Page 1

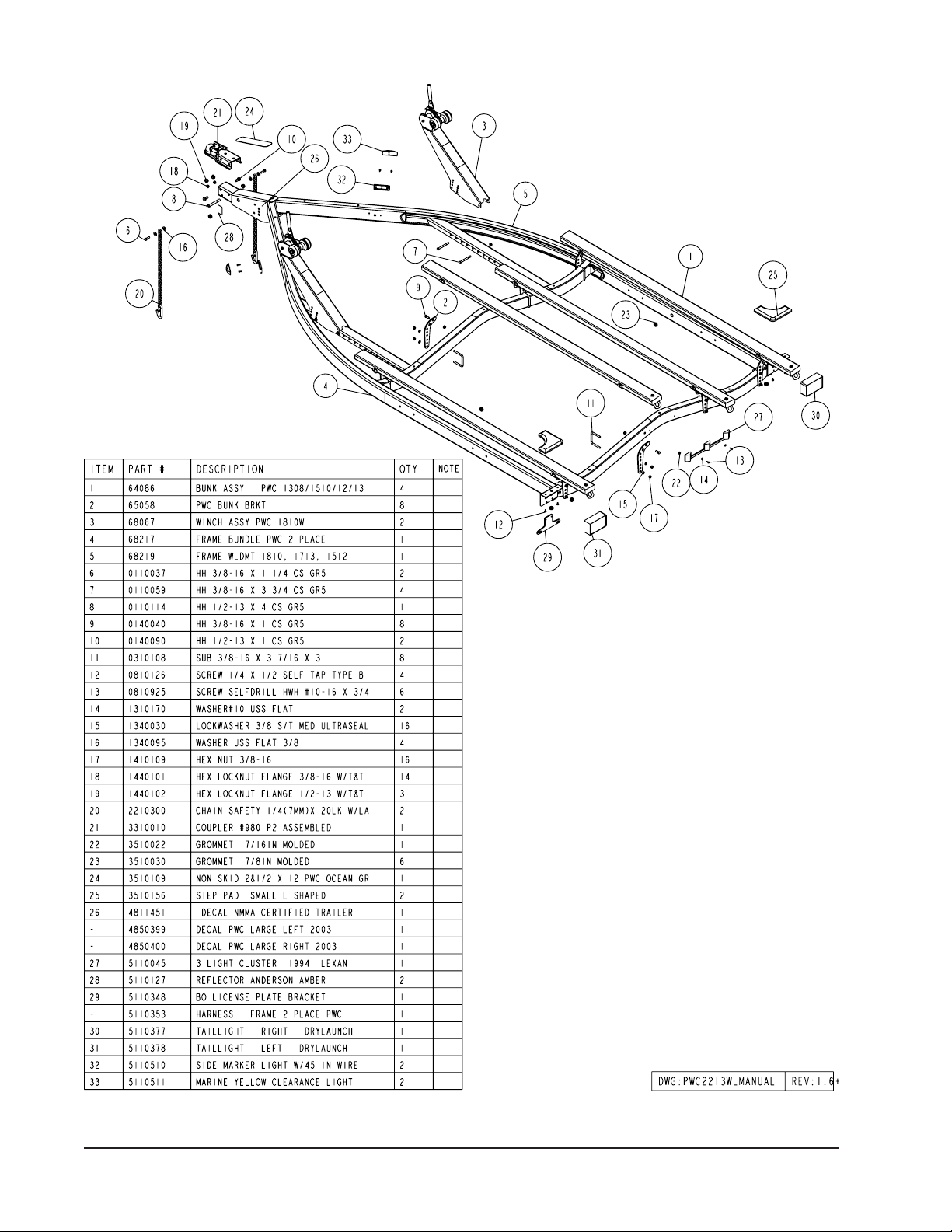

PWC2213W & PWC2413W

PWC2213W

1 62340 Literature Bag - Trailers

1 64085-- PWC Walkboard W/Carpet

2 4300241

1 68218-- Frame Bundle

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

Page 1 11/17/05

ST175/80R13C Tire/MSilver Dir Rim

PWC2413W

1 62340 Literature Bag - Trailers

1 64085-- PWC Walkboard W/Carpet

2 4300236

1 68218-- Frame Bundle

ST185/80R13C Tire/MSilver Dir Rim

Page 2

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

Page 2 11/17/05

Page 3

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

Page 3 11/17/05

Page 4

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

Page 4 11/17/05

Page 5

Tire Size & Carrying Capacity Chart

Tire Load Carrying

Size Range Capacity

ST175/80R 13 C 2200 lb.

ST185/80R 13 C 2400 lb.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

Page 5 11/17/05

Page 6

FINAL ASSEMBLY INSTRUCTIONS

Remove all banded items from the frame and sort hardware

by size.

Springs:

Install one of the spring bushings Item #96 in the rear of

one of the spring brackets and secure it in place with a

9/16” x 3-1/4” hex bolt and 9/16” flange lock nut. Hook the

hook end of the spring around this bushing and then swing

the front up into the spring bracket. Align the eye of the spring

with the hole provided in the spring bracket and secure in

place with another 9/16” x 3-1/4” hex bolt and 9/16” flange

lock nut. Tighten. Repeat on the other spring.

Axle:

Position the axle under the springs just installed. Align

the pin on the bottom center of the spring with the hole

provided in the spring pad welded to the top of the axle.

Place a spring clamp Item #97 on the topside of the spring.

Drop two 1/2” x 2-5/16” x 6-1/2” U-bolts down over the spring

clamp, spring and then the axle. Place on a spring and axle

U-bolt plate (Item #99) and secure in place with 1/2” flange

lock nuts.

Repeat on the other spring. Tighten all nuts on the U-bolts

just installed.

Tire and Wheel Assemblies:

Mount the tire and wheel assemblies using the 1/2” fine

threaded tapered lug nuts provided. Tighten to 85-95 ft/lb.

of torque using the rotation pattern as shown in the Shore-

Landr’s Owners Manual. Re-torque the lug nuts after 50

miles of driving and then periodically thereafter.

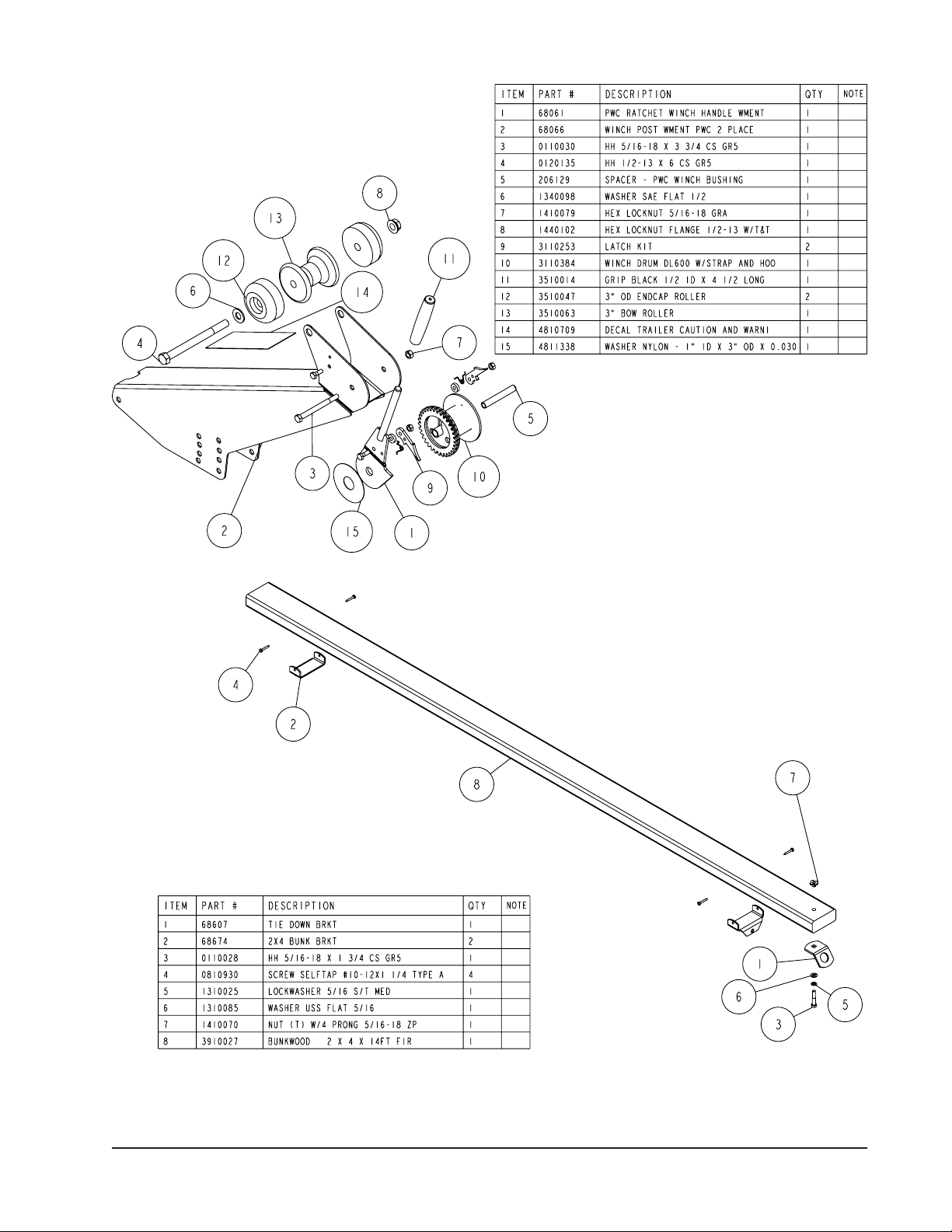

Winch Posts:

Locate one of the winch posts weldments Item #12. Place it

onto the winch post weldment mounting section of the frame

as shown. Note that there is a series of hole positions that

the winch post can be mounted in. Select the one that will

best adapt to your PWC and secure the winch post weldment

to the frame using (2) 3/8” x 3-3/4” hex bolts and flange lock

nuts. Repeat this process on the remaining winch post weldment. Do not tighten at this time because they will have to be

adjusted to the PWC’s once they are placed on the trailer.

Walk Board:

Locate the front walkboard mounting bracket. (Item #3)

Place it on the front of the frame and align the holes in

the bracket with the holes provided in the frame. Mount

the front walkboard bracket to the front of the frame by

placing two (2) 3/8” x 5” carriage bolts in the holes provided from the top side down through the frame. Secure with

3/8” lock washers and hex nuts.

Mount one of the back walk board plates to the middle cross

member by placing 3/8” x 3-1/2” carriage bolts from the top

side down through the plate and cross member.

Place the walkboard down the centerline of the trailer on

top of the walk board mounting brackets just installed.

Ce n t e r on t h e b r a c k e t s si d e w a y s a n d l e n g t h wise. Attac h the walk boa rd to the brack ets by placing No. 10 x 1-1/2” Phillips-head screws in the holes

provided in the mounting brackets from the bottom side up into

the carpeted walkboard. Thread in the screws until tight.

Bunks:

Front Crossmember

Outside PWC bunk brackets on each side of the trailer:

Slide a 3/8” x 3-7/16” x 3” square U-bolt (Item #31) over the

front crossmember so the threaded end of the U-bolt is pointing forward. Position the PWC bunk bracket on the front side

of the cross member so that the dog leg end of the bracket is

pointing outward. Align two holes in the PWC bunk bracket

with the legs of the U-bolt, then insert U-bolt through the holes

in the PWC bunk bracket and secure with 3/8” flange lock

nuts. Repeat this process on the other outside PWC bunk

bracket on the front crossmember.

Inside PWC bunk brackets on each side of the trailer:

Repeat the above process except point the dog-leg of the

PWC bunk brackets toward the center of the trailer.

Rear Crossmember

Outside PWC bunk brackets on each side of the trailer:

Slide a 3/8” x 3-7/16” x 3” square U-bolt (Item #31) over

the rear crossmember so the threaded end of the U-bolt is

pointing rearward. Position the PWC bunk bracket on the

rear side of the crossmember so that the dog leg end of the

PWC bunk bracket is pointing outward. Align two holes in the

PWC bunk bracket with the legs of the U-bolt, then insert Ubolt through the holes and secure with 3/8” flange lock nuts.

Repeat this process on the other PWC bunk bracket on the

rear crossmember.

Inside PWC bunk brackets on each side of the trailer:

Repeat the above process except point the dog-leg of the

PWC bunk brackets toward the center of the trailer.

Lo c ate the bu n k assem b l ies. Not e that one en d of

the bunks have a tie down bracket fastened to it. Posi t ion the bu nk abov e the PWC bu nk brac k ets jus t

installed so that the tie down bracket is to the rear of the trailer.

Align the holes in the bunk brackets (Item #98) with a hole in

the PWC bunk brackets. Note that the PWC bunk bracket must

be on the correct side of the leg of the bunk bracket attached

to the bunk so that the metal of both brackets will hinge bind

themselves when the bunks are pivoted. This will keep the

bunks from pivoting too far when the machines are removed

from the trailer. Attach the two together using 3/8” x 1” hex

bolt and 3/8” flange lock nuts. Tighten but do not over tighten.

The bunks must be allowed to pivot so they can conform to

the PWC boat bottom when it is placed on the trailer. Repeat

this process on the other bunks.

Secure with a 3/8” flange lock nut. Tighten. Repeat this process on the rear crossmember.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

Page 6 11/17/05

Page 7

Final Adjustment:

Place the PWC’s on the trailer so the rear of the machines are

positioned at the rear of the bunks. Check the bunk positioning

for clearance with the strakes. Loosen the U-bolts securing the

PWC bunk brackets to the crossmembers and slide the bunks

either in or out so that they are located just to the outside of

matching strakes. This will not only help with loading but will

also give you proper support for your machine. Re-tighten

the bunks when in the proper location. Repeat on the other

machine.

Note the PWC bunk brackets also have multiple holes for

raising or lowering the position that the machine sets on the

trailer with respect to the frame and fenders. It may require

a change in the height adjustment to clear the fenders on

certain machines.

Winch Post Weldments:

Once the machines are properly positioned on the bunks

the winch post weldments can now be adjusted.

Remove the two 3/8” x 3-3/4” hex bolts installed earlier to

hold the winch post weldment to the frame. Slide the winch

posts weldment either forward of backward so it corresponds

with the front of the machine. Rotate the winch post weldment

so that the bow stop roller is positioned just above the bow

eye of the machine. Attach the winch strap, route under the

bow stop roller, then to the bow eye and tighten the winch

strap slightly to help hold the winch post weldment in position. Locate and align the mounting holes in the winch post

weldment with the holes in the frame member. Re-install the

3/8” x 3-3/4” hex bolts in the new location. Secure with the

3/8” lock nuts removed. Tighten in position.

Pull the machine into the winch post weldment bow eye

roller and check to make sure the positioning is correct. The

bow eye roller must be positioned just above the bow eye to

properly stop the machines in the event of a sudden stop.

The winch strap must run under the bow eye roller when it is

attached to the bow eye.

Repeat the above process on the other machine.

Tongue Weight:

Check the trailer for proper tongue weight. Best towing is

achieved when the tongue weight is 5-7% of the total gross

load of the complete unit.

Axle Adjustment:

The amount of tongue weight on you r trailer can be

adjusted as follows:

To lower the tongue weight, adjust the axle assembly

fo r w a rd, to incre a s e th e tongue weig h t , adjust the

axle assembly backward.

The distance that the axle assembly has to be moved

will vary because it is directly related to the weight and

center of gravity of the machines placed on it.

Re-check all nuts and bolts for tightness to make sure that

none have been missed during assembly. Unit is now ready

to be towed.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

Page 7 11/17/05

Page 8

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003599

Page 8 11/17/05

Loading...

Loading...