Page 1

®

SLIB29B-00 & SLIB29B-03

2x4x74 Inboard Trailer

SLIB29B-00

69082 Lit Packet - Brake Trailers

4300198 ST215/75R14-C GY Galv Dir Rim

6643800 Axle Assembly w/Brakes 2x4x74W

8055700 Frame Bundle - Inboard Single

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003800

Page 1 05/01/07

SLIB29B-03

69082 Lit Packet - Brake Trailers

4300199 ST215/75R14-C GY TSilver Dir Rim

6643803 Axle Assembly w/Brakes 2x4x74W

8055703 Frame Bundle - Inboard Single

Page 2

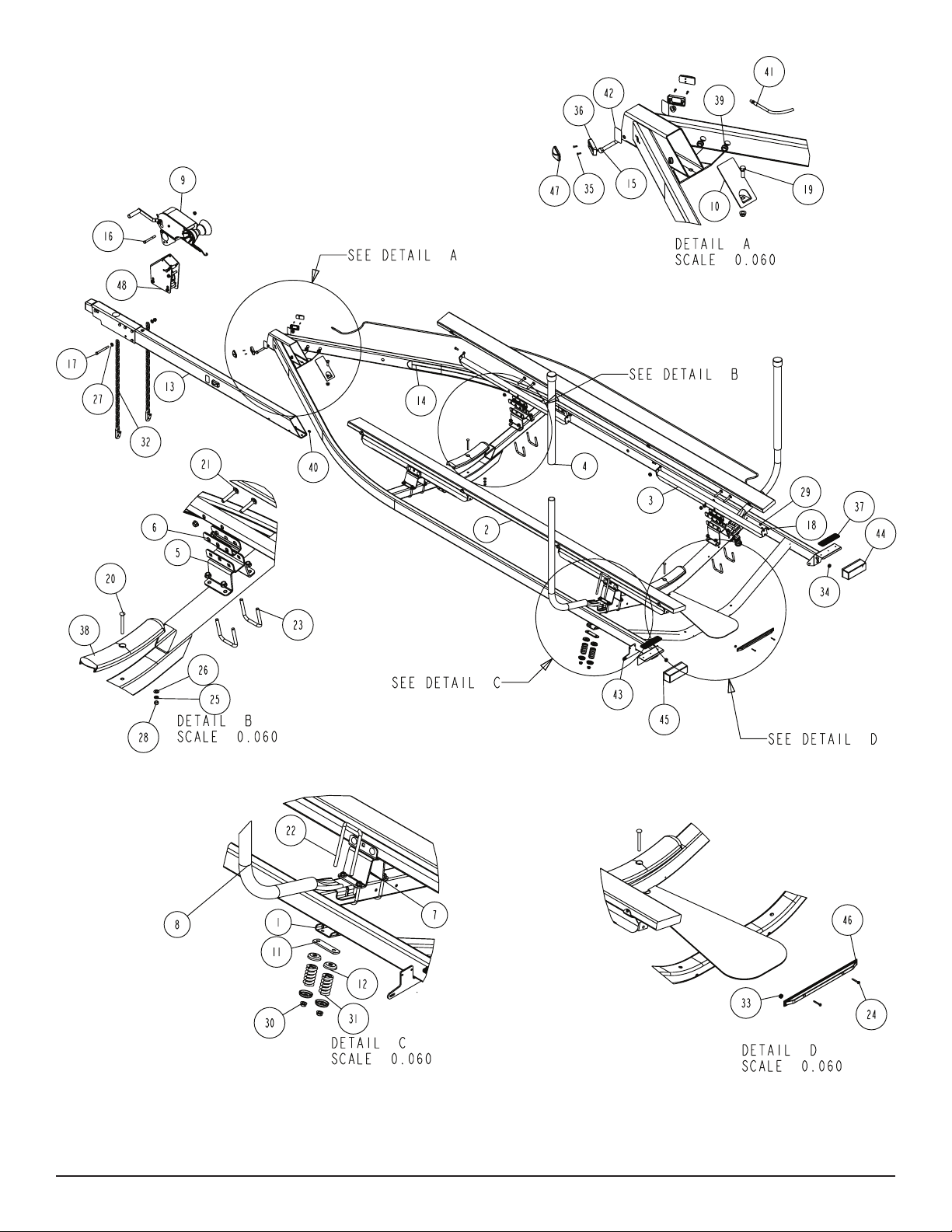

Diagram A

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003800

Page 2 05/01/07

Page 3

Refer to your ShoreLand’r Owner’s

Guide and other decals on trailer for

additional information.

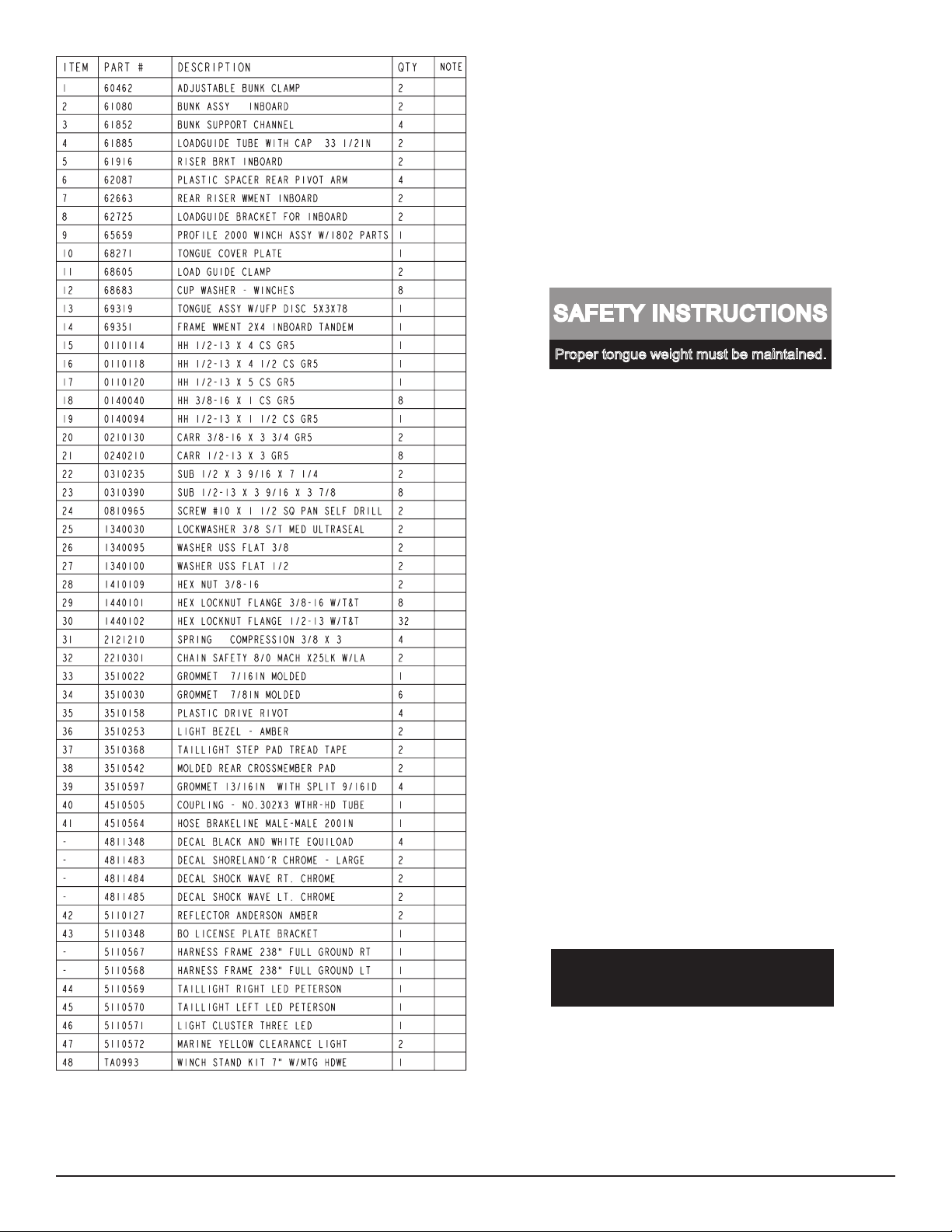

SAFETY INSTRUCTIONS

4810709

Proper tongue weight must be maintained.

Rev C 8/28/06

Before towing, check the following to ensure

that:

1. All parts, bolts, nuts and wheel lug

nuts are tight.

2. All wheel lug nuts must be tightened

to a minimum torque rating of 85 ft/lb.

3. Lug nuts must be re-torqued after the

first 50 miles, then periodically there

after.

4. Tires are inflated to manufacturer’s

standards. (See tire sidewall)

5. Wheel bearings have adequate

grease.

6. Hitch ball is the proper diameter and

has a rating equal to or greater than

the GVWR of the trailer.

7. Coupler is properly attached and

secured to coupler ball.

8. Trailer safety chains are crossed

under the tongue and attached to

towing vehicle.

9. All lights are operational. Note: It is

recommended that the trailer lights

be disconnected before backing into

the water.

10. Tie downs, winch strap and bow eye safety chain are secure.

11. Trailer tongue jack is in up or travel

position.

ShoreLand’r offers their product line a painted nish. When ordering

parts it is important that you specify the nish or color you have on

your product. The ve (5) digit number along with a two (2) digit space

_ _, note the parts which can be purchased with various nishes.

When ordering these items use the ve (5) digit number along with

a two (2) digit sufx for the proper nish.

00..........Galvanized

03..........Black

FINAL ASSEMBLY INSTRUCTIONS

Remove all banded items and the hardware bag from the frame.

Remove the parts and sort by size.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003800

Page 3 05/01/07

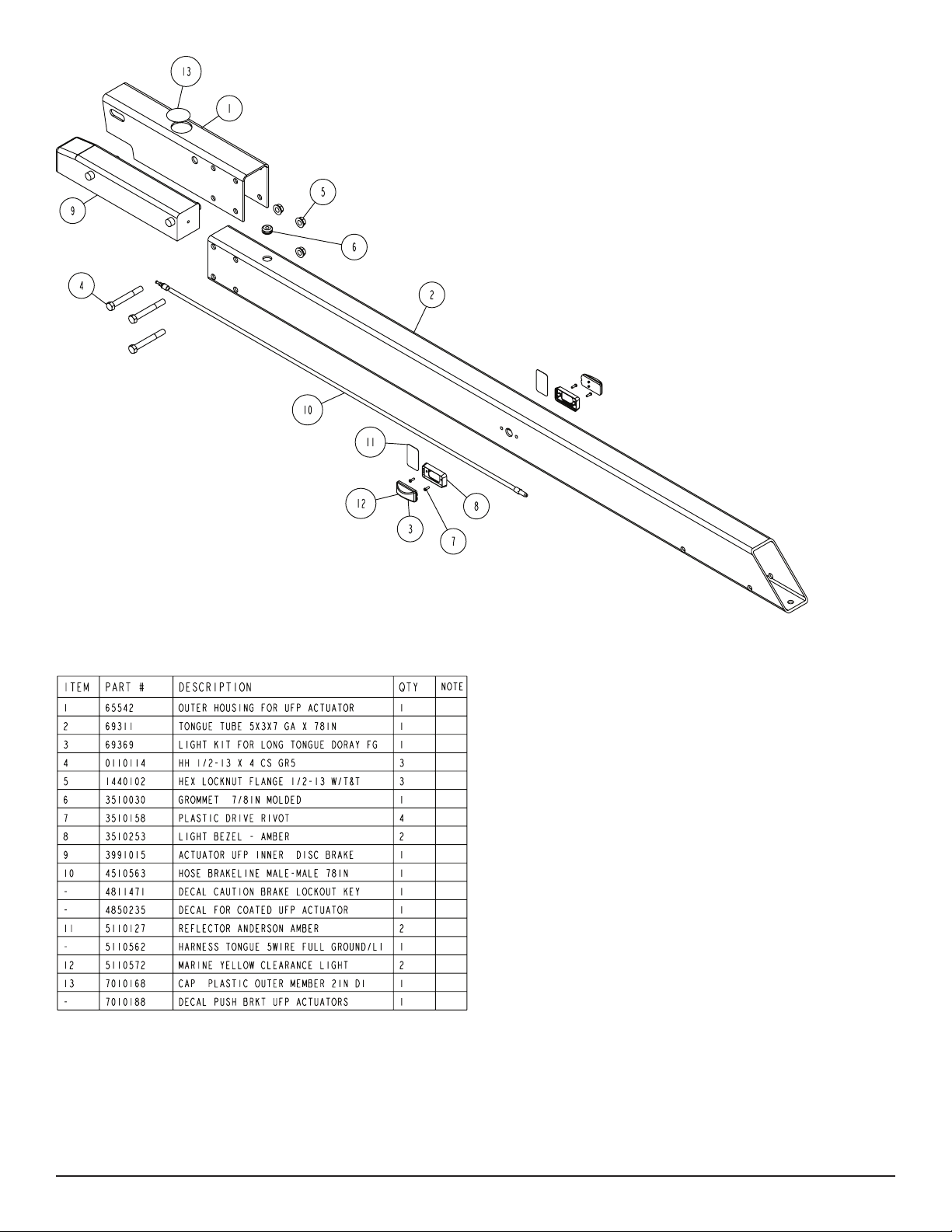

Page 4

TONGUE

Locate the tongue and install by sliding it in the front of the tongue

channel.

Line the holes in the tongue with the holes in the tongue channel.

Install the 1/2” x 4” hex bolt in the front cross hole and secure with

a 1/2” ange lock nut.

Remove the wire harness from the rear of the tongue. Place the

wire harness and the brake hose through the hole provided in the

tongue cover plate.

Secure the tongue cover plate in position with the same 1/2” x 11/2” hex bolt that secures the back on the tongue to the tongue

channel of the frame. Secure with a 1/2” lock nut. Tighten both bolts

just installed.

Diagram B

Plug the tongue wire harness ends into the frame harnesses by

matching colors and ends. Push the extra wire provided into the

rear of the tongue. The wire should be positioned so the only thing

exposed to the outside of the tongue and side frame is the black

wire loom.

TONGUE BRAKE HOSE CONNECTION

Locate the brass brake line coupling. Remove the plastic cap from

the tting on the end of the tongue hose. Thread into one end of the

coupling. Remove the hose from the side frame enough to reach

into the rear of the tongue. Remove the plastic cap from the tting

on the side frame hose, then thread into the other end of the coupling. Tighten.

Push the excess hose back inside the tongue so that the coupling

just installed is located inside the rear of the tongue.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003800

Page 4 05/01/07

Page 5

Diagram C

SAFETY CHAINS

Locate the 1/2” x 5” hex bolt. Slip the bolt through a 1/2” at washer,

then place through the last link of one of the safety chains.

Place the bolt with chain attached through the hole provided in the

bottom front of the actuator mount on the tongue. Place the second

chain on the portion of the bolt extending through the other side

of the tongue. Place on another 1/2” at washer and hex lock nut.

Tighten.

Place the inside jack spacer on the winch base so the center pro-

trusion ts down into the indent in the winch base.

WINCH POST INSTALLATION

The height that the bow eye is placed in your boat will determine

the length winch post required. Once this is determined, attach the

winch base to the tongue with three 1/2” x 4-1/2” carriage bolts and

lock nuts.

Align the holes in the Prole 2000 mounting channel with the holes

in the top of the winch base. Attach the front of the winch head

mounting channel to the base by placing a 1/2” x 4-1/2” hex bolt

through the hole closest to the front of the winch base. Secure with

a lock nut. Do not tighten.

Note that the winch head can now be rotated either up or down.

Identify the correct hole combination to use to position the bow eye

roller just above the bow eye of your boat. When determined, secure in this position by placing the bushing as shown in Diagram D

inside the winch base so it aligns with the hole just identied for the

proper adjustment. Insert another 1/2” x 4-1/2” hex bolt through the

determined mounting hole in the mounting channel and winch base

making sure the bolt passes through the bushing as well. Secure

with a 1/2” lock nut. Tighten all bolts.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003800

Page 5 05/01/07

Page 6

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003800

Page 6 05/01/07

Page 7

Diagram D

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003800

Page 7 05/01/07

Page 8

Disc Brake Axle

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003800

Page 8 05/01/07

Page 9

Tire Size and Carrying Capacity Chart

Tire Size ............................ST215/75R 14-C

GVWR ...............................3740 lb.

Carrying Capacity ............2900 lb.

Axle ...................................Brake

Refer to the tire side wall for correct tire pressure.

Recommended carrying capacity is based on shipping weight

of the trailer with standard equipment. Adding optional equipment may decrease the trailer’s carrying capacity.

SPRINGS

Position the axle so it is properly aligned with the trailer. The end of

the axle that has the brake line hose attached must be to the right

side of the trailer when standing at the rear of the trailer and looking forward. This positioning places the disc brake calipers on the

backside of the axle.

Place the springs on the topside of the spring pads welded to the

axle. (See Diagram D). Note that the hook end of the spring must be

mounted to the rear of the trailer. Place a spring clamp on the top

center of the spring as shown. Next place the 1/2” x 6-1/2” U-bolts

down over the top of the spring clamp, spring and axle as shown.

Place the spring and axle U-bolt plate onto the ends of the two Ubolts just placed around the axle. Secure with 1/2” lock nuts. Thread

onto the U-bolts but do not tighten securely until the complete unit

is in position on the trailer. Repeat on the other spring.

AXLE

Place one of the spring bracket bushings into the rear of the spring

bracket and secure with a 9/16” x 3-1/4” hex bolt and hex lock nut.

Repeat in other spring bracket.

Position the axle under the frame, then hook the hook loop of the

spring around the bushings just installed. Note that if the axle is

positioned too low when trying to hook, the hooks will not hook

around the bushings.

Raise the front of the springs up so they align with the front hole

of the spring bracket. Secure in place with 9/16” x 3-1/4” hex bolts

and lock nuts.

Tighten all axle U-bolts and spring bolts not tightened at this time.

ONE AXLE BRAKE INSTALLATION

Cut the tape securing the brake line hose to the axle. Remove the brass plug from the port in the brass block on

the right brake caliper. Thread in the brake hose male

end and tighten. Repeat on opposite side of axle.

Carefully pull brake line hose from the side frame tube, threading it

through the brake line clip and down to the port in the brass block

on the right caliper. Remove the plastic cap and thread into the port

on the brass block and tighten. Insert grommet into the brake line

clip to protect hose. All bleeding of the line can be done through the

bleeder on the caliper.

Fill the actuator reservoir with brake fluid and bleed the line per

the instructions in the brake manual. All bleeding to the line can be

done through the bleeders on the left calipers.

ATTACHING THE AXLE HOSE TO THE SPRING PLATE

It is important that the brake hose on each end of the axle be attached to the spring plate to eliminate the loops that are formed in

the hose when it is attached to the calipers. Doing so will eliminate

the possibility of the hose getting caught or damaged while towing.

Locate one of the hose clamps. Spread open the clamp so it can be

slipped around the hose in the loop that is formed under the spring

as it is routed to the caliper. Once in position, squeeze the clamp

back together.

Raise the hose clamp and the loop up until the hose clamp is on top

of the spring bracket raising the loop up so it is on the back side of

the axle. Align the hole in the clamp with the hole in the rear of the

spring bracket between the two U-bolts.

Place a No. 10 flat washer on a No. 10 x 1” machine bolt. Insert the

bolt into the clamp, then down through the spring bracket. Place

another No. 10 flat washer over threaded end of bolt and secure

with a No. 10 hex nut. Tighten.

Repeat this process on the other loop on the other end of the axle.

TIRE & WHEEL ASSEMBLIES

Mount the tire and wheel assemblies using the 1/2” fine threaded

tapered lug nuts provided. Tighten to 85-95 ft/lb. of torque using the

rotation pattern as shown in the ShoreLandr’s Owners Manual.

Re-torque the lug nuts after 50 miles of driving and then periodically thereafter.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003800

Page 9 05/01/07

Page 10

BUNKS

Locate the bunks. Position one of them so it is above the Equiload

arms on the trailer. Align the holes in the bunk brackets attached to

the bunk with the holes in the ends of the Equiload arms. Secure

with 3/8” X 1” hex bolts and lock nuts. Tighten but do not over tighten because the bunks must be able to rotate enough to conform to

the bottom of the boat.

Repeat on the other bunk.

POST LOAD GUIDES (See Diagram A - Detail C)

Locate the post load guides. Position one of them as shown on

the rear cross member of the trailer frame. Drop a 1/2” X 3-9/16” x

7-1/4” square U-bolt down through the holes in the load guide so

one leg of the U-bolt is on each side of the cross member. Pace on

an adjustable bunk bracket clamp so the legs of the bracket t up

around the cross member. Place on one of the 1-1/2” wide X 5” long

straps over the legs of the U-bolt. Next place a cup washer onto the

U-bolt legs so the cup is down. Place on a 3” compression spring

on each leg of the U-bolt, then a second cup washer on each U-bolt

leg so the cup is up. Secure the parts on the U-bolt legs with 1/2

ange lock nuts. Tighten. Note that the load guide can be slid in out

from the center line of the trailer to accommodate for different width

boats. Adjust for width once the boat is on the trailer.

Repeat the above process on the other load guide.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003800

Page 10 05/01/07

Page 11

TRAILER ADJUSTMENTS

The adjustment of the trailer to your boat is very important not only

for the trailer, but also the boat. Failure to do so may lead to potential failure or damage to either the trailer or boat.

Adjust as follows:

Axle Adjustment

The amount of tongue weight on your trailer can be adjusted as

follows:

To lower the tongue weight, adjust the axle assembly forward. To

increase the tongue weight, adjust the axle backward.

The distance that the axle assembly has to be moved will vary because it is directly related to the weight and center of gravity of the

boat placed on it.

Winch Post

The winch post is pre-assembled. If it does not t, use the following

instructions to adjust to properly t your boat.

Once all other adjustments are complete the winch post can be adjusted. Slide the winch post base backward on the tongue until the

bow roller comes in contact with the boat. This bow roller needs to

be positioned directly above the boat bow eye to prevent your boat

from moving forward in the event of a sudden stop. It can be moved

up or down by removing the back bolt that mounts the winch head

to the base. When this bolt is removed, the head can be rotated up

or down to reach the desired height required to t your boat. Once

in this position, align the closest pair of holes in the brackets and

reinsert the bolt just removed. Tighten. Attach the winch strap and

crank winch tight. Attach the bow eye safety chain into the bow eye

of the boat as well. This is just another level of protection to keep

your boat and trailer together as one unit.

Best towing is achieved when the tongue weight is 5-7% of the total

gross load of the complete unit.

Wire harnesses and brake line lines will need care when moving

the axle assembly.

Rear Support System

Place the boat on the trailer so that the transom is located at the

rear of the support system. The transom of the boat should be within 1-2” of the end of the bunks.

Bunks

Make sure the bunks are positioned far enough apart to give your

boat as much stability as possible while transporting. Position the

bunks so they are located just to the outside of a strake.

Front Support System

Bunk

Adjust the bunks up so that there is approximately 1-2 inches clearance between the keel of the boat and the center cross member

pad.

Check the boat to make sure it is in the desired location forward

and backward on the trailer. If location is as instructed above, tighten the three bolts in the winch base securing the winch base to the

tongue.

Once all adjustments are complete and checked, connect to the

tow vehicle to make sure all of the lights are operating properly and

match the tow vehicle.

Re-check all fasteners on the complete trailer to make sure they

are all tight and ready for towing. All fasteners should be periodically checked before towing.

See your ShoreLand’r Owner’s Guide for further technical information regarding your trailer and its components.

Recommended carrying capacity is based on shipping

weight of the trailer with standard equipment. Adding

optional equipment may decrease the trailer’s carrying

capacity.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003800

Page 11 05/01/07

Page 12

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003800

Page 12 05/01/07

Loading...

Loading...