Page 1

INSTALLATION INSTRUCTION

HEASHRINK JOINT TO SUIT 2-4 CORE XLPE/SWA/PVC

CABLE 0.6 TO 3.6kV TYPE: SPA

DATE OF ISSUE:- 20.01.05

©

Page 2

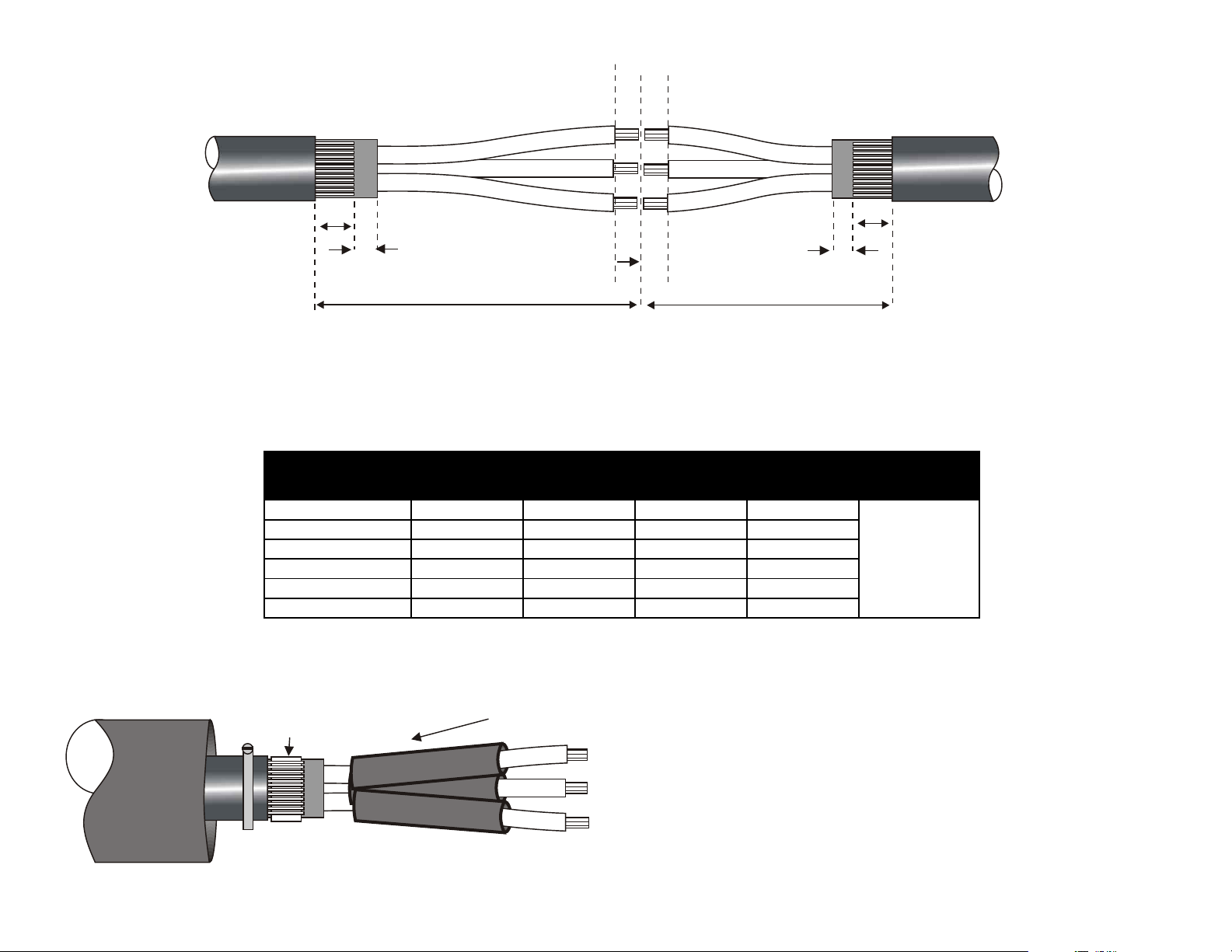

ONLY THREE CORES

CONDUCTOR

SIZE (mm2)

LONG SIDE

(mm)

SHORT SIDE

(mm)

BEDDING

B (mm)

ARMOUR

A (mm)

X

1.5-6 150 90 10 30

10-16 170 135 15 35 HALF

25-50 215 135 20 45 CONNECTOR

70-95 300 200 20 50 LENGTH

120-185 400 300 20 60

240-400 530 390 30 75

SHOWN FOR CLARITY

X

Fig 1

A

B

LONG SIDE

STRIP TO ½ LENGTH OF

CONNECTOR

X

SHORT SIDE

A

B

1. Ensure that the Cables overlap and prepare as above using the dimensions given in Table 1 below.

2. Slide the Outer Shrink Tubes, Armour Clamps and Copper Sock (If used) over the Cable end/s.

TABLE 1

CONNECTOR

ARMOUR

SUPPORT RING

INSULATION TUBES

OUTER

SHRINK

TUBE

Fig 2

LONG SIDE

3. Fit the Armour Support Rings (No need if Cable is

Steel Tape Armoured) before positioning the

Connector Insulation Tubes down the longer of the

Cores.

Page 3

OUTER

SHRINK

TUBE

Fig 3

4. Expose the Conductors to half the length of the Connectors and fit using a suitable tool to crimp them. Note:-

Mechanical Shearbolt Connectors can be used, but user should advise as Insulation Tubes will need to be increased in

size.

5. Position the Tubes centrally over the Connectors and shrink from the centre to one end at a time. Keep the flame on

the move to ensure an even wall thickness. Sealants will be visible at Tube ends once fully shrunk.

Note:- Heavy Duty Copper

Sock is supplied as opposed to

Cages for small Multicore and

Power Joints up to 50mm

2

OUTER

SHRINK

TUBE

Fig 4

6. Wrap the Armour Cage around the joint gap and secure to the Armours at both sides with the Armour Clamps provided

(Roll Springs if Copper Sock). Note:- User may need to apply Tape to the Cores to keep the joint profile down, particularly

in the case of core crossing.

Page 4

OUTER

SHRINK

TUBE

Fig 6

7. Tape over any sharp points including Clamp Buckles.

Figure 5 shows Copper

Sock secured to Armours

With Roll Springs

Fig 5

OUTER SHRINK TUBE

Fig 7

8. De-grease the Cable Sheaths with the Tissues provided.

Centralise the Tube and shrink from the centre to one end at

a time. Keep the flame on the move all around the Tube to ensure an even wall thickness.

9. Allow the completed Joint to cool before applying any mechanical strain.

IMPORTANT NOTICE TO PURCHASER:- Sellers and Manufacturere’s only obligation shall be to replace such quantity of the product proved to be defective. Neither the Seller nor

Manufacturer shall be liable for any injury, loss or damage, direct or consequential, arising out of the use or inability to use the product. Before using, User shall determine the

suitability of the product for his or her intended use and User assumes all risk and liability whatsoever in connection therewith.

UNITS P1-P3 GROVEMERE COURT BICTON INDUSTRIAL PARK KIMBOLTON CAMBS PE28 OEY

TEL: +44 (0) 1480 861001 FAX: +44 (0) 1480 861002 EMAIL: info@shrinkpolymersystems.co.uk WEBSITE: www.shrinkpolymersystems.co.uk

©

Loading...

Loading...