthing Option

If using the Heatshrink ‘Bolt On’ Gland

with solderless earthing, prepare Cable to

dimensions shown. Note:- User may wish

to adjust these dimensions so that the

Breakout Boot fits down within the Gland

Body.

See separate instruction sheets for Pilc

and Picas Earthing using ‘Bolt On’ Gland

with Roll Spring (Lead) and Clamp System

(Picas).

2. Belted Cable Preparation

BELT

PAPERS

CARBON

PAPERS

LEAD OR

ALUMINIUM

SHEATH

20mm

5mm

BELL THE

LEAD

SHEATH

Expose the Lead or Aluminium Sheath to

a dimension of 250mm from the outer

Cable Sheath.

Unwind the Black Carbon Paper and

remove to a binder positioned 5mm from

the Metal Sheath cut.

Using a further binder, remove the Belt

Papers to 25mm from the Metal Sheath

cut.

CLEAR SHRINK

SLEEVES

Fitting the Clear Shrink Sleeves

With a clean dry cloth, carefully remove

any Grease from the Cores.

Position the Clear Shrink Sleeves over

each Core approx 50mm up from the

Cable Crutch. With a suitable heat sourse,

shrink the end’s of the Sleeves for about

50mm, before fully shrinking, rotate the

Sleeves and push down into the Crutch.

Note: E

nsure there are no air voids and

the Sleeves are wrinkle free, also note

that excessive heat may dry out and

damage the Paper Insulation.

Fitting the Stress Control Tubes

50mm

STRESS

CONTROL

TUBE

Position the Stress Control Tubes onto the

Cores at a distance of 50mm up from the

Metal Sheath Cut.

Shrink the Tubes one at a time, starting

from the bottom working upwards. Ensure

that the Tubes are evenly shrunk and

aligned.

Cable Crutch Preparation

MASTIC

CRUTCH

WEDGE

Remove the Grey Mastic Crutch Wedge

from its container and insert well down

into the Cable Crutch so that any Air gaps

are eliminated.

10mm

10mm

LEAD OR

CAS SHEATH

With tension, wrap the Grey Mastic Tape

around the Crutch area and overlap the

Stress Control Tubes and Lead or

Aluminium Sheath by approx 10mm.

Note:- Ensure that the space between the

Bell of the Lead Sheath and the entire

area between the Cores is fully covered by

the Mastic tape to eliminate Air Voids.

With a suitable solvent, clean the Metal

Sheath before proceeding.

3. General Cable Preparation

Installing the Breakout Boot

SEMI-CONDUCTIVE

BREAKOUT BOOT

X

Slide the 3 Leg Semi-Conductive Breakout

Boot down the Cores and press firmly

down into the Crutch.

The Legs of the Boot should be in contact

with the Stress Control Tubes and the

Skirt should cover the Grey Mastic Tape

and make contact with the Lead or

Aluminium Sheath.

Shrink the Boot from the centre to one

end at a time. The Boot may need to be

held in place during installation.

4. Installing Cable Lugs

Allowing for dimension X (Lug Barrel +

5mm), cut the Cores to suit the fixing

point on the equipment being used.

L + 200mm

Measure a distance of X (See Table 1)

back from the end of each Core and

remove Insulation.

With a suitable tool, install Cable Lugs

ensuring that any sharp points are

removed.

Note:- Where Mechanical Connectors are

to be used, user should check that the

Core Tubes are able to slide over prior to

fitting.

DISTANCE (d) PHASE/PHASE TOP OF STRESS TUBE

& PHASE/GROUND TO LUG BARREL

VOLTAGE d (mm) E

7.2kV 15mm 30mm

12kV 20mm 50mm

17.5kV 20mm 75mm

24kV 25mm 95mm

36kV 40mm 250mm

NUMBER OF SHEDS PER PHASE

VOLTAGE INDOOR OUTDOOR

7.2kV - 1

12kV - 1

17.5kV - 1

24kV - 2

36kV 1 3

ANTI-TRACK

TUBE

RED SEALANT

TAPE

5. Installing Anti-Track Tube

Preheat each Cable Lug and wrap two

layers of Red Sealant Tape over the Lug

Barrel extending onto the Insulation by

approx 10mm.

Also apply a turn of Red Sealant around

the tops of the Breakout Boot fingers.

Position the Anti-Track Core Tubes so that

they cover the Fingers of the Breakout

Boot and the Barrels of the Lugs.

Shrink the Tubes starting from the bottom

towards the top. Keep the flame on the

move to ensure an even wall thickness

and that the Tubes are wrinkle free. Allow

to cool to hand hot and trim at the Lug

end with a sharp knife if necessary.

AIR CLEARANCE REQUIRED

BY LOCAL SPECIFICATION

E

Indoor Terminations - Requirements

Table 2

d

Note:- Bushing protection boots will be

required for the majority of installations.

6. Installation Of Rain Sheds

r = SEE d DIMENSION

IN TABLE 2

A Strain Relief Shed is required for

Outdoor Terminations. This should be

fitted first by positioning it as low down as

possible but above the end of the

Breakout Fingers (Approx 60mm).

120mm

60mm

STRAIN RELIEF

SHED

Continue to install the appropriate number

of Rain Sheds in accordance with the

details shown in Table 3.

Table 3

All subsequent sheds should be fitted at a

distance of 80mm from edge to edge.

Note:- It is advisable not to position rain

sheds at the top of stress control tubes,

re-position if necessary.

If a termination is to be mounted for

connection above the equipment i.e in the

reverse position, sheds should be installed

through 180 as shown.

0

7. Core Crossing

Screened Cable

If the Cores on a Paper Screened Cable

have to be crossed, ensure that the cross

takes place within the screened area

below the Stress Control Tubes.

STRESS CONTROL

TUBES FITTED IN

A HIGHER POSITION

Belted Cable

Core crossing on Belted construction is

not recommended unless the minimum

clearances are achieved (See Table 2).

Note:- Core Crossing/Improved Clearance

kits utilising Heatshrink Conductive

Tubings can be supplied if requested.

Loading...

Loading...