Shortening Shuttle SS-914 Service Manual

Worcester Industrial Products Corp

How to Assemble,

Use, and Care For

The

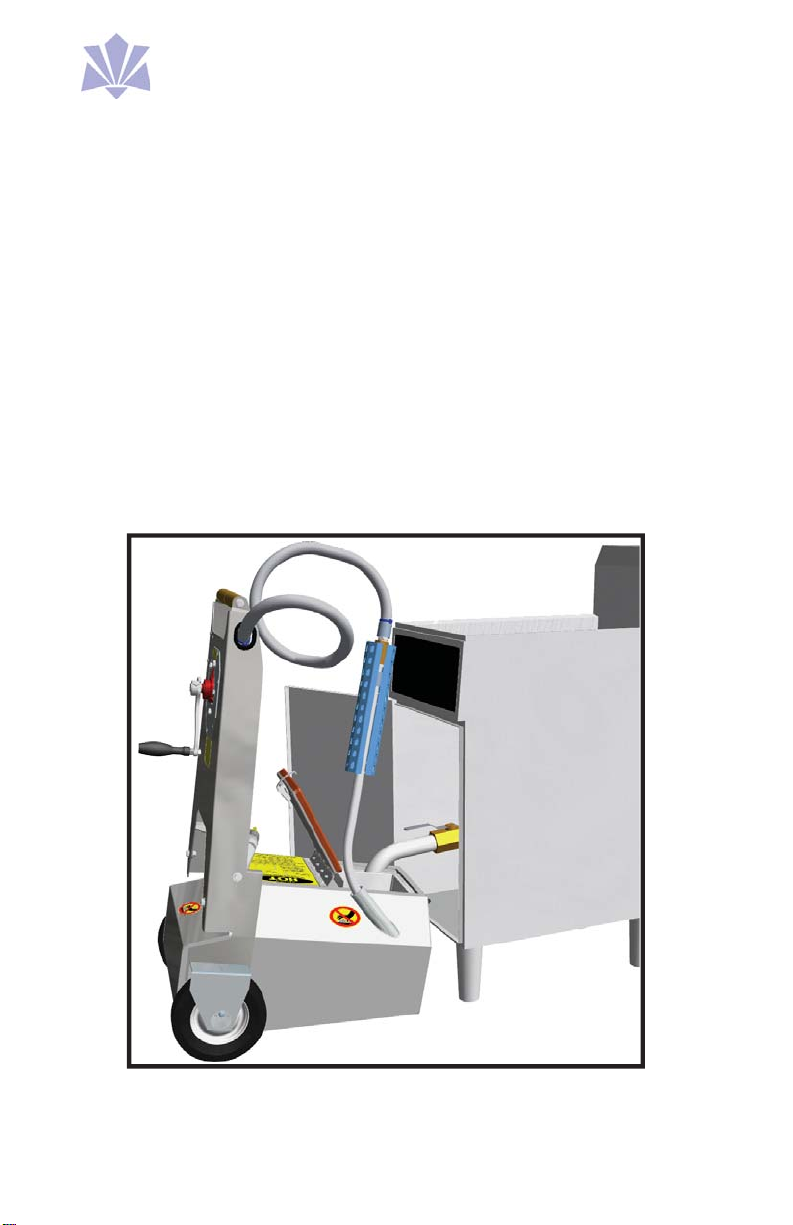

Shortening Shuttle® Pump

Shown with Optional Shuttle Wand

Model # SS-914

(SS-WAND)

Safety Precautions

Please read carefully and follow all safety

precautions to ensure maximum safety.

)Maximum temperature the tank of the Shuttle Pump will safely

withstand: 300º F

)Warning:

)Caution: Skin burns at 120

You MUST wear proper clothing when operating

this unit. W e recommend using heat resistant Safety

Gloves. See OSHA guidelines for handling hot oil.

º

F . For maximum safety use when

hot oil is below 120º F.

Operating Precautions

)Caution: Debris must be kept out of the pump when not in use.

Make sure that a Basket Strainer & the suction tube

strainer (

)Warning: Do Not use excessive force to rotate the pump.

Excessive force will damage the pump.

)Warning: If water is pumped through the unit, the pump will

be damaged by subsequent rust deposits. If water

is accidently run through the pump, then pump

four(4) to eight(8) cups of clear warm oil (80 to

º

90

F) through it to clear out the water and coat the

internal parts with oil.

at end of hose) are in place at all time.

)Cleaning: Rinse outside only with hot water and a mild

detergent (Do Not use any caustic cleaning agents).

Clean the inside by wiping with a cloth or paper

towels. Do Not put water inside the Shortening

Shuttle

®

Pump.

)Never leave water in the unit. Never run water thru pump.

)Never mix hot oil with water in the unit.

2

Assembly Instructions

ts

The following parts are included in the 2 boxes for the Shuttle Pump:

1 Pump/Handle Assembly

1 Long

H2 Hose

Assembly

1 pair of Safety Gloves

1 Crank Handle

4 3/8-16 x 3/4 long Bolts

& 4 Washers

4 3/8-16 Lock Nuts

1 T ank Assembly

1 Universal Assembly Tool

1 SP-BS-100, Basket Strainer

Optional

Shuttle Wand

(SS-WAND)

Note: Before beginning assembly inspect all included parts to be sure

there is no shipping damage. Contact the shipper immediately

if there is any damage.

3

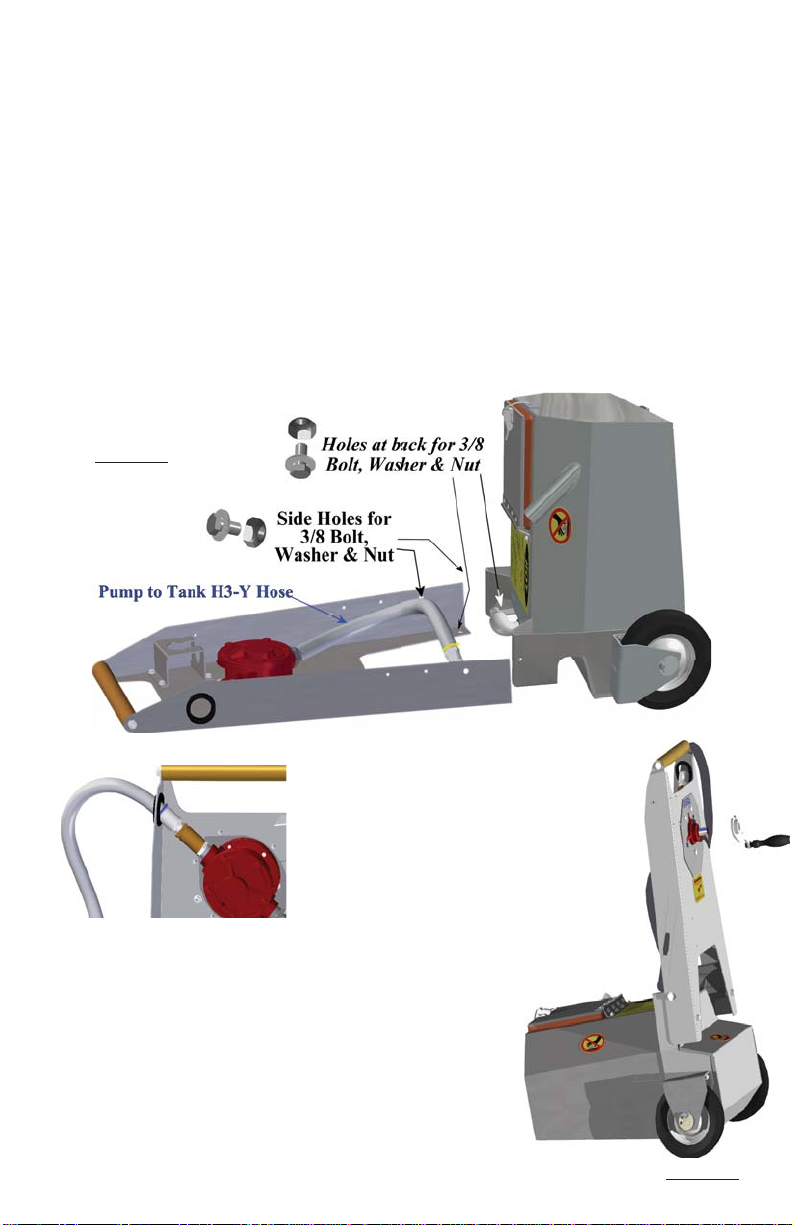

The Shortening Shuttle® Pump. has been designed for quick and

easy assembly . The Pump/Handle Assembly and the T ank Assembly

have been shipped in two boxes to minimize shipping damage.

Orient the Pump/Handle Assembly and the Tank Assembly as

shown in fi gure 1. Slide the two assemblies together so that the Side

Holes line up, then insert a 3/8 Bolt, Washer & Nut at each side, fi nger

tight.

Now insert a 3/8 Bolt & Washer up from the back and a Nut from

the top side, then repeat for the other side. Tighten fi rmly all of the 3/8

Bolts & Nuts using the Universal Assembly Tool.

Attach the Pump H3-Y Hose to the Tank by sliding the Quick

disconnect onto the fi tting on the tank. Make sure that the Quick connector

clicks in place and is fi rmly seated.

fi gure 1

Slide the Quick disconnect

of the Long H2 Hose Assembly

onto the fitting on the pump as

shown. Make sure that the Quick

connector clicks in place and is

fi rmly seated.

Lastly, attach the crank handle onto the Pump Shaft as

shown in fi gure 2. Be careful that the bolt is

lined up with the hole in the side of the pump

shaft. Firmly tighten the bolt. Caution:

Overtightening will break the handle.

This completes the assembly of the

Shortening Shuttle

®

Pump. Please read the

next section to learn how to operate the unit

safely.

4

fi gure 2

Loading...

Loading...