Page 1

®

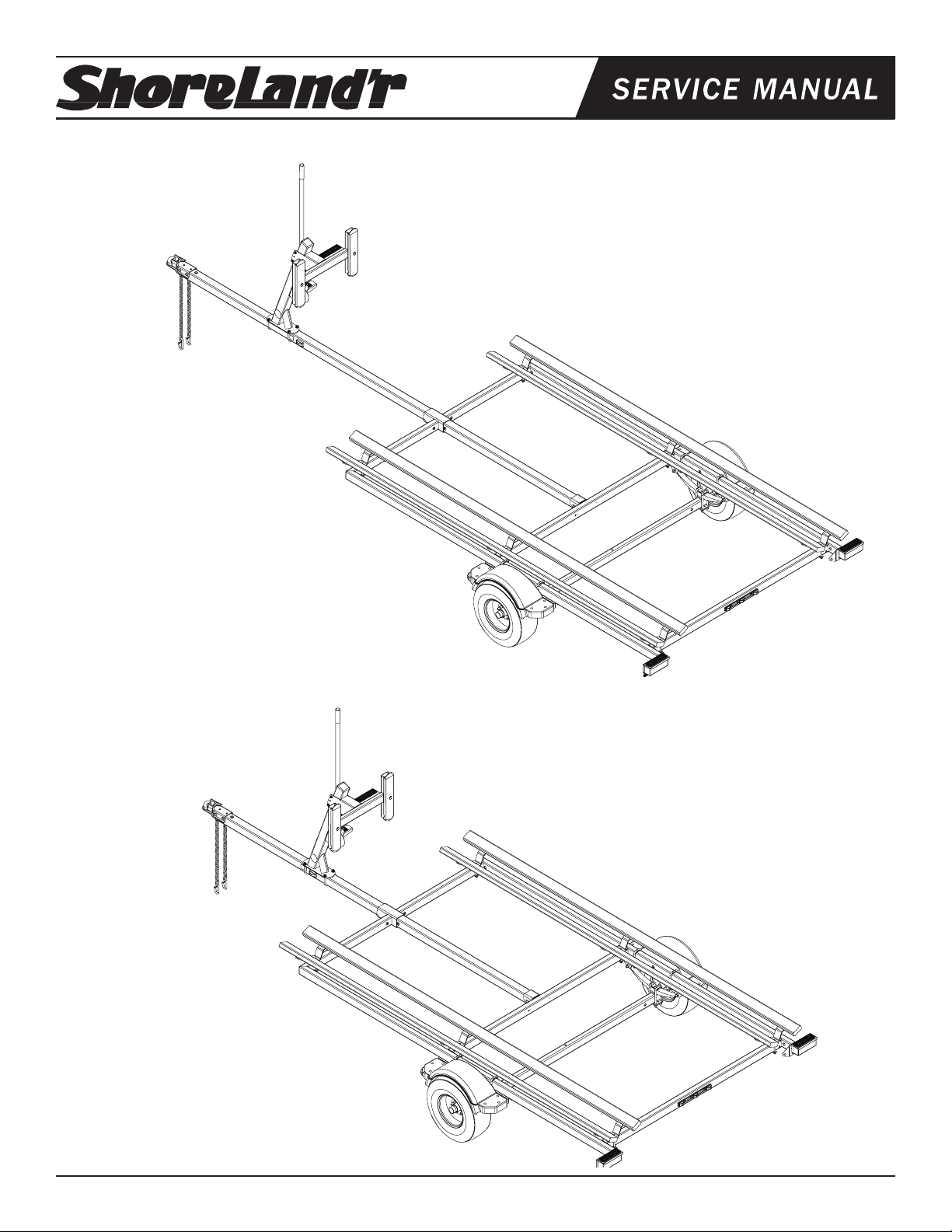

PT1720 & PT1420 Pontoon Trailer

PT1720 Pontoon Trailer

70275 Hdwe Box Pontoon PT1420/1720

62340 Lit Packet - Trailers

80672__ Frame Bundle - PT1720

*20.5X8X10E Tire/Rim

70260__ Tongue Assy Pontoon 3X3X174IN

*Check with your dealer/customer service representative for current tire/rim assembly part number.

PT1420 Pontoon Trailer

70275 Hdwe Box Pontoon PT1420/1720

62340 Lit Packet - Trailers

80673__ Frame Bundle - PT1420

*20.5X8X10E Tire/Rim

70261__ Tongue Assy Pontoon 3X3X138IN

*Check with your dealer/customer service representative for current tire/rim assembly part number.

ShoreLand’r offers its product line in painted nish-

es. When ordering parts, it is important that you spec-

ify the nish or color you have on your product. The

5-digit number along with a 2-digit space _ _, note

that the parts can be purchased in various nishes.

00........ Galvanized

03........ Black

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004034

Page 1 Rev C 05/13/2010

Page 2

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004034

Page 2 Rev C 05/13/2010

Page 3

Remove the small parts from the frame by cutting the banding. Remove the bolt bag and sort all the nuts and bolts by size.

the pontoon that is going to be placed on the trailer and position

accordingly.

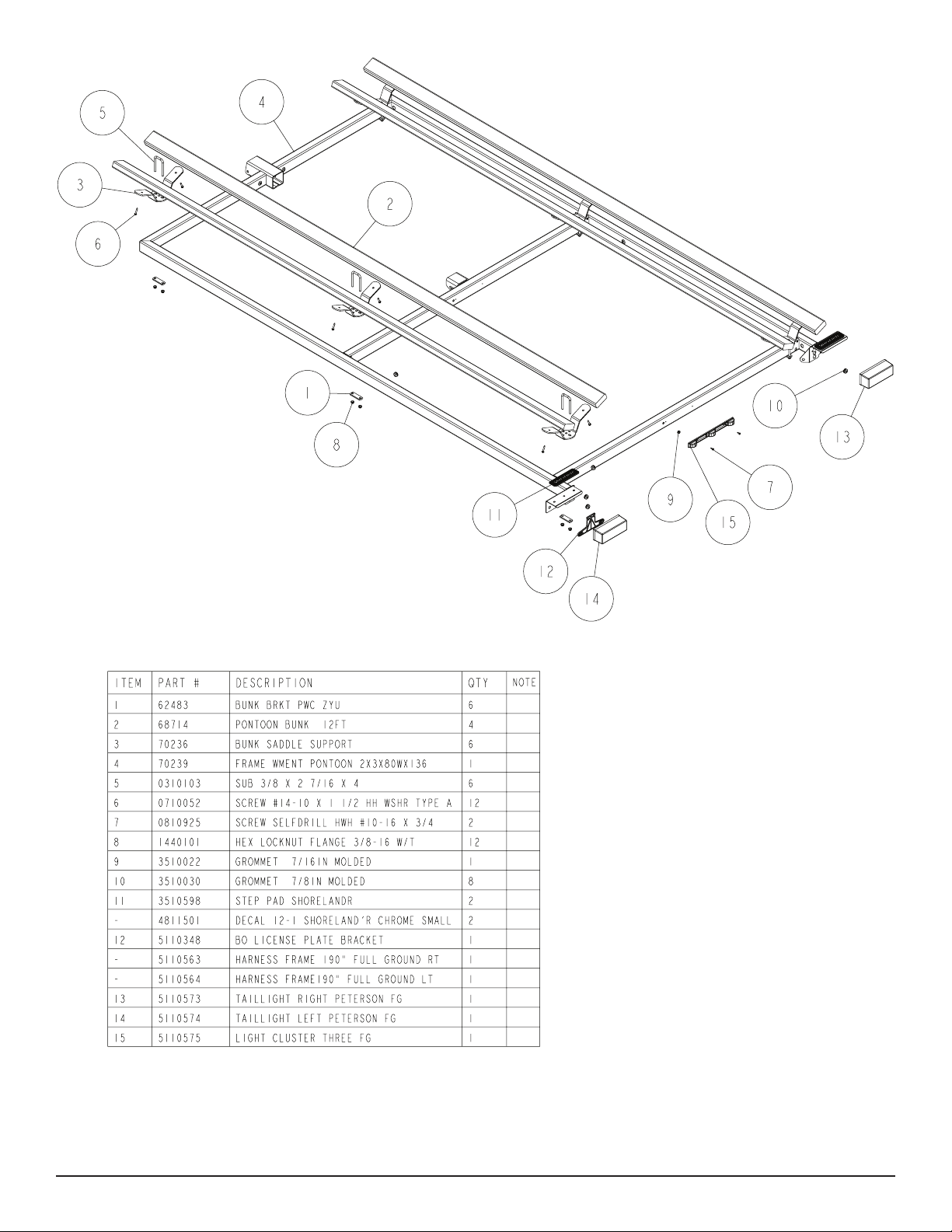

BUNKS

Note that the bunk system is adjustable for widths up to 76” to

t most center dimensions of the pontoon tubes. Determine the

centers of the bunk support system that ts the pontoon tubes for

Place the bunk saddle bracket on the crossmember with the arms

of the bracket parallel to the crossmember. Insert a 3/8 x 2 7/16 x

4 square u-bolt into the holes on the bracket so that the legs of the

u-bolt are on each side of the crossmember. Place item #1 over the

legs of the u-bolt on the bottom of the crossmember and secure

with 3/8” ange locknuts. Do not tighten at this time. Repeat this

process for the remaining bunk saddle brackets.

Now determine the center point of the crossmembers dividing the

center to center dimension in half. Measuring from the center point

of the crossmember to the u-bolt on the bunk saddle brackets

sliding them in or out till dimension is aquired. Secure brackets in

place. Repeat on the remaning brackets.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004034

Page 3 Rev C 05/13/2010

Page 4

Position the carpeted bunks so approximately 10” extends past

the back of the rear bunk saddle support. Attach the bunks to the

brackets using the ¼” x 1 ½” lag screws provided.

Repeat this process on the bunk on the other side of the bunk saddle support and then on the other side of the trailer.

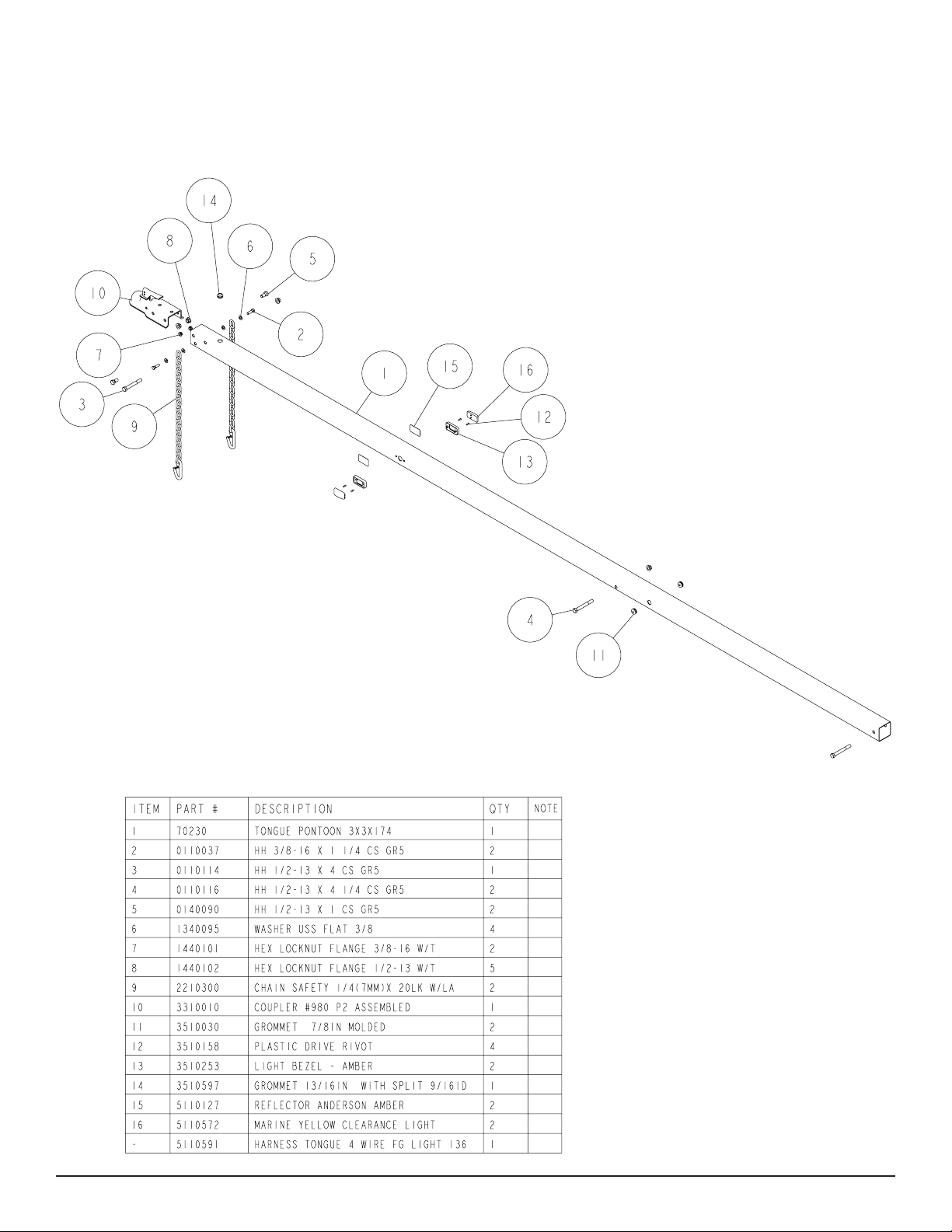

TONGUE

See Page 4 (assembly for PT1720) and Page 5 (assembly for

PT1420)

Once the proper tongue is identied place it on the stands so it can

be prepared for installation into the frame. Locate the two amber

side marker lights shipped in the hardware box. Uncoil the wire

insert the plug into the larger, center hole that is drilled in the side

of the tongue. As the wire is inserted into the hole direct the wire so

it will go to the forward end of the tongue. Pull the wire out the front

of the tongue. It will be connected to the tongue harness at a later

time. Attach the light to the tongue using two (2) No. 10 x 3/4” self

tapping screws provided. Repeat this process on the other light on

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004034

Page 4 Rev C 05/13/2010

Page 5

the other side of the tongue.

COUPLER

Locate the proper length tongue. Insert the rear of the tongue into

the frame tongue channel sliding it thru until it slides into the mounting channel on the second crossmember until the mounting holes

line up. Secure the tongue into the frame by placing a ½” x 4 1/4”

Locate the coupler. Drop it into position on the front of the tongue.

Secure it to the tongue using a ½” x 4” hex bolt through the rear

mounting hole of the coupler housing. Insert completely through

the tongue, then secure in place with a ½” ange lock nut.

hex bolt in the front tongue channel and the channel on the second

crossmember. Secure both mounting bolts with ½ ange lock nuts.

Tighten.

Locate the wire harness that is in the tongue. Plug the tongue wire

harness ends into the frame harnesses by matching colors and

Attach the front of the coupler to the tongue using two- ½” x 1” hex

bolts. Insert the bolt through one side of the coupler housing and

the tongue. Secure inside the tongue using a ½” ange lock nut.

Repeat this process on the other side of the tongue. Tighten all at-

taching bolts securely.

ends. Push the excess wire provided either into the side of the

tongue or else remove the grommet in the front crossmember and

insert the excess wire. Replace grommets just removed.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004034

Page 5 Rev C 05/13/2010

Page 6

SAFETY CHAINS

Insert a 3/8” x 1 ¼” hex bolt through a 3/8” at washer and then into

the end link of one safety chain. Insert the bolt into the front bottom

hole punched in the tongue. Place another 3/8” at washer on the

bolt and secure with a 3/8” ange lock nut. Tighten.

Repeat this process on the other safety chain.

WINCH POST.

Position the winch post on the tongue and secure in place using ½”

x 3 9/16” x 3 7/8” square U-bolts. Secure with ½” ange lock nuts.

Tighten only to hold in position because they will have to be moved

when the pontoon is placed on the trailer.

Attach the adjustable bow stop section to the winch post using

three 3/8” X 3 3/4” Carriage bolts and securing with 3/8” ange lock

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004034

Page 6 Rev C 05/13/2010

Page 7

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004034

Page 7 Rev C 05/13/2010

Page 8

Tire Size and Carrying Capacity Chart

Tire Size ............................20.5X8X10E

GVWR ...............................2960 lb.

Carrying Capacity ............2000 lb.

Axle ...................................Single

Refer to the tire side wall for correct tire pressure.

NOTE: Brakes available as optional equipment.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004034

Page 8 Rev C 05/13/2010

Page 9

Refer to your ShoreLand’r Owner’s

Guide and other decals on trailer for

additional information.

SAFETY INSTRUCTIONS

4810709

Proper tongue weight must be maintained.

Rev C 8/28/06

Before towing, check the following to ensure

that:

1. All parts, bolts, nuts and wheel lug

nuts are tight.

2. All wheel lug nuts must be tightened

to a minimum torque rating of 85 ft/lb.

3. Lug nuts must be re-torqued after the

first 50 miles, then periodically there

after.

4. Tires are inflated to manufacturer’s

standards. (See tire sidewall)

5. Wheel bearings have adequate

grease.

6. Hitch ball is the proper diameter and

has a rating equal to or greater than

the GVWR of the trailer.

7. Coupler is properly attached and

secured to coupler ball.

8. Trailer safety chains are crossed

under the tongue and attached to

towing vehicle.

9. All lights are operational. Note: It is

recommended that the trailer lights

be disconnected before backing into

the water.

10. Tie downs, winch strap and bow eye safety chain are secure.

11. Trailer tongue jack is in up or travel

position.

nuts. Note the three sets of holes in the very front of the bow stop

bracket. Place two of the three bolts in the top & bottom sets of

holes. The bolt in the top set of holes may be moved to the center

holes in the event that the bow stop needs to be adjusted higher.

This will have to be adjusted to meet the bow of the boat.

Attach the winch handle to the winch using the nylon locking nut

provided on the winch.

SPRINGS

Position the axle under the frame so it is properly orientated. All

axles have holes drilled for mounting brake lines. These attaching

holes must be positioned to the rear of the trailer.

Place the springs on the axle as shown so the closed eye of the

spring is to the front of the trailer. Drop two ½´x 2 9/16´x 6 1/2”

square U-bolts down over the spring clamp and over the springs

and on each side of the axle as shown.

Align the legs of the U-bolt with the holes in a spring pad and then

secure with ½” ange lock nuts. Tighten to keep all items in position

but do not securely tighten until the axle assembly is completely

installed under the frame.

AXLE

Place one of the spring bracket bushings into the rear of the spring

bracket and secure with a 9/16” x 3 1/4” hex bolt and hex lock nut.

Repeat in other spring bracket. Position the axle under the frame,

then hook the loop end of the spring around the bushings just installed. Note that if the axle is positioned too low when trying to

hook, the loops will not hook around the bushings.

Raise the front of the springs up so they align with the front hole

of the spring bracket. Secure in place with 9/16” X 3-1/4” hex bolts

and lock nuts. Repeat this process on the other spring.

Tighten all axle U-bolts and spring bolts not tightened at this time.

TIRE AND WHEEL ASSEMBLIES

Mount the tire and wheel assemblies using the ½” ne threaded

tapered lug nuts provided. Tighten to 85-95 ft/lb. of torque using the

rotation pattern as shown in the ShoreLandr’s Owners Manual.

Re-torque the lug nuts after 50 miles of driving and then periodically thereafter.

ADJUSTING INSTRUCTIONS

Place the pontoon on the trailer so that the pontoon tubes are ush

with the ends of the bunks. This will give you maximum support.

The bunk spacing has already been determined and set for width

when the trailer was assembled.

WINCH POST

With the pontoon in its proper position, slide the winch post assembly backward until it contacts the deck. The plastic stops allow

for the variance in most deck heights. It is adjustable up or down

if required. This is accomplished by loosening the three bolts that

attach the top winch post assembly to the winch base.

Once the winch post is contacting the deck, tighten in position.

Hook the winch strap into the bow eye and tighten by cranking the

winch.

AXLE ADJUSTMENT

The amount of tongue weight on your trailer can be adjusted as

follows:

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004034

Page 9 Rev C 05/13/2010

To lower the tongue weight, adjust the axle assembly forward. To

increase the tongue weight, adjust the axle assembly backward.

The distance that the axle assembly has to be moved will vary be-

cause it is directly related to the weight and center of gravity of the

boat placed on it.

Best towing is achieved when the tongue weight is 5-7% of the total

gross load of the complete unit.

Recheck all fasteners on the complete trailer to make sure they are

all tight and ready for towing. All fasteners should be periodically

checked before towing.

See your ShoreLand’r Owner’s Guide for further technical information regarding your trailer and its components.

Loading...

Loading...