Showven X-F3600 User Manual

USER MANUAL

CIRCLE FLAMER X-F3600

V1.2

Showven Technologies Co.,Ltd.

CIRCLE FLAMER X-F3600

USER MANUAL

★ Please read this manual carefully before operating this product.

★ Warranty card attached in the manual, please keep it well.

▲WARNING

• Unauthorized repair are prohibited, it may cause serious incident.

• Make sure power supply in consistent with the rated voltage of the equipment, and the socket must well grounded. Unplug

and turn off the machine when not use.

• Before connect the power cable, communication DMX cable should well connected and ensure the command keep at firing

OFF status. And safety lock stay at test mode.

• The device can only be placed horizontally. Safety distances are marked on the device (at least 15m in all projection direc

tions, at least 5m to the other sides of the device).

• After turning on the device, no person allows to stay in the danger area. Ensure all persons that are part of the show be

informed about the safety distance, risks and functions of the device.

• Always have a CO2 fire extinguisher and an extinguishing blanket in case of needed.

• If there be any doubt as to the safety operation of the device in any circumstances, the device should be taken out of service

immediately. Be sure the device is in good operating condition before use. If fail to fire correctly, immediately shut down

and check it accordingly

• Be sure to use high quality flame fluid, otherwise, it is easily lead to failure or danger. Be careful when refill the flame fluid

tank. Please keep flame fluid away from heat source, sparks, fire or other possibility of ignition. Do not smoke!

• The operator responsible for the control of Circle Flamer must always have a clear view of the device, so that he/she can

stop the show immediately when there is danger. The main AC power switch should near operator. So that operator can

turn off the power of all devices in case of abnormal.

• The device shall not be altered and applied to other use purpose

• Notes for use of Battery power supply: CIRCLE FLAMER with stable internal circuit design, please support X-F3600 with

battery voltage higher than 12V. The driving speed of motor won’t change because of the decrease of battery power

supply. Battery options: 12V lead-acid battery (above 30AH, with more than 24h standby). For Lithium battery, please use

battery with output above 30A. Socket type: NEUTRIK-NL4FX, 4 pin sound coupliers (1+ connect 12V anode, 1- connect

12V cathode). Connecting power cables should above 14AWG.

• Nozzle Protection Cover of X-F3600 should be removed before power-on, otherwise the rotating mechanism of the equip

ment will be damaged. The Nozzle Protection Cover is only used during the transportation.

• The firing nozzle of X-F3600 is strictly forbidden to rotate over ±90° manually in case of power-off, otherwise the rotating

mechanism of the equipment will be damaged.

▲Foreword

Thanks for choosing SHOWVEN CIRCLE FLAMER X-F3600. Please read following manual carefully and completely before

operating this product. Operate according to instructions is very important for safety, and can elongate the service life of the

machine.

Strictly follow the instruction in the manual when operate Circle flamer X-F3600. If you have any doubts, please contact

SHOWVEN technologies Co., Ltd by info@showven.cn.

We assume the person who use or come in contact with the device are familiar with how the device should be handled. This

includes proper use, maintenance and repair of the machine as defined in this user manual.

1

Disclaimers:

SHOWVEN technologies Co., Ltd excludes liability for unsafe situations, accidents and damages resulting from:

1. Ignoring warnings or regulations as shown on circle flamer or this manual.

2. Use for other applications or circumstances other than those indicated herein.

3. Changes to the circle flamer, including use of non-original spare parts.

4. Removed safety cover without authorization from SHOWVEN.

5. Use this machine by unqualified or untrained personnel.

6. Improper use of machine.

▲Functional Characteristics

• Compact pumping system ensure compact size of machine.

• Double electromagnetic valves design for additional safety.

• Tilt protection, the tilt sensor will be activated when machine slant Over 45° .

• Unique safety lock design, device can't firing when locked, avoid spurious triggering.

• Intelligent control system: pressure monitoring, safety warning, no fuel alarming, system failure warning etc.

• High performance nozzle, reliable and durable.

• High-accuracy rotating head driving and controlling system, allows for fast and precise flame bursts.

• Strengthened and rustproof metal panel, water-proof design.

• Neutrik PowerCON TRUE1 and DMX socket.

• Standard battery connector configuration, support 12V battery power supply.

• Fitted with fireworks igniter signal port, can be triggered by fireworks igniter.

• Flame effects up to 8-10m (no wind), with maximum rotation of 3 cycles.

• As much as 160 preset flame sequences are available. It is easier and stable to running the CIRCLE FLAMER when controlled

by SHOWVEN original host controller ZK6200/ZK6300.

▲Technical Specifications

MODEL Circle Flamer X-F3600

Rotation Mode Switch FULL CIRCLE MODE / HALF CIRCLE MODE

Dimension 640 x 360 x 370mm

Input AC100-240V,50-60Hz

Work power 380W

Interface Double DMX Interface;

9V-60V Fireworks igniter signal port

Control Standard DMX

Effect Maximum Height 8-10m (no wind)

Effect Angles 1080° (up to 3 cycles)

Fuel ISOPROPANOL, ISOPAR G,H,L,M, BIOETHANOL

Fuel Bottle Capacity 10L

Weight (no fuel) 30Kg

Fuel Consumption Rate 60ml/s

2

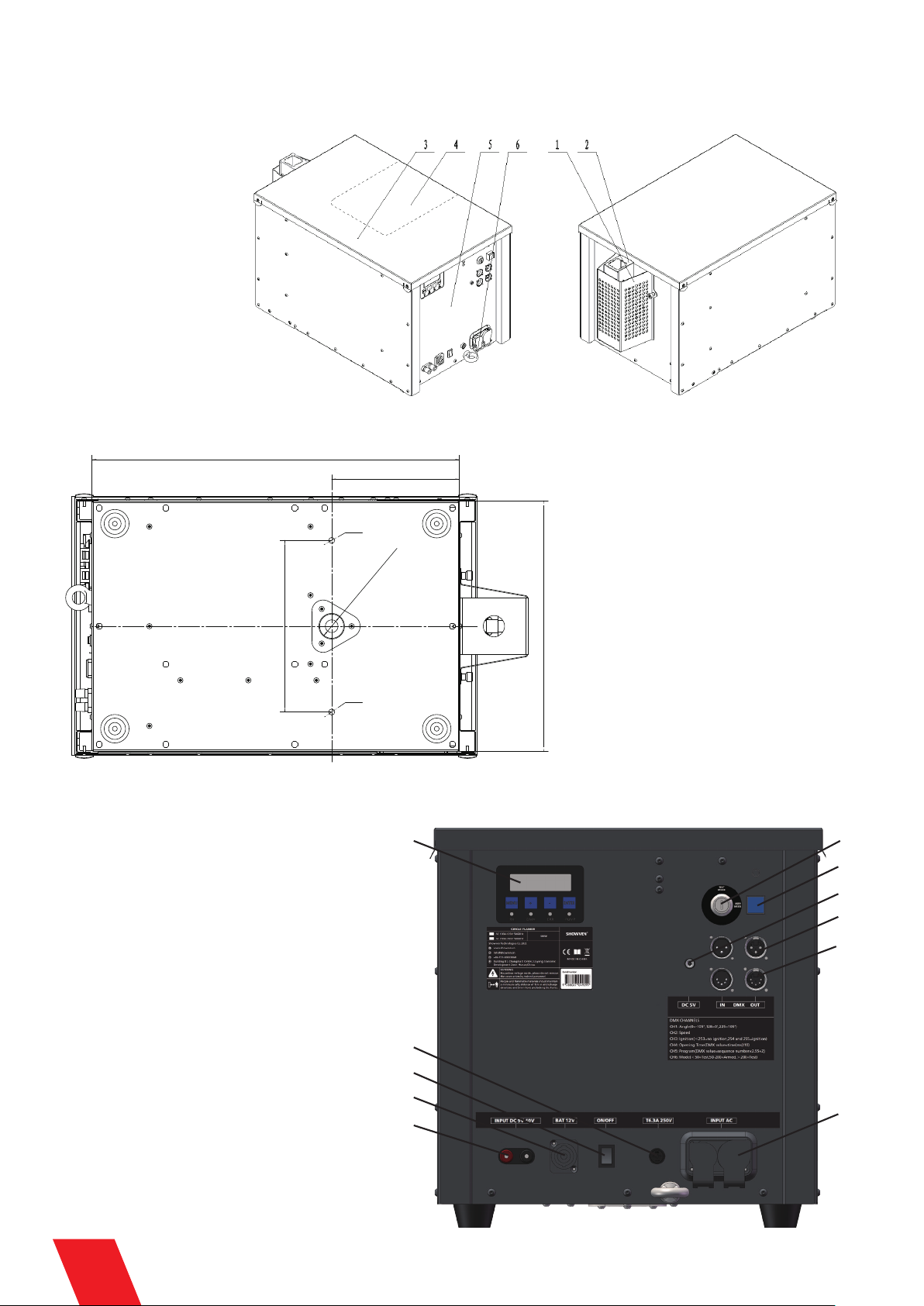

▲Structure of Circle Flamer

1. Nozzle Protection Cover

2. Firing Nozzle

3. Top Panel

4. Fuel Bottle Area

5. Control Panel

6. Safety Loop

• Connection dimension diagram of bottom bracket of the flamer

516

179.5

M10

φ34 fixing hole

241

M10

▲Overview of Control Panel

1. LCD screen operate panel

2. Safety Lock

3. Indicator Light

4. DC 5V output

5. 3-pin DMX socket

6. 5-pin DMX socket

7. 110V/220V Power socket

8. Fuse

9. ON/OFF switch

10. 12V Battery socket

11. DC 9V-60V fireworks igniter signal port

1

8

9

10

11

352

2

3

4

5

6

7

3

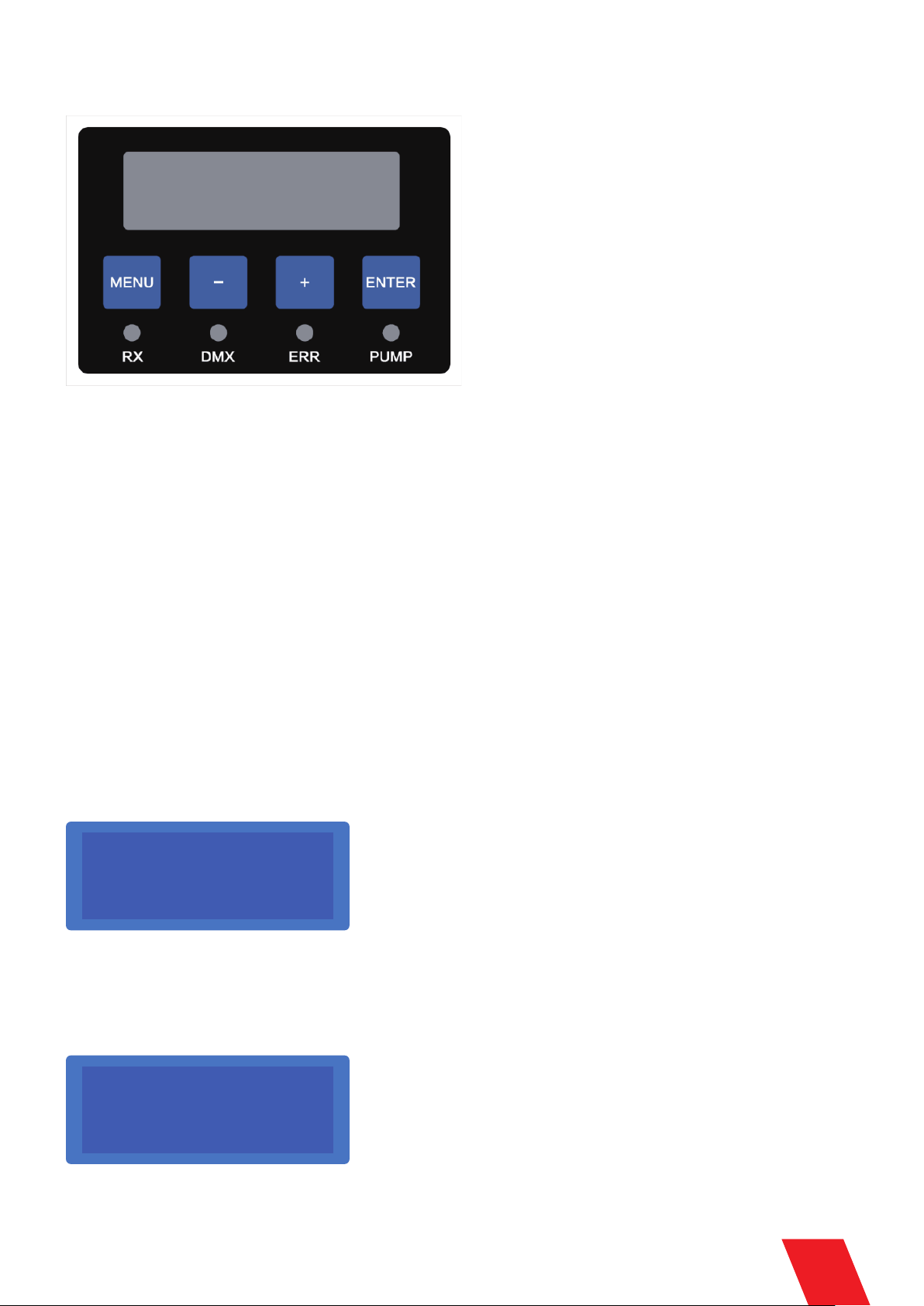

▲Operation Panel

1. LED Display Area

RX: Radio receiving (reserved);

DMX: DMX signal. Flash means DMX signal available, otherwise no DMX signal;

ERR: Light on when there is an error;

PUMP: Light on when pump is running.

2. Button Funtions:

MENU: Switch interface to setup parameter;

+: Parameter Up;

-: Parameter Down;

ENTER: Confirm and save parameters (screen will flash when parameters saved);

Note: screen display will switch to main interface if don't press button for a long time.

3. Welcome Interface

First Line: Product model and software version number;

Second Line: Equipment factory number.

F3600-B181023

B180921016

4. Main Interface

First Line: Rotation Mode(Full Cycle Mode(360) or Half Cycle Mode(180) );DMX address;

Second Line: Pressure100 (e.g. 100=10bar); V: 13.6 means internal voltage is 13.6V.

360 DMX Add 1

P: 100 V: 13.6

4

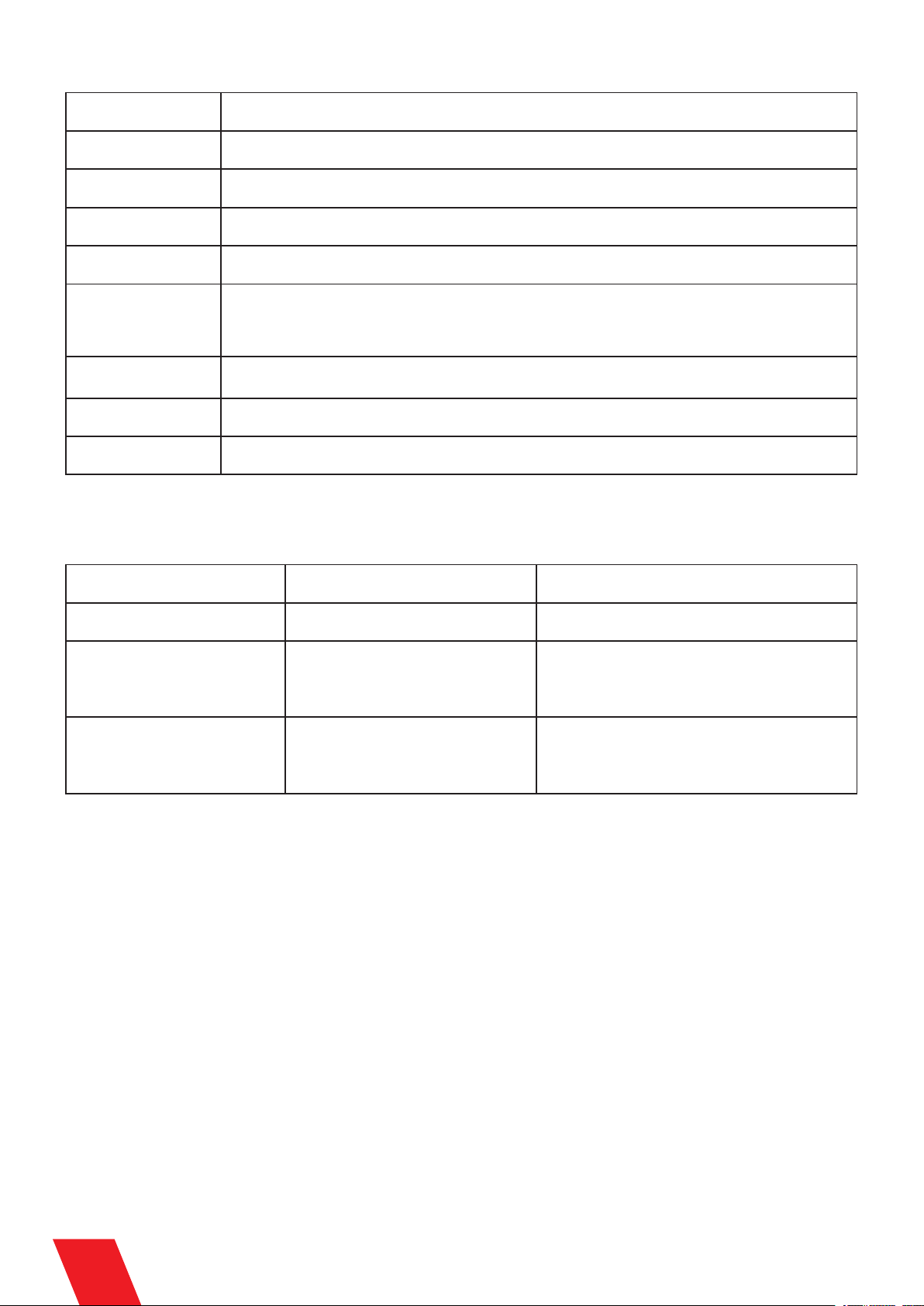

5. Alert Message

Alert Message

E0 System Lock

E1 Pressure Err

E2 P Relief Err

E3 Motor Err

E4 Ext Ignition

E5 Voltage Err

E6 Tip Err

Explanation

Safety lock located at TEST MODE.

Pressuriser for about 13s, pressure value failed to reach 100%, system will report E1.

Possible fault: No fuel, pump failure, pipeline problem etc.

Pipeline can't release pressure leads to pressure relief error.

Possible fault: pressure release valve failure, pipeline problem or control system problem etc.

Motor fault Possible fault: swiveling nozzle stuck, motor failure etc.

When Ext Ignite is ON, device will pressuriser automatically when switch safety lock to USER

MODE; decompression when switch to TEST MODE. 9V-60V fireworks ignitor signal will

trigger related firing sequences.

Battery voltage>15V or <10V for continuous 5s, machine stops running.

Possible fault: the battery is low.

if the machine slant over 45° , it stops running,system will report E6.

DMX signal blocked in factory mode.E7 Factory Mode

6. Interface setup

Press “MENU” to switch through setup menu.

Menu Range Explanation

Set DMX Address 1~512 DMX address setup

Set Rotation Mode

Angle Limit

Note: Angle limit activate

under half cycle mode

Full Cycle Mode(360)/

Half Cycle Mode(180)

MIN: NO.1-NO.15

MAX: NO.1-NO.15

Switch Cycle Mode

Restrict nozzle rotate angles: Set by "+" and

"-" , and confirm by "ENTER"

5

7. Advanced Interface

Press “MENU” 3s enter advanced interface, press “MENU” to switch interface, press “MENU” 3s can back to main

interface.

Contents DescriptionItems

OFF / Motor/ Pump / Igniter / Relief Valve / Jet Valve

Drive Test

Ext Ignite

Set Ext Sequence

Language

Mode Select

Tip Setting

Reset Parameter

1. Motor

2. Pump

3. Igniter

4. Relief Valve

5. Jet Valve

ON / OFF

Full Cycle Mode: 1~94

Half Cycle Mode: 1~70

Chinese / English

Factory Mode / Normal Mode

ON / OFF

YES / NO

Swiveling and stop at target angle.

Pump running 1s, if pressure reached the

target value, the pump will not running.

Ignite 1s

Release pressure 1s

Safety lock located at user mode, release

pressure for 5s, open jet valve and close to

check the working status of jet valve.

Trigger through 5-60V fireworks ignitor

signal

Preset sequence triggered by fireworks

ignitor

Language switch

Factory mode is for test in factory only

Turn ON/OFF tip over function

Reset default parameter settings

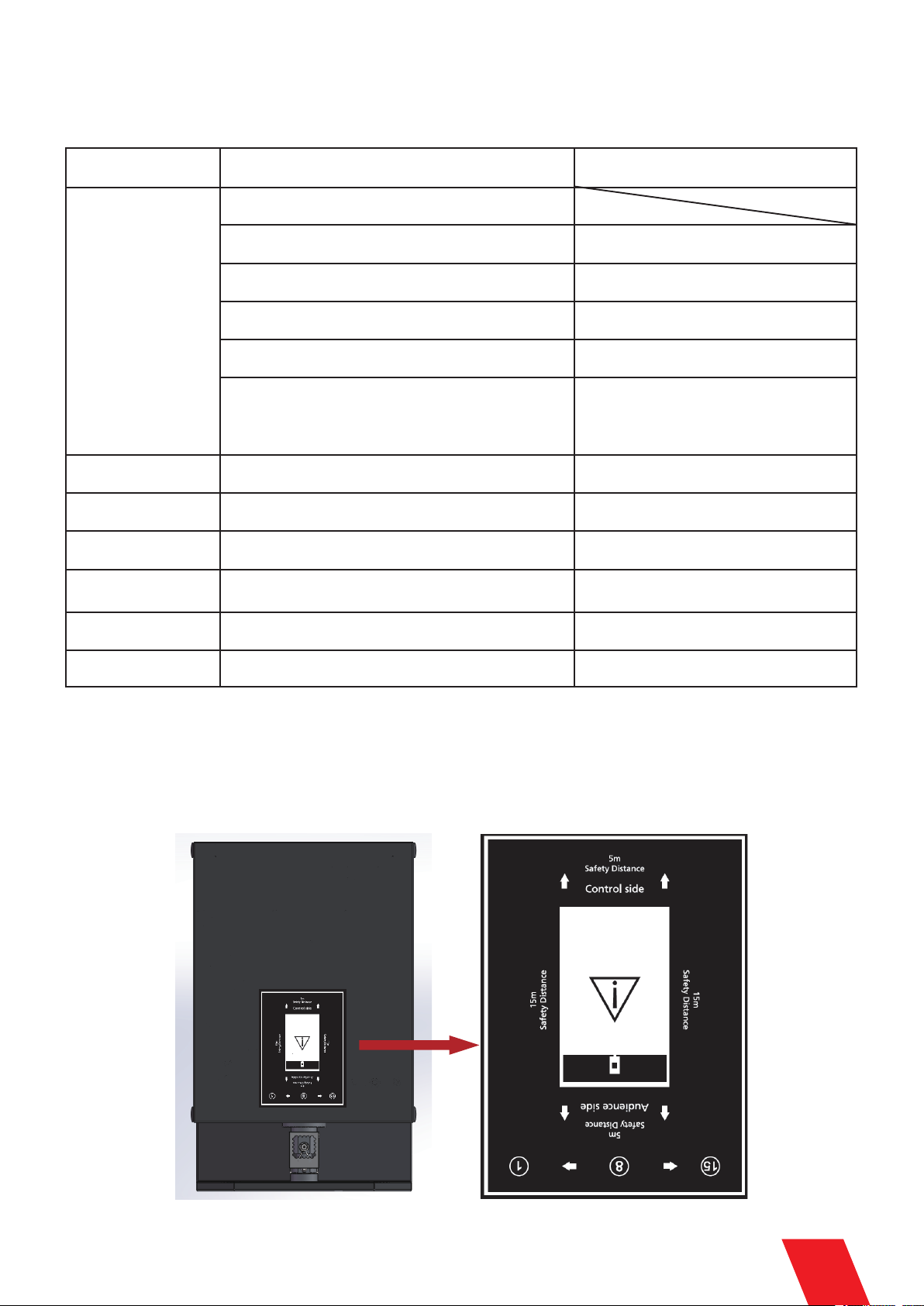

▲Operation Instructions

1. Direction explanation

Please read the safety distance print on the top panel of CIRCLE FLAMER carefully.

6

(1) 1 to 15 is the firing angle when Circle flamer running in half cycle mode.

(2) AMGS is the firing direction when running in full cycle mode, A is downward, M is upward, G is left side, S is right side.

For more detail please refer to angle definition in under full cycle mode.

(3) Audience side and control side are indicated in above picture.

(4) Safety distances for CIRCLE FLAMER are indicated in above picture. At least 15m in all projection directions, at least 5m

to the other sides of the device.

Note: in order to indicate correct direction, please place the top panel correctly.

2. Quick Operation Sheet

Immediately upon receiving the machine, carefully unpack the carton, check the machine received in good condition. Ensure

safety operation of machine, please do following below operation procedures when operate CIRCLE FLAMER.

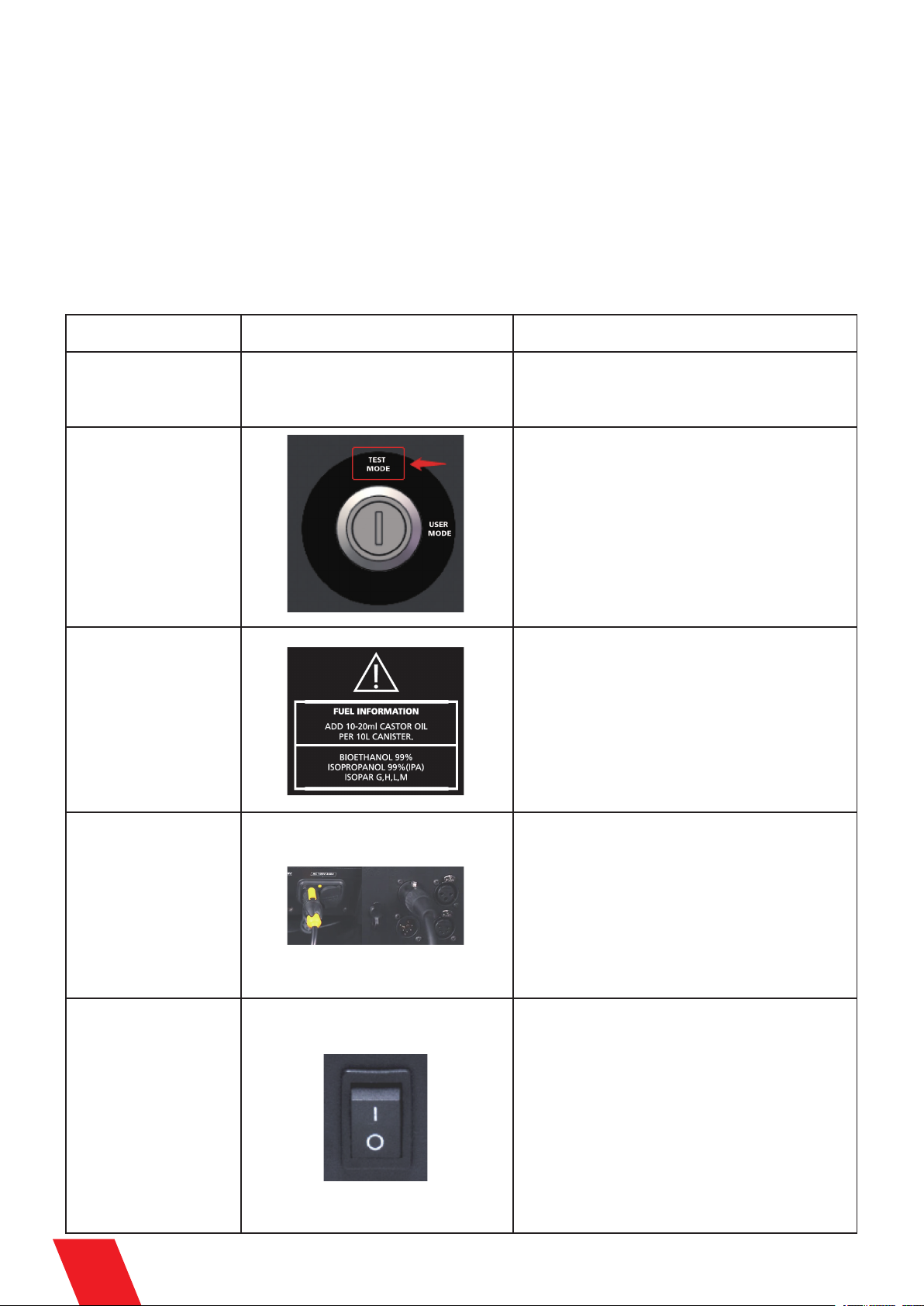

Operation step Schematic diagram and explanation Explanation

The device can only be placed horizon-

1. Installation

2. Locate safety lock at

TEST MODE

tally, if placed on truss, please locked

with extra safety ropes,Remove nozzle

protection cover if it exist.

Before operate machine please locate safety

lock at TEST MODE.

TEST MODE: operator can test the rotate of

nozzle, but the fuel ejection function disabled,

so there is no fuel eject and flames.

USER MODE: the device can generate flames

normally. Please strictly follow the safety

distance requirement, remove all human,

animal or flammable objects in the danger area.

3. Fueling

4. Power and DMX cable

connection

5. Switch ON the

machine

Please fueling with high quality fuel according

to requirement of this manual.

Two kind of power supply optional:

1. 110V/220V main power supply

2. 12V battery power supply

Please confirm safety lock located at TEST

MODE before switch on the POWER ON/OFF.

7

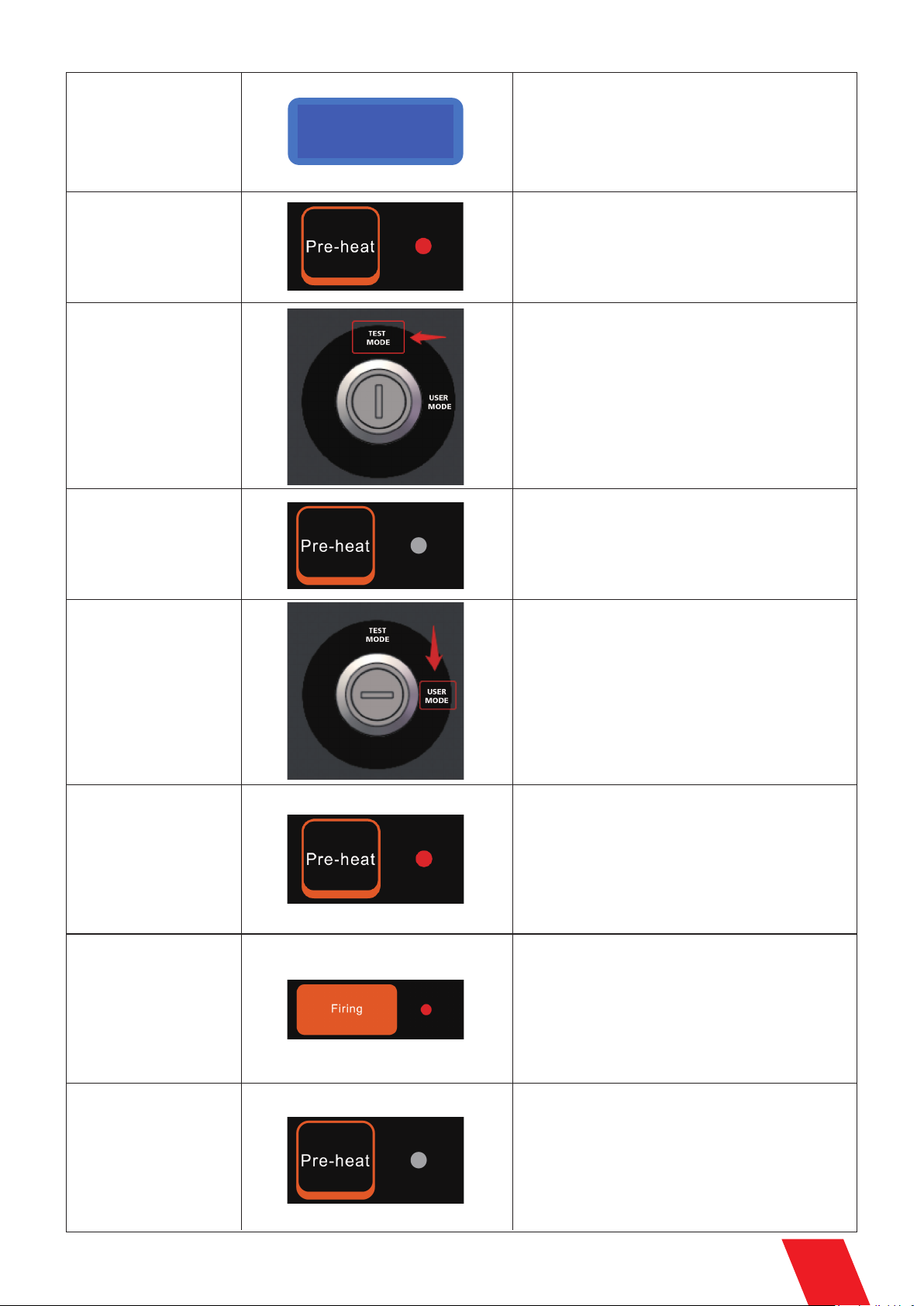

6. Set DMX address

7. Pressuriser

8. Check device status

in TEST MODE

9. Pressure Relief

Set DMX Address

1

CIRCLE FLAMER occupy 6 channels.

Detail information please refer to the table of

page18.

Host controller: Press”pre-heat” button (light on).

DMX console: switch DMX value of channel 6 to

50-200.

Reconfirm safety lock located at TEST MODE before

test. In this status, the nozzle will rotate, and igniter

will activated, but there is no flame.

When use DMX console to test the sequence,

suggest to set CH1 at 128, so that nozzle stay at

straight up position after each sequence.

Host controller: Press “pre-heat” key (light off).

DMX console: switch DMX value of channel 6 to

0-49/201-255.

10.Switch safety lock to

USER MODE

11. Pressuriser

12. Firing

Before switch to USER MODE, Please strictly follow

the safety distance requirement, remove all human,

animal or flammable objects in the danger area.

Host controller: Press”pre-heat” button (light on).

DMX console: switch DMX value of channel 6 to

50-200.

Set firing sequence

Host controller: Press “FIRING” key.

DMX console: switch DMX value of channel 3 to

254-255.

13. Pressure Relief

Relief pressure when show finished or CIRCLE

FLAMER not use for a long period.

Host controller: Press “pre-heat” key (light off).

DMX console: switch DMX value of channel 6 to

0-49/201-255.

8

Loading...

Loading...