Operating, Field Maintenance, and Parts Manual Model 998 UL®

Thank you for choosing Shrinkfast products. Please visit us on the web at

www.shrinkfast998.com for our latest product information and updates.

Customer Service Issues:

Before returning any Shrinkfast product, please call:

(800)867-4746 or

(603)863-7719

SAVE THIS MANUAL FOR FUTURE REFERENCE

TABLE OF CONTENTS

GENERAL SAFETY PRECAUTIONS............................................................................. pages 2-4

REGULATOR OPERATION & MAINTANANCE........................................................... pages 5-7

STARTING THE HEAT TOOL .............................................................................................. page 8

REGULATOR MAINTANANCE & SAFETY FEATURES ........................................... pages 9-10

EXCESS FLOW DEVICE ...................................................................................................... page 9

CHOOSING THE CORRECT PROPANE TANK ......................................................... pages 11-12

TANK PRESSURE, TEMPERATURE & OPERATION............................................... pages 13-14

VENTILATION REQUIREMENTS .................................................................................... page 15

GENERAL INFORMATION ON SHRINK FILM & SHRINK BAGS........................ pages 16-18

SHRINK WRAPPING TECHNIQUES

OPERATING OVERVIEW............................................................................................ pages 23-24

PRINCIPLES OF OPERATION .................................................................................... pages 25-27

HEAT TOOL PARTS DIAGRAM.................................................................................. pages 28-30

ASSEMBLY AND DISASSEMBLY ............................................................................. pages 31-35

HEAT TOOL SERVICE INSTRUCTIONS .......................................................................... page 36

DAILY HEAT TOOL INSPECTION .................................................................................... page 37

MONTHLY HEAT TOOL INSPECTION ............................................................................ page 38

TROUBLESHOOTING GUIDE .................................................................................... pages 39-40

TECHNICAL SPECIFICATIONS........................................................................................ page 41

(PALLET BAGS & ODD SHAPED OBJECTS)

..... pages19-22

GGEENNEE RRAALL SSAAFFEETTYY PPRREE CCAAUUTT IIOO NNSS --

RREEAA DD AA LL LL IINN SS TT RR UU CC TT IIOO NN SS

BB EE FF OO RR EE OOPPEERR AA TT IINN GG TTHH IISS HH EE AA TT TTOO OO LL

• Do not operate this heat tool below 15 PSI or damage to the heat tool will

occur.

• Before using any heat tool, check all parts for proper function and damage to

component parts including the hose, regulator and heat tool.

• "Hidden areas such as behind walls, ceilings, floors, soffit boards and other

panels may contain flammable materials that could be ignited by the heat tool

when working in these locations. The ignition of these materials may not be

readily apparent and could result in property damage and injury to persons.

When working in these locations, keep the heat tool moving in a back and forth

motion. Lingering or pausing in one spot could ignite the panel or the material

behind it."

• Do not use the heat tool to remove paint.

• Do not point this heat tool at anyone and do not operate in an area where there

is a risk of an explosion or fire.

2

GENERAL SAFETY PRECAUTIONS

•

When working with any type of heat or open flame, always keep a fire

extinguisher close by.

•

Always were safety glasses and gloves (flame retardant or leather is suggested)

when shrink wrapping. Never obstruct or cover the air inlet at the back of the

heat tool. If the air flow is reduced the heat tool will not work properly.

•

When shrink wrapping outdoors, do not shrink wrap when the wind is stronger

the 10 mph.

•

When shrink wrapping indoors, make sure the work area is well ventilated.

•

Keep the work area clear of debris, wood shavings, paper products, flammable

chemicals and anything else that may catch fire from the heat of the tool.

•

Do not wear loose clothing while shrink wrapping and also keep long hair tied

back.

•

Stay alert, watch what you are doing, and use common sense when operating

the heat tool. Do not use tool while tired or under the influence of drugs,

alcohol or medication. A moment of inattention while operating the heat tool

may result in serious personal injury.

•

Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the heat tool in unexpected situations.

3

•

Never operate the heat tool with the combustor nozzle hard up against a surface;

this could ignite any material you are shrink wrapping.

•

Do not place the combustor nozzle (where the flame comes out of the heat tool)

next to anything while it is hot. Never allow the combustor nozzle to come in

contact with clothing or skin.

•

Do not look down the combustor nozzle while the tool is in operation or

attached to a fuel source.

•

The heat tool should be kept 6” – 8” away from the shrink film when in

operation. Never keep the heat on one area for more than a few seconds.

Once heat is applied to the shrink film, it will continue to shrink even after

the heat is moved away from the area.

•

Never modify the tool in any way and use only Shrinkfast replacement parts

.

•

Never operate in a basement or closed in, non-ventilated area.

•

Never operate the heat tool on an area that you cannot see.

•

Always operate the heat tool with the UL® Guard installed.

4

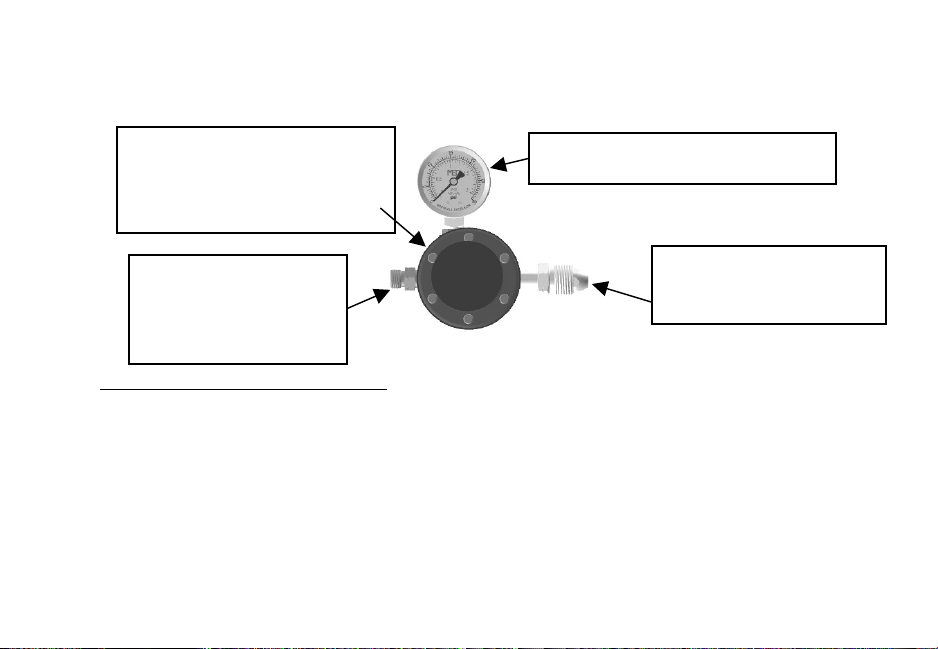

REGULATOR OPERATION & MAINTANENCE

Regulator Technical Overview:

•

The MEGR-6120 is a high capacity, pounds to pounds, industrial gas regulator.

It is designed to conform to UL® Standard 144 for use with LP Gas. The

maximum supply pressure is 250 PSIG. The maximum output pressure is

printed on the regulator nameplate.

•

This regulator is not intended for use in pressure applications below 3 PSIG and

the heat tool should not be operated at a pressure below 15 PSIG. The

operating temperature range is -40 to +200 degrees Fahrenheit.

0 – 30 PSI Pressure Gauge

POL – Attaches to

the Propane Tank

Hose Adapter –

Attaches to the

Supplied 25’ Hose

Adjustable Hand Wheel

– Adjusts PSI Setting of

the Regulator

5

This is a variable regulator assembly and the heat tool will operate

properly between 15 PSI and 30 PSI. The pressure can be changed by

loosening the hex nut located under the black, round hand wheel on the

regulator assembly and then turning the hand wheel to the desired pressure.

However, the optimum and factory recommendation is that you do not

adjust the pressure and keep the regulator set at the factory setting of 22

PSI.

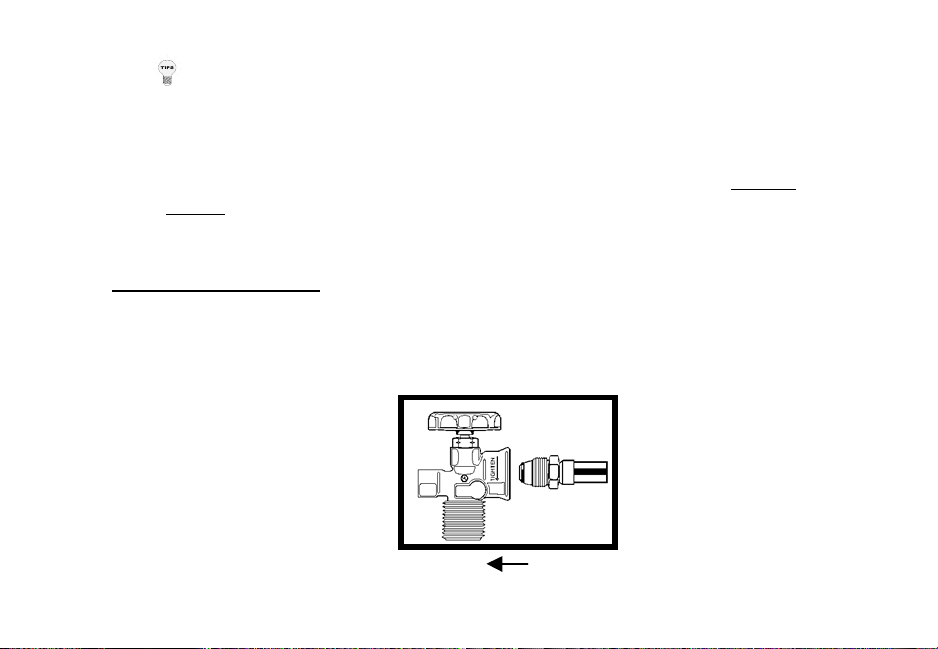

Regulator Installation:

1. Remove the yellow cap from the POL (brass, bull nose fitting) and connect the

POL to your propane tank and tighten with the supplied wrench (all threads

are left handed thread, so tighten counter clockwise).

Propane Tank Regulator POL

6

2. Connect one end of the supplied 25’ hose to the hose adapter on the regulator

and the other end of the hose to the heat tool. Tighten all fittings with the

supplied wrench (left handed threads, so tighten counter clockwise).

3. Open the propane tank valve and check for any leaks by spraying a soapy

water mixture on the fittings. If any bubbles are visible, shut off the propane

tank and tighten the fittings.

4. When you first turn on the propane tank, the pressure gauge on the regulator

will slowly move toward the factory setting of 22 PSIG. Once the hose is fully

pressurized, the needle on the gauge will stop at 22 PSIG. Now the heat tool is

ready to be fired.

To open the flow of

propane, turn the tank

hand wheel in a counter

clockwise motion and

watch the regulator gauge

increase to the required

22 PSI.

Pictured: Hand wheel

on top of your supplied

propane tank.

7

STARTING THE HEAT TOOL

1. Depress the yellow safety that sits in the palm of your hand. If you do not

depress the safety first, you will not be able to pull the trigger with your finger

tips and ignite the heat tool.

2. With the safety depressed, slowly pull the trigger with your fingertips so you

first hear a slight “hissing” of propane flow, then pull the trigger completely

and the heat tool will “click” then ignite.

3. Should the gun fail to ignite, release both the safety and trigger fully to ensure

that the igniter is reset and repeat the starting procedure.

WARNING: MANY NEW USERS PULL THE TRIGGER TOO

QUICKLY AND MULTIPLE TIMES BELIEVING THIS IS THE BEST

WAY TO IGNITE THE HEAT TOOL. PULLING THE TRIGGER TOO

QUICKLY DOES NOT ALLOW THE PIEZO CRYSTAL INSIDE THE

IGNITER TO SEND PROPER VOLTAGE TO THE SPARK PLUG, SO

PULL THE TRIGGER SLOWLY IN ORDER TO IGNITE EVERY TIME.

WARNING: DO NOT TOUCH THE WIRE METAL SHIELD (UL®

GUARD) AFTER THE HEAT TOOL HAS BEEN FIRED.

!

8

REGULATOR MAINTENANCE & SAFETY FEATURES

• Because the Shrinkfast UL® approved regulator assembly is assembled and tested at the

factory to conform to UL® Standard 144, any maintenance or repairs should be in

accordance with this listing as well as any other applicable regulations. Regulator parts

showing wear should be replaced as necessary. Contact your local distributor or

Shrinkfast directly for descriptions and part numbers.

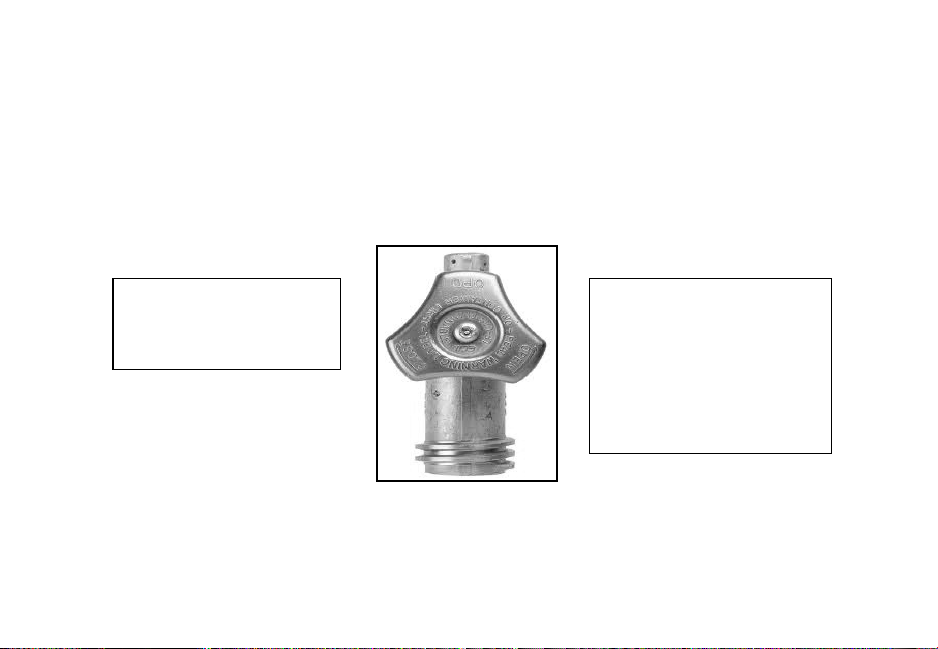

IMPORTANT SAFETY FEATURE: Inside the POL fitting on the

Regulator Assembly there is a safety featured called the “Excess Flow Device”.

• This safety feature is designed to stop the flow of propane if the hose becomes

cut or detached from the regulator or heat tool during operation.

• The Excess Flow Device does not stop the propane flow 100%, but it does

reduce the flow so the user has time to get to the tank and shut off the propane

and prevent a dangerous situation from occurring.

How the Excess Flow Device Works:

• When the propane tank is first turned on the Excess Flow Device believes there

may be a downstream leak and temporarily closes the POL. The POL does not

stop the flow entirely, so there is enough propane entering the hose to begin

pressurizing the system.

9

• Once the fuel has filled the entire hose and the regulator gauge reaches 22 PSI,

the Excess Flow Device reopens and the heat tool is ready for operation (you

will hear an audible “click” from the POL when the pressurization is

complete).

• This pressurization process can take anywhere from 7-10 seconds from when

the tank is first turned on and may take a little longer with propane tanks that

are partially filled. This feature is all for the safety of the user, but you must

wait the 7-10 seconds for the pressurization to complete before operation.

Attempting to Ignite the Heat Tool before Pressurization is Complete:

• If the user attempts to fire the heat tool before the pressurization is complete,

the pressure gauge will drop down to 0 PSI and the heat tool will not ignite. In

order to ignite the heat tool, the user must wait for the system to pressurize (22

PSI) and then the heat tool will operate properly. *This wait time will only

occur when the user first turns on the propane tank.*

WARNING: As the amount of propane in the tank drops, the pressure

gauge on the regulator will decrease accordingly. Do not operate the heat

tool once the pressure drops down to 15 PSIG. Operating the heat tool

below 15 PSIG, will result in damage to the heat tool’s internal components.

10

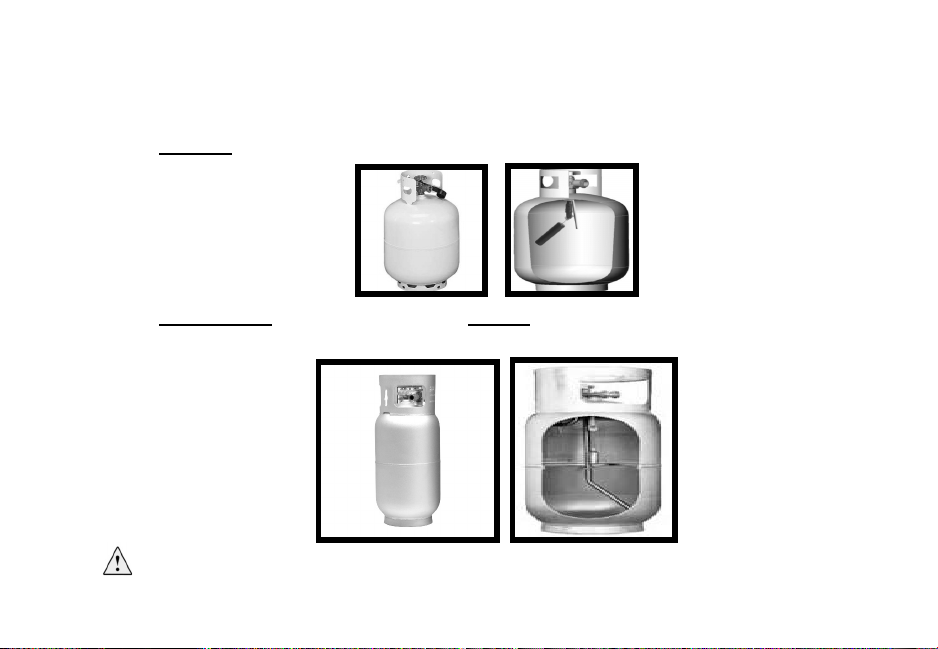

CHOOSING THE CORRECT PROPANE TANK

• !"#$#%&$#%'()%'*+#,%)-%+$)+&.#%'&./,%0)11).2*%&3&42&52#6%

A.

Correct: Vapor withdrawal—Use this style (exactly the same as a BBQ grill tank)

B.

Not Correct: Liquid withdrawal—Do not use this style (used on fork trucks)

%% %

WARNING: Using a liquid withdrawal (fork truck) propane tank will clog

the orifice in the heat tool and result in an extremely long and dangerous flame.

11

%

CHOOSING THE CORRECT PROPANE TANK (CONTINUED)

• Propane tanks are available in a variety of sizes. The most popular tank sizes:

• 20 lb. tank similar to a BBQ propane tank for smaller

applications.

• 40 lb. tanks are commonly used in most industrial applications.

12

TANK PRESSURE, TEMPERATURE & OPERATION

• Tank pressure depends on the temperature of the tank. At room temperature (72°F) the

pressure in a full tank is 110 PSI and drops to 22 PSI at 0°F.

If the propane tank ices up during operation:

When the heat tool is in operation, the temperature of the tank drops due to the

evaporation process of liquid propane to propane gas. After prolonged use and

continued drop in propane pressure, the temperature of the tank may drop to 0°F

usually accompanied by icing on the outside of the tank and regulator.

13

WARNING: Icing of the tank and regulator is quite common when

running the heat tool continuously with a partially filled propane tank.

However, if you are ever in doubt regarding the safety or operation of

your heat tool, shut off the tank and contact your authorized Shrinkfast

distributor or Shrinkfast directly.

• Small or nearly empty tanks ice up faster than larger, full tanks. Typically, a

full 20 lb. tank, if operated continuously, will run for 90 minutes before ice

builds up on the outside of the tank.

• If your shrink wrapping project requires continuous use of the heat tool, try the

following methods:

• Use multiple tanks—Switch the heat tool from one tank to

another.

• Use a portable fan—Point an ordinary desk fan at the tank, and

the air flow around the tank will help the tank from icing up.

14

VENTALATION REQUIREMENTS

WHEN OPERATING HEAT TOOL

WARNING: During operation, the heat tool consumes propane and air

and produces carbon dioxide, carbon monoxide (CO), and water vapor.

Prolonged exposure to Carbon Monoxide is lethal and adequate

ventilation must be provided if the heat tool is to be operated indoors.

•

To maintain a safe CO concentration (50 parts per million as set by OSHA

Standard 1910.1000 – Air Contaminants), ventilation requirements are 2,000

cu. ft. /min. of fresh air while the heat tool is operated at a maximum operating

pressure of 30 PSI.

•

Based on a 1 1/2 minute heating cycle per pallet, the fresh air requirements are

3000 cu. ft. /pallet. Example: If the production rate is 10 pallets per hour, a

ventilation system needs to provide 500 cu. ft. /minute.

•

In areas where ventilation is provided by open doors or windows, a safe level of

CO will be maintained as long as the room temperature does not rise above

150°F.

15

GENERAL INFORMATION ON SHRINK FILM & SHRINK BAGS

Shrink Wrap (#4 LDPE):

• The shrink wrap is manufactured in multiple colors and is typically a 6 or 7 mil,

low density polyethylene (#4 for recycling purposes). What makes this material

different than construction plastic sheeting is that it contains shrinking resins,

UV inhibitors, anti-brittling compounds, and strengtheners so that it will not rip

or tear. Make sure the shrink film is manufactured using only virgin resin

material.

WARNING: Shrink wrap can burn. If heat is applied incorrectly, shrink

wrap can ignite into open flame. It can also drop down on to other

combustible material and cause secondary ignition and fire. If at any time

you observe the shrink wrap on fire, immediately stop what you are doing

and carefully inspect the area where you are working for a possible fire.

Keep a fire extinguisher available at all times.

Measuring for the Shrink Film:

• Regardless of the shape of the object you are covering, it must be viewed as a

cube in order to find the proper shrink film size. In general, you measure the

width by starting at the lowest point of the object or however far down you

16

want the film cover to reach. Measure up the side, over the top, and down the

opposite side to the lowest point. Add one foot to this number to accommodate

heat welds and this will indicate how wide your shrink wrap should be. This

process will determine the square footage of the object being shrink wrapped.

• For boat wrapping or storage purposes, a 6 or 7 mil shrink film is installed, but

the mil thickness depends on the project requirements and can be best

determined by a shrink film distributor.

Measuring for the Shrink Pallet Bags:

• For shrink wrapping a pallet, a 4 mil shrink bag is typically used for loads of

1,000 lbs. or less. You should always add at least 2" to the length and width of

your measured object when sizing the correct pallet bag and at least 4-6" to the

height (including the pallet) to account for the material shrinking when

applying the heat.

• Again, not all plastic bags are shrink bags; therefore, be specific. Shrink film

should be made of virgin resin, and not reprocessed material.

17

MEASURING FOR A SHRINK PALLET BAG

1) Measure the length, width and height of the

pallet to be covered.

2) Determine the Length (L) of the bag, by

adding 2" to the length of the pallet.

3) Determine the Width (W) of the bag, by

adding 2" to the width of the pallet.

4) The Height (H) of the bag is determined by

measuring the height of the pallet (including the

height of the pallet itself) and adding 4-6”. The

added length allows you to tuck the ends of the

bag under the pallet before applying heat so

that it does not pull up over the pallet edges.

Example: If the pallet size is 48"(length) x

40"(wide) x 50"(height), the bag dimensions are

as follows: Length (L) is 50", Width (W) is 42"

Height (H) is 56" (always go higher in height if

they do not have the exact bag height available).

18

19

SHRINK WRAPPING TIPS

• During operation, always have the heat tool moving in a side to side motion.

The most important fact to keep in mind is that heat only softens the film. The

greatest amount of shrinking occurs as the film cools.

• It is a common mistake to apply too much heat to one particular area of the

shrink film, thus burning a hole in the film. Keeping the heat tool continuously

moving will prevent this from occurring.

• With a little practice, you will find that you can hold the heat tool closer to the

film and sweep faster often shrinking a pallet in less than 4 minutes.

• It is absolutely necessary that the four corners of the bag be taut under the pallet.

If this is not done, the effectiveness of shrink palletizing is considerably

reduced.

20

PATCHING HOLES IN SHRINK WRAP FILM!

• MISTAKES HAPPEN! Occasionally holes will appear in the shrink film, but

they can be easily repaired. Holes in the film can be patched by laying a square

piece of shrink film over the hole and applying heat around the edges, thus heat

welding the patch to the bag. Note: Make sure you cut the film patch at least 2”

larger on all sides before applying heat to the patch.

After applying heat to the patch of film, tap the warm film with the back of your

glove to ensure the film is secured over the hole. The same technique can be

applied to reinforce edges or corners. After the patch has cooled, apply shrink

tape to all four sides to further secure the patch.

WARNING: After shrink wrapping, never touch the shrink film with

your bare hands.

!

21

SHRINK WRAPPING LARGE OR ODD SHAPED LOADS!

• Shrink wrapping is a versatile process that can be employed in a variety of

applications. For example, shrink wrappers routinely wrap irregular objects

such as industrial equipment.

Objects, which are too big to fit under a bag, can be wrapped by using several

sheets of shrink film joined together if the following the precautions are observed:

• When adjoining sheets of film there should be an 18 inch overlap. This

overlap allows the sheets to weld together during the shrink process.

• The sheets of film must be secured around the entire base of the pallet and

attached to the skid with strips of wood strapping or any other method that

can secure the film and prevent it from pulling up on the object when heat

is applied.

• Once the film is firmly attached to the pallet, the heat tool is used to shrink

the film, again using a back and forth motion, starting at the bottom of

the object and working your way to the top.

22

OPERATING OVERVIEW

O

PERATING O

23

PART AND FUNCTION

1 Safety: Prevents accidental gas release

2. Trigger: Activates gas valve and igniter

3. Valve: Opens fuel flow

4. Igniter: Fires the piezoelectric spark igniter

5. Fuel Line: Carries fuel to orifice

7. Orifice: Controls fuel flow through pump body

8. Spark Plug: Ignites fuel

9. Flame Holder: Prevents flashback and flame out

10. Hose: Connects regulator and heat tool

11. Adjustment Knob: Adjusts pressure on regulator

12. Regulator: Regulates fuel pressure to heat tool

13. Pressure Gauge: Indicates pressure in the line

14. POL Fitting: Connects regulator to tank and contains excess flow valve

15. Propane Tank: See “Choosing the Correct Propane Tank” section

24

16. Tank Valve: Opens/closes fuel supply

25

PRINCIPLES OF OPERATION

The Model 998 offers an improved jet pump using a multi nozzle orifice. The jet

pump is shorter and more efficient with the benefits of a wider and more powerful

heat pattern. The 998 is basically a simple jet engine, the high energy exhaust of

which is used to pump and heat the surrounding air and deliver an air blast of high

velocity and moderate temperature. Its’ effectiveness is based on the high level of

technical development which has gone into optimizing each stage of operation:

1. Jet Pump. The propane jet (A) draws the correct amount of combustion air

through the air inlet (B). They mix together in the straight section (C).

2. Compression. The conical section (D) turns speed into pressure.

3. Combustion. The combustion process is carried out inside the combustor (E).

The flame holder (F) prevents flashback (where the flame travels back into the jet

pump) and the flame out (where the flame is blown out of the combustor).

Another proprietary function of the flame holder is to achieve the effect of

maintaining cold combustor walls in spite of the fact that the combustion is

substantially completed inside the combustor. This is done by imparting a swirl to

the mixture. During combustion, the burned portion of the mixture expands, and

26

its’ density diminishes. The swirl centrifuges the unburned, heavier portion

outward and thereby creating a blanket of cold mixture along the walls. As

combustion proceeds, the process draws from the protective layer of unburned

mixture, and when combustion is completed the cooling effect stops. The size of

the combustor ensures that for rated flow the point of completion coincides with

the outlet. Operating at less than rated pressure, the blanket of unburned mixture

does not extend all the way to the outlet and results in a red hot combustor outlet.

4. Expansion. By virtue of the internal combustion process at elevated pressure a

portion of the heat energy is converted to exhaust gas velocity. The gasses are

expanded into the atmosphere through the combustor (E) with a velocity of over

160 MPH and a noticeable amount of thrust.

5. Entrainment. A second jet pump effect is created by the exhaust gases as they

leave the combustor. The slot shaped outlet of the combustor creates a large

mixture interface and promotes high volume entrainment within an unusually

short distance. The exhaust gases transfer their heat and momentum to the

entrained air and thus create a stream of high volume, low temperature air.

27

28

29

MODEL 998 PART NUMBER AND DESCRIPTION

Part #

Description

Part #

Description

1

Filter Holder

25

Contact Screw

2

O ring

26

Contact Spring

3

Filter Screen

27

Socket

4

Filter Spring

28

Spark Plug

5

Orifice Assembly

29

Assembly Screws (10)

6 & 24

O ring

30

Combustor

7

Retainer

31

Button

8

Inlet

32

Flame holder

9

Fuel Line

33

O ring

10

Pump Body

34

Strap

11

Label, Right Hand

35

Button Spring

12

Label, Left Hand

36A

Hose Assembly

14

Name Plate

37

Regulator

15

Housing, Right Hand

38

POL

16

Housing, Left Hand

39

Gauge

17 & 18

Trigger/Igniter Assy

40

Carrying Case

20

Safety

41

Guard Screw

21

Spring

43A

UL® Guard

22

Valve Assembly

44A

Wrench

23A

Hose Adapter

30

ASSEMBLY AND DISASSEMBLY

1. Filter Cleaning

1.1 Unscrew filter holder (1) using a screw driver or a coin. Pull out the filter holder.

1.2 Pull out the filter screen/spring assembly (3, 4) and clean with compressed air or

replace.

2. Spark Plug Replacement

2.1 Depress button (31) and remove combustor assembly (30).

2.2 Pull spark plug (28) and flame holder (32) out with a pair of pliers.

ASSEMBLY AN

nianel Crtel

i

retlfwercnsU

vidrwerc

ng

iusrdehol

tlfhet

outlulPn.oicorr

rdeholre

t

tlfhet

outlulP2 ec

lpre

l Pk

p

2. S

on tbut

epreD2.

n

iprn/eercrey blme

g

t

l

ortbusomc

ovemernd

epromch tiwn elcnd

4)

(

y

blme

orrid e

ug

pl

k

rpalulP2 2.

rdeholemfnd

28)

reiplofripah tiwout

31

2.3 Unscrew spark plug. Note: spark plug the cable (17, 18) and the contact spring gap

should be set to 3-5mm. (26).

3. Trigger/Igniter Replacement

3.1 Undo the 5 mounting screws (29) and remove right housing (15).

3.2 Undo contact screw (25) which retains the trigger/igniter cable (17, 18) and the

contact spring (26).

3.3 Snap off the strap (34) with a screw driver.

k

rpawercnsU2.ottebdlu

o

ug

pl

ce thglu pk

rpte

o

26)

m

ctano ce thdn

a

)

(

le

b

p gg

in

rpt s

3. /te

I

oumhetndo Utcontcndo U2 )2gnirptnco

t mel

R

omernd

29)

wer

c

ng

i

unthetnsiterh chi

w

25)

wer

c

ng

i

hous

ght

irleb crite

n

/ig

r

e

g

ig

tr

)

(

n ahetd

hetofp na

r

p

reivr dwerc s a

ith

w)4

(

32

3.4 Pull out trigger/igniter cable (17, 18).

3.5 Trigger/igniter assembly (17, 18) can now be lifted out.

4. Orifice Replacement

WARNING: The orifice (5) consists of 6 slender, thin walled tubes which can easily

be bent or damaged if dropped or mishandled. Once bent, the performance of the gun can

be seriously impaired. For this reason the following operation should be performed with

utmost care.

outlulP4 re

g

ig

tr/r

e

g

g

irite

n

ig

r

ite

n

/ig

e lcab

).

y

lbemwonn

c

)

tuodefile

b

l Rfi

NINRWA Td gemdaorntbe

be

t

(

eifr oeho

c) oftinsd.endlhasimord

oppe

drfi

hwubetd ellwn hitr

ndeelencmf

rpehetntbee

nc

y

lien ch cn a

c

gun

hetof

r

ipam

iy l

ousirebeerctosm

ut

d.eollfehtnoerihtr

Fo

epebdluohnoitrepogniw

htiwdemrf

r

33

4.1 Remove the right housing (15) as shown in operation 3.1

4.2 Undo the 3 mounting screws holding the pump body (10) and remove the pump first

by sliding it away from the orifice and then lifting it out. This sequence is important

because the orifice reaches inside the pump. Lifting the pump before sliding it away will

damage the orifice tubes.

4.3 Unscrew the orifice (5).

4.4 Use a .6mm drill to clean out each orifice stem.

omeR4.girhetveomhet

ndo U2

4.

ng

i

hous

ninwo

h

)

pu

he

t

ng

di

holwerc

ng

i

unt

noitra

epo

p

y

do b (tevomred

n

)

trsfpm

upe

h

fy wti

ng

diil

by

ecfiorheteuscbeecfiorhe

tgemdaorhetwercnsU

4.

filn hetnd ecfiorhetomdeinsihecer

ipm

u pethubetecf

i

)

(

iiencehioutti

ng

iinlid serfe bpm

u pe

th

g

nt

t

por

m

ill

wyaw it a

g

idrmesU4

4.

ecfiorh ceoutn aelco tl

l

met

34

35

HEAT TOOL SERVICE INSTRUCTIONS

•

In the event that your heat tool requires servicing or repair work performed,

Shrinkfast and/or your distributor can provide a parts list and assembly diagram

as a reference tool only.

•

Neither Shrinkfast nor the distributor make any representation or warranty of

any kind to the buyer that he or she is qualified to replace any parts of this or

any other Shrinkfast product. Shrinkfast and/or your distributor expressly states

that all repairs and part replacements should be undertaken by certified and

licensed technicians and not by the buyer.

•

The buyer assumes all risks and liability arising out of his or her repair to the

original product or replacement parts thereto, or arising out of his or her

installation of replacement parts.

•

If you require any assistance with servicing or repair work, you can contact your

local distributor or Shrinkfast direct at 603.863.7719 or via email at

info@shrinkfast-998.com

•

Shrinkfast provides free estimates on any repair or service request.

36

DAILY HEAT TOOL INSPECTION

•

Before turning on the heat tool, visually inspect the hose for any cracks or

breaks that can cause a propane leak.

•

When you turn on the gas at the propane tank, make sure the regulator gauge

pressurizes to 22 PSI before firing the heat tool and then leak check all fittings

and connections.

•

If you suspect a leak, use a spray bottle of soapy water and spray directly on

each connection to detect any leaks – indicated by bubbles coming from the

connection.

•

Before firing the heat tool, make sure you do not have a strong smell of propane

or hear any “hissing” which would indicate a possible leak inside the heat tool.

•

When you are finished using the heat tool (at any time during the day), shut off

the propane tank and pull the trigger on the heat tool to purge any remaining

gas inside the hose.

WARNING: Do not operate the heat tool if the pressure on the gauge

drops below 15 PSI. Operating the heat tool below 15 PSI will cause the

flame to burn inside the heat tool and damage the internal components

voiding the warranty.

37

MONTHLY HEAT TOOL MAINTANENCE

•

Using compressed air, depress the yellow button and then pull off the combustor

(part # 30 in assembly diagram) and clean out any debris inside the combustor

assembly.

•

Using compressed air, clean out the main body of the heat tool (part # 10).

•

Using compressed air, remove the filter holder assembly with a flat blade

screwdriver (part # 1, 4, 3) in the back of the heat tool and clean the screen.

•

Inspect the o rings (part # 33) inside the combustor for cracks and replace if

necessary or apply o ring lubricant.

38

TROUBLESHOOTING GUIDE

Problem

Probable Cause

Remedy

Gun will not ignite

Safety and/or trigger are not fully

depressed.

Depress the safety first, and then pull the

trigger to ignite.

Trigger is pulled to quickly

Squeeze the trigger slowly to ensure the

propane has entered the combustor before

firing.

Propane tank pressure too low

Check the regulator to make sure the Gauge is

reading a minimum of 15 PSI.

Propane tank valve is not turned

on.

Turn on tank valve and check the regulator

gauge for proper pressure setting.

Defective igniter

With propane turned off and gas purged from

the hose, check for spark in the combustor.

39

Problem

Probable Cause

Remedy

Gun will not

The POL excess check valve

has not fully opened.

Turn on propane tank valve and wait 10

seconds or until the needle on the regulator

has reached the factory setting of 22 PSI.

An audible “click” will be heard when the

hose has fully pressurized with gas.

Clogged orifice

Remove and clean with compressed air.

Clogged fuel line

Remove and clean with compressed air.

Clogged pump body

Remove and clean with compressed air.

Clogged hose assembly

Disconnect and clean with compressed air.

Combustor turns

glowing red

Low pressure from tank

Increase pressure from tank or replace tank.

Extremely large

flame

Wrong fuel type

Do not use a fork truck tank; only vapor

withdrawal tanks like a BBQ tank.

Tank, regulator or

hose fittings have

iced up.

Low pressure from tank

Increase pressure on regulator or change to

a new tank.

40

TECHNICAL SPECIFICATIONS

OUTPUT CHARACTERISTICS

MODEL 998 TECHNICAL SPECIFICATIONS

OPERATING PRESSURE of 22 PSIG

Distance / Ft.

Temperature / F

Velocity / Ft./Min.

6”

1120

2100

1’

650

1200

2’

390

660

Heat Capacity

172,500 BTU / Hr.

Propane Consumption

8.0 Lbs. / Hr.

Operating Pressure

22 PSIG

Weight

2 Lbs. 2 Oz.

Air Consumption

30 CFM

Emission

.015 CO/CO2

41

SHRINKFAST

460 Sunapee Street

Newport, NH 03773-1488

(800)867-4746 or (603)863-7719

Loading...

Loading...