Page 1

®

PS8X17TB & PS8X17TBB

Powersport - 4000 lb. Capacity

Bundles Required - PS8X17TB

1 69082 Literature Packet - Brake Trailer

1 8064003 Frame Bundle -PS8X17

4 *

1 7008303 Axle Assembly - Electric Brake

1 6762503 Axle Assembly - Non Brake

1 5110618 Harness Tonge 7-Pin/Battery/Box

*Check with your dealer/customer service representative for current tire/rim assembly part number.

ST185/80D13-C Bias Tire/TS Dir Rim

Tongue Weight Adjustment

Approximate Tongue Weight for Best Towing.

NOTE: Axle is adjustable. Shift load to obtain proper tongue

weight. Tongue weight should be 5-7% of total gross weight of the

trailer and load combined.

Tire Size & Carrying Capacity Chart

Tire Load Carrying

Size Range Capacity

ST185/80D13 C 1480 lbs.

Bundles Required - PS8X17TBB

1 69082 Literature Packet - Brake Trailer

1 8064003 Frame Bundle -PS8X17

4 *

2 7008303 Axle Assembly - Electric Brake

1 5110618 Harness Tonge 7-Pin/Battery/Box

*Check with your dealer/customer service representative for current tire/rim assembly part number.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004005

Page 1 Rev D 08/08/2011

ST185/80D13-C Bias Tire/TS Dir Rim

Refer to tire side wall for correct tire pressure.

Page 2

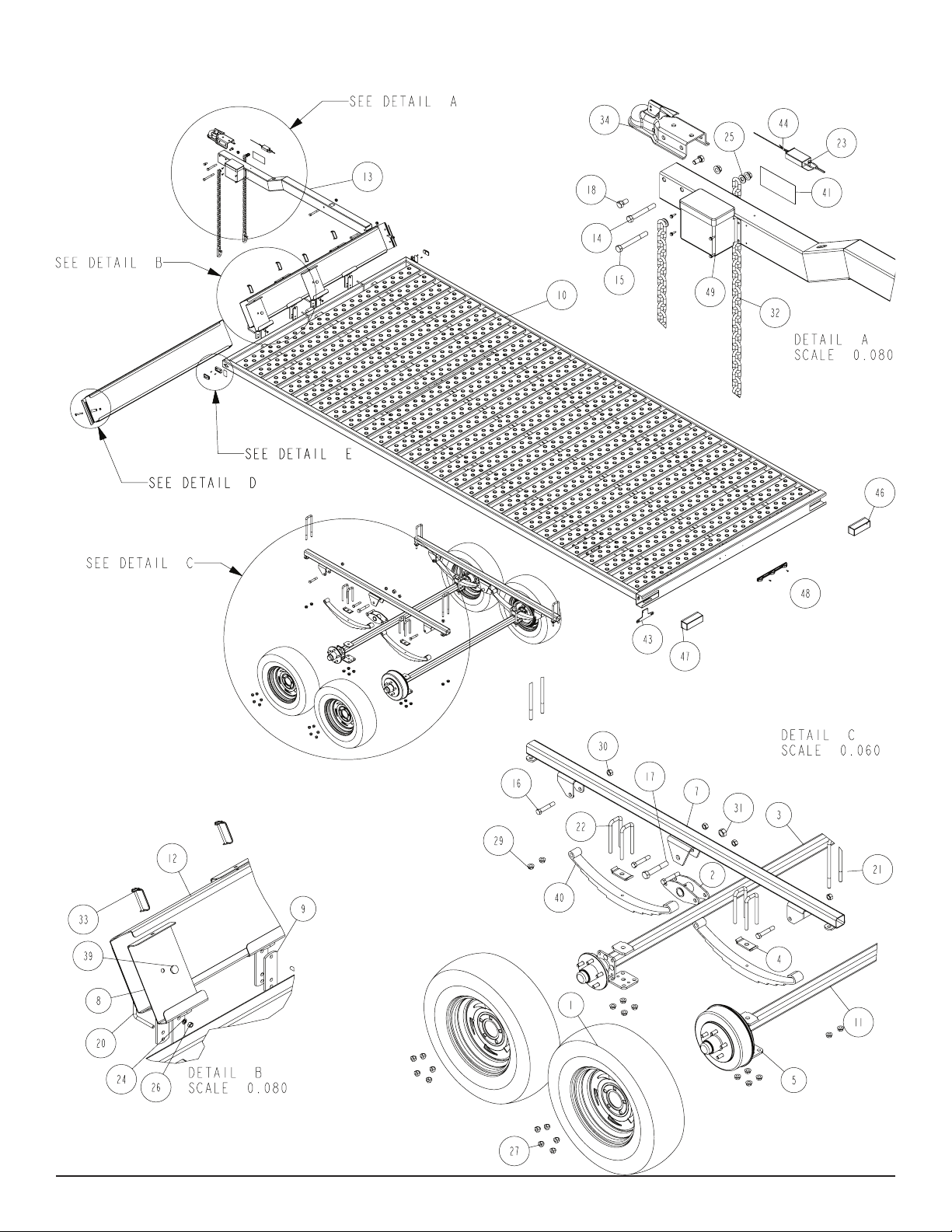

FRAME SETUP for PS8X17TB

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004005

Page 2 Rev D 08/08/2011

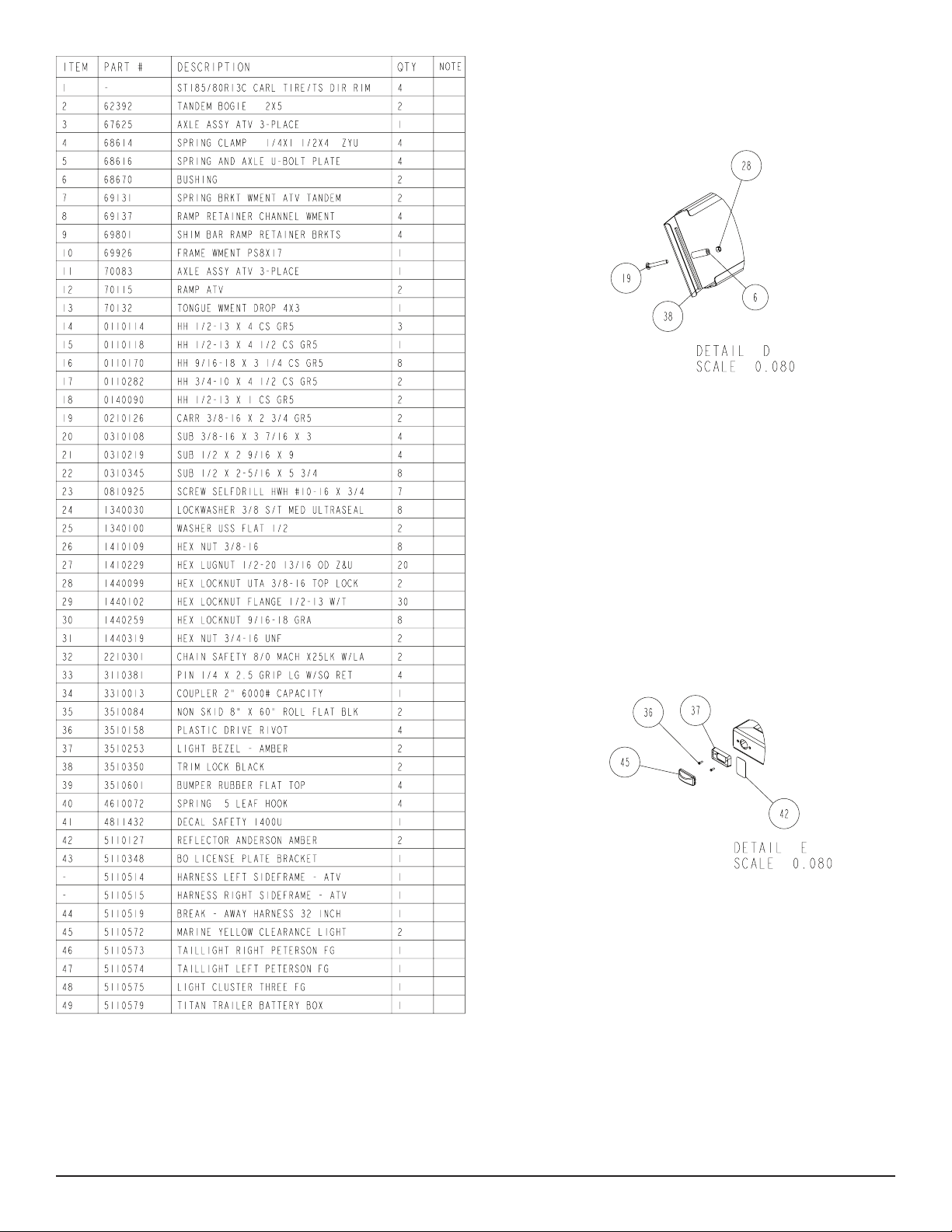

Page 3

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004005

Page 3 Rev D 08/08/2011

Page 4

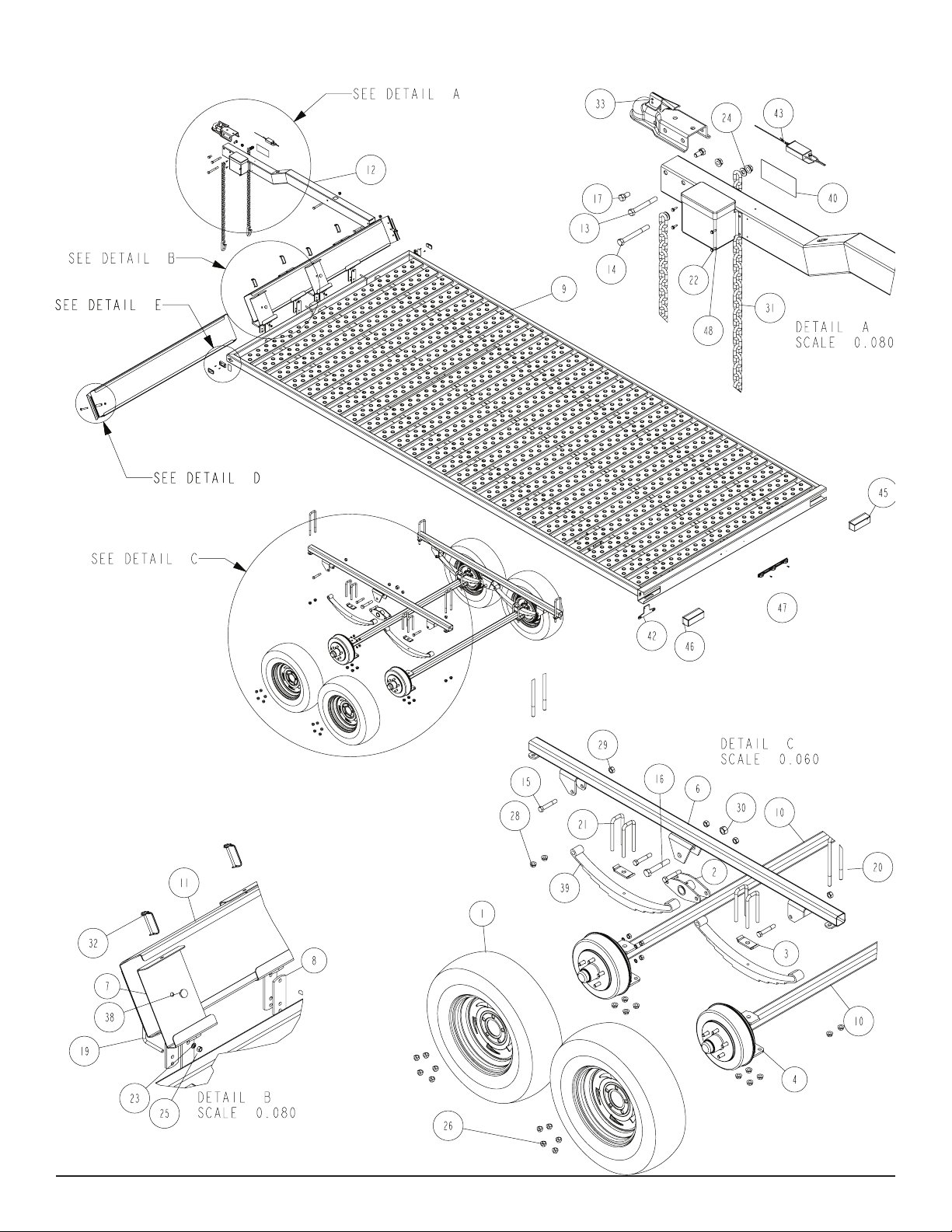

FRAME SETUP for PS8X17TBB

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004005

Page 4 Rev D 08/08/2011

Page 5

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004005

Page 5 Rev D 08/08/2011

Page 6

Standard Non Brake Axle

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004005

Page 6 Rev D 08/08/2011

Page 7

Electric Brake Assembly

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004005

Page 7 Rev D 08/08/2011

Page 8

FINAL ASSEMBLY INSTRUCTIONS

Remove the hardware bag from the frame, remove all parts and sort by

size.

TONGUE

Locate the tongue and the tongue wire harness. Thread the wire harness

into the slotted hole in the drop section of the tongue and then route the

wires out the hole in the top of the tongue midway to the rear. The seven

prong plug and the breakaway switch will remain out the front of the

tongue and will be addressed later.

between deck planks 7 and 8. Raise one of the spring brackets up into

position and place the rear mounting holes of the spring bracket over the

legs of the U-bolt just installed. Thread on ½” lock nuts to hold in position. Place the front mounting U-bolts (nine planks forward of the U-bolt

just installed) over the center frame mating it with the front mounting

holes of the spring bracket. Attach it with ½” lock nuts as well. Tighten

the spring bracket securely to the center frame.

Repeat this process on the other spring bracket.

TANDEM BOGIE

Locate the tandem bogies shown in Detail C. Note that the center bushing has a grease zerk in it. Position the tandem bogie up into the center

channel welded in the center of the tandem spring bracket so that the

grease zerk is pointing down. Align the holes in the channel with the

tandem bogie. Secure in place with a 3/4” x 4-1/2” hex bolt and lock

nut. Tighten. Repeat this process on the other tandem bogie and spring

bracket. Grease the bogie at this time by applying grease through the

zerk just discussed.

NOTE: The grease zerk is positioned down so that it is accessible for

servicing when needed.

SPRINGS

Position the axles so they are properly aligned with the trailer. The brake

axle backing plates are marked with white letters ”L” or “R” identifying

them as Left or Right so they can be mounted under the trailer correctly.

When standing behind the trailer, your Left is the trailers Left and your

Right is the trailers Right. It is very important that the axle is placed in

the correct orientation to function properly.

Place the springs on the topside of the spring pads welded to the axle.

(See chassis diagram). Note that the hook end of the spring must be to

the rear of the axle. Place a spring clamp on the top center of the spring

as shown. Next place the 1/2” x 5 ¾” U-bolts down over the top of the

spring clamp, spring and axle as shown.

Place the spring and axle U-bolt plate onto the legs of the two U-bolts

just positioned. Secure in place with 1/2” lock nuts. Thread onto the Ubolts but do not tighten securely until the complete unit is in position on

the trailer. Repeat on the other spring.

Position the tongue assembly under the front of the trailer in its approximate installed position. Remove the wire harness plugs from the trailer

frame. Mate the mating plugs so the wires colors match in each plug.

Note that the 2 two wire mating plugs are for the electric brakes and are

interchangeable.

Once all plugs are mated place all excess wire into the tongue. Raise

the tongue up into the mounting channels of the trailer frame. Secure in

position with ½” x 4” hex bolts and ange lock nuts. Tighten.

SAFETY CHAINS

Locate the 1/2” x 4” hex bolt. Slip the bolt through a 1/2” at washer,

then place through the last link of one of the safety chains. Insert the bolt

through the mating holes provided in the hole in the tongue for mounting

the safety chains. Place a second safety chain and at washer on the bolt

on the opposite side of the tongue. Secure with a 1/2” ange lock nut.

Tighten.

TANDEM AXLE SPRING BRACKETS

The undercarriage for the tandem trailer can be adjusted forward or

backward to best suit your need. The location suggested in these instructions is satisfactory for most applications.

Locate the ½” x 2 9/16” x 9” U-bolts supplied. Counting from the rear

cross member, drop one of the U-bolts down over the center frame tube

Repeat this process on the front axle.

AXLE

Place one of the spring bracket bushings into the rear of the spring bracket and secure with a 9/16” x 3-1/4” hex bolt and hex lock nut. Repeat in

other spring bracket.

Raise the rear axle into position up under the spring brackets. Hook the

loop of the springs around the bushings just installed. Note that if the

axle is positioned too low when trying to hook, the loops will not hook

around the bushings. Raise the front of the springs up so they align with

the rear hole in the tandem bogie just installed. Secure in place with

9/16” x 3-1/4” hex bolts and lock nuts.

Install another spring bracket bushing in the front hole on the tandem

bogie assemblies. Secure with a 9/16” x 3-1/4” hex bolt and lock nut.

Tighten. Hook the hook end of the springs mounted to the front axle over

the bushing just installed in the rocker arm assembly. Swing the front of

the spring up and attach the front mounting hole in the spring bracket

with an¬other 9/16” x 3-1/4” hex bolt and lock nut.

Tighten all axle U-bolts and spring bolts.

ELECTRIC BRAKE SYSTEM

Note there are brake wires routed out of the holes located on the inside

of the center frame tube close to the axle positions. Remove the tape

securing the wires to the center frame. Route them down to the wires

coming out of the rear of the brake backing plate.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004005

Page 8 Rev D 08/08/2011

Page 9

BATTERY BOX

Locate the section of shrink wrap material and wire connectors that are

provided in the brake kit. Place a shrink wrap section over the wires

before splicing them together. Connect the wires to each other using

the crimp connectors provided. Once the connections have been made,

center the shrink wrap material over the splices. Using a heat gun heat

the shrink wrap material until it is shrunk down and creates a water tight

seal over the connections.

Place all excess wire into the center frame tube and insert the rubber

grommet.

Repeat this process on the brake on the other side of the trailer.

Repeat this process on the second axle brakes.

BREAKAWAY SWITCH

Place the breakaway switch on the tongue harness so it is located behind

the decal on the top of the tongue. Align the mounting hole in the

breakaway switch with the hole pre-drilled in the tongue at this location.

Secure the breakaway switch to the tongue using the self-tapping screw

provided.

Locate the battery box. Position it on the side of the tongue aligning the

holes in the battery box with the pre-drilled mating holes in the side of

the tongue. Secure in place using four (4) self-tapping screws provided.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004005

Page 9 Rev D 08/08/2011

Page 10

Place the battery inside the battery box. Route the section of the wire

harness over to the battery and connect it to the battery using the connector spades of the wire harness. Connect the Red wire to the positive

terminal and the white wire to the negative terminal. The battery will

maintain its charge when it is connected to the tow vehicle and is used

only in the event the trailer becomes disconnected from the tow vehicle.

In the event it does become disconnected the pin will be removed from

the breakaway switch allowing the battery to power the brakes causing

them to stop and trailer and hold it in position for up to twenty minutes

after disconnect.

TIRE & WHEEL ASSEMBLY

Mount the tire and wheel assemblies using the 1/2” ne threaded tapered

lug nuts provided. Tighten to 85-95 ft./lb. torque using the rotation pattern as shown in the ShoreLandr’s Owners Manual.

Re-torque the lug nuts after 50 miles driving and then periodically

thereafter.

Front Ramp Kit

The front ramp kit is designed to attach to the front cross frame tube

of the PS5x10, PS5x14, and the PS8x17 series. The kit includes

the ramps and all attaching hardware for converting the ramps into

a front shield while being stored for transport. The ramp retainer

channels are designed to accommodate U-bolts for attaching them

to either a 2x3” or 2x4” frame tube.

Installing the ramps in the following manner will allow for the removal of the ramp from the *left side of the trailer rst.

*Left and Right side of trailer is indicated by standing at the

rear of the trailer.

Installation Instructions

• Locate the four ramp retainer attachment channels. Note that

they are all identical.

• The two ramp retainer attachment channels on the *right side

of the trailer will be installed on the front side of the trailer front

frame tube so it will support the ramp as shown.

• Note that the kit is supplied with two different size U-bolts. Select the proper size to t your frame tube. Place one of the

correct size square U-bolt around the front frame tube so the

legs of the U-bolt are pointing forward. Align the holes in one of

the ramp retainer attachment channels with the U-bolt legs, then

slide into position. Note that this channel is mounted on the

front side of the frame tube. Secure in place with 3/8” lock

washers and 3/8” hex nuts.

• Position the U-bolt so it is 24” from the outside of the side

frame tube.

• Repeat the mounting process on the second channel. Position

this ramp retainer attachment channel so that the center hole

in the ramp retainer bracket is 27” from the center hole in the

ramp retainer channel just installed. Tighten enough to hold in

position until the ramp is installed for nal spacing.

• Install the remaining two ramp retainer attachment channels

on the left side of the trailer to the rear side of the front frame

tube using the steps above. Placing them on the rear of the

frame tube allows the ramps to overlap past each other in the

middle.

• Once all four of the ramp retainer attachment channels are at-

tached to the frame, position the right ramp into the ramp retainer attachment channels. The ramp can either be slid into

the end of the channels or else placed in the approximate position, then rotated into place.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004005

Page 10 Rev D 08/08/2011

Page 11

• Align the holes provided in the edge of the ramp with the holes

in the center of the ramp retainer attachment channels as

follows:

Place one of the ¼” pins with the wire retainer through the •

aligned holes in the ramp and the retainer attachment channel.

Align the hole in the second ramp retainer attachment channel •

with the second hole in the ramp. Note that the U-bolt may

have to be loosened so the ramp retainer attaching channel

can be moved either direction to align the holes. When aligned,

insert a second ¼” pin with wire retainer. Once the pin is in-

serted, retighten the U-bolt just loosened to adjust for proper

hole spacing. The two pins will secure the ramps in the transport position.

Special Instructions:

Always check lighting and turn signal operations before towing.

Secure or tie-down your load before towing.

To prevent damage to your ATV trailer, tighten all fasteners before

towing.

Your ATV traile r is equi pped with a tota lly groun ded wir e

harness. You must be sure the wire harness plug that comes from

the tow vehicle is grounded to the tow vehicle using the white

grounding wire.

Check all lug nuts for proper torque before towing.

• Note the (right) passenger side ramp must always be installed

rst.

• Repeat the above process on the second ramp on the (left)

drivers side of the trailer.

There are two carriage bolts and plastic bushing supplied in •

the kit. These bushing, when mounted on the ramp, will keep

the ramps from moving either inward or outward when loading your machine. The bushings will extend down between the

deck planks to eliminate the side movement during loading.

Mount the bushing to the end of the ramp that attaches to the

trailer side frame. The bushing can be installed in one of three

positions to create the appropriate spacing width for loading

your machines.

• Installation is complete. The ramps can now be stored secure-

ly during the towing process and can be easily removed for

either loading or unloading the machines.

Using The Ramps

• Always remove the ramp that is on the *left side of the

trailer rst. The ramps are removed from its normal trans-

port position by removing the two ¼” retainer pins that attach

the ramp to the ramp retainer attachment channels.

Contact your authorized ShoreLand’r dealer if you experi-

ence a problem with your trailer. To locate a dealer, please use

www.shorelandr.com - the dealer locator feature.

For more information or assistance, contact ShoreLand’r at 1-800859-3028 or visit www. shorelandr.com.

• Once the pins are removed, rotate the ramp backward on top

to remove it from the ramp retainer attachment channels.

• Place the hook end of the ramp over the side frame tube or

the rear tube of the trailer deck so the hook end catches over

the inside top of the tube. This will secure it in place while loading the machine.

• Repeat the above process on the second ramp. Space the

ramps to mate the wheel centers of the machine.

• Once the machines are loaded and the ramps are ready for

storage, place them in the ramp retainer attachment channels

using a reverse process of removing them.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004005

Page 11 Rev D 08/08/2011

Loading...

Loading...