Page 1

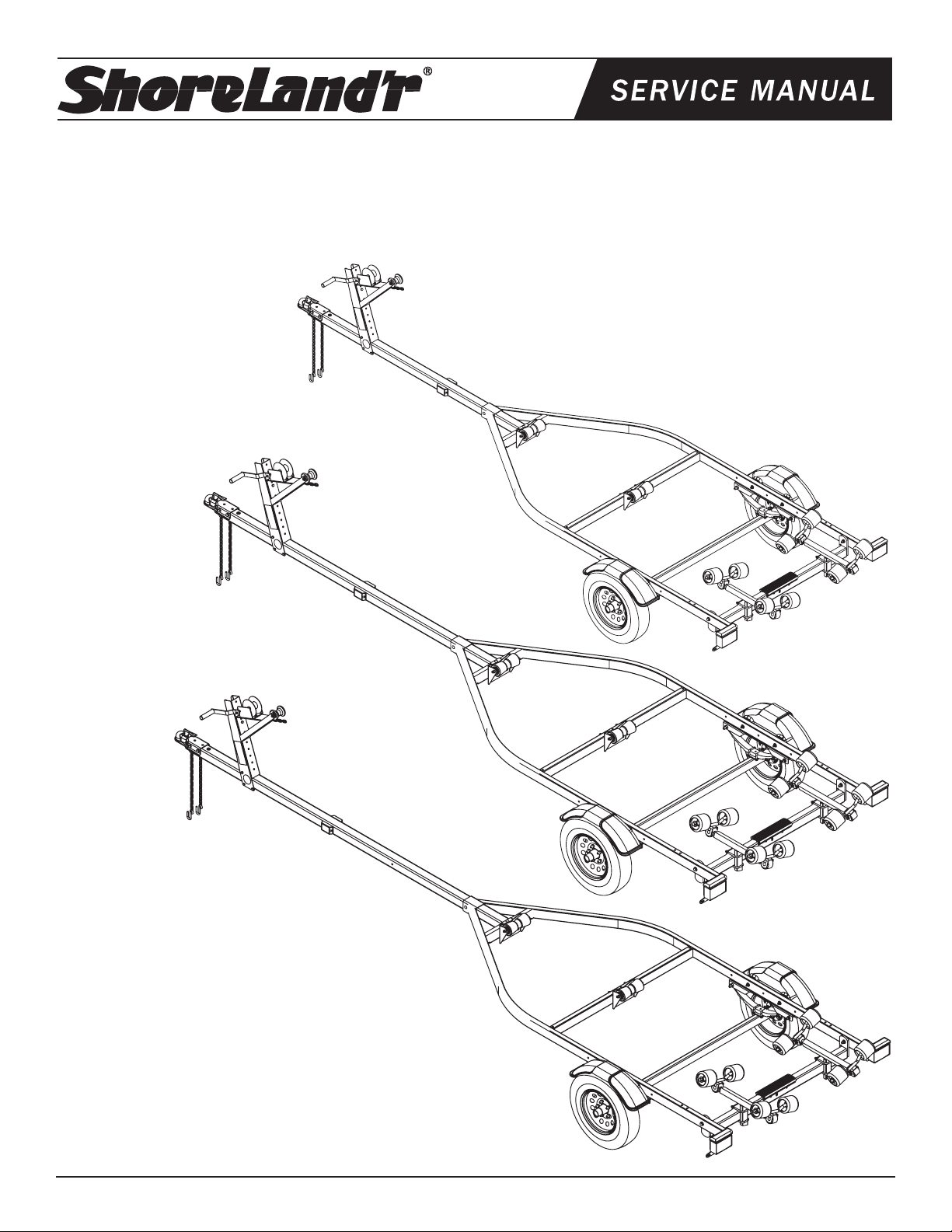

SLR14TM-__

SLR14TS-__, SLR14TM-__ & SLR14TL-__

SLR14TS-__

ShoreLand’r offers their product line a painted finish. When ordering

parts it is important that you specify the finish or color you have on

your product. The five (5) digit number along with a two (2) digit space

_ _, note the parts which can be purchased with various finishes.

When ordering these items use the five (5) digit number along with

a two (2) digit suffix for the proper finish.

00 .........Galvanized

03 .........Black

SLR14TL-__

SLR14TS, SLR14TM & SLR14TL (All Colors) Bundles Required:

*5.30 X 12-C Tire/MSilver Mod Rim .............................. 2

68758-- Hardware Box - Roller 56 Fishing Series ..................... 1

62340 Literature Bag - Trailers ................................................. 1

68828-- Frame Bundle - 56 Wide Fish - Roller ........................... 1

65780-- Tongue 3X3X14 GA X 7’ ................................................ 1

or

65537-- Tongue 3X3X14 GA X 8’ 6” ............................................1

or

65516-- Tongue 3X3X14 GA X 10’ .............................................. 1

64449-- Axle Assembly ............................................................... 1

*Check with your dealer/customer service representative for current tire/rim assembly part number.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003306

Page 1 REV A 2/17/06

Page 2

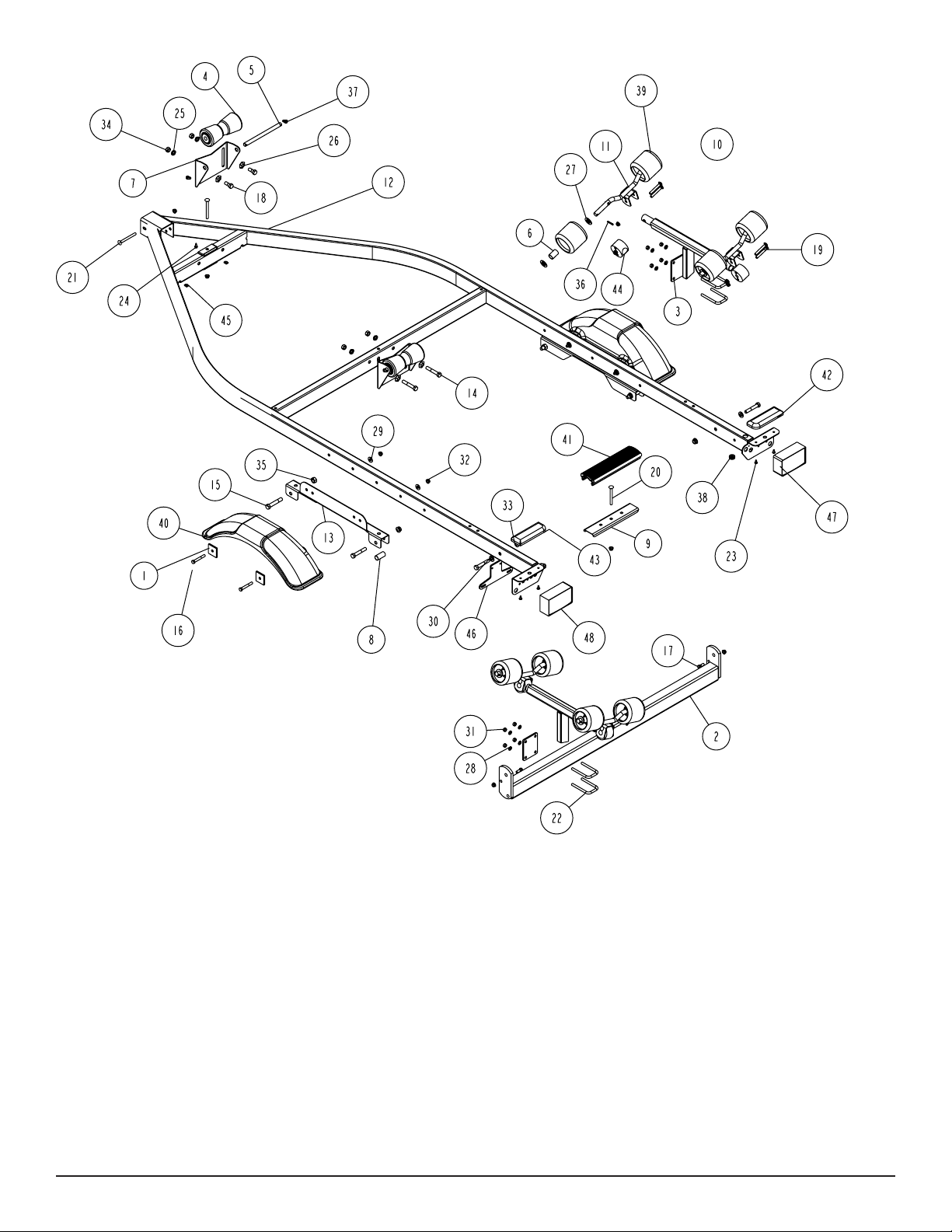

Diagram A

Keel Roller Installation

Remove the keel roller assembly from the hardware box. Position it

on the back side of the front cross member of the frame as shown

in Diagram A. Attach it to the cross member by placing a 1/2” star

washer on a 1/2” x 1-1/4” hex bolt. Align the slot in the keel roller

bracket with the hole provided in the cross member. Insert the bolt

into the hole and attach to the cross member with a 1/2” lock washer and hex nut. Repeat this process on the second bolt used to

attach the keel roller assembly to the cross member.

Repeat the above process on the second keel roller assembly.

The keel roller assembly can be left loose until the boat is placed on

the trailer for final adjustment.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003306

Page 2 REV A 2/17/06

Page 3

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003306

Page 3 REV A 2/17/06

Page 4

TONGUE ASSEMBLY

Place the frame to be assembled on saw horses or stands to assist

in the assembly. Remove all items that are banded to the frame.

Sort the items in the hardware box by item and the hardware by

size.

Place the coupler on the top of the tongue. Align the holes in the

coupler with the holes in the tongue. Place a 1/2” x 4” hex bolt

through the back holes of the coupler and the tongue. Secure with

a 1/2” flange lock nut but do not tighten at this point.

See Diagram B.

Locate the tongue for the trailer. Note that there are three different

lengths of tongues designed to fit this particular frame. The length

of tongue will determine the length of boat that can be placed on

the trailer when assembled. The 7’ tongue will accommodate boats

12-14 feet in length, the 8’-6” tongue will fit boats 14’ - 16’ 6” in

length and the 10’ tongue is used for boats 15’ 6”- 18’ long.

Once the proper tongue is identified place it on the stands so it can

be prepared for installation into the frame. Locate the two amber

side marker lights shipped in the hardware box. Uncoil the wire and

insert the plug end into the larger, center hole that is drilled in the

side of the tongue. As the wire is inserted into the hole direct the

wire so that it will go to the forward end of the tongue. Pull the wire

out the front of the tongue. It will be connected to the tongue harness at a later time. Attach the light to the tongue using two (2) No.

10 x 3/4” self-tapping screws provided. Repeat this process on the

other light on the other side of the tongue.

Locate the tongue wire harness. Insert the end of the harness with

the small plug into the hole located in the top of the tongue. Pull

the wire backward through the tongue until the end comes out the

rear of the tongue. As the wire harness is inserted note that there

are two single bullet wires towards the front plug of the tongue wire

harness. Pull these wires forward as the wire harness is inserted

into the tongue. Plug the single wires from the side marker lights

installed earlier into the two single bullets of the tongue harness.

Push the additional back into the front of the tongue to keep it from

damage during use. Place a rubber grommet around the wire harness and in the hole in the top of the tongue to protect the wires

from damage during use.

Route the harness plug at the rear of the tongue through the hole

provided in the side of the tongue. Pull both the plug and the white

ground wire out the hole. They will be attached later once the

tongue is installed in the frame.

Locate the bolt on tongue stand Item No. 4 in Diagram B. Look at

the bottom side of the tongue and locate the slotted key slot hole

in the tongue. Note that one end of the tongue stand has a dart or

arrow shaped end. With the tongue stand positioned 90 degrees

to the centerline of the tongue, insert the dart or arrow end of the

tongue stand into the key slotted hole. Once it is inserted, turn the

tongue stand 90 degrees so that it now is in line with the centerline

of the tongue. Attach the front end of the tongue stand to the tongue

using a 1/2” x1” hex bolt and flange lock nut. Tighten.

Place a 1/2” x 1” hex bolt through the front hole on one side of the

coupler and the tongue so that the head of the bolt is to the outside.

Place a 1/2” flange lock nut on the bolt inside the tongue. Repeat

this process on the other side of the tongue. Once the bolts are

installed, tighten all nuts left loose at this time.

Insert the tongue assembly through the front channel of the frame

far enough so the rear of the tongue is inserted into the front cross

member. Align the cross hole in the front channel and the tongue

and insert a 3/8” x 4” hex bolt. Secure with a 3/8” flange lock nut.

Place a second 3/8” x 4” hex bolt down through the hole in the rear

of the tongue and the front cross member. Place on a 3/8” flange

lock nut. Tighten.

Connect the tongue wire harness into the side frame harness of

the trailer by matching plugs. Attach the white ground wire of the

tongue harness to the frame using a No. 10 x 3/4” self-tapping

screw provided so that a good ground connection is made between

the frame of the trailer and the tow vehicle. Push all extra wires

used to make the connection back inside either the side frames of

the trailer or else into the tongue. Place a second rubber grommet

into the hole where the wires exit the tongue to protect them from

damage during normal use.

Winch Post Assembly

The winch post assembly is pre-assembled and is shipped banded

to the frame. See Diagram C. Place the winch post on the tongue in

the approximate location. Attach to the tongue using three (3) 3/8”

x 4” hex bolts and 3/8” flange lock nuts. It can be left loose until the

boat is placed on the trailer for final adjustment.

Place the winch handle on the drive shaft of the winch by mating

the flat sides of the drive shaft with the punched hole in the winch

handle. Secure the handle to the drive shaft with the 1/2” lock nut

provided. Tighten.

Locate the bow eye safety chain in the hardware box. Place a 3/8”

x 1” carriage bolt into the square hole located in the small winch

bracket as shown in Diagram C. The head of the bolt is to be on the

top of the bracket. Place the chain over the bolt just installed on the

bottom side of the small winch bracket. Secure to the small winch

bracket with a 3/8” flat washer and flange lock nut. Tighten.

Locate the safety chains. Place a 3/8” flat washer on a 3/8” x 1-1/4”

hex bolt. Insert the bolt through the last link in the safety chain and

then into the lower hole provided in the front of the tongue. Secure

with a 3/8” flange lock nut. Tighten. Repeat on the other chain.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003306

Page 4 REV A 2/17/06

Page 5

Diagram B

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003306

Page 5 REV A 2/17/06

Page 6

Diagram C

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003306

Page 6 REV A 2/17/06

Page 7

Diagram D

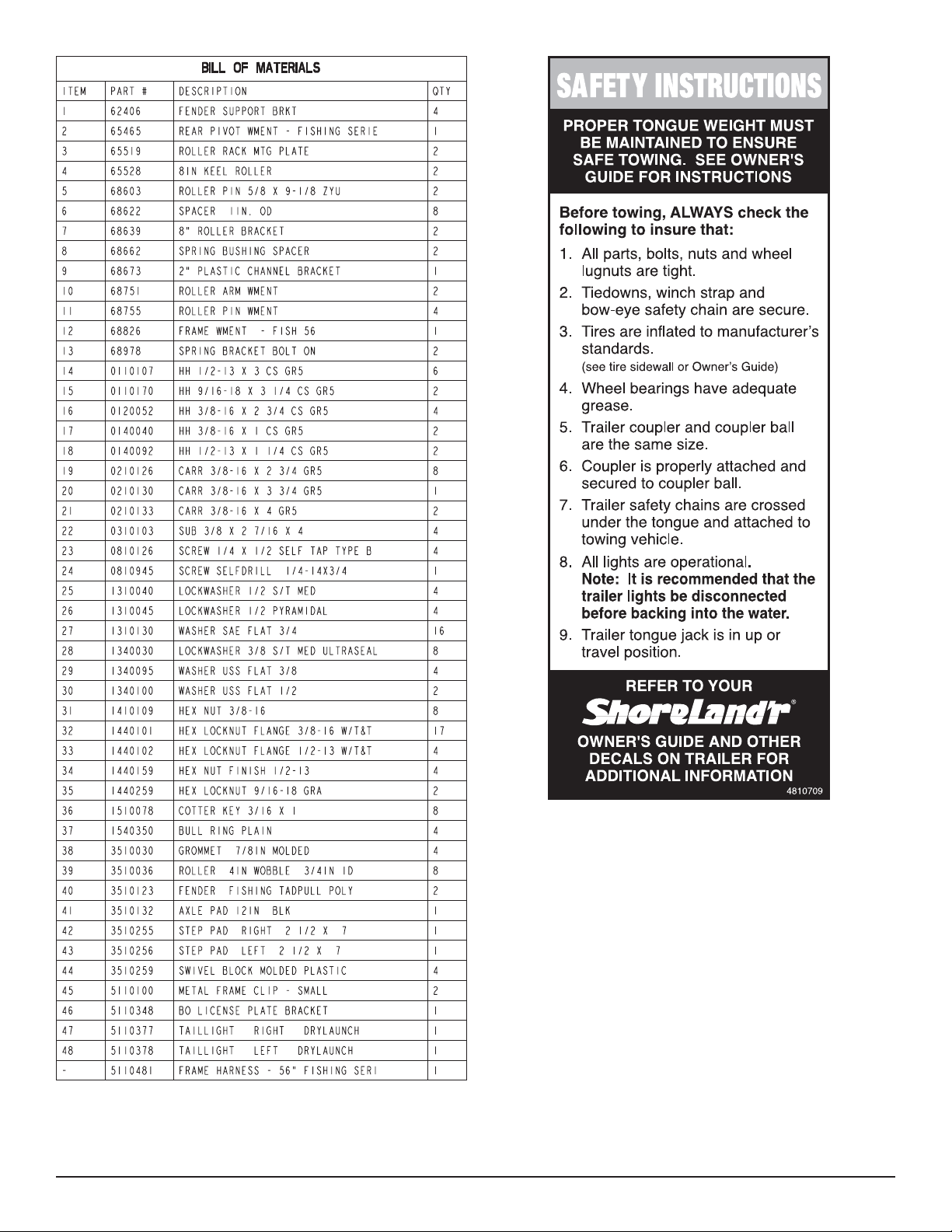

Tire Size and Carrying Capacity Chart

Tire Size ............................5.30 X 12-C

GVWR ...............................2000 lb.

Carrying Capacity ............1400 lb.

Axle ...................................Non-Brake

Recommended carrying capacity is based on shipping weight

of the trailer with standard equipment. Adding optional equipment may decrease the trailer’s carrying capacity.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003306

Page 7 REV A 2/17/06

Refer to the tire side wall for correct tire pressure.

NOTE: Brakes available as optional equipment.

Page 8

Axle and Wheel Assembly

Locate the axle for the trailer. Note that there isn’t a right or left to

the axle assembly. Place one of the springs on top of the spring

pad welded to the axle as shown in Diagram D. Drop two (2) 3/8”

x 2-3/16” x 2” U-bolts over the springs and down through the holes

in the spring pad. Secure with 3/8” flange lock nuts. Repeat this

process on the other spring mounting it so that it is oriented on the

axle the same as the first spring.

Slip a spring bushing spacer into the rear of the spring bracket,

align the bushing with the hole in the bracket and secure in position

using a 1/2” x 3” hex bolt and 1/2” flange lock nut. Tighten. Repeat

on the other spring bracket.

Slide the axle assembly under the trailer frame, raise up and slide

the rear of the springs above the bushings just installed. Rotate the

assembly up until the front spring eyes align with the front holes in

the spring bracket. Insert a 9/16” x 3-1/4” hex bolt and secure with

a 9/16” lock nut. Tighten. Tighten the U-bolt attaching the springs

to the axles at this time and any other bolts that may have been left

loose for ease of assembly.

Place the tire and wheel assemblies on the hubs and secure with

the 1/2” tapered lock nuts.

Tire And Wheel Assemblies

Mount the tire and wheel assemblies using the 1/2” fine threaded

tapered lug nuts provided. Tighten to 80-90 ft/lb. of torque using the

rotation pattern as shown in the ShoreLandr’s Owners Manual.

Re-torque the lug nuts after 50 miles of driving and then periodically thereafter.

Rear Roller Racks

Locate the swivel block molded plastic pieces (Item No. 12 in Diagram D). Slide them onto the ends of the roller arm weldment as

shown. Place the channel bracket of the roller pin assembly down

over the plastic pieces and secure them together with two (2) 3/8”

x 2-3/4” carriage bolts and 3/8” flange lock nuts. Note that one bolt

will be on the top side of the metal tube while the other will be installed so the bolt passes through the large hole in the metal tube.

This will allow the roller assemblies to rotate on the roller arm weldment to conform to the boat bottom and still support the load applied to it when the boat if carried on the trailer. Tighten. Repeat this

process on the other roller arm weldment.

Loosen the two bolts that attach the rear pivot to the trailer side

frames and rotate the rear pivot from its ship position down into its

normal position. Locate the roller rack mounting plates (Item No. 9

in Diagram E). Place two of the 3/8” x 2-7/16” x 4” U-bolts into the

holes of the plate as shown and thread on 3/8” flange lock nuts.

Slide the plate with U-bolts just installed onto the rear pivot so that

the roller rack mounting plate is to the front side of the rear pivot

with one U-bolt above the rear pivot and one below the rear pivot

cross member. Push the U-bolts rearward creating all of the spacing between the inside of the U-bolts and the front side of the rear

pivot cross member. Place one of the roller arm assemblies so that

the roller pin assemblies tip inward towards the centerline of the

trailer. Drop the mounting tube of the roller arm weldment down

inside the U-bolts and behind the rear pivot cross member. Adjust

the roller arm assemblies up to the desired height to carry your boat

properly and tighten the U-bolts.

Assembly is now complete and ready to be adjusted to fit the boat

that it will carry.

Diagram E

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003306

Page 8 REV A 2/17/06

Page 9

Diagram F

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003306

Page 9 REV A 2/17/06

Page 10

Trailer Adjustments

Place the boat on the trailer so that the center of the rear rollers on

the roller rack is approximately 4” from the transom of the boat.

Check the boat for clearance with the frame and tongue. Enough

clearance is required between the two so that the boat does not

contact the frame during loading and unloading.

Rear Roller Rack

The spacing between the rollers on the roller rack can be changed

so that they will adapt to the spacing of the boat strakes. To change

the spacing remove the cotter key that holds the roller to the roller

pin. Remove the washers and roller. Note that there is a spacer on

the roller pin as well as the roller. This spacer can be installed either

to the inside or outside of the roller. Depending where it is placed

will change the spacing with regards to the roller on the other end

of the roller pin. The roller and spacer on the other end of the pin

can be interchanged as well if needed. As a result the spacing can

be changed either 1-1/2” or 3” between the rollers. Once installed in

the proper location to fit your boat, reinstall the roller and washers.

Secure in place with the cotter key just removed.

The height of the roller rack with respect to the frame can be

changed. Loosen the U-bolts attaching the roller arm assemblies

to the rear pivot arm. Raise or lower the roller arm assemblies to

the desired height, then retighten the U-bolt securing in the new

location.

The roller racks spacing between the individual rack can be changed

by sliding the roller arm assemblies to the desired location before

tightening the U-bolts attaching them to the rear pivot arm.

Winch Post

Once the boat is in the desired location and correct height on the

trailer the winch post can now be adjusted.

Slide the winch post on the tongue until it contacts the boat. Note

that the bow eye roller on the winch post must be positioned directly

above the boat bow eye. This location is necessary to prevent the

boat from sliding forward during normal use as well as in the event

of a sudden stop. This positioning will also allow the winch strap

to pull directly from the winch into the bow eye for better retention.

Change the bow stop height by removing the bolts attaching it to

the winch post. Relocate to the proper height and refasten with the

bolts just removed.

Once the winch post is set secure the winch post to the tongue with

the three mounting bolts used to attach it to the tongue.

Place the bow eye safety chain in the bow eye of the boat as a

secondary means of keeping the boat attached to the trailer in the

event of a winch, winch strap or hook failure.

The axle is adjustable on this model trailer so that the proper tongue

weight can be achieved. To change the tongue weight remove the

four 3/8” x 2-3/4” hex bolts attaching the spring brackets and fender

to the trailer frame. The axle can then be moved forward or backward to get the proper tongue weight.

A recommended tongue weight for your trailer is 7-10% of the total

load including boat, motor, and trailer.

Adjustments are now complete. Double check your boat for fit. If

desired fit has been achieved, tighten all fasteners that may have

either been left loose or have been loosened to do the adjusting.

Keel Roller

Check the front of the boat for clearance between the frame and

tongue. The keel roller has slotted holes so they can be adjusted up

or down to fit your boat. Once the boat is positioned on the trailer

as desired loosen the bolts and nuts attaching the keel roller to the

cross member. Raise the keel roller assembly up against the keel

of the boat. Retighten in the new location. Note that the boat will

settle into the keel roller a little during normal use so it may be necessary to adjust them slightly higher to compensate for this.

Note: All nuts and bolts must be tightened before towing.

The law requires that the white ground wire on both the tongue

wire harness and vehicle harness be properly grounded to respective trailer and vehicle frames.

Re-check all fasteners on the complete trailer to make sure they

are all tight and ready for towing. All fasteners should be periodically check before towing.

See your ShoreLand’r Owner’s Guide for further technical information regarding your trailer and its components.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003306

Page 10 REV A 2/17/06

Loading...

Loading...