ShoreLand'r SL40TBAL User Manual

®

SLB40TBAL, SLR40TBAL & SLRB40TBAL

Aluminum Trailers

SLB40TBAL

Bundles Required for SLB40TBAL

62340 Literature Bag - Trailers 1

6744300 Frame Bundle, SLB40TBAL 1

4300213 ST175/80R 13C Tire / Galv. Dir Rim 4

SLR40TBAL

Bundles Required for SLR40TBAL

62340 Literature Bag - Trailers 1

6816000 Frame Bundle, SLR40TBAL 1

4300213 ST175/80R 13C Tire / Galv. Dir Rim 4

SLRB40TBAL

Bundles Required for SLRB40TBAL

62340 Literature Bag - Trailers 1

6744700 Frame Bundle, SLRB40TBAL 1

4300213 ST175/80R 13C Tire / Galv. Dir Rim 4

Midwest Industries, Inc. Ida Grove, IA 51445 (800)859-3028 www.shorelandr.com M301237

Page 1

IMPORTANT:

All hardware for your trailer is stainless steel. It is

important that you use an anti-seize material on the bolt

threads when assembling to prevent gaulding.

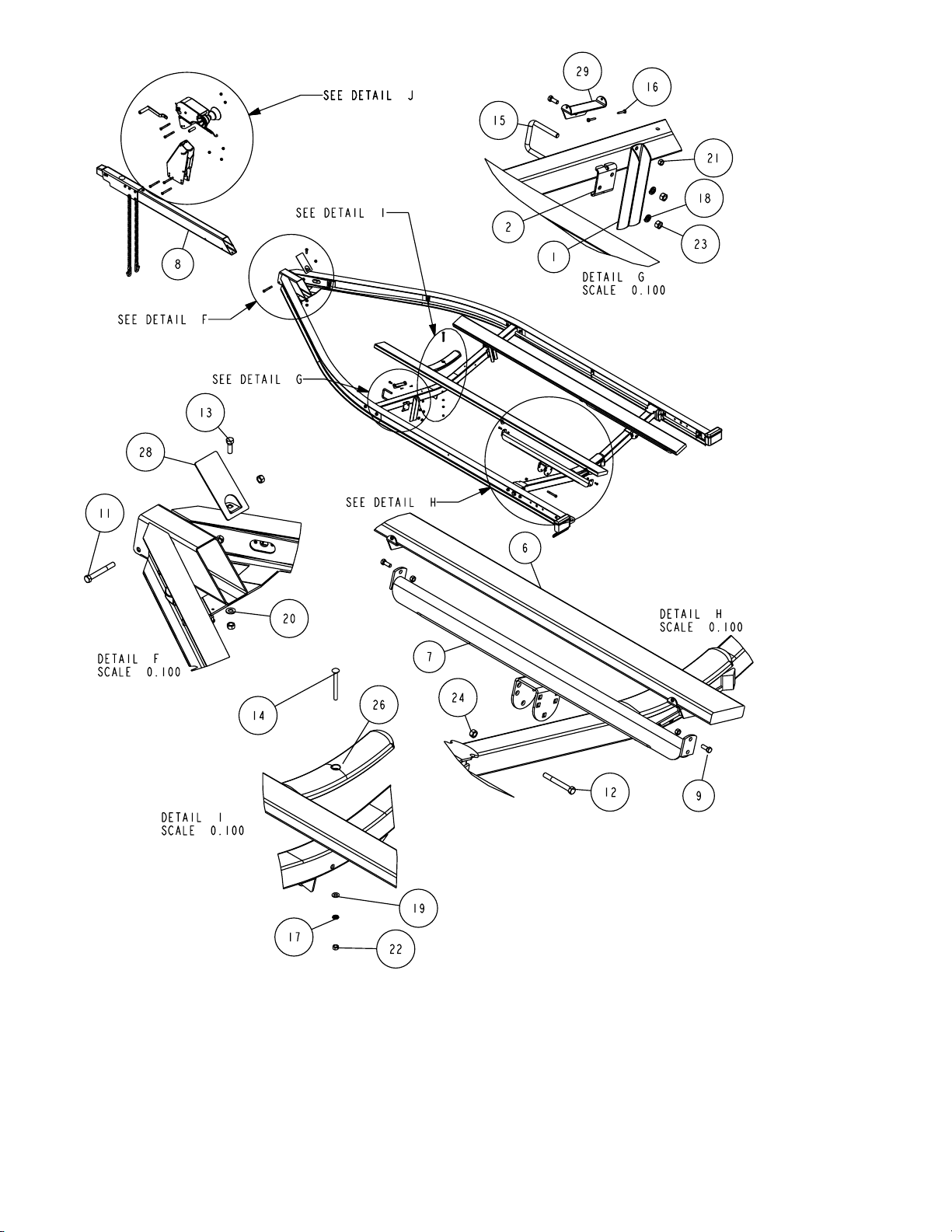

TONGUE

The tongue comes shipped positioned backwards in the

frame.

Remove the nut and bolt that holds the tongue in place and

discard. Remove the tongue from its shipping position and

install correctly in the front tongue channel.

See pages 4 & 5.

Line the holes in the tongue with the holes in the tongue

channel. Install the 1/2” X 4” hex bolt in the front cross hole

and secure with a 1/2” lock nut.

Remove the wire harness from the rear of tongue. Place the

wire harness and the brake line through the hole provided in

the tongue cover plate. (See Detail F).

Secure the tongue cover plate in position with the same 1/2”

x 1-1/2” hex bolt that secures the back on the tongue to the

tongue channel of the frame.Secure with a 1/2” lock nut.

Tighten both bolts just installed.

Plug the tongue wire harness ends into the frame harnesses

by matching colors and ends. Push the extra wire provided

either into the rear of the tongue or else remove the grommet

in the side frame and place the extra wire in the side frame.

Replace grommets just removed.

White Ground Wire Installation

Place the self-tapping screw provided through the round metal

ring on the white ground wire of the tongue harness located

at the rear of the tongue. Attach the ground wire to the main

frame by driving the screw in the hole provided next to the

tongue channel of the frame. This will assure a positive ground

for the lighting.

Locate the brass brake line coupling. Remove the plastic cap

and thread the brake line coming out the rear of the tongue

into one end of the coupling. Bend the line in a smooth gradual

radius being careful not to kink the line. Bend so it can be

mated to the brake line from the side frame. Once aligned

thread the side frame brake line into the other end of the

coupling. Tighten both lines into the coupling.

SAFETY CHAINS

Slip the 1/2” x 5” hex bolt through a 1/2” flat washer, place

through the last link of one of the safety chains.

Place the bolt with chain attached through the hole in the

bottom front of the actuator mounted on the tongue.

Position the second chain on the portion of the bolt

extending through the other side of the tongue. Secure with

1/2” flat washer and hex lock nut.

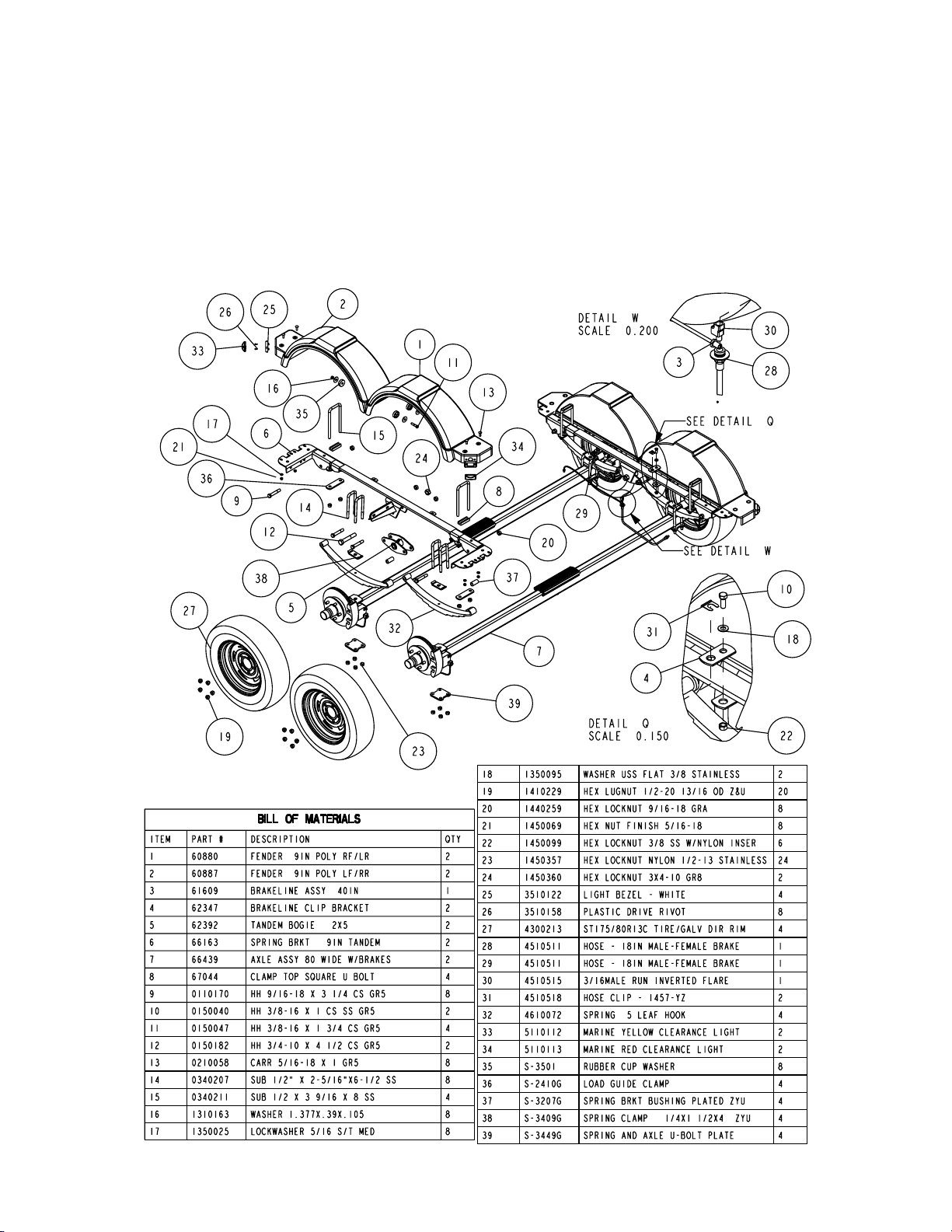

ROCKER ARMS

Locate the rocker arms (Ref. No. 5 of the chassis schematic,

Page 3). Note that the center bushing has a grease zerk in it.

Position the rocker arms up into the center channel welded

in the center of the tandem spring bracket so that the grease

zerk is pointing down. Align the holes in the channel with the

rocker arm. Secure in place with a 3/4” x 4-1/2” hex bolt and

lock nut. Tighten. Repeat this process on the other rocker

arm and spring bracket. Grease the rocker at this time by

applying grease through the zerk just discussed.

NOTE: THE GREASE ZERK IS POSITIONED DOWN SO

THAT IT IS ACCESIBLE FOR SERVICING WHEN NEEDED.

SPRINGS

Position the axles so they are properly aligned with the trailer.

Position the brake axle so that the disc brake calipers are on

the back side of the axle. The brake axle must always be

mounted as the rear axle to give you the best braking

possible (See Page 6). There is no right and left to the axle

without brakes. It can be mounted either way.

Place the springs on the topside of the spring pads welded to

the axle. (See chassis diagram). Note that the hook end of

the spring must be to the rear of the trailer. Place a spring

clamp on the top center of the spring as shown. Next place

the 1/2” x 6-1/2” U-bolts down over the top of the spring clamp,

spring and axle as shown.

Place the spring and axle U-bolt plate onto the ends of the

two U-bolts just placed. Secure in place with 1/2” lock nuts.

Thread onto the U-bolts but do not tighten securely

until the complete unit is in position on the trailer. Repeat on

the other spring.

AXLE

Place one of the spring bracket bushings (Ref.#37) into the

rear of the spring bracket and secure with a 9/16” x 3-1/4”

hex bolt and hex lock nut. Repeat in other spring bracket.

Position the rear axle under the frame, then hook the hook

loop of the springs around the bushings just installed. Note

that if the axle is positioned too low when trying to hook, the

hooks will not hook around the bushings.

Raise the front of the springs up so they align with the rear

hole in the axle boogie just installed. Secure in place with

9/16” x 3-1/4” hex bolts and lock nuts.

Install another spring bracket bushing in the front hole on the

rock arm assembly. Secure with a 9/16” x 3-1/4” hex bolt and

lock nut. Tighten.

Hook the hook end of the springs mounted to the front axle

over the bushing just installed in the rocker arm assembly.

Then swing the front of the spring up and attach the front

mounting hole in the spring bracket with another 9/16” x

3-1/4” hex bolt and lock nut.

Tighten all axle U-bolts and spring bolts.

ONE AXLE BRAKE INSTALLATION

Cut the tape securing the brake line hose to the axle.

Remove the brass plug from the port in the brass block on

the right brake caliper. Thread in the brake hose male end

and tighten. Place the other end of the hose up through the

hole provided in the brake line clip bracket. Secure in place

with the hose clip provided. (Item # 29, Page 6)

Remove the plastic cap from the end of the frame brake line

coming out of the black plastic tube in the side frame by the

axle. Carefully uncoil the brake line so that it will reach the

end of the hose just attached to the brake line clip bracket.

Thread the brake line fitting into the brake line hose. Tighten.

All bleeding to the line can be done through the bleeder on

the right caliper.

Midwest Industries, Inc. Ida Grove, IA 51445 (800)859-3028 ww.shorelandr.com M301237

Page 2

DUAL AXLE BRAKE INSTALLATION

If your trailer is equipped with dual axle brakes connect the

line to the axle as follows:

Cut the tape securing the brake line hose to the axle.

Remove the brass plug from the port in the brass block on

the right brake caliper. Thread the brake hose male end into

the block and tighten. Attach the brake hoses from the axles

to the spring bracket with the brake line clip brackets as shown

in Detail Q. Once the brake hoses are secured in place with

the hose clips (Ref. No. 31) the lines can be attached.

Identify which brake line hose that the side frame brake line

tubing will be connected to. In a dual axle installation it can

connected to either one. When identified, locate the brass

tee connector. Screw the male port of the tee into the brake

line hose. Tighten. Next connect the side frame brake line

into the top port on the tee. Connect the two axle together

using the 40” brake line supplied. Thread one end of the line

into the brass tee just installed. Route the line over to the

other axle, form a loop in the line and then connect the other

end into the brake line hose for the second axle.

Fill the actuator reservoir with brake fluid and bleed the line

per the instructions in the brake manual. Note that the axle is

already bled at the factory during assembly. All bleeding to

the line can be done through the bleeder on the right caliper.

DUAL AXLE BRAKE ASSEMBLY

Midwest Industries, Inc. Ida Grove, IA 51445 (800)859-3028 www.shorelandr.com M301237

Page 3

B-SERIES BUNK ASSEMBLY

Locate the two 2 x 6 bunk assemblies. Note that the bunk

mounting brackets are assembled at the factory. Place the

end with the two brackets towards the rear of the trailer. Place

the assembly on the equiload bunk arm and secure by

placing a 3/8” x 1” hex bolt through the bracket on the bunk

and the ear on each end of the equiload arm. Secure in place

using a 3/8” lock nut. Repeat on the other end of the arm.

(See Detail H.)

The front bracket is not attached to the bunk because the

Tire And Wheel Assemblies

Mount the tire and wheel assemblies using the 1/2” fine

threaded tapered lug nuts provided. Tighten to 80-90 ft/lb. of

torque using the rotation pattern as shown in the Shore

Landr’s Owners Manual. Re-torque the lug nuts after 50

miles of driving and then periodically thereafter.

Midwest Industries, Inc. Ida Grove, IA 51445 (800)859-3028 www.shorelandr.com M301237

trailer can be adjusted to two different lengths. Once the

proper position for the rear cross member is determined, the

front of the bunk can now be attached to the bracket using

two- No. 10 x 1-1/4” self tapping screws as shown in Detail G.

The 3/8” bolts can be tightened but not over

tightened because the bunks should be allowed to rotate

slightly to conform to the boat’s bottom.

Page 4

See Page 2 for Tongue and Safety Chain Assembly

Instructions.

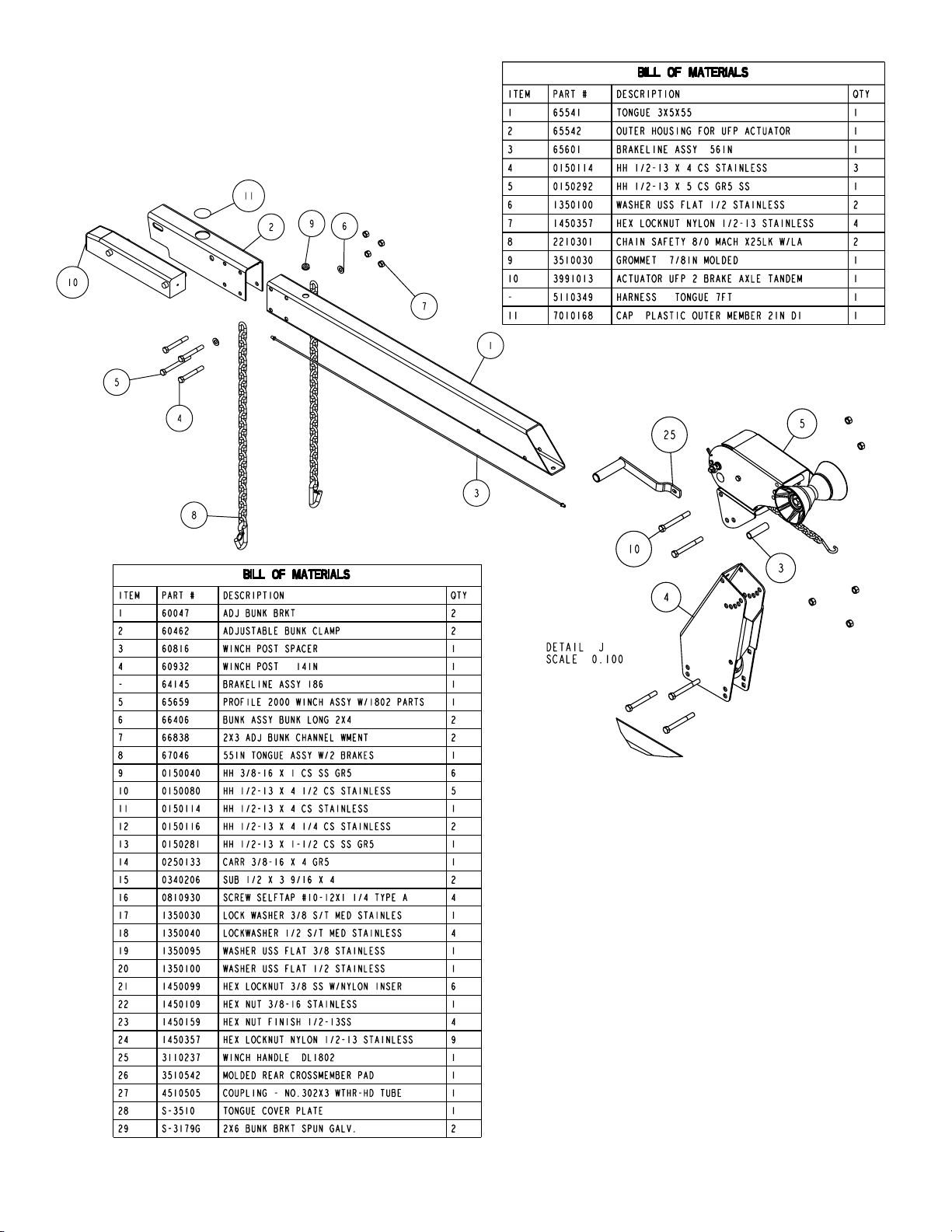

WINCH POST ASSEMBLY

(See Detail J). The height that the bow eye is placed in your

boat will determine the length winch post required. Once this

is determined, attach the winch base to the tongue with three

1/2” x 4-1/2” hex bolts and lock nuts.

Align the holes in the Profile 2000 mounting channel with the

holes in the top of the winch base. Attach the front of the

winch head mounting channel to the base by placing a 1/2” x

4-1/2” hex bolt through the hole closest to the front of the

winch base. Secure with a lock nut. Do not tighten.

Note that the winch head can now be rotated either up or

down. Identify the correct hole combination to use to position

the bow eye roller just above the bow eye of your boat. When

determined, secure in this position by placing the bushing as

shown in Detail J inside the winch base so it aligns with the

hole just identified for the proper adjustment. Insert another

1/2” x 4-1/2” hex bolt through the determined mounting hole

in the mounting channel and winch base making sure the

bolt passes through the bushing as well. Secure with a

1/2” lock nut. Tighten all bolts.

Midwest Industries, Inc. Ida Grove, IA 51445 (800)859-3028 www.shorelandr.com M301237

Page 5

Loading...

Loading...