Page 1

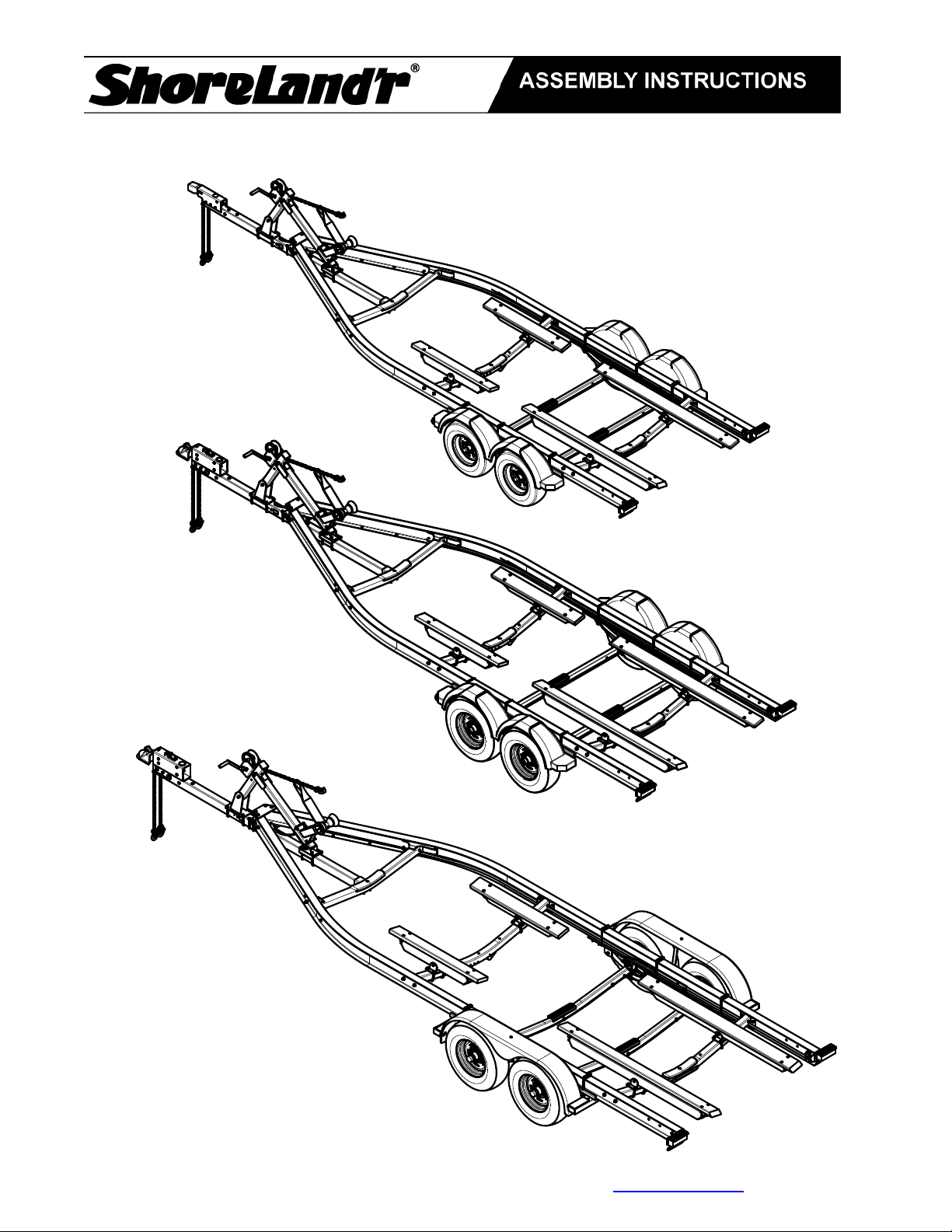

SLB60TAL, SLB70TAL, & SLB82TAL

ASSEMBLY INSTRUCTIONS

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 www.shorelandr.com 0004303

Page 1 of 13 2/15/2011

Page 2

Special caution should be taken that while assembling these stainless steel

components to use Anti-seize compound on the threads to help prevent gauling.

Final Assembly Instructions

Remove the small parts from the frame by cutting the bands. Remove the bolt bag and sort all

nuts and bolts by size.

Refer to the following pages for assembly instruction by components.

Reference: Standing at the rear of the trailer will determine the right and left side of the trailer

in the assembly instructions.

The trailer side frames and crossmembers are assembled at the manufacturer. The spring

brackets and fenders are also assembled at the manufacturer.

Tools for Assembly

Wrenches: 9/16, 3/4, 7/8, & 1 1/8

Sockets: 9/16, 3/4, 13/16. & 1 1/8

Tools for connecting brakes:

Wrenches: 7/16, 3/8, 5/8, & 12mm and also a 3/8 nut driver

Safety Instructions

• Always wear personal protective equipment (safety glasses, gloves, etc) when

assembling and installing components.

• Inspect all fasteners regularly for deterioration and fastener tension. Refer to the

exploded part views for fastener locations in the appropriate parts manual.

• Replace any and all components that show deterioration due to wear or misuse before

using your boat trailer.

• Never modify parts and components. Always replace components with genuine

Shoreland’r replacement parts.

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 www.shorelandr.com 0004303

Page 2 of 13 2/15/2011

Page 3

Assembly Instructions

r

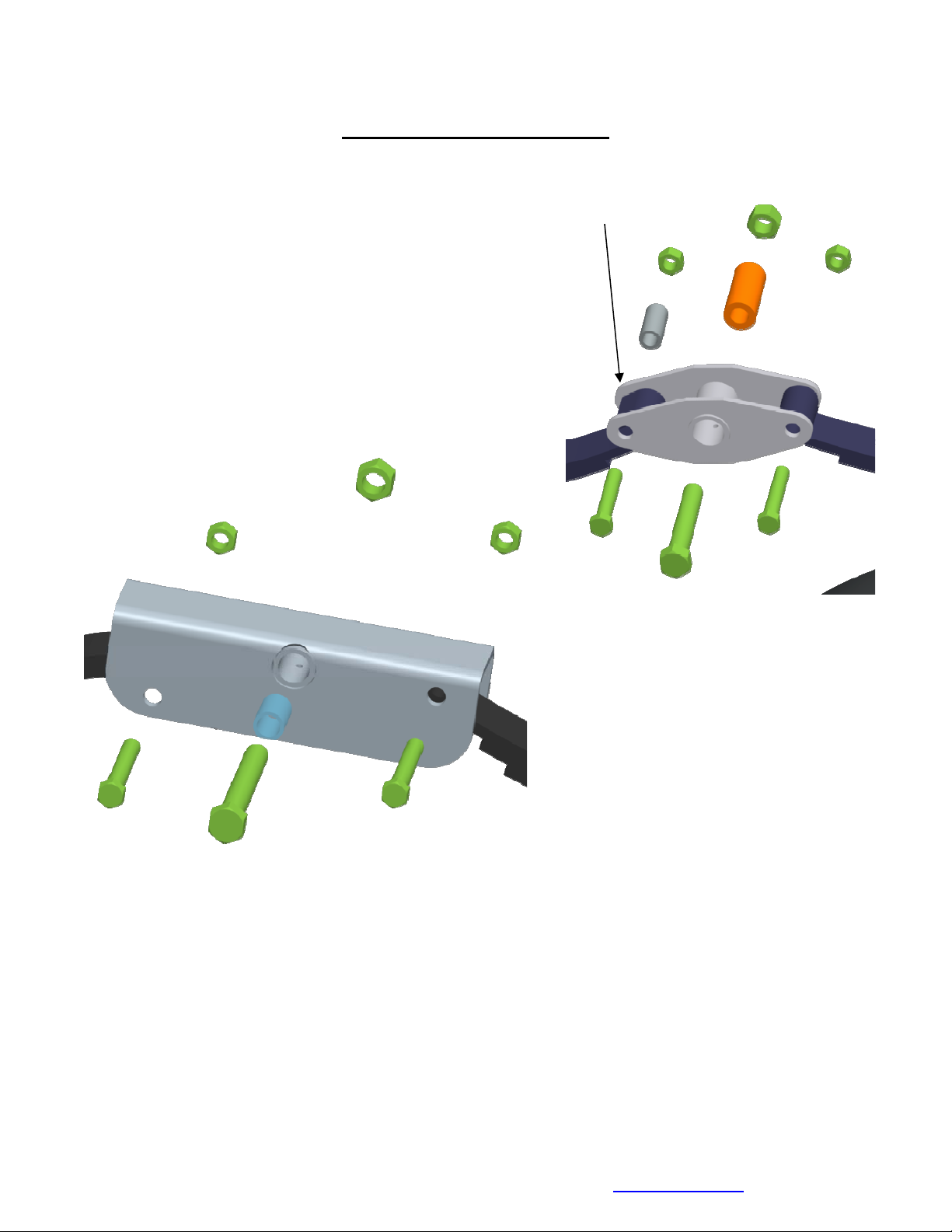

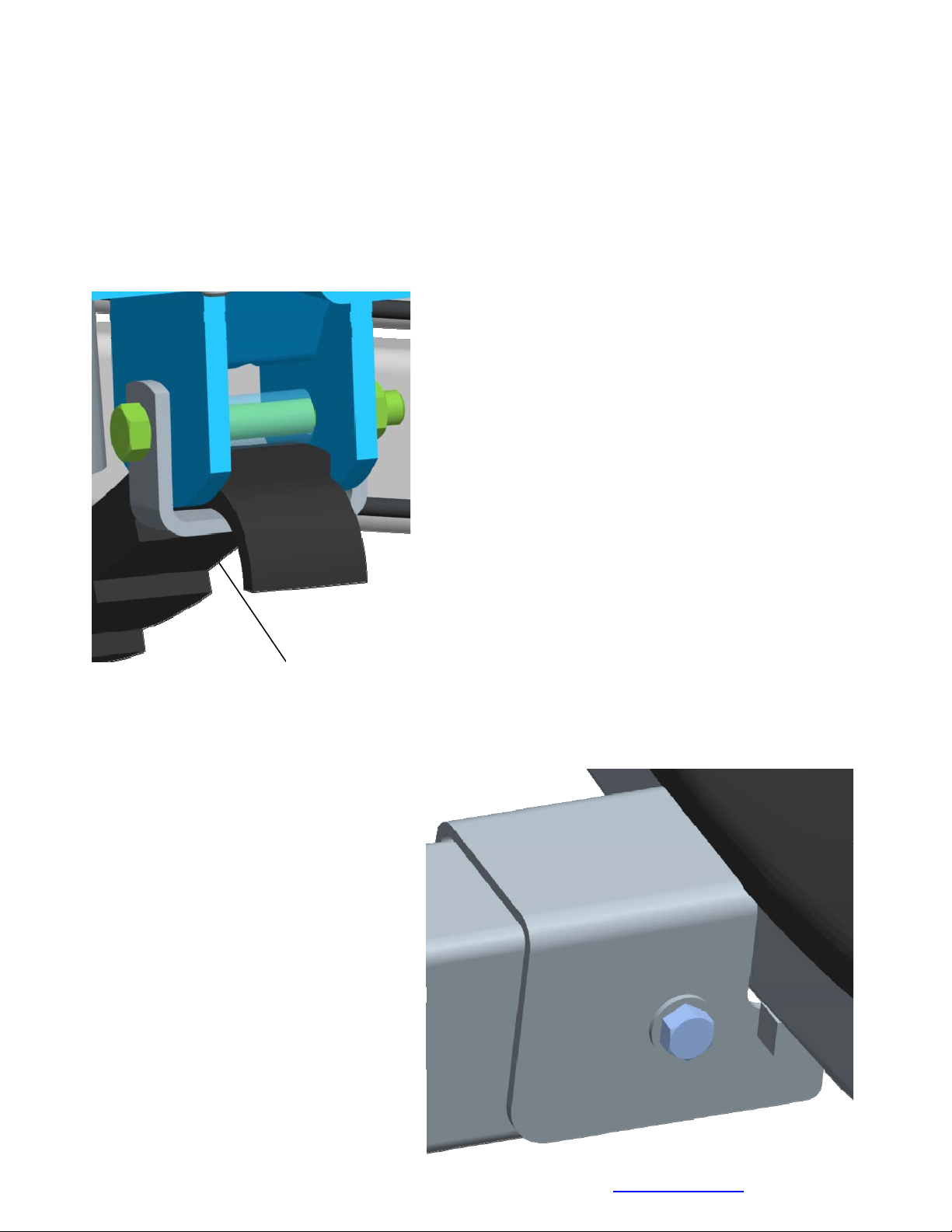

Rocker Bushings and/or Bogie:

Note there is a grease zerk in the center bushing of

the rocker bogie. Position the rocker bogie into the

center mounting channel of the spring bracket so

that the grease zerk is pointing down. This is

necessary so that it can be serviced in the field

when needed. Align the center hole of the rocker with

the center hole of the spring bracket. Insert and secure

with a 3/4” X 4-1/2” stainless steel hex bolt from the

outside in and tighten with a 3/4” stainless steel hex lock

nut. Install the 3/4” ID X 1” OD X 1-1/2” bronze bushings

into the inside the rocker matching the middle and rear

Rocker/Boogie 8200#

Trailer

To Front of

Traile

hole patterns. The middle rocker

bushing must be secured with a 3/4” X

5-1/2” stainless steel hex bolt through

the rocker, bushing and the middle

shackle on the spring bracket. Tighten

using a 3/4” stainless steel hex lock nut

with nylon insert. The front rocker

bushing must be secured with a 9/16”

X 3-3/4” stainless steel hex bolt and

9/16” stainless steel hex lock nut with

nylon insert. Repeat this procedure o

the other rocker on the opposite side of

the trailn er.

Spring Bracket Bushings:

Place one of the spring bracket bushings into the rear of the spring bracket and secure with a

9/16” x 3 1/4” stainless steel hex bolt and 9/16” stainless steel hex lock nut. Repeat in other

spring bracket. Install another spring bracket bushing in the front hole on the rock arm

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 www.shorelandr.com 0004303

Page 3 of 13 2/15/2011

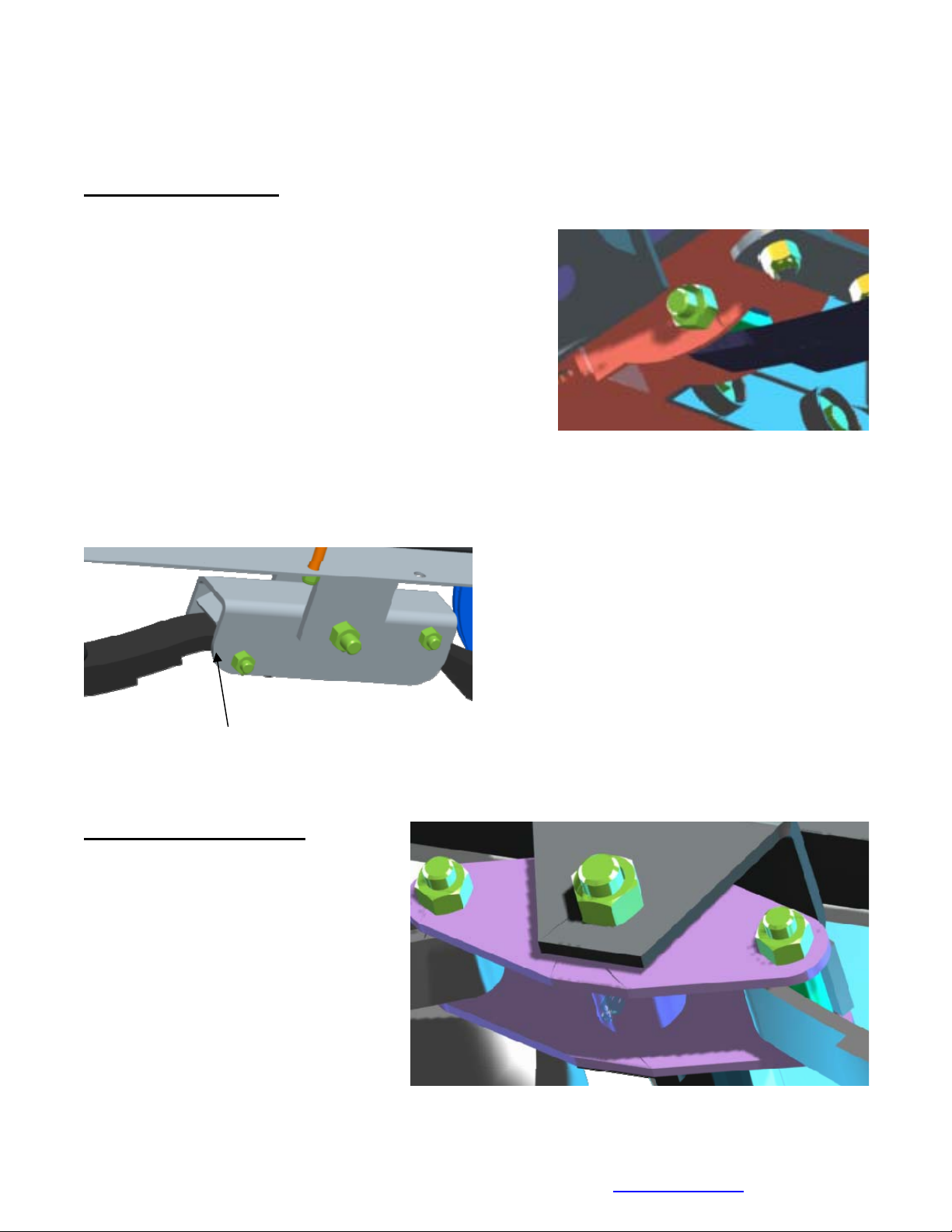

Page 4

assembly. Secure with a 9/16” x 3-1/4” hex bolt and lock

nut. Install the spring bracket bushing into the spring

support channel. This assembly is then inserted into the

rear spring bracket shackle and secured with a 9/16” X

4-3/4” stainless steel hex bolt and 9/16” stainless steel

hex lock nut with nylon insert. Repeat this procedure on

the other spring bracket on the opposite side of the

trailer.

Axle:

Note: The hook end of the springs must be toward the rear of the trailer, on both axles!

Spring Bracket Bushing

Position the axles so they are properly aligned

with the trailer. Position the brake axle so that the

disc brake calipers are on the back side of the

axle. Place the springs on the topside of the spring

pads welded to the axle. Place a spring clamp on

the top center of the spring. Place the 1/2” x 6-1/2”

stainless steel square U-bolts down over the top of

the spring clamp, spring and axle.

Place the spring and axle U-bolt plate onto the

ends of the two U-bolts. Secure in place with 1/2”

stainless steel lock nuts. Thread onto the U-bolts

but do not tighten securely until the complete unit

is in position on the trailer. Repeat on the other

spring.

Hook on

leaf spring

& Brake

Caliper to

the rear of

Trailer

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 www.shorelandr.com 0004303

Page 4 of 13 2/15/2011

Page 5

NOTE: The hook end of the springs must be

p

of the trailer - on both axles!

First Axle Installation:

For rear axle 6000 & 70

Position the rear axle under the frame

loop of the spring around the bushings just installed.

Note that if the axle is positioned too low when trying to

hook, the hooks will not hook around the bushings.

Raise the front of the springs up so they align with

rear hole in the axle rocker bogie just installed. Secure

in place with 9/16” x 3-1/4” stainless steel hex bolts and

9/16” stainless steel lock nuts.

00lb trailers:

, hook the hook

installed in the same direction, to the rear

the

F

or front axle 8200lb trailers:

Align the eye of the spring on the

the outside in, insert a 9/16” x 3 3/4” hex bolt through the spring bracket and the eye of the

spring. Secure with a 9/16” hex lock nut.

first axle with the hole provided in the spring bracket. From

Raise the rear hook end of the spring and

axle assembly up so it is up inside the rocker

bogie. Secure in place by placing a 9/16” x

3/4

” hex bolt through the hole in the rocker

bogie just below the spring leaf. Secure with a

9/16” lock nut.

3

Hook end of leaf

ring

s

Second A

For front axle 6000 & 7200lb

trailers:

Hook the hook end of the springs

mounted to the front axle over the

bushing just installed in the rocker

arm assembly. Then swing the front

of the spring up and attach the front

mounting hole

ith another 9/16” x 3-1/4” hex bolt

w

nd lock nut.

a

xle Installation:

in the spring bracket

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 www.shorelandr.com 0004303

Page 5 of 13 2/15/2011

Page 6

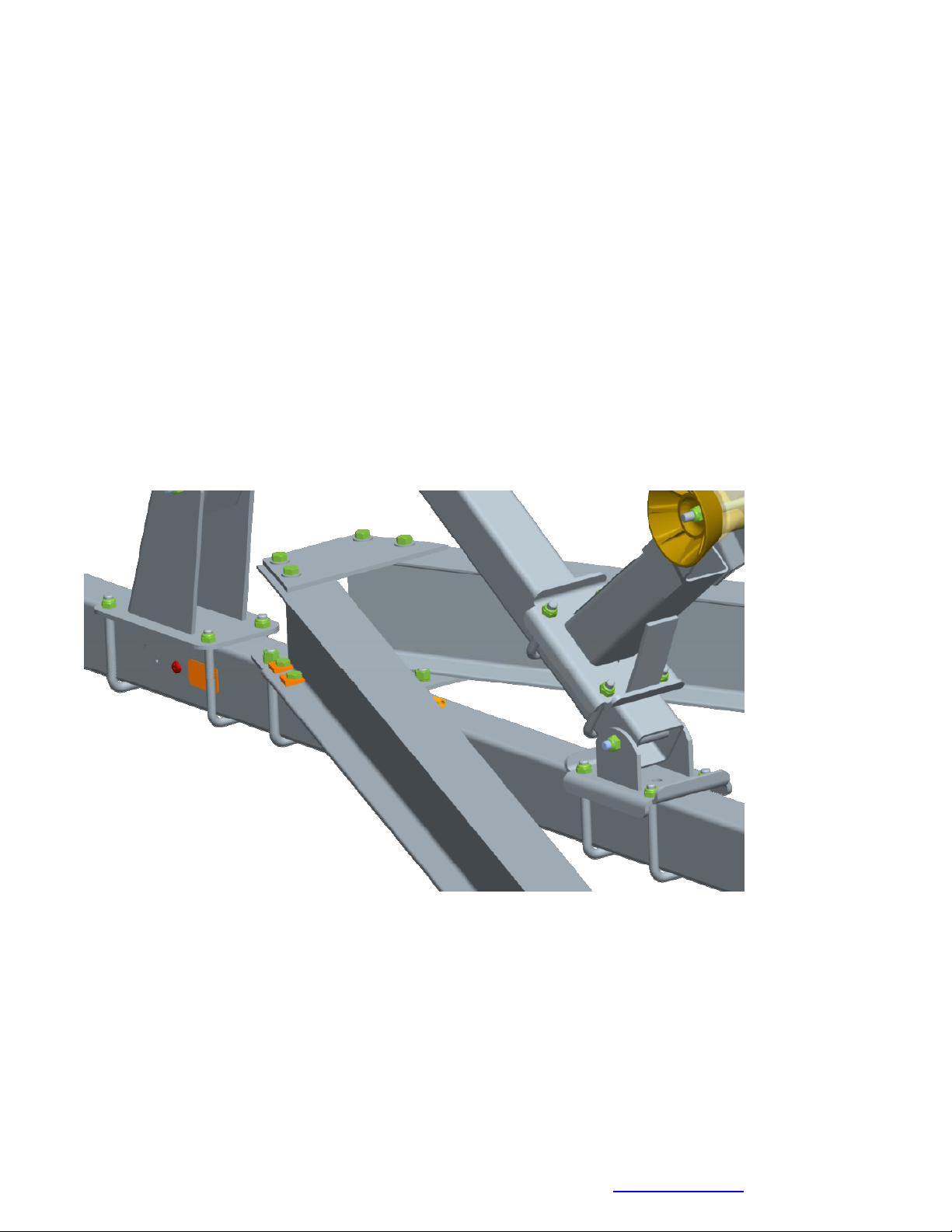

For rear axle 8200lb trailers:

Align the eye of the spring on the second

bogie holding the rear of the first axle.

through the rocker bogie and the eye of the

Raise the rear hook end of the springs on the th

axle with the hole provided in the rear of the rocker

om the outside in, insert a 9/16” x 3 3/4” hex bolt

Fr

spring. Secure with a 9/16” hex lock nut.

spring bushing above the hook leaf of the spring

located inside the spring bracket channel. Secure the

spring in the spring bracket by placing a spring

support channel under the spring. Insert a 9/16” x 43/4” hex bolt from the outside-in through the spring

support channel, spring bracket and then through the

spring bushing just placed above the hook spring

leaf. Secure u

other spring.

Tighten all axle U-bolts and spring bolts.

ird axle up into the spring bracket. Place a

sing a 9/16” lock nut. Repeat on the

Spring Support

Channel

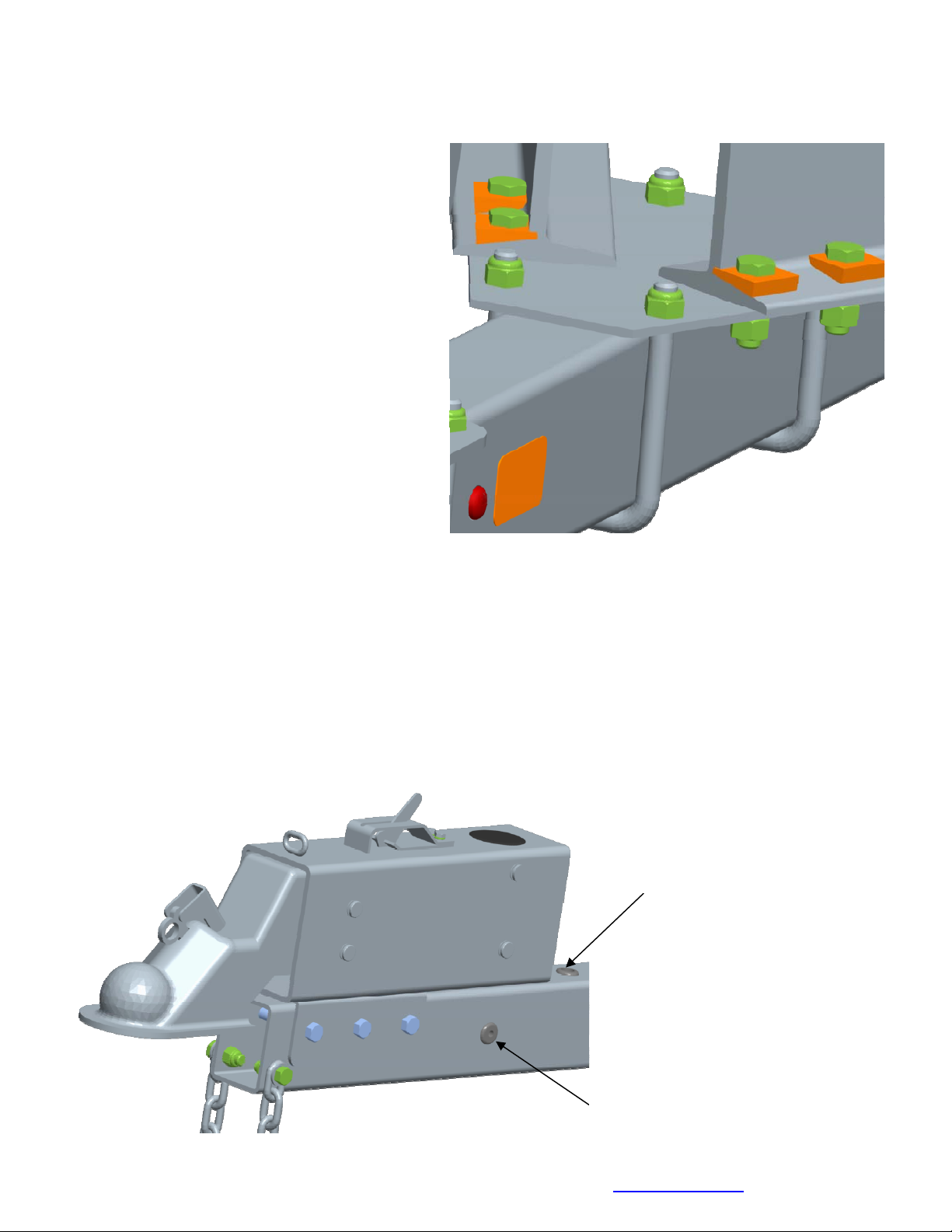

ongue Assembly:

T

lide the tongue into the tongue

S

annel weldment on front

ch

ossmember. Secure the tongue with

cr

1/2” X 4 1/2” stainless steel hex bolt,

a

/2” stainless steel flat washer and 1/2”

1

ainless steel hex lock nut with nylon

st

sert.

in

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 www.shorelandr.com 0004303

Page 6 of 13 2/15/2011

Page 7

Secure the tongue to the tongue plate on

e frame using two (2)1/2” X 3 9/16” X 5”

th

quare u bolts and four (4) 1/2” stainless

s

teel hex lock nut with nylon inserts.

s

ctuator/ Safety Chain:

A

ount the actuator onto the tongue (matching the hole pattern)

M using three (3) 1/2” X 4 1/2”

ainless steel hex bolts and three (3) 1/2” stainless steel hex lock nuts with nylon inserts.

st

ount the safety chains to the front of the tongue using a 1/2” X 1-1/2” stainless steel hex

M

olts, followed by a 1/2” stainless steel flat washer and safety chain. Secure the components

b

on the inside of the tongue

the above instructions on the other side of the tongue.

Remove the 58" brake hose that is included in the brake kit box and attach to the rear of th

actuator. Route brake hose thru holes in the top of the tongue and insert grommets to prote

using a 1/2” stainless steel hex lock nut with nylon insert. Repeat

the brake line hose. Connect

line to the frame hose with a

tube coupling and tighten.

Insert hose here

e

ct

Tongue Harness Vehicle

onnections comes thru herec

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 www.shorelandr.com 0004303

Page 7 of 13 2/15/2011

Page 8

BSrake Line Installation

ort all of the items in brake kit box.

ocate the long (90’) brake lines

L

nd straighten out by uncoiling.

a

Locate five (5) line clamps

elf tapping screws provided is

it.

k

Remove the lower plastic

and 1/4”

n the

plug from

the port in the brass block on the

left brake caliper. Note also that the

bolt holding the brass block to the

caliper can be loosened so that the

brass block can be rotated to better

accommodate the angle that the

brake hose approaches the block

on the caliper. Thread the brake hos

rub or touch the spring. Re-tighten th

the block. Route the hose along the

(5) clamps and self tapping screws.

Route the brake hose over to the bra

the right caliper block. Thread the ot

e fitting into this port making sure that the line does not

e bolt in the brass block if it has been loosened to rotate

back side of the axle and secure to the axle with the five

Note that the axle is pre-drilled for the mounting screws.

ss block on the right brake caliper. Remove both plugs on

her end of the brake hose into the bottom port on the

brass block. Thread the 18” brake hose male end into the other port. Tighten.

Set the position the brass block so that no components will make contact or rub on the sprin

Tighten all fittings.

Place the other end of the hose up

through the hole provided in the

brake line clip bracket. Secure in

place with the hose clip provided.

Repeat this process on the second

axle.

g.

Connecting the Axles Together

Locate the brass tee. Thread the

male port of the tee into the femal

end of the 18” brake hose running

up from the axle just installed on

the se

R

cond axle. Tighten.

emove the plastic cap from the end of the frame brake hose coming out of the side frame by

the axle. Carefully pull the brake ho

on the second axle and tighten.

Thread the 60” brake hose into the o

clip thru the large hole on the end a

block. Tighten these connections.

things take two (2) clamps and two (2) self-tapping screws and attach to the I-beam.

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 www.shorelandr.com 0004303

Page 8 of 13 2/15/2011

e

se enough so that it will reach the top port of the tee just

ethreaded into the brake hose. Thr

ad the brake hose fitting into the top port of the tee installed

ther port on the tee. Route the hose over to the brake line

nd then down and thread into the side port on the brass

To prevent the hose from sagging and getting caught on

Page 9

Brakes:

Refer to the brake manual for service and maintenance.

Tire/Rim Assemblies:

ount the tire and wheel assemblies using the 1/2” fine threaded tapered lug nuts provided. M

Tighten to

Owners Manual.

R

e-torque the lug nuts after 50 miles driving and then periodically thereafter.

Winch Assembly:

The winch post assembly comes factory assembled and ready to mount on the tongue.

Position the winch assembly on the tongue in a location that would best fit your watercraf

Using two (2) 1/2”

th

e tongue. Tighten with four (4) 1/2” stainless steel lock nuts so that the winch assembly will

85-130 ft./lb. torque using the rotation pattern as shown in the ShoreLandr’s

X 3 9/16” X 5” stainless steel square u-bolts, secure the winch assembly to

t.

not slide on tongue. Set the other mounting plate in position and secu

3 9/16” X 5” stainless steel square u-bolts and four (4) 1/2” stainless steel lock nuts. Refer to

winch adjustments in the trailer adjustments section in the last section.

re it using two (2) 1/2” X

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 www.shorelandr.com 0004303

Page 9 of 13 2/15/2011

Page 10

Front Bunk:

M

ount the bunk bracket weldment

in

to the pivot base weldment using

a

1/2” X 4-1/2” stainless steel hex

h

ead bolt and secure with a 1/2”

st

ainless steel hex lock nut with

nylon insert.

Mount the bunk assembly onto the

bunk bracket weldment using two

(2) 1/2” X 1-1/2” stainless steel

hex bolts and secure with two (2)

1/2” stainless steel hex lock nuts

with nylon insert. Repeat this pro

cedure on the opposite side of the trailer.

Rear Bunk:

Mount the bunk bracket weldment

into the pivot base weldment using a 1/2” X 4-1/2” stainless

steel hex head bolt and secure with a 1/2” stainless steel hex lock nut with nylon insert.

Mount the bunk assembly onto the bunk bracket weldment using two (2) 1/2” X 1-1/2” stainless

steel hex bolts and secure with a two (2) 1/2” stainless steel hex lock nuts with nylon inserts.

Repeat this procedure on the opposite side of the trailer.

Tongue Weight Adjustment:

Tongue weight should be 5% to 7% of the total gross weight of the boat and trailer comb

Tongue weight too high, move the axle assembly forward.

Tongue weight too low, move the axle assembly backward.

NOTE: Brake line and wire harness will need care when moving the assembly.

ined.

Adjustments

Winch Post:

rt. Once the boat is positioned Place the boat on the trailer and position it for proper suppo

adjust the winch post as follows: Loosen the U-bolts attaching the winch post mounting bases

to the tongue. Rotate the winch post assembly either upward or downward until

oming off the winch is at the same height as the boat bow eye. Slide the assembly backward c

until the bow eye ro

the winch post pivot tube so that the retainer strap is directly above the boat bow eye as the

bow roller contacts the boat. This is a good starting point for the fine adjustment of the winch

post as described below.

ller about contacts the boat. Place the retainer strap up over the top of the

that the bow roller assembly may have to be adjusted either up or down on

Noteboat bow eye.

the strap

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 www.shorelandr.com 0004303

Page 10 of 13 2/15/2011

Page 11

Winch Strap Adjusting Instructions:

Route the winch strap through the loop in the end of the

winch post retainer strap, then attach into the boat bow eye.

Winch the boat on the trailer until the boat is just touching the

bow roller of the winch post assembly. Loosen the bow roller

ssembly and either raise or lower until the loop in the winch

a

post retainer strap is positioned on the t

eye. Re-tighten in new position. Winch the boat securely

op of the boat bow

on

the trailer.

Proper adjustment is when the bow roller is in contact with

the boat and the winch post retainer strap is securely pulled

onto the top of the boat bow eye at the same time. Note that

they must both make contact at the same time to create the

maximum retaining force of the boat propelling forward in the

event of a p

anic or sudden stop.

Once the above adjustment is accomplished, hook the bow

eye safety chain into the boat bow eye as extra security to

keep the boat from sliding off the back of the trailer in the

event that the winch fails.

Rear Support System:

Place the boat on the trailer so that the transom is located at

the rear of the support system. On an bunk trailer, the

transom of the boat should be within 1-2” of the end of the

bun

k. This gives you maximum

support on the transom.

he rear cross member is adjustable forward or

T

various length boats. This

is accomplished by

the rear cross member to each side frame. Slide the assembly

in the side frames that is more desirable, and then re-a

backward to allow the trailer to be adjusted to

removing the two bolts that attach the ends of

to another set of holes provided

ttach th

e cross member in the new

location with the bolts just removed.

The wire harness for the

three-light identification light must be repositioned where it comes

from the black wire harness tubing to eliminate slack and sagging of the wiring.

Bunks:

Make sure the bunks are positioned far enough apart to give your boat as much stability as

possible while transporting. Position t

he bunks so they are located just to the outside of a

strake that your boat may have. This will help center your boat and assist when loading. The

bunks need to be adjusted up high enough to keep the keel from resting on the c

inimum of one to two inches of clearance is desirable.

m

enter pads. A

Front Support System

Bunk

The front bunks should be adjusted either in or out so that the bunk will run just to the outside

of the strake of the boat. The bunks can be adjusted either farther in or out from the location of

the rear bunk position. Adjust the bunks up so that there

etween the keel of the boat and the center cross member pad.

b

is approximately 1” clearance

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 www.shorelandr.com 0004303

Page 11 of 13 2/15/2011

Page 12

Read your ShoreLand’r Owner’s Guide and all safety decals on the trailer.

Wash and wax your trailer regularly. Always rinse your trailer after each use, especially when

boating in salt or brackish water.

e-check all fasteners for tightness before towing.

R

heck the tire pressure before towing.

C

Contact your authorized ShoreLa

or further information or assistance, contact ShoreLand’r at 1-800-859-3028 or visit

F

nd’r dealer if you experience a problem with your trailer.

www.shorelandr.com.

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 www.shorelandr.com 0004303

Page 12 of 13 2/15/2011

Page 13

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 www.shorelandr.com 0004303

Page 13 of 13 2/15/2011

Loading...

Loading...