INSTALLATION INSTRUCTION

HEASHRINK JOINT TO SUIT 3 CORE 33kV

POLYMERIC CABLE TYPE SPAJ 36X

* THESE INSTRUCTIONS SHOULD BE FOLLOWED BY A TRAINED COMPETENT FITTER

* A PROPANE GAS TORCH IS THE PREFERRED METHOD FOR SHRINKING THESE MATERIALS

* ENSURE THAT THE MATERIALS ARE KEPT CLEAN AND DRY AND ARE FREE FROM DUST, SAND AND GREASE

* PLEASE CALL SHRINK POLYMER SYSTEMS FOR ANY ADVICE

©

DATE OF ISSUE:- 04.10.05

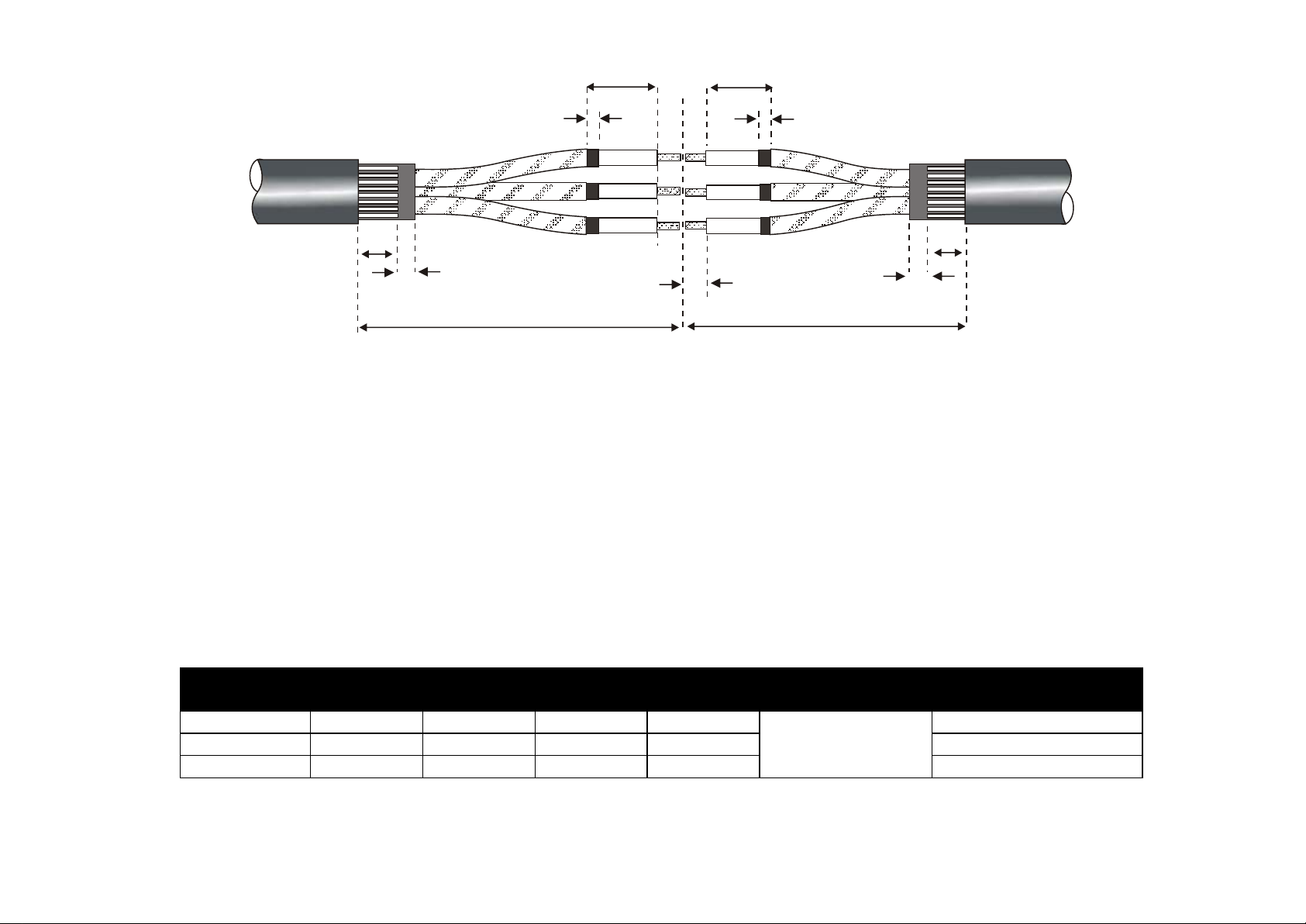

ALL DIMENSIONS SHOWN IN mm

SIZE

(mm2)

A B C D X

MAX CONNECTOR

LENGTH

35-95 1200mm 750mm 220mm 220mm HALF LENGTH 110mm

120-185 1300mm 750mm 220mm 220mm CONNECTOR 150mm

240-300 1375mm 750mm 220mm 220mm +5mm

160mm

10

C

X

D

10

Fig 1

75

STRIP TO ½ LENGTH OF

30

CONNECTOR + 5mm

LONG SIDE (A)

X

+ 5mm

SHORT SIDE (B)

75

30

1. Ensure the Cables overlap before preparing to the dimensions above and in accordance with the Table below for

Conductor size.

2. Expose Armour to 75mm and Bedding to 30mm.

3. Remove Copper Tape Screens for a distance of 220mm + ½ Connector length + 5mm.

4. Remove the Black Semi-Conductive layer leaving 10mm exposed. Important:- Do not damage or ‘Nick’ the Primary

Insulation at the Screen cut, an approved Tool can be supplied if required for this purpose.

5. Expose the Conductor to ½ the Connector length + 5mm. Note:- Connector should not exceed maximum length

stated in Table 1 below.

Note:- These Joints are designed for use with HV Compression Ferrules. Please consult if using Mechanical type

Connectors.

Table 1

Fig 2

MASTIC CRUTCH

WEDGE

6. De-grease Primary Insulation and remove all traces of

Carbon/Semi-Con.

7. Push the Star shaped Mastic Wedge well into each Cable Crutch

and wrap the 212D Black Mastic Tape around each Cable Bedding.

212D MASTIC TAPE

INSULATION / SEMI-CONDUCTIVE TUBE (DWMV)

INSULATION BUILD UP TUBE (BTT) (24kV=x1) (33kV=x2)

STRESS CONTROL TUBE (SCT)

OUTER

SHRINK

TUBE

OUTER

SHRINK

TUBE

LONG SIDE (A) SHORT SIDE (B)

Fig 3

8. Slide the Outer Shrink Sleeve/s, Armour Clamps and Support Rings over one or both of the Cable ends. Position the

“Nested” Connector Insulation Tube sets onto the Cores on the Long side of the Joint.

PICTURE SHOWS

MECHANICAL CONNECTORS

Fig 4

9. Fit the MV type Connectors and crimp with an

approved Tool. Ensure they are free from grease

and any sharp points.

10

10. Wrap the Yellow Stress Tape (TS 31785Y)

around the Connector area with stretch and ½

width overlap. Extend the Tape onto Primary

TS 31785Y YELLOW

STRESS TAPE

Fig 5

Insulation by 10mm only.

If fitting Mechanical Connectors, use a Socket or

wrench, tighten the bolts until they shear. Degrease Connectors and check for any sharp points

which should be removed before proceeding.

Important:- Fill in the gap between Primary

Insulation and Connector. Also fill any voids that

the Bolts leave after they have been sheared.

HEATSHRINK TUBE REQUIREMENT PER PHASE

VOLTAGE SCT BTT DWMV

7.2kV 1 --- 1

12kV 1 --- 1

17.5kV 1 1 1

24kV 1 1 1

36kV 1 2 1

10 10

11. Apply one piece of TS 31785Y Yellow Stress Tape with stretch and half

width overlap to each Screen end as shown in Fig 6. Overlap the Tape onto

the Copper Tape Screen and Primary Insulation by 10mm either side.

Fig 6

Table 2

BTT

Fig 7

Fig 8

Fig 9

20

SCT

BTT

4SC HV GREY TAPE

DWMV

ONLY ONE CORE SHOWN FOR CLARITY

SCT = BLACK STRESS CONTROL TUBE

BTT = RED INSULATION TUBE

DWMV = COMBINED INSULATION/CONDUCTIVE TUBE

12. Position the Stress Control Tubes (SCT) centrally over the Connectors

overlapping the end of Screen points and onto the Copper Tape Screens.

With a suitable heat source, shrink all three Tubes at the same time,

starting from the centre, working all around the Tubes to one end at a

time. Note:- Allow the Tubes to cool before cleaning the surfaces with the

Tissues provided. This improves electrical performance.

13. Dependant on Voltage class (See Table 2), shrink the required

quantity of Red BTT Tubes centrally over the Stress Control Tubes. Two BTT

Tubes are required at 36kV, one at 17.5-24kV with none being required at

12kV or below. Finally position the DWMV combined Red Insulation/Semi

Conductive Tubes and as before, shrink into place and ensure an even wall

thickness is obtained. Note:- Remember to clean each layer with a

Cleaning Tissue.

14. Take the six pieces of 4SC HV Grey Mastic Tape and apply to the ends of

the DWMV Tubes and Copper Tape Screens by approx 10mm each as

shown in Fig 9.

Fig 10

KM 50 COPPER

SCREENING BANDAGE

BINDING

WIRE

15. Wrap the Copper Screening Bandage (KM 50) with slight overlap on

each Core extending onto the Copper Tape Screens by approx 50mm

and secure with Binding Wire.

16. Secure the six Earth Braids to the Copper Tape Screens with the

Constant Force Springs provided (The Braids will be clamped to the

Armours at a later stage).

Fig 11

OUTER

SHRINK

TUBE

17. Bend back the Armour Wires

and apply 212D Black Mastic Tape

onto the Bedding directly under

the Sheath cut (SWA only).

ARMOUR

SUPPORT

RING

Fig 12

PVC TAPE

18. Position the Armour Support Rings

and fold back the Armour Wires upon

them. Note:- Armour Support Rings do

not need to be fitted if Cable is Steel

Tape Armoured.

APPLY PVC TAPE TO

ARMOUR CLAMP

BUCKLES

OUTER

SHRINK

TUBE

Fig 13

ARMOUR CLAMPS

19. Wrap the Armour Protection Cage around the joint gap and use the Pvc Tape to hold it in place. Using the Armour

Clamps, clamp the Cage down onto the Armours at each end ensuring that the Flat Earth Braids that are attached to the

Copper Tape Screens are also clamped down with it. Tape over the Clamp buckles and Cage fingers with the Pvc Tape.

4SC GREY TAPE

100

OUTER

OUTER SHRINK TUBE

SHRINK

TUBE

Fig 14

20.Make a mark at 100mm on the Outer Cable Sheath on the Long side of the Joint and position one of the Shrink Tubes

to this point. With a suitable heat source, start shrinking from the centre of the Tube to one end at a time. Keep the

flame on the move to ensure an even wall thickness. Apply a turn of 4SC Grey Tape approx 75mm in from the end of the

Tube as in Fig 14.

100

OUTER SHRINK TUBE

Fig 15

OUTER SHRINK TUBE

21. Make a mark at 100mm on the Outer Cable Sheath on the Short side of the joint and position the second Tube at this

point. Shrink as previous keeping the flame on the move. Once fully shrunk Sealants should be visible at Tube ends.

22. Allow the completed Joint to cool before applying any mechanical strain.

IMPORTANT NOTICE TO PURCHASER:- Sellers and Manufacturere’s only obligation shall be to replace such quantity of the product proved to be defective. Neither the Seller nor

Manufacturer shall be liable for any injury, loss or damage, direct or consequential, arising out of the use or inability to use the product. Before using, User shall determine the

suitability of the product for his or her intended use and User assumes all risk and liability whatsoever in connection therewith.

UNITS P1-P3 GROVEMERE COURT BICTON INDUSTRIAL PARK KIMBOLTON CAMBS UK PE28 OEY

TEL: +44 (0)1480 861001 FAX: +44 (0)1480 861002 E-MAIL: info@shrinkpolymersystems.co.uk

WEBSITE: www.shrinkpolymersystems.co.uk

©

Loading...

Loading...