Page 1

®

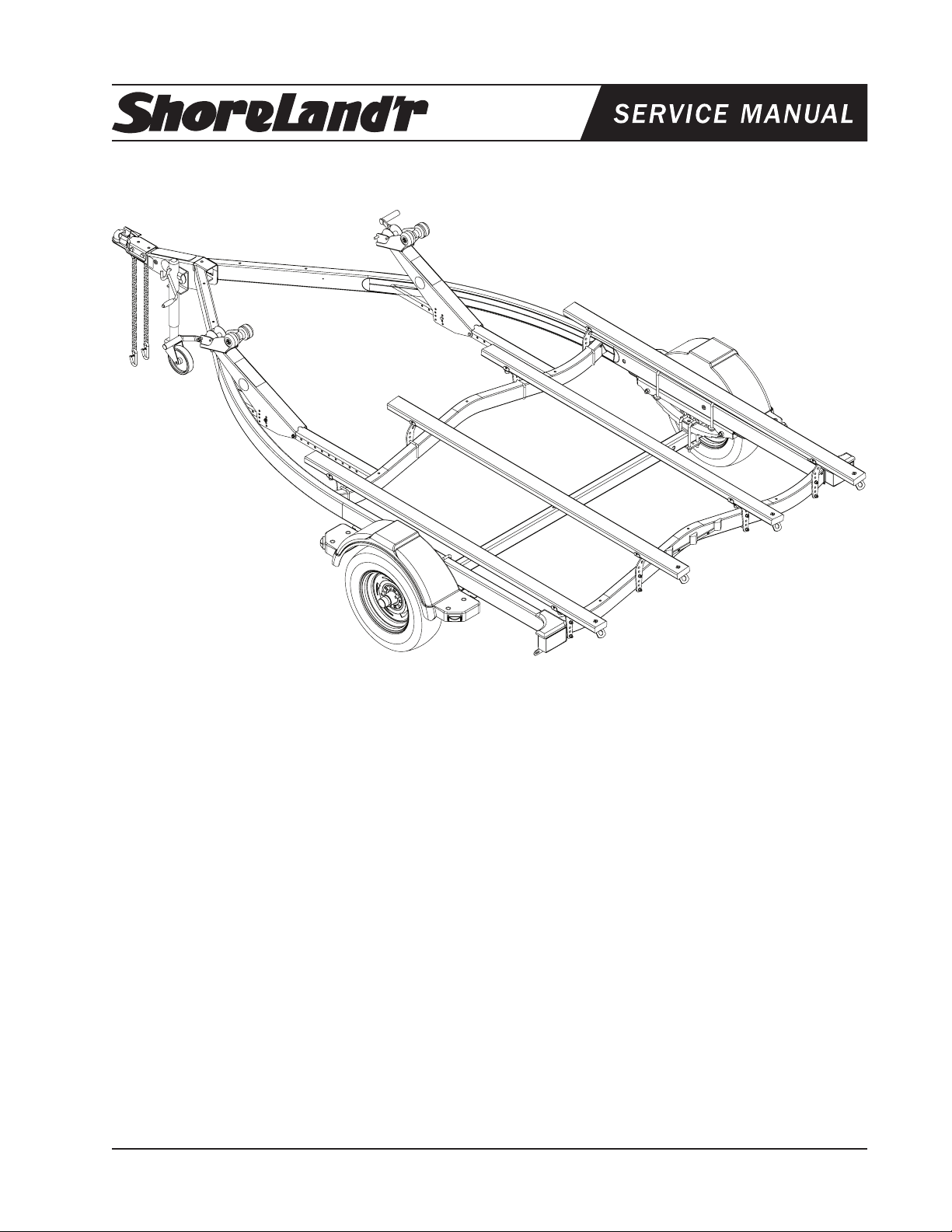

PWC2213W & PWC2413W

Note; Optional jack and jack mounting hardware are

shown

PWC2213W PWC 2200 Trailer

1 62340 Literature Bag - Trailers

2 *ST175/80R13-C Tire/Dir Rim

1 68218-- Frame Bundle - PWC 2-Place

PWC2413W PWC 2400 Trailer

1 62340 Literature Bag - Trailers

2 *

ST185/80R13C Tire/Dir Rim

1 68218-- Frame Bundle - PWC 2-Place

*Check with your dealer/customer service representative for current tire/rim assembly

part number.

Note; Special attention should be paid when ordering

replacement bunks for these trailers as very carefull

measurements should be taken to insure that the correct

one’s will be sent.

Tire Size & Carrying Capacity Chart

Tire Load Carrying

Size Range Capacity

ST175/80R13 C 1360 lb.

ST185/80R13

ShoreLand’r offers their product line in either galvanized or

painted nish. When ordering parts it is important that you

specify the nish or color you have on your product. The ve

(5) digit number along with a two (2) digit space _ _, note the

parts which can be purchased with various nishes. When

ordering these items use the ve (5) digit number along with

a two (2) digit sufx for the proper nish.

03 .................Black

00 .................Galvanized

C 1480 lb.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

REV C 03/30/2009

Page 1

Page 2

PWC2213W (All Colors) Specications:

Refer to your ShoreLand’r Owner’s

Guide and other decals on trailer for

additional information.

SAFETY INSTRUCTIONS

4810709

Proper tongue weight must be maintained.

Rev C 8/28/06

Before towing, check the following to ensure

that:

1. All parts, bolts, nuts and wheel lug

nuts are tight.

2. All wheel lug nuts must be tightened

to a minimum torque rating of 85 ft/lb.

3. Lug nuts must be re-torqued after the

first 50 miles, then periodically there

after.

4. Tires are inflated to manufacturer’s

standards. (See tire sidewall)

5. Wheel bearings have adequate

grease.

6. Hitch ball is the proper diameter and

has a rating equal to or greater than

the GVWR of the trailer.

7. Coupler is properly attached and

secured to coupler ball.

8. Trailer safety chains are crossed

under the tongue and attached to

towing vehicle.

9. All lights are operational. Note: It is

recommended that the trailer lights

be disconnected before backing into

the water.

10. Tie downs, winch strap and bow eye safety chain are secure.

11. Trailer tongue jack is in up or travel

position.

Capacity: 2200 lbs.

GVWR: 2720 lbs.

GAWR: 2720 lbs.

Ship Wt: 500 lbs.

Frm Size: 2X4 (12 Ga)

Tire Size: ST175/80R 13-C

Rim Size: 13 X 4.5 “J”

Brake: N/A

Coupler: 2”

Suspension: 5 Leaf Hook Springs

PWC2413W (All Colors) Specications:

Capacity: 2400 lbs.

GVWR: 2960 lbs.

GAWR: 2960 lbs.

Ship Wt: 505 lbs.

Frm Size: 2X4 (12 Ga)

Tire Size: ST185/80R 13-C

Rim Size: 13 X 4.5 “J”

Brake: N/A

Coupler: 2”

Suspension: 5 Leaf Hook Springs

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

REV C 03/30/2009

Page 2

Page 3

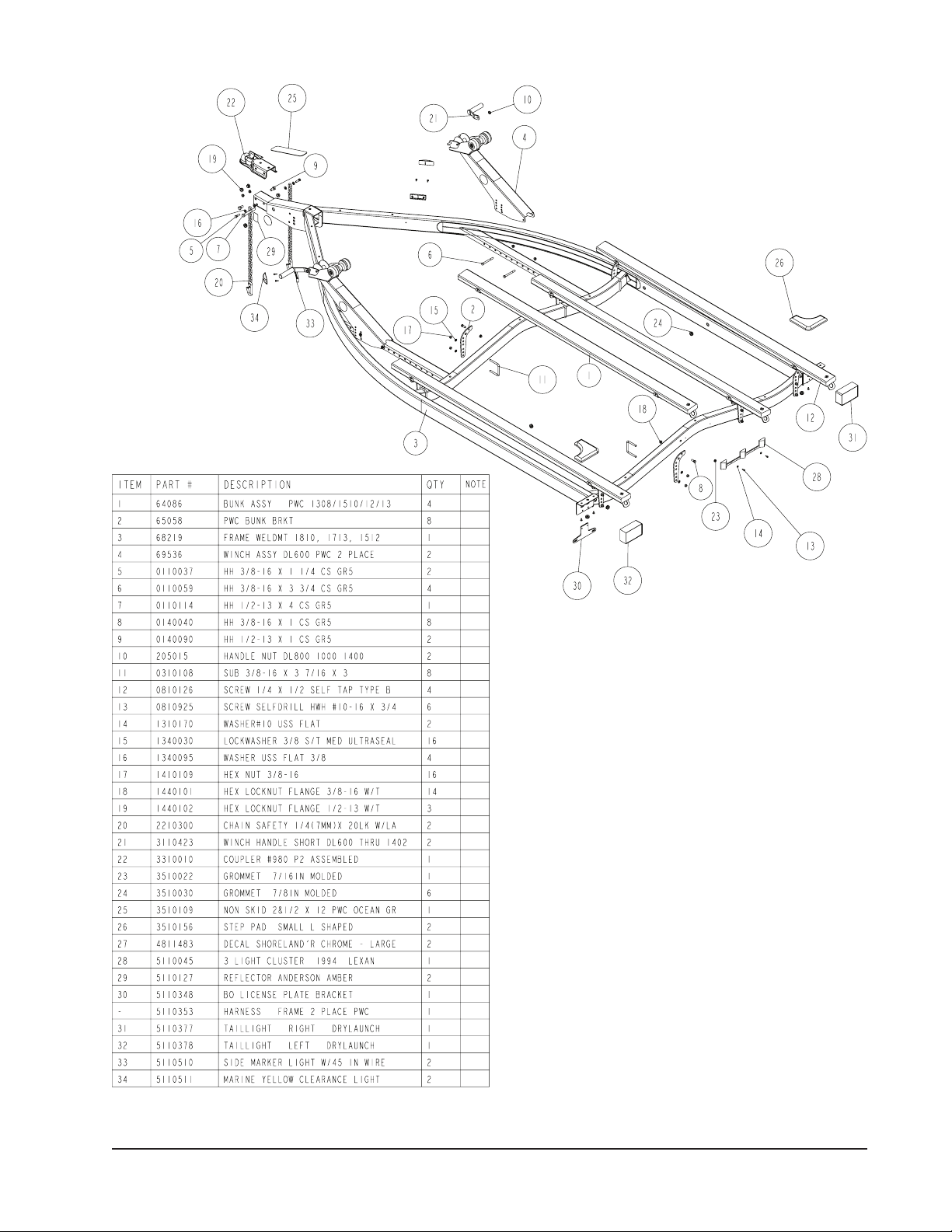

Frame Drawing

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

REV C 03/30/2009

Page 3

Page 4

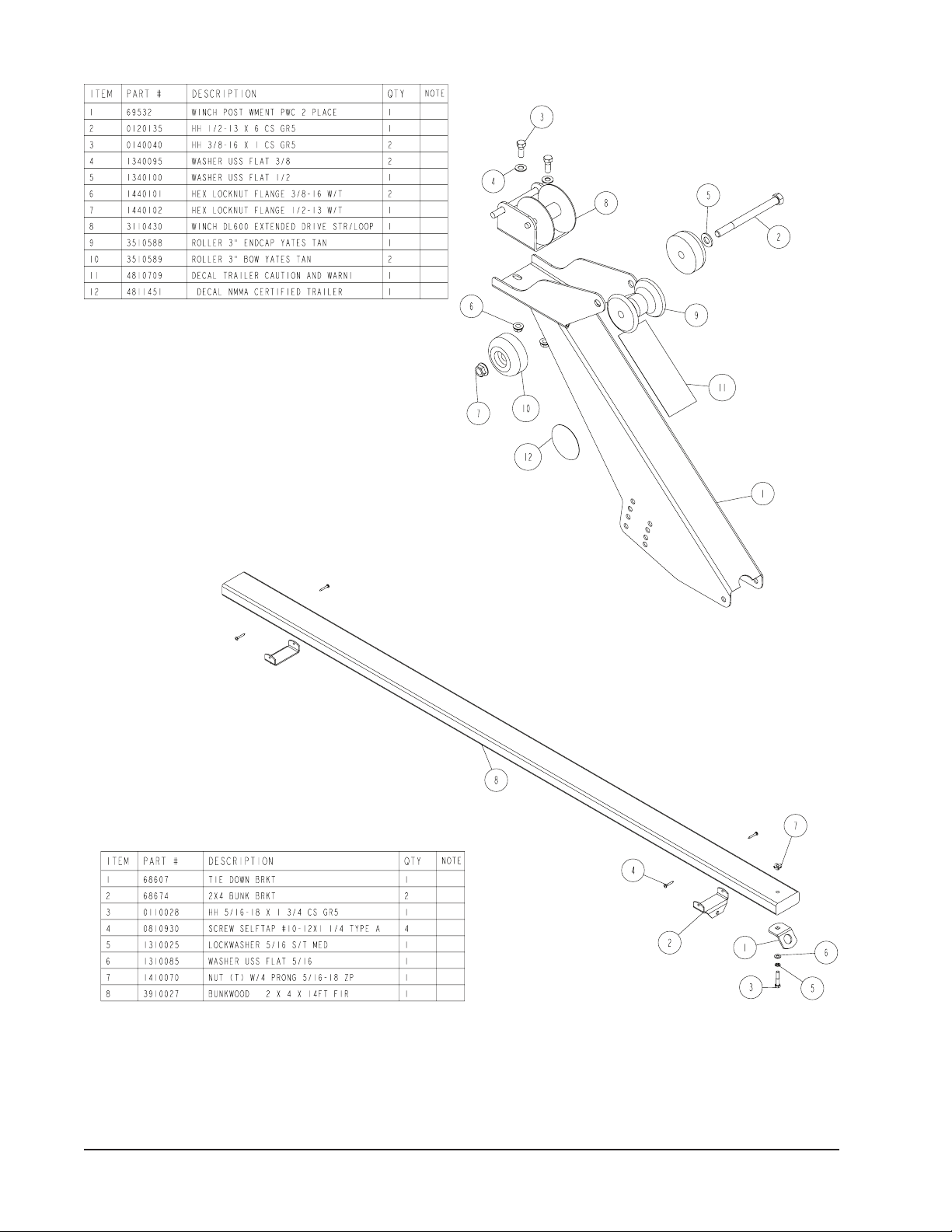

Winch Assembly

Bunk Assembly

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

REV C 03/30/2009

Page 4

Page 5

Optional Jack Assembly

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

REV C 03/30/2009

Page 5

Page 6

Chassis

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

REV C 03/30/2009

Page 6

Page 7

FINAL ASSEMBLY INSTRUCTIONS

Remove all banded items from the frame and sort hardware

by size.

SPRINGS

Position the axle so it is properly aligned with the trailer. Place

the springs on the top side of the spring pads welded to the

axle. (See chassis diagram). Note that the hook end of the

spring must be mounted to the rear of the trailer. Place a

spring clamp on the top center of the spring as shown. Next

place the 1/2” x 6-1/2” U-bolts down over the top of the spring

clamp, spring and axle as shown.

Place the spring and axle U-bolt plate onto the ends of the

two U-bolts just placed. Secure in place with 1/2” lock nuts.

Thread onto the U-bolts but do not tighten securely until the

complete unit is in position on the trailer. Repeat on the other

spring.

AXLE

Place one of the spring bracket bushings into the rear of the

spring bracket and secure with a 9/16” x 3 1/4” hex bolt and

hex lock nut. Repeat in other spring bracket.

Position the axle under the frame, then hook the hook loop

of the spring around the bushings just installed. Note that if

the axle is positioned too low when trying to hook, the hooks

will not hook around the bushings.

Raise the front of the springs up so they align with the front

hole of the spring bracket. Secure in place with 9/16” x 3-1/4”

hex bolts and lock nuts.

Tighten all axle U-bolts and spring bolts not tightened at this

time.

TIRE & WHEEL ASSEMBLY

Mount the tire and wheel assemblies using the 1/2” ne

threaded tapered lug nuts provided. Tighten to 85-95 ft./lb.

of torque using the rotation pattern as shown in the Shore-

Landr’s Owners Manual.

Re-torque the lug nuts after 50 miles of driving and then

periodically thereafter.

WINCH POSTS

The winch posts can be mounted as far forward on the mounting channels as possible until the PWC’s are placed on the

trailer. Attach by placing the 3/8” bolts through the holes in the

bottom of the winch posts and the mounting channels.

Place the winch handles onto the winch drive shafts and se-

cure using the 1/2 “ nuts provided. All other adjustments will

be done after the PWC’s are positioned on the trailer.

OPTIONAL JACK & MOUNTING HARDWARE (Page 5)

The hardware for the optional jack should be included in

the winch base kit box. After opening the bag and sorting

the components place jack inside spacer on the winch

stand base aligning the slots with the holes in the base

and the dimple on the plate in the dimple on the winch

base. Place the jack over this and slide the jack retainer

platin place over the spacer plte aligning the square holes

with the slots in the spacer plate. Insert two (2) 12/ x 1

1/4” carriage bolts and secure on the inside with 1/2” lock

washers and 1/2” hex nuts.

BUNKS: FRONT CROSSMEMBER

Outside PWC bunk brackets on each side of the trailer:

Slide a 3/8” x 3-7/16” x 3” square U-bolt (Item #10, Page 3)

over the front cross member so the threaded end of the U-bolt

is pointing forward. Position the PWC bunk bracket on the

front side of the cross member so that the dog leg end of the

bracket is pointing outward. Align two holes in the PWC bunk

bracket with the legs of the U-bolt, then insert U-bolt through

the holes in the PWC bunk bracket and secure with 3/8” lock

washers and hex nuts. Repeat this process on the other

outside PWC bunk bracket on the front cross member.

Inside PWC bunk brackets on each side of the trailer:

Repeat the above process except point the dog-leg of the

PWC bunk brackets toward the center of the trailer.

BUNKS: REAR CROSS MEMBER

Outside PWC bunk brackets on each side of the trailer:

Slide a 3/8” x 3-7/16” x 3” square U-bolt (Item #10, Page 3)

over the rear cross member so the threaded end of the U-bolt

is pointing rearward. Position the PWC bunk bracket on the

rear side of the cross member so that the dog leg end of the

PWC bunk bracket is pointing outward. Align two holes in

the PWC bunk bracket with the legs of the U-bolt, then insert

U-bolt through the holes and secure with 3/8” lock washers

and hex nuts.

Repeat this process on the other PWC bunk bracket on the

rear crossmember.

Inside PWC bunk brackets on each side of the trailer:

Repeat the above process except point the dog-leg of the

PWC bunk brackets toward the center of the trailer.

Locate the bunk assemblies. Note that one end of the bunks

have a tie down bracket fastened to it.

Position the bunk above the PWC bunk brackets just installed so that the tie down bracket is to the rear of the

trailer. Align the holes in the bunk brackets (Item #2, Page

3) with a hole in the PWC bunk brackets. Note that the PWC

bunk bracket must be on the correct side of the leg of the

bunk bracket attached to the bunk so that the metal of both

brackets will hinge bind themselves when the bunks are pivoted. This will keep the bunks from pivoting too far when the

machines are removed from the trailer. Attach the two

together using 3/8” x 1” hex bolt and 3/8” flange lock

nuts. Tighten but do not over tighten. The bunks must be

allowed to pivot so they can conform to the PWC boat bottom

when it is placed on the trailer. Repeat this process on the

other bunks.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

REV C 03/30/2009

Page 7

Page 8

FINAL ADJUSTMENT:

Place the PWC’s on the trailer so the rear of the machines

are positioned at the rear of the bunks. Check the bunk po-

sitioning for clearance with the strakes. Loosen the U-bolts

securing the PWC bunk brackets to the crossmembers and

slide the bunks either in or out so that they are located just to

the outside of matching strakes. This will not only help with

loading but will also give you proper support for your machine.

Re-tighten the bunks when in the proper location. Repeat on

the other machine.

Note the PWC bunk brackets also have multiple holes for

raising or lowering the position that the machine sets on the

trailer with respect to the frame and fenders. It may require

a change in the height adjustment to clear the fenders on

certain machines.

TRAILERADJUSTMENTS

The adjustment of the trailer to your boat is very important

not only for the trailer, but also the PWC’s. Failure to do so

may lead to potential failure or damage to either the trailer

or PWC’s.

AXLE ADJUSTMENT

The amount of tongue weight on your trailer can be adjusted

as follows:

closest pair of holes in the front of the winch post and the

mounting channel. Insert another bolt in the aligned holes.

Tighten. Attach the winch strap and crank winch tight.

Adjust the winch post for the second PWC as described

above.

Adjustments are now complete. Double check for t. If desired t has been achieved, tighten all fasteners that may

have either been left loose or have been loosened to do the

adjusting.

NOTE: All nuts and bolts must be tightened before towing.

All fasteners should be periodically checked before towing.

See your ShoreLand’r Owner’s Guide for further technical

information regarding your trailer and its components.

To lower the tongue weight, adjust the axle assembly forward. To increase the tongue weight, adjust the axle back-

ward.

The distance that the axle assembly has to be moved will

vary because it is directly related to the weight and center of

gravity of the PWC’s placed on it. The tongue weight is also

dependant on whether your trailer is equipped with a stor-

age box and how much gear you will normally carry in it.

Best towing is achieved when the tongue weight is 5-7% of

the total gross load of the complete unit.

NOTE: Wire harnesses and brake line lines (if equipped with

brakes) will need care when moving the axle assembly.

WINCH POST ADJUSTMENT

Once all other adjustments are complete the winch post can

be adjusted. Slide the winch post backward until the bow

roller comes in contact with the PWC. Align the rear hole

in the bottom of the winch post with the closest hole in the

frame mounting channel. Insert a 3/8” hex bolt into the rear

hole. Position the bow roller directly above the bow eye to

prevent your PWC from moving forward in the event of a

sudden stop. The winch post can be rotated on the rear bolt

just installed until the bow roller is at the desired height required to t your PWC. Once in the correct position, align the

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

REV C 03/30/2009

Page 8

Loading...

Loading...