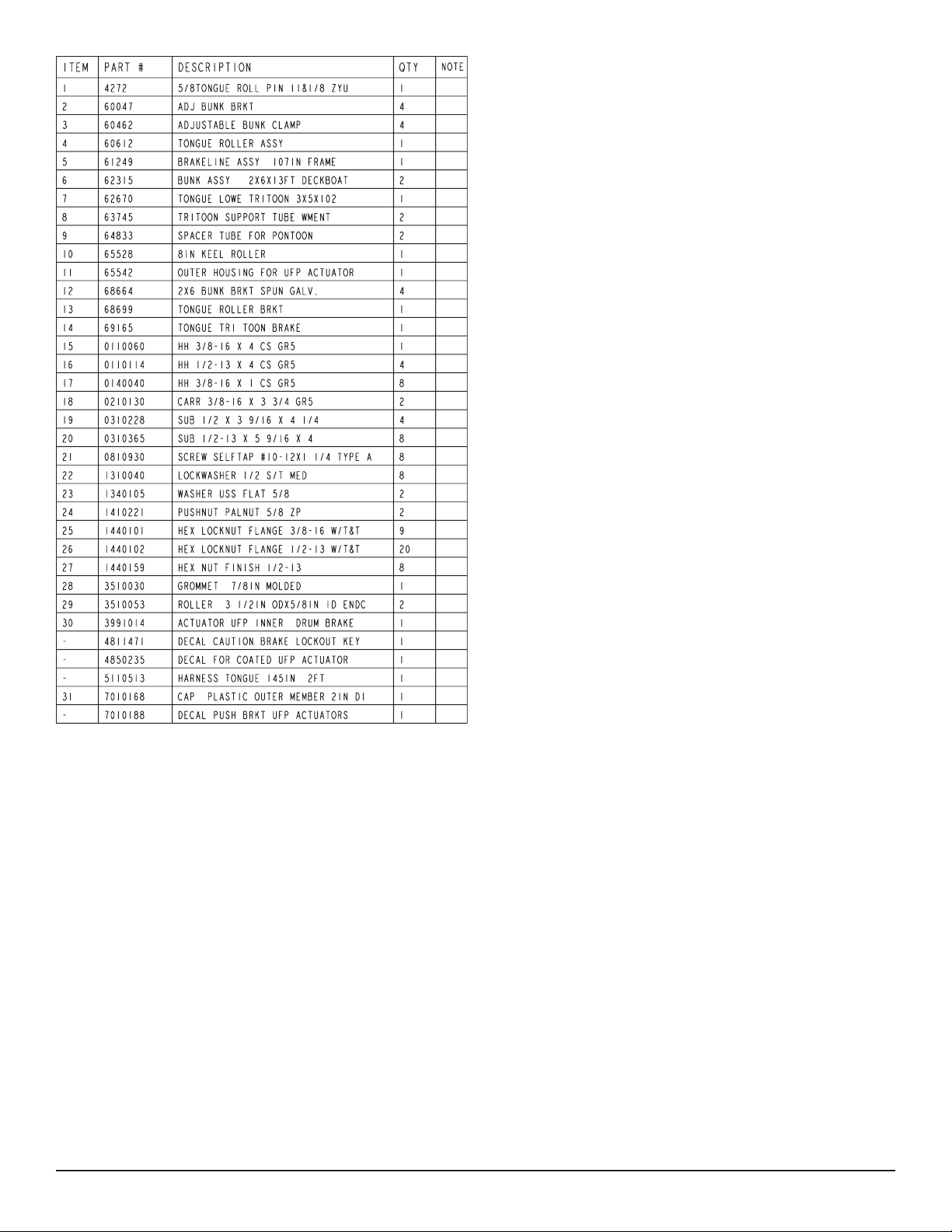

ShoreLand'r TA1067 User Manual

ACCESS ORY

TA1067

Pontoon/Tritoon Brake Kit

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003601

Page 1 11/17/05

brake line. Thread the brake line into the coupling. Tighten.

Note that the brake system will have to be bled using the proper

bleeding method as described in the brake manuals to remove any

air that may have entered the system during the assembly process.

Place a ½” x 5” hex bolt through a ½” flat washer, and then though

the last link of a safety chain. Insert the bolt through the hole provided in the tongue until it is completely in and the excess bolt is

extending out the other side of the tongue. Slide the last link of the

second safety chain onto the bolt, a flat washer and secure with a

½” flange lock nut. Tighten.

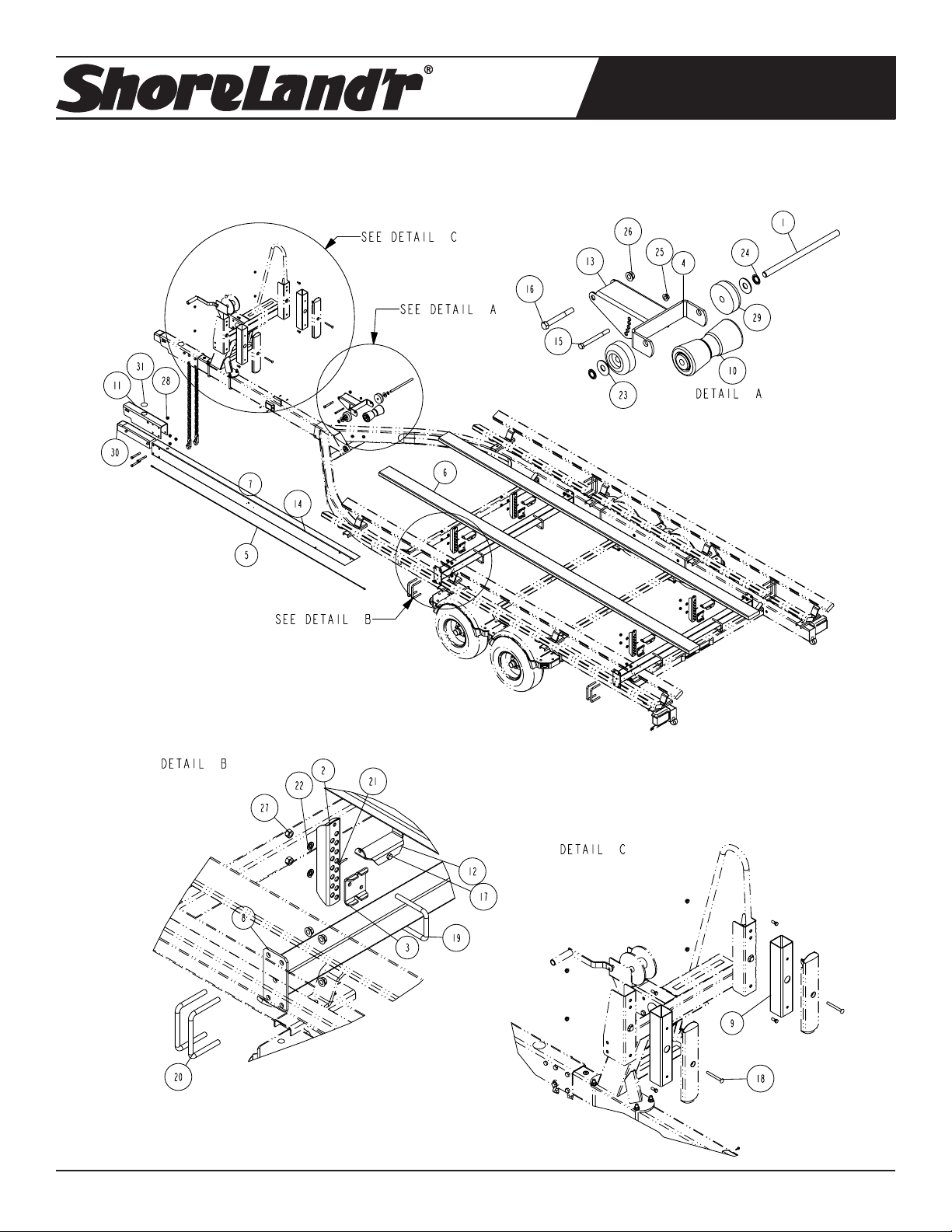

REAR TONGUE ROLLER ASSEMBLY

Locate the tongue roller assembly that will be attached to the rear

of the tongue. Align the holes in the assembly with those drilled in

the rear of the tongue. Attach it to the tongue using a ½” x 4” hex

bolt in the pivoting hole of the bracket. Secure with a ½” flange lock

nut. Tighten but do not over tighten because this roller assembly

must pivot to fit the center pontoon tube once the boat is placed

on it.

Place a 3/8” x 4” hex bolt in the remaining hole attaching the assembly to the tongue. Position the roller assembly so it is in its lowest position. Leave the bolt loose for now until the final adjustments

are made.

TA1067 ASSEMBLY INSTRUCTIONS

The TA1067 kit is used to build a standard pontoon trailer into a

trailer to fit tritoon pontoons. The kit includes all of the necessary

items to add proper support to the tritoon tube during transporting.

It is accomplished as follows:

INSTALLING THE TRITOON TONGUE

Insert the Tritoon tongue into the tongue channel of the frame.

Note that this tongue is cut at the opposite angle so the longer portion of the tongue to the rear will be on the top.

Secure it in place by inserting the ½” x 4” cross bolt into the hole in

the front of the tongue channel. Attach the rear of the tongue using

a ½” x 1-½” hex bolt. Secure with ½” flange lock nuts. Tighten.

Mate the plugs with the side frame harnesses and plug together.

Attach the white ground wires to the frame using the screw removed when disassembling the old tongue.

Carefully form the rear of the brake line coming out the rear of the

tongue so it can mate to the coupling attached to the side frame

TRITOON SUPPORT TUBE WELDMENTS

Locate the two support tube weldments. Place one at the rear of

the trailer just ahead of the rear cross member. Attach it to the side

frames using ½” x 5 9/16” x 4” U-bolts and ½” flange lock nuts.

Square with the side frames, and then tighten in position.

Place the second support tube weldment 90” forward from the rear

one just installed. (See diagram for approximate placement). Attach it to the side frames using ½” x 5 9/16” x 4” U-bolts and ½”

flange lock nuts. Position the support tube weldment so it is square

in the frame. Tighten.

Place a ½” x 3 9/16” x 4 ¼” square U-bolt around the support tube

weldment just installed so the U-bolt legs are pointing to the front

of the trailer. Locate one of the adjustable bunk brackets. Position

it on the front side of the support tube weldment, align a pair of the

lower adjustment holes with the legs of the U-bolt and then slide

over the U-bolt legs. Next place on a ½” lock washers and hex nuts.

Turn the nuts until they are finger tight only because they will need

to be readjusted when the boat is put on the trailer. Repeat this

process on the remaining brackets.

Attach the bunk brackets to the top of the adjustable bunk brackets

using 3/8” x 1” hex bolts and lock nuts. Tighten but do not over

tighten because they must be allowed to pivot so the bunks can

conform to the pontoon tube.

Place one of the carpeted bunks on the top of the bunk brackets

on one side of the trailer just installed so that the rear of the bunk is

even with the rear of the other bunks on the trailer (Approximately

22” behind the bunk bracket). Tap the bunk until it is completely

down into the bunk bracket. Secure the bunk in place using two-No.

10 x 1 ¾” phillip head screws.

Repeat the process in step 5 on the front bracket.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003601

Page 2 11/17/05

Loading...

Loading...