Installation Instruction

Heatshrink Termination For Single

Core Polymeric Cables 7.2kV to 36kV

* PLEASE READ INSTRUCTIONS THOROUGHLY BEFORE PROCEEDING *

INDOOR

OUTDOOR

UNITS P1-P3 GROVEMERE COURT BICTON INDUSTRIAL PARK KIMBOLTON CAMBS PE28 OEY

TEL: +44 (1480) 861001 FAX: +44 (1480) 861002 E-MAIL: info@shrinkpolymersystems.co.uk

WEBSITE: www.shrinkpolymersystems.co.uk

©

General Fitting Instructions

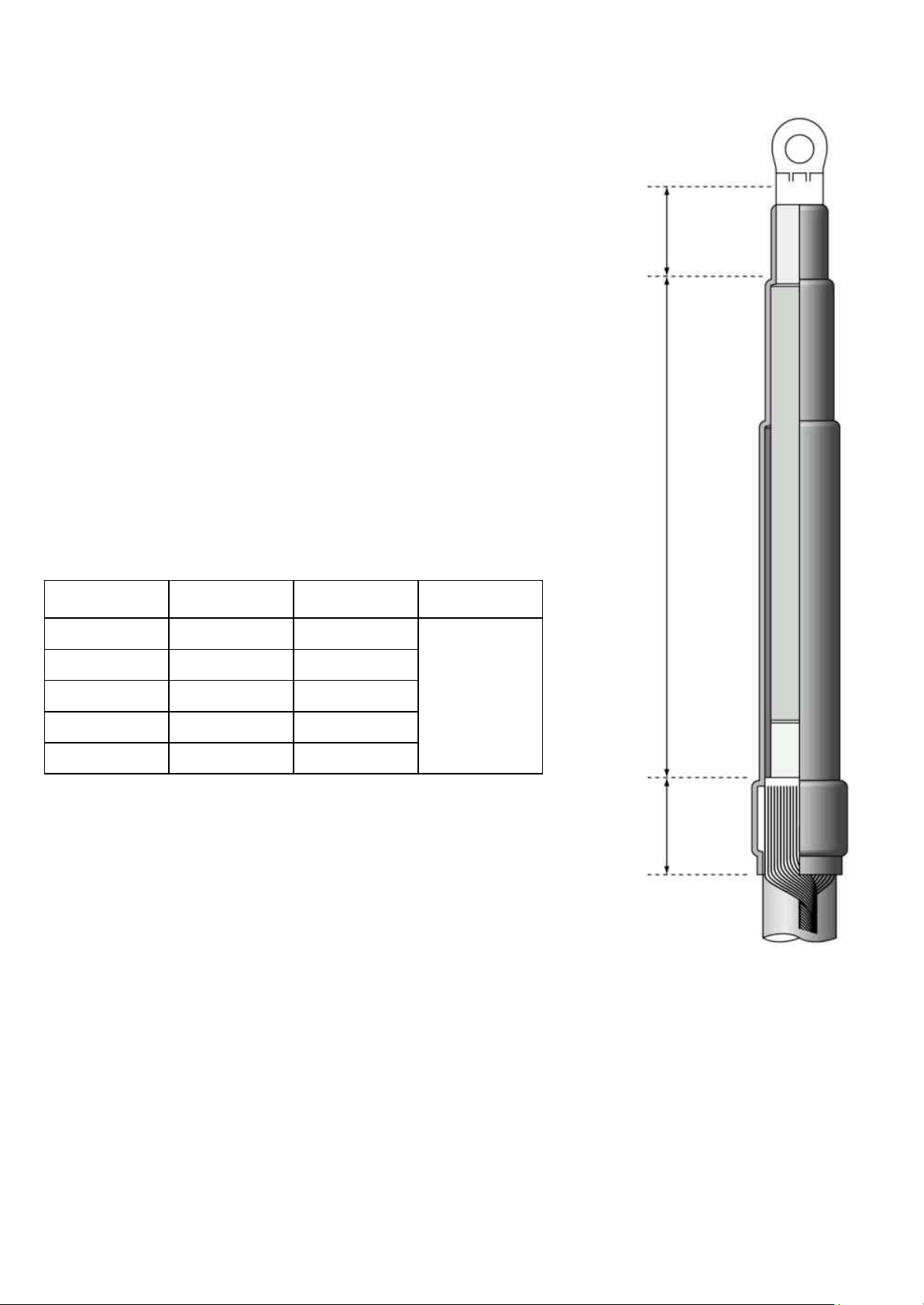

VOLTAGE

INDOOR

L

OUTDOOR

L

X

7.2kV 150mm 200mm

12kV 190mm 270mm LENGTH OF LUG

17.5kV 250mm 300mm BARREL + 10%

24kV 310mm 360mm

36kV 510mm 600mm

! It is highly recommended that a tool suitable

for the removal of the semi-conductive screen

is used to provide a reliable discharge free

termination screen point

! Use a propane gas torch with a soft flame

! Avoid a pencil like blue flame which is caused by

unregulated supply

! Keep the flame on the move to ensure even

shrinkage of all the materials and also helps to

reduce scorching

! Ensure that all components are kept clean and

grease free during installation

! Allow to cool before applying any mechanical

strain

Remove Outer Cable Sheath:

X

L

Table 1

Single Core Armoured Cables

If the Cable is Armoured, bonding of the Armours must be

completed

using the appropriate Armour Earthing kit.

A) For Indoor T erminations (Cable End Box) - Order Bolt On

Aluminium Earth Gland Ref: SPS 560*

B) For Outdoor Terminations (Pole Top) - Please advise

Conductor and Voltage rating.

* SPS 560 size range = 50-630mm2 7.2-36kV

IMPORTANT NOTICE TO PURCHASER:- Sellers and Manufacturere’s only obligation shall be to replace such quantity of the product proved to be defective. Neither the Seller nor

Manufacturer shall be liable for any injury, loss or damage, direct or consequential, arising out of the use or inability to use the product. Before using, User shall determ ine th e

suitability of the product for his or her intended use and User assumes all risk and liability whatsoever in connection therewith.

60

mm

Fig1

30mm

Fig 2

CONSTANT

FORCE

1. Installation

Remove the Outer Cable Sheath to the

dimensions L + X given in Table 1.

Remove any fillers before cleaning and

de-greaseing the Cable Sheath below.

2. Screen Treatment

Copper Wire Screen

Apply one turn of the Red Mastic Sealant

Tape at a point 30mm below the sheath

cut (Fig 2).

Bend back the Copper Wires and press

them into the Tape. Apply one more turn

of Red Mastic Tape over this point. The

Wires should be twisted together and

Bonded to a suitable earth point.

PRIMARY

INSULATION

40mm

RED

MASTIC

40mm

30mm

Fig 3

20mm

MOISTURE

BLOCK

CONDUCTIVE

LAYER

CONSTANT

FORCE

SPRING

Copper Tape Screen

Apply one turn of the red Mastic Tape at a

point 30mm below the sheath cut (Fig 3).

Remove the Copper Tape Screens to a

point 40mm above the Cable Sheath cut

as shown opposite in Fig 3.

Position a Copper Earth Braid onto the

Copper Screen and secure with a Constant

Force Roll Spring. Ensure the Moisture

Block in the Braid is bedded into the Red

Mastic and apply one more turn of Tape

over this point. Secure the end of the

Braid to a suitable Earth point.

Note:- A full range of Solderless Earth

Bonding kits are available for all Voltages

and Conductor sizes.

3. Conductive Layer Treatment

INSULATION

10mm

10mm

PRIMARY

Fig 4

Fig 5

Extruded Conductive Layer

Remove the Conductive layer using a

suitable Tool to the dimensions shown in

Fig 3 and 4. Avoid scoring and damage to

the Primary Insulation.

Note:- The Screen should be removed

leaving a cleanly cut end. Do not roughen

the Insulation with Emery Cloth.

STRESS

RELIEF

TAPE

STRESS

RELIEF

TAPE

10mm

Soluble Conductive Layer

Cover the Conductive screen with Non

adhesive Tape for 40mm on Wire

Screened Cables and 20mm on Copper

Tape Screened Cables (see Fig 4).

10mm

Fig 6

STRESS CONTROL TUBES

Remove the layer after this point with a

suitable solvent until totally clean.

Remember to remove the Tape when

finished.

4. Apply Stress Relief Tape

Remove the release paper, stretch the

TS31785Y Yellow Stress Tape to double its

length and apply around the end of each

Core Screen to cover Copper Tape(if

present) and Insulation by 10mm

(see fig 5,6).

5. Stress Control Tubes

Position the Stress Control Tubes so that

they cover the Earth connection point and

the Conductive Screen end. However do

not extend past this point onto the Outer

Cable Sheath.

Fig 7

L + X

Fig 8

RED SEALANT TAPE

Shrink the Tubes one at a time starting

from the bottom. Ensure the tubes are

wrinkle free and have an even wall thickness.

6. Installing Cable Lugs

The Cable should be cut to dimension L+X

as given in Table 1. Remove the Insulation

at X and install the Lug using the appro-

X

priate method.

Preheat each Lug and wrap two layers of

Red Sealant Tape over the Lug barrel and

extend onto the Insulation by approx

10mm. Ensure the Tape is applied as

shown.

Fig 9

NUMBER OF SHEDS PER PHASE

VOLTAGE INDOOR OUTDOOR

7.2kV - 2

12kV - 2

17.5kV - 2

24kV - 3

36kV 1 4

60mm

VOLTAGE (kV) 7.2 12 17.5 24 36

DIS TANCE (mm ) 15 20 20 25 35

ANTI-TRACK TUBE

Fig 10

7. Installing Anti-Track Tube

Position the Anti-Track Tubes so that they

overlap the Earth connection point and

outer Cable Sheath by 60mm as shown in

Fig 10.

Shrink the Tubes starting from the bottom

towards the top. Keep the flame on the

move to ensure an even wall thickness.

User may trim the Tubes at the Lug end

with a sharp knife if necessary.

8. Indoor Terminations

Anti-Track Rain Sheds are not required on

Indoor Terminations rated between 7.2

and 24kV. One Shed per phase is required

on 36kV types (see Table 2).

Table 2

Clearance Dimen ions

s

Minimum clearances should be observed

for phase to phase and phase to ground

(see Table 3).

Table 3

9. Outdoor Terminations

Anti-Track Sheds should be fitted starting

from the bottom up as per the dimensions

given in Fig 12.

The number of Sheds required depends on

the system voltage (see Table 2).

Fig 11

80mm

Fig 12

200mm

Positioning of Sheds

The first Shed should be fitted at a distance of 200mm from the lower edge of

the Anti-Track Tube to the edge of the

Shed. All subsequent Sheds should be

fitted at a distance of 80mm from edge to

edge.

Note:- It is advisable not to position

Sheds at the top of the Stress Control

Tubes. Re-position if necessary.

Fig 13

Min Bending Radius r=15xD

Reverse Connection

If a Termination is to be mounted for

connection above the equipment i.e in the

reverse position, Sheds should be

installed through 180º.

10. Cable Bending Radius

If required The Cable can be heated to

approximately 70ºC to enable a bend to

be introduced. See Fig 14 showing the

bending radius.

D

Fig 14

IMPORTANT NOTICE T O PURCHASER:- Sellers and Manufacturere’s only obligation shall be to replace such quantity of the product proved to be defective. Neither the Seller nor

Manufacturer shall be liable for any injury, loss or damage, direct or consequential, arising out of the use or inability to use the product. Before using, User shall determine the

suitability of the product for his or her intended use and User assumes all risk and liability whatsoever in connection therewith.

UNITS P1-P3 GROVEMERE COURT BICTON INDUSTRIAL PARK KIMBOLTON CAMBS PE28 OEY

TEL: +44 (1480) 861001 FAX: +44 (1480) 861002 E-MAIL: info@shrinkpolymersystems.co.uk

WEBSITE: www.shrinkpolymersystems.co.uk

©

Loading...

Loading...