Page 1

POWERSPORTS OWNER’S GUIDE

Thank you for choosing ShoreLand’r®!

Here are the operating instructions for your new trailer. Please read this document

carefully before using your trailer and keep it in a safe place for future reference.

If you have any questions about your trailer contact your local ShoreLand’r

Customer Service Department at 800-859-3028 or e-mail: shorelandr@midwestindustries.com,

so we can assist you in contacting a dealer.

You should have recieved a packet of warranty documents with your trailer. Be sure to ll out and

mail your Warranty Registration Card to activate your trailer’s warranty. If you did not recieve this

information ask your dealer for a copy or visit www.shorelandr.com and register online.

®

dealer or contact our

Please ll in the following information for your records

Model Year:

Model:

Vehicle Identication Number:

Carrying Capacity:

Date Purchased:

Purchased From:

Models and specications are subject to change. Some models are shown with optional equipment. Because of the continual improvements to our

trailers, ShoreLand’r® reserves the right to add or discontinue models at any time or to change design and specications without notice and incurring obligations.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 1 REV B 4/11/2008

Page 2

Table of Contents

Specications & General Information

Matching Your ShoreLand’r® to Load Hauling ..............2

Load Carrying Capacity ..................................................3

Weight Distribution / Tongue Weight ...............................3

Tow Vehicles ...................................................................3

Trailer Balls and Coupler ................................................4-5

Safety Chains..................................................................5

Proper Winch Post Adjustment .......................................6

Bow Eye Safety Chain ....................................................6

Winch Handles ................................................................6

Bow Pulpits and Winch Post Lengths .............................6

Wiring Diagram and Color Code .....................................6

Rim ..................................................................................6

Torquing Procedure For Mounting Wheels .....................7

Wheel Torquing Chart .....................................................8

Toubleshooting & Maintenance

Lighting ...........................................................................9

Paint and Its Care ...........................................................9

Repacking Bearings ........................................................9

Hubs, Bearings, Races & Seals Chart ............................10

Grease Seals ..................................................................10

Recommended Lubricant ................................................10

Bearing Repacking..........................................................10

Bearing Adjustment ........................................................10

Brakes .............................................................................10

Brakes Service & Maintenance .......................................11

Backing Up Trailer With Disc Brakes ..............................11

Tire Information ...............................................................12-17

Determining Correct Load Limits ..............................12

Tire Safety .................................................................12

Basic Tire Maintenance.............................................12

Recommended PSI & Maximum Load Capacity .......12

Understanding Tire Pressure & Load Limits .............12-13

Maintaining Proper Tire Pressure .............................13

Tire Size ....................................................................13

Tire Tread ..................................................................13

Tire Balance and Wheel Alignment ...........................13

Tire Repair ................................................................13

Tire Fundamentals ....................................................13

Information on Passenger Vehicle Tires ...................14

UTQGS (

Glossary of Tire Terminology ..........................................15-17

Reporting Safety Defects ................................................18

Warranty Information ......................................................18

Uniform Tire Quality Grading System) Info .......14

You and Your ShoreLand’r

We at ShoreLand’r® would like to thank you for purchasing one

of our trailers!

Our goal is your complete satisfaction, that is why we recommend

leading this manual in its entirety. A better understanding of your

trailer’s features, regulations and adjustments will make your towing experience more pleasurable.

It is important that you give your new trailer proper care and maintenance to ensure that it continues to provide the dependable performance year after year.

Happy trailering!

®

IMPORTANT: Read this manual carefully with special attention

directed toward all WARNING, CAUTION and IMPORTANT

information.

Because of the continual improvements being made in our line,

ShoreLand’r® reserves the right to add or discontinue models at

any time or to change design and specications without notice and

incurring obligations.

All specications contained herein were in effect at the time this

manual was printed.

Should a problem arise, please contact the dealer from whom the

original purchase was made. You may also call our distributor for

your area or call our Customer Service Department by phone at

800-859-3028 or e-mail shorelandr@midwestindustries.com.

NOTICE

This trailer is equipped to meet applicable U.S. Federal safety standards. Check local and state requirements regarding brakes and any additional

equipment that my be required. Any modications or additions including load equalizing hitches, without written factory consent; usage in an abnormal

manner including overloading voids all manufacturers warranties and liability.

Referencing the Powersports Trailer in this Manual

All references to the trailer or component parts to either left or right are made with the assumption that you are standing behind the trailer

facing forward. Your left-hand or right-hand is the equivalent on the trailer.

Matching Your Shoreland’r® to the Load You Intend to Haul

The key to carefree trailering is purchasing a trailer that is designed with a carrying capacity large enough to carry the loads you intend to

haul on it. This includes all excess gear and tie down materials used to contain the load on the trailer when towing.

The trailer should also be long enough to properly support the materials you are hauling. It must also be of sufcient width to offer stability

while towing.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 2 REV B 4/11/2008

Page 3

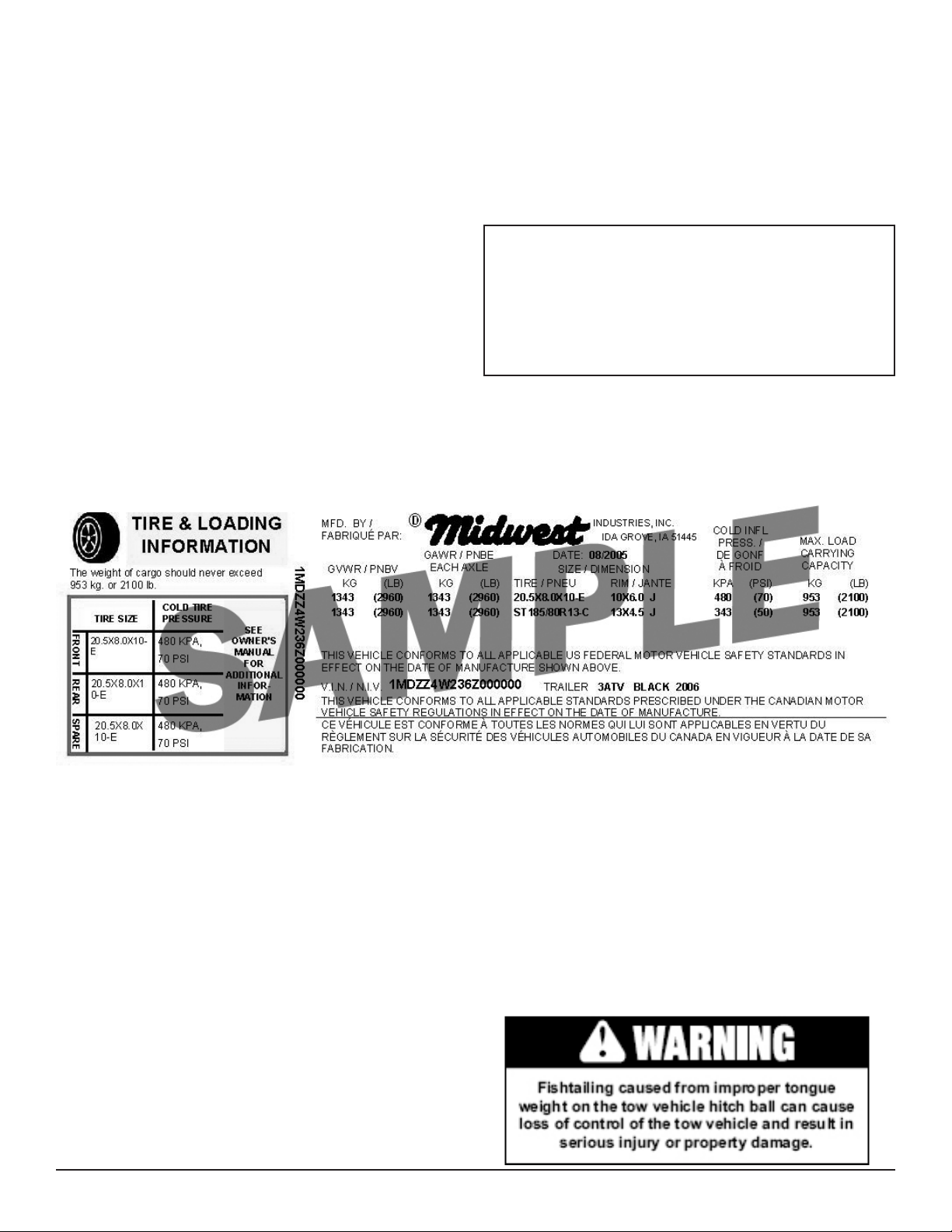

Load-carrying Capacity

Located on the front left-hand side of the frame, (either the inside

or the outside) is the VIN (Vehicle Identication Number) tag. It will

show the GVWR (Gross Vehicle Weight Rating) which is the maximum load that can be applied to the tires on the trailer. Note that

the VIN tag may have as many as three different GVWR ratings

listed because some trailers frames have more than one tire option

available. The GVWR and the carrying capacity of the trailer may

vary based on the tire size installed on the trailer.

Also listed on the VIN tag is the carrying capacity of the trailer.

This is the maximum carrying capacity of the trailer with its respective tire option. It may not necessarily equal the total GVWR of the

trailer less the empty weight of the trailer because there may be

another controlling factor such as frame strength that reduces the

carrying capacity to what is listed on the VIN tag.

The tire label will list the size tire that was installed on the trailer as

original equipment when it was sold to you, the consumer. It also

lists the maximum carrying capacity of the trailer.

IMPORTANT

The total weight of the load must never exceed the weight of cargo

listed on the tire label and/or the maximum load carrying capacity

listed on the VIN tag on your trailer. The GVWR (Gross Vehicle

Weight Rating) listed is the maximum total weight of the trailer with

accessories and all cargo allowable to be carried on the tires that

are installed on the trailer.

Some model trailers have a different limiting factor other than the

tires, example frame, or brake law limitations. The maximum load

carrying capacity that is listed should never be exceeded.

CAUTION: The maximum load applied to the trailer

must never exceed the carrying capacity of the trailer

as stated on the VIN label and/or the tire placard. Doing

so may cause failure of one or more component parts of

the trailer causing potential damage to the trailer and/

or a potential accident. All concentrated loads must be

spread over as large an area as possible to eliminate

potential damage to the decking.

Shown below is an example of the VIN and tire label that is placed

on your trailer showing the items just discussed above. Once you

have familiarized yourself with the information supplied on the example tire label and VIN tag, check the tire size and capacity of

your trailer as shown on the VIN tag on your trailer.

Proper Weight Distribution & Tongue Weight

Ensuring that your trailer has the proper GVWR is very important.

Once that has been established and you have the load on the trailer

it is equally important that you have proper weight distribution.

Tongue Weight

The tongue weight on your trailer should range from 5-10% of the

total weight of the trailer and all the cargo that it is carrying. This

is the amount of weight that is then transferred to the tow vehicle

through the ball hitch. Smaller trailers should have a tongue weight

that ranges closer to the 10% while larger trailers will tend to be

closer to the 5% range. This should be checked when the tongue

is parallel to the ground. A bathroom scale can be used to help

determine the tongue weight as long as the above conditions are

adhered to.

Example: The total weight of the trailer with load is 2,000 pounds.

The tongue weight should not be less than 100 pounds (5%) nor

more than 200 pounds (10%). A reasonable tongue weight for a

trailer this size is 125-150 pounds.

Too light of tongue weight can cause the trailer to “shtail” (sway

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 3 REV B 4/11/2008

from side to side) as you travel down the highway. This creates

excessive strains on the tow vehicle, hitch and also the trailer itself.

It can very easily lead to an accident.

To adjust for too light tongue weight the load must be shifted forward with respect to the axle. This will increase the weight that is

transferred to the tongue. Adjustments should be made until the

tongue weight falls within the 5% and 10% recommended range.

Likewise, if you have too much tongue weight adjust the weight

backwards with respect to the axle until the tongue weight falls in

the recommended range.

Tow vehicles vary on how much tongue weight they can support for

proper towing.

Page 4

IMPORTANT: Before towing this trailer be sure to read the

instructions and warnings supplied in this manual. Also read

the information supplied with your tow vehicle so you know

and understand it’s limitations.

NEVER TOW THIS TRAILER BEFORE CHECKING:

It is also important that the lighting system in the tow vehicle has

sufcient capacity to support the additional load the trailer lighting

will add to the system. A heavy duty asher may be required to

make your turn signals function properly.

TRAILER BALLS & COUPLERS

Coupler and latch assembly show no signs of wear or damage.•

Coupler hitch and hitch ball are of the same size.•

Coupler and safety chains are safely secured to the hitch.•

Check all fasteners for proper tightness.•

Load is securely tied down to the trailer.•

Wheel lug nuts are properly tightened to the right torque.•

Wheel bearings are properly adjusted and maintained.•

Load is within the maximum load carrying capacity of trailer.•

Tires are properly inated and are road worthy.•

All trailer lighting is working properly.•

Trailer brakes are properly adjusted and in working condition.•

IMPORTANT: The load must be distributed equally on the

bed of the trailer if possible. Heavy, concentrated loads may

cause damage or possible failure of the trailer decking. If

concentrated loads are placed on the trailer deck, spread the

load over a larger area by placing a larger size steel plate or

multiple layers of plywood on the trailer decking before placing on the concentrated load.

WARNING: Loads placed on the trailer must be securely

tied to the trailer frame or decking. Always use appropriate

tie downs designed to restrict loads from moving when properly attached. Failure to do so will allow shifting of the load

causing potential trailer failure and/or loss of the load and

personal injury.

WARNING: The hitch ball must be the proper diameter and

have a rating equal to or greater than the GVWR of the trailer. Failure to do so may cause possible loss of the trailer and

serious injury or property damage.

Trailer couplers shall be permanently marked with (A) Coupler

manufacturer name, initials, or trademark, (B) Part, style or model

number, (C) SAE coupler designation and gross trailer weight, (D)

Ball diameter for which rating (GVWR) shall not exceed the gross

trailer weight marked on the trailer coupler.

The hitch balls have the rated load they are capable of towing

stamped into the top of the ball.

Make sure the ball that you use to tow your trailer has the

same capacity rating as the coupler.

Do not use a different size ball than the size the coupler is

designed to use.

Class Coupler Ball Diameter

II 3,500# GVWR 2”

III 5,000# GVWR 2”

This trailer is equipped to meet all applicable federal safety

standards in effect the day of manufacture. Check local and

state requirements regarding brakes and any additional equipment that may be required.

Check regulations on maximum trailer width in the states you

plan to tow your trailer.

The addition of optional equipment to your trailer may increase the total weight of your trailer package to where it now

exceeds the maximum load carrying capacity of the trailer.

TOW VEHICLES

WARNING: Serious injury or property damage can result if

the total weight of your loaded trailer exceeds the capacity of

the hitch and/or your tow vehicle.

It is very important that you know and understand the towing capabilities of your tow vehicle. This is especially true with the braking

abilities of the tow vehicle. You should check with your authorized

dealer to see what the capabilities are for the total towing load and

the maximum allowable tongue weight for the vehicle you plan on

using for towing. Several options are available for these cars or

pickups which will help your towing ability. They include transmission coolers, engine oil coolers, proper rear end ratios, air shocks,

over-size tires, and also heavy duty radiators. Many can be purchased with the optional trailer package that includes some or all of

the above mentioned items.

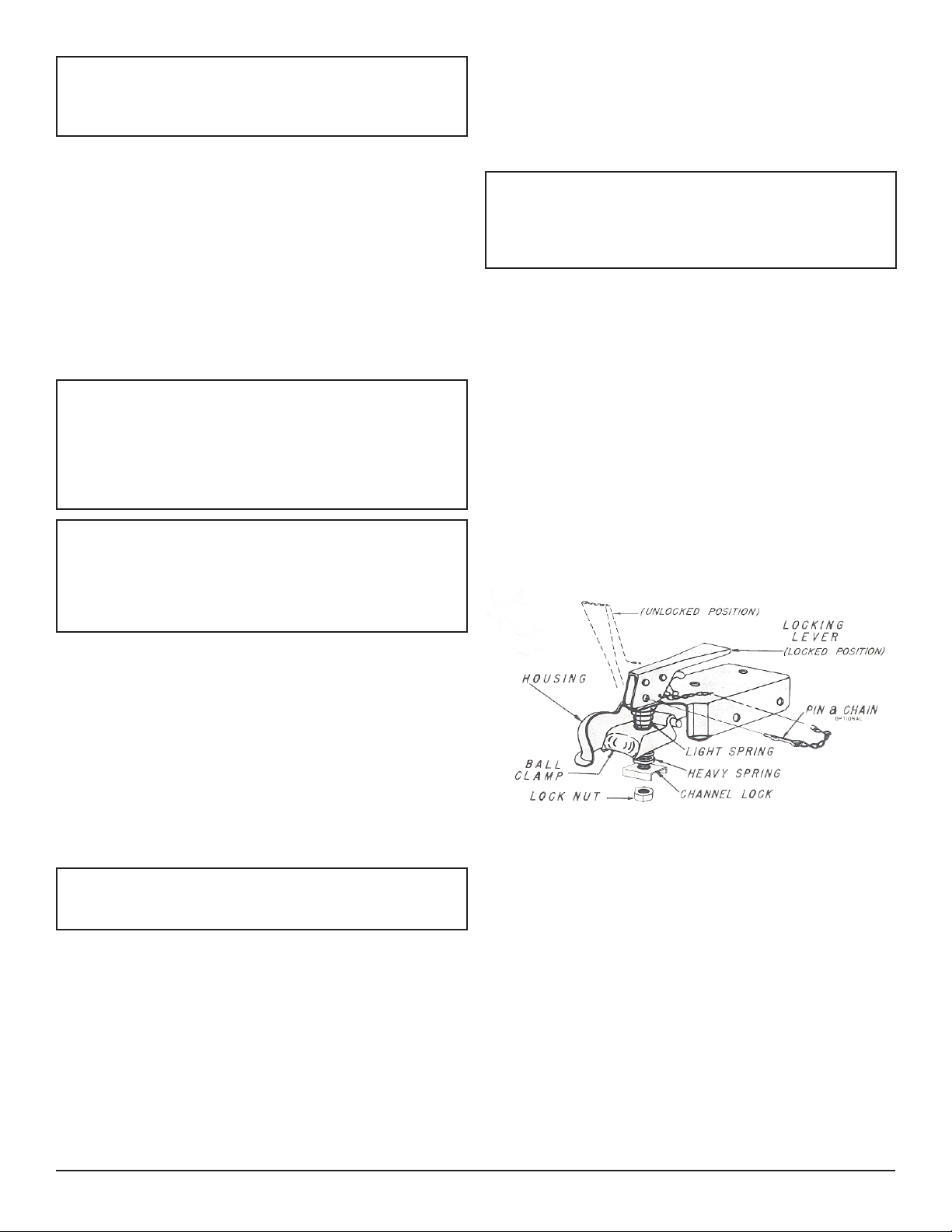

To adjust your Class II and Class III coupler to your trailer ball, remove the coupler from the ball. Reach under the coupler and raise

the channel lock up so the nut can be turned. Turn the adjusting nut

clockwise to tighten the ball clamp grip on the ball, counterclockwise to loosen ball clamp grip on the ball. Once the nut has been

adjusted make sure the channel lock has positioned back down

around the at surfaces of the nut so it is locked from turning. Replace the hitch back on the ball and latch. Repeat this process until

the ball clamp latches securely around the ball.

HITCH COUPLER TROUBLESHOOTING

If the coupler becomes damaged it must be repaired or replaced

before towing. When the coupler is placed on the ball, the latch

should close rmly. Keep the latch mechanism lightly oiled and

clean. Items to check for are as follows:

1. Latch does not grasp ball securely:

A. Check the ball size. Make sure the ball and coupler are

the same size.

B. Unlatch the mechanism and reach under the ball clamp.

Raise the retainer clip that keeps the nut from turning,

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 4 REV B 4/11/2008

Page 5

then turn the adjustment nut clockwise to tighten

the grip on the ball. Make sure the nut returns to its proper

position in the retainer clip, then latch the hitch on the ball.

If it is still loose repeat the process until the grasp on the

ball is right.

2. Latch does not snap into full latch position:

A. Check adjustment. Latch mechanism may be to tight.

Loosen by reversing procedure in step #l and turning the nut

counterclockwise.

B. Check to see that the coupler housing has not been

damaged, keeping the ball hitch from tting completely into the

housing as designed.

3. Keep the tongue blocked up when not in use so the coupler

and mechanism are not in the ground being exposed to dirt

and moisture.

4. Apply a small amount of an automotive grease to the ball

before hitching coupler to prevent wear of the two parts during

towing.

WARNING: Failure to properly attach safety chains between

the trailer and tow vehicle can result in a run away trailer.

WARNING: Before trailering to avoid accidents...

Hitch only to ball size marked on coupling.•

Ball clamp must capture ball and lever or handwheel •

is fully clamped.

Cross safety chains under coupling.•

Allow only enough slack for turns.•

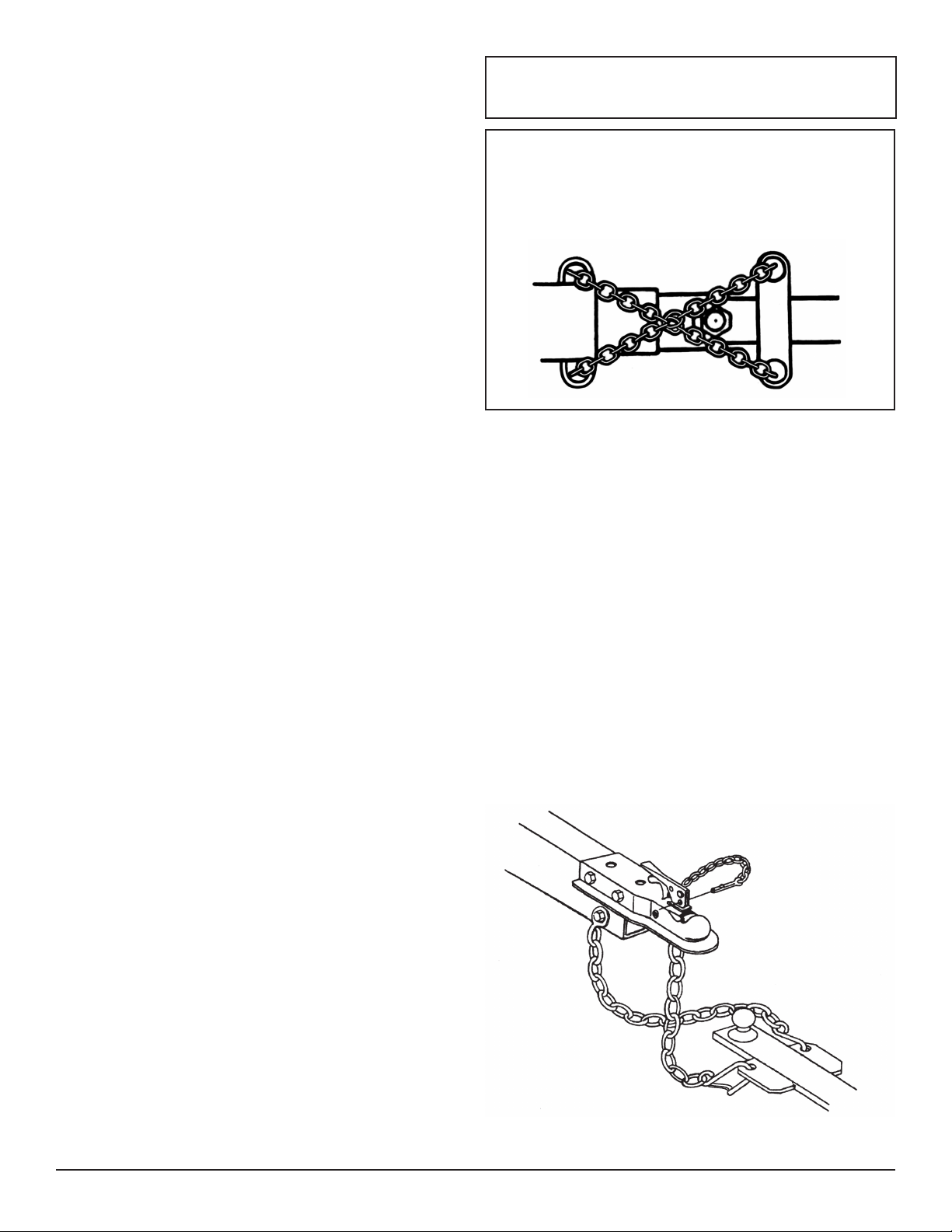

Bottom View Shown

5. Make sure the latch safety pin is in position before towing.

COUPLER & BALL ENGAGEMENT

If the coupler and towing ball resist attempts to make engagement,

do not force latch assembly. Instead, check the ball diameter to

verify that it conforms to Society of Automotive Engineers (SAE)

specications. Standard two-inch diameter ball should be within

the limits of 2.000-inches to 1.970-inches. Balls larger than 2.000-

inches will not readily t the coupler. A two-piece coupler ball is not

recommended.

If the coupler becomes damaged it must be repaired or replaced

before towing. When the coupler is placed on the ball, the latch

should close rmly. Keep the latch mechanism lightly oiled and

clean.

Improper engagement of the coupler and ball can cause damage if

the vehicles separate in transit: thus, caution must be exercised to

insure a secure hook-up. Lower the coupler onto the ball with the

coupler latch in the vertical position. Continue to lower the trailer

tongue until the jack clears the ground, then ip the coupler latch

to its locked (horizontal) position. At this point visually observe that

the ball is fully engaged in the ball hitch. An even better check to

make sure the two are fully engaged is to raise the tongue of the

trailer again using the jack. Raise until the ball hitch connection

starts to raise the rear of the tow vehicle. If the connection was not

properly made, the ball and socket will separate as the tongue of

the trailer is raised.

The safety chains on your trailer are an added insurance that it

will not become detached from the tow vehicle. ShoreLand’r®

provides all safety chains with an added clasp to keep them

from becoming accidentally detached from the tow vehicle.

Your trailer hitch on the tow vehicle should have two attaching holes or rings for attaching the safety chains, preferably one

on each side of the ball hitch. Crisscross the chains under the

tongue, the chain on the left side of the trailer tongue attached

to the right side of the ball hitch, the chain on the right side of

the trailer tongue attached to the left side of the ball hitch.

This prevents the trailer tongue from dropping to the road should

the coupler or ball hitch fail. The chains should be rigged as tight as

possible with just enough slack to allow tight turns to be made. This

can be accomplished by twisting the chain hook in a clockwise or

counterclockwise direction thus twisting the link spacing and making the chain shorter. Also by keeping your chains as short as possible you prevent them from dragging on the road and wearing the

chain links.

If for any reason you nd it necessary to replace a safety chain, use

only original equipment.

SAFETY CHAINS

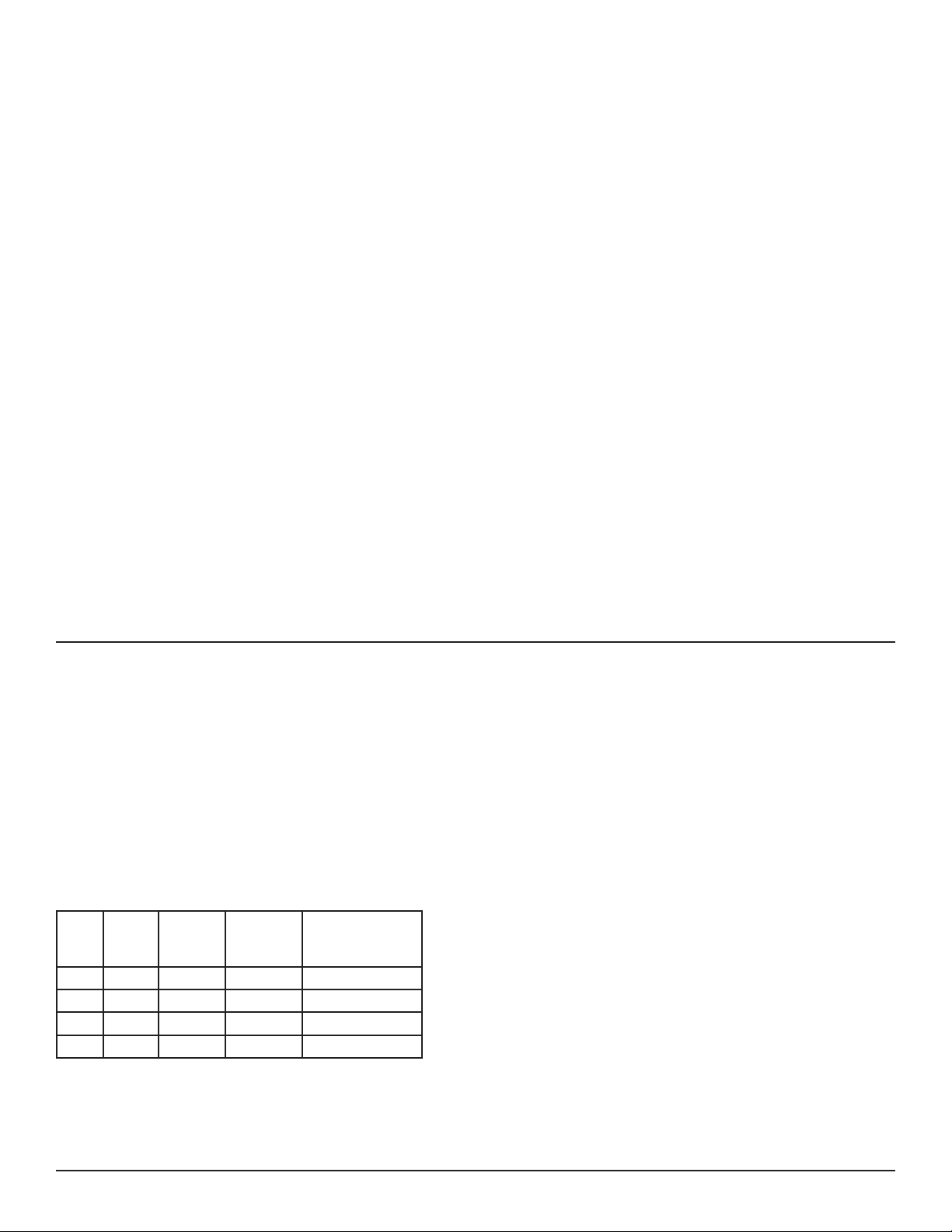

Listed in the chart below are the different class sizes of safety chains

and the rated load each chain must be capable of withstanding.

TRAILER TRAILER WEIGHT MINIMUM BRAKING

CLASS GVWR IN LBS. STRENGTH IN LBS.

I to 2,000 2,000

II 2,000 to 3,500 3,500

III 3,500 to 5,000 5,000

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 5 REV B 4/11/2008

Page 6

WIRING DIAGRAM & COLOR CODE

WIRING COLOR CODE

All trailer lights must be in proper working order before towing.

There are two basic wire harness plugs that ShoreLand’r

uses for plugging the trailer lighting into the tow vehicle.

They are as follows:

A at four plug that is used on either all trailers without brakes or

else on trailers that are equipped with drum brakes. This plug is

used in these applications because the only thing needing to be

connected to the tow vehicle are lights. A solenoid lock out system

is not required to operate drum brakes. The drum brakes have a

mechanism in them that prevents the brake shoes from contacting

the drums when the trailer is backed up.

The at ve plug is used on all trailers equipped with disc brakes.

Disc brakes operate as well in reverse as they do going forward.

This results in the trailer not being able to be backed up without the

use of a solenoid to block the brake uid from activating the brakes.

The solenoid is activated by the extra blue wire in the at ve plug

that is attached to the backup lights of the tow vehicle. When the

tow vehicle is placed in reverse, the backup lights are activated

which then activates the solenoid diverting the brake uid generated by the actuator back into the actuator reservoir causing the

brakes not to function in reverse.

The wiring in your ShoreLand’r® is color coded as per wiring spec-

ications. The following colored wires are connected to the proper

®

lights to perform the required functions as listed:

Flat Four Wire Harness Plug

Yellow Wire - Left Stop and Turn

Green Wire - Right Stop and Turn

Brown Wire - Taillights, Rear Side Marker Lights, Front

and Rear Side Marker Lights, Rear Clear ance Lights Including the Three-Light Rear

Clearance Bar

White Wire - Ground Wire

Flat Five Wire Harness Plug (For Disc Brake Trailers Only)

Yellow Wire - Left Stop and Turn

Green Wire - Right Stop and Turn

Brown Wire - Taillights, Rear Side Marker Lights, Front and

Rear Side Marker Lights, Rear Clearance

Lights Including the Three-Light Rear

Clearance Bar

White Wire - Ground Wire

Blue Wire - Brake Solenoid that is mounted to the rear

of the actuator to disengage the disc brakes

on the trailer so it can be backed up.

RIMS

WHEEL SIZES

ShoreLand’r® uses various size tires on different model trailers to accommodate the load that is being placed on the trailer. This results

in the use of different size and width of rims. ShoreLand’r® recommends that you use only genuine replacement parts for spare tires.

However, should you need to purchase one elsewhere the following table lists information needed to purchase the right style rim to t

your trailer.

All wheels used on ShoreLand’r® trailers have a zero offset meaning that the center mounting face of the wheel is in the center

of the tire.

Rim

Rim

Size

Width

8” 7” 5 4.5” 90

10” 6” 5 4.5” 90

12” 4” 5 4.5” 90

13” 5” 5 4.5” 90

Bolt

Holes

Number

Bolt

Circle

Diameter

Recommended

Torque ft./lb.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 6 REV B 4/11/2008

Page 7

RECOMMENDED PROCEDURE FOR

MOUNTING WHEELS

TORQUING PROCEDURE FOR MOUNTING WHEELS

WARNING: Maintain proper torque on lug nuts. Failure to do so

may result in serious injury or property damage.

The following procedures apply to both steel and aluminum wheels

and must be adhered to very closely when mounting wheels to the

hubs.

NOTE: See page 8 for wheel torquing assembly and recommended torque ratings.

The contact surfaces of both the hubs and wheels must be free 1.

of paint, contamination and damage. Smooth, clean surfaces

provide the most uniform clamping pressure and best retain

torque.

Surfaces of contact on the axle (the at hub surface and the 2.

threaded studs) must be free of excessive paint, oils, grease,

contamination and physical damage.

When replacing a wheel assembly or repairing a at tire, al-3.

ways remove all dirt, rust, grease and oil from the surfaces as

well as the stud threads. Never lubricate the threads.

Position the wheel on the hub making sure the two match cor-4.

rectly. This is especially true if a spare wheel assembly or new

replacement is being installed. Inspect to make sure full contact between the mounting surface (seat pads) of the wheel

and the mounting surface of the hub, brake drum or rotor.

Start the wheel lug nuts on the studs.5.

Finger tighten the top nut, then rotate the wheel so that the 6.

number 2 nut (see diagram) is at the top and then nger

tighten.

Repeat step 6, rotating the wheel and nger tightening nuts 7.

until all nuts are snug.

Use a torque wrench or an impact wrench with a torque stick 8.

as a tool initially to lightly secure the wheel, applying a crisscross or star pattern as shown in the diagram.

The nuts should be tightened to 85-95 ft. lbs. of torque. A 9.

calibrated torque wrench is recommended for tightening the

wheels so that all the nuts are tightened equally. Re-torque

nuts again after 50 miles of use and then check for tightness every time before towing.

After the wheels with tires have been mounted, visually inspect 10.

to insure that the tires are not rubbing any other portion of the

trailer or fender. There must be ample clearance for extreme

road conditions and sharp turns.

In the event that the axles are rusted and you want to paint 11.

them, make a mask or shield (cover) to protect all fastener

contact surfaces (mounting surfaces and studs) before painting axles, whether for improved cosmetics or for corrosion protection.

The following is a list of “don’ts” when mounting wheels on your

trailer.

DON’T1. deviate from the component manufacturer’s recom-

mendations regarding compatible components without a competent engineering review.

DON’T2. substitute any component for the components the sup-

pliers have specied without a competent engineering review.

DON’T3. deviate from the component suppliers’ fastener torque

specications, where provided, without a competent engineering review.

DON’T4. use adhesive products to maintain fastener tension.

DON’T5. use lubricants or oils on threaded fasteners (studs

or lugs) to make applying the torque easier unless assembly

specications require it.

DON’T6. apply any additional paint on fastener contact surfaces

(mounting surfaces/hub faces or studs).

ALUMINUM WHEELS PURCHASED FROM ANOTHER SOURCE

Wheel torque may vary from one aluminum wheel manufacturer to

another. In the event that you purchased aluminum wheels from a

wheel supplier other than ShoreLand’r

you use the torque specications for that particular wheel.

Aluminum wheels purchased elsewhere must also have a carrying

capacity equivalent to the load carrying capacity of an ST rated tire.

ST rated tires have a greater carrying capacity than an automotive

tire.

®

, it is recommended that

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 7 REV B 4/11/2008

Page 8

WHEEL TORQUING & ASSEMBLY INSTRUCTIONS

5 Lug Nuts

1

2

43

5

6 Lug Nuts

1

4

63

5

8 Lug Nuts

2

1

4

83

7

2

56

TORQUING

PROCEDURES

Wheel Lug Nut

Diagrams:

WHEEL TORQUE INSTRUCTIONS

1. Start the lug nuts on the studs using ngers to avoid cross

threading.

2. Stage 1, Torque: Impact the lug nuts in the appropriate star

pattern above until snug to the rim.

– See Wheel Lug Nut Diagram above.

3. Stage 2, Torque: Use a calibrated torque wrench to torque

each lug nut, in a star pattern shown above, to the value indicated in the chart below. Wheels must remain stationary during the torquing process for control purposes.

See Wheel Lug Nut Chart below for appropriate torque readings

using the star pattern shown above.

4. Stage 3. Torque all lug nuts to the Recommended Torque

listed in the chart below.

WHEEL LUG NUT TORQUE CHART

Stage 3 Acceptable

Rim Rim Stage 1 Stage 2 Recommended Torque Range

Lug Nuts Size Type Torque ft./lb. Torque ft./lb. Torque ft./lb. ft./lb.

5-Lug 8” Steel 20-25 30-50 90 85-95

5-Lug 10” Steel 20-25 30-50 90 85-95

5-Lug 12” Steel 20-25 30-50 90 85-95

5-Lug 13” Steel 20-25 50-70 90 85-95

5-Lug 13” Alum. 20-25 50-70 90 85-95

5-Lug 14” Steel 20-25 50-70 90 85-95

5-Lug 14” Alum. 20-25 50-70 100 85-120

6-Lug 15” Steel 20-25 50-70 100 85-120

6-Lug 15” Alum. 20-25 50-70 100 85-120

8-Lug 16” Steel 20-25 50-70 110 85-130

8-Lug 16” Alum. 20-25 50-70 110 85-130

All TORQUE READINGS MUST FALL WITHIN THE

ACCEPTABLE RANGE SHOWN IN THE LAST COLUMN.

IF TORQUE FALLS BELOW THE ACCEPTABLE RANGE,

ADDITIONAL TORQUE IS REQUIRED.

See the wheel Torque Instructions and Wheel Lug Nut Dia-

gram for the correct pattern and recommended torque value.

DURING TRAVEL, WHEEL LUG NUTS MUST BE CHECKED

AND RE-TORQUED, as required, after the rst, 50 miles, then

periodically thereafter during travel.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT

IN WHEEL LOSS, OR LOSS OF CONTROL, RESULTING IN

DEATH OR SERIOUS INJURY.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 8 REV B 4/11/2008

Page 9

TROUBLESHOOTING & MAINTENANCE

LIGHTING

The ShoreLand’r

pecially with the use of the automotive type wire harnesses. This

eliminates shorts in the system due to bad or corroded connections. We suggest, however, that you use the following precautions

for trouble-free trailering:

The taillights on your trailer are manufactured by either 1. Dry

Launch or Peterson Manufacturing. Carry a spare bulb

for each application on your trailer. Determine the brand

taillight and side marker lights you have by looking at the

lens on the light. Their name will appear on it somewhere.

The replacement bulbs required are as follows: 2.

3. Once a year remove the light lens and spray or coat the

metal components with either WD40 or CRC. A light coat

of petroleum jelly also works quite well.

®

electrical system is virtually trouble-free, es-

For the • Peterson taillight. The large taillight bulb is a

#GE1157. The smaller bulb is #1895. The Peterson

Mfg. side marker light (Rec. amber side light) has a

GE193 bulb in it.

The large replacement bulb in the • Dry Launch tail-

light is the same #GE1157 large bulb as used in the

Peterson. The small bulb is the #GE194 bulb.

Your trailer may be exposed to salt conditions while towing it down

the road. We recommend that you take the time to wash your trailer

with soap and water, then rinse thoroughly to remove any residue

that may have accumulated on the nish each time you tow on

icy roads or salted road conditions. It should also be washed and

rinsed before storing your trailer at the end of the season.

CAUTION: Make sure the loading ramps are in their ship positions and securely attached before towing. Failing to do so

may cause an unwanted disconnect or the potential loss of the

ramps while in transport. This may cause a potential accident

involving other vehicles.

REPACKING BEARINGS

WARNING: Keep wheel bearings lubricated. Failure to properly

lubricate may cause bearing failure and possible wheel loss resulting in serious injury or property damage.

ShoreLand’r® uses an over-based Calcium Sulfonate grease

that is very compatible with other greases. We would recommend

that you use an over-based Calcium Sulfonate grease if possible.

It is available under Part No. 2500038 and is packaged in 14 oz.

tubes. You can purchase this grease from any ShoreLand’r®

dealer or else contact ShoreLand’r® direct. (1-800-859-3028)

Pack the bearings by forcing the grease into all the small 1.

cavities in the bearings. Fill the cavity in the hub with grease.

4. Make sure the electrical system on the tow vehicle is

capable of powering the additional lights on the trailer.

Check with your local automotive dealer for specications

and any options available that will increase the electrical

capacity.

5. In order to insure a positive ground connection between

the trailer and the tow vehicle, it is important that the white

ground wires are secured properly to both the trailer and

the towing vehicle. A poor ground connection will cause

the lights to not function properly.

PAINT AND ITS CARE

ShoreLand’r® offers their Powersports trailers in a black powder

coated paint nish. It is a very durable nish and should remain

very eye appealing for years. However, it still requires some maintenance and care as does your tow vehicle. Touch up paint is available in either a bottle with a paint stick or else a spray can. All

nicks and scratches should be touched up before rusting sets in

and starts to deteriorate the nish.

Fill the dust cap half full with grease when greasing the hubs. 2.

Make sure the grease seals are in good, usable condition 3.

and do not show signs of them allowing grease to seep

around the spindle. Most likely the seals will receive damage when removed and should be replaced with new seals.

Keep the bearings and grease free of any dirt or foreign 4.

matter.

The wheel bearings should be packed anytime during the 5.

year should you plan on storing the trailer for a period of

time.

Be sure the bearings are adjusted properly accord-6.

ing to the bearings adjustments mentioned under Bearing

adjustment. Too tight of bearing adjustment will cause the

bearings to heat up faster than one that is properly adjusted.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 9 REV B 4/11/2008

Page 10

HUBS, BEARINGS, RACES, SEALS AND SPINDLE SLEEVES

CHART

®

ShoreLand’r

trailers. Measurements listed are both spindle size and hub size.

uses the following sizes of hubs on all of its model

damage to the rear seal. A new one should be installed when reassembling.

Hub Size Bearing, Race & Seal

Manufacturer’s #

Size

1-1/16”- 1-1/16”

5 ½” ange

1-3/8” – 1- 1/16”

Hubs, Drums & Rotors

GREASE SEALS

Inspect the grease seals periodically. A visual inspection is sufcient and is done quite easily on a trailer without brakes. It is normal

to see a small oil lm around the seal area. This should not hurt

anything. However, if the leakage becomes excessive it is time to

replace the seal before too much grease escapes causing bearing

failure. It will also cause the brakes to grab on a brake equipped

trailer. Replacement of the seal requires removing the complete

hub assembly from the spindle. Trailers equipped with disc brakes

will have to have the brake calipers removed so the rotors can be

removed from the spindle.

On axles with brake drums you must remove the complete brake

drum assembly to inspect the seals. It is very important that you

check the seals on brake axles periodically to make sure they are

not leaking. Leaking seals allows the grease to get on the brake linings thus causing grabby brakes. Eventually the brake linings will

become saturated with grease and will have to be replaced.

Grease Seal and Bearing Protectors

If you decide to add bearing protectors to an older model trailer or

one that is not equipped with bearing protectors, we suggest you

install the Spindle Seal Kit available through your dealers. It offers

stainless steel sleeves and spring loaded seals for your axle. This

will prevent rust from chewing up the seals allowing grease to leak

out.

RECOMMENDED LUBRICANT

Over-based calcium sulfonate grease is installed at the factory

because it is a very compatible grease that will blend well with most

other greases. We recommend that you continue to add grease

to the hubs when grease is needed. ShoreLand’r

available in a 14 oz. tube to t a standard size grease gun. The

part number is 2500038 and can be obtained from any authorized

ShoreLand’r® dealer. However, any good marine grade water re-

sistant grease that is compatible to over- based calcium sulfo-

nate is recommended.

BEARING REPACKING

Check the grease in your hubs once a year. In most instances, if

a good quality lubricant is used and the lubricant levels are maintained, it may not be necessary to repack the bearing. However,

should the grease appear to be contaminated or broken down, remove all of the old grease from the bearings and hubs and completely repack. Removing the rear bearing will most likely cause

Inner & Outer Brg. 1-1/16”

Inner & Outer Race 1-1/16”

Dust Seal

(1.250 I.D. –1.979.O.D.)

Inner Bearing 1-3/8”

Inner Race 1-3/8”

Outer Bearing 1-1/16”

Outer Race 1-1/16”

Dust Seal

(1.750 I.D. – 2.565 O.D.)

®

has this grease

Timken L-44649

Timken L-44610

TCM12192TB

Timken L-68149

Timken L-68111

Timken L-44649

Timken L-44610

TCM174243TB

BEARING ADJUSTMENT

The wheel bearings have been adjusted at the factory. To maximize bearing life, however, we suggest that you check the bear-

ing adjustment periodically to the recommended 30” lb. of torque,

and every time the bearings are repacked. Contact an authorized

ShoreLand’r® dealer for service.

Over-based calcium sulfonate is installed at the factory because

it is a very compatible grease that will blend well with most other

greases. We recommend that you continue to use over-based calcium sulfonate grease in your hubs. ShoreLand’r® has this grease

available in a 14 oz. tube to t a standard size grease gun. The part

number is 2500038 and can be obtained from an authorized dealer

or contact ShoreLand’r directly. If neither is an option use a good

grade of wheel bearing grease.

Repeat the above process on the other wheels.

BRAKES

ShoreLand’r® provides all trailers with a GVWR (Gross Vehicle

Weight Rating) of 1,500 lbs. or more with the ability to have brakes

installed on them. On the lower capacity trailers (1,500 - 2,400 lbs.)

a special axle adaptable to brakes is part of the brake kit when

brakes are ordered for a trailer this size. All trailers with a GVWR

of 2720 lbs. or greater come with the brake anges already welded

on the axles.

Most of the trailer brakes are hydraulic surge brakes and are designed to operate automatically when the brakes on the tow vehicle

are applied. When the tow vehicle slows down or stops, the forward momentum of the trailer pushing against the ball hitch applies

pressure to a master cylinder in the trailer actuator. This pressure

activates the brakes on the trailer similar to the brakes on the tow

vehicle. This is a hydraulic surge brake system.

ShoreLand’r

vide technical assistance.

Contact ShoreLand’r® for more technical and specic information

on its different brake systems, bleeding procedures, and maintenance.

®

reserves the right to have it’s brake vendors pro-

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 10 REV B 4/11/2008

Page 11

BRAKE SERVICE & MAINTENANCE OF

BRAKING SYSTEMS

ShoreLand’r®uses only a hydraulic surge brake system with a

hydraulic surge actuator on their Powersports trailers. This system

has an actuator on the tongue of the trailer that attaches to the tow

vehicle. It is designed that when the brakes are applied on the tow

vehicle the trailer will push into the tow vehicle. As this load is applied to the actuator a master cylinder inside the actuator generates

pressure on the brake uid that is then supplied to the wheel cylinders of the drum brakes or into the calipers on disc brake systems.

As this brake uid is supplied the pressure is applied to the brake

shoes or pads causing the brakes to apply on the trailer.

BACKING UP A TRAILER WITH DISC BRAKES

OPERATING TRAILERS WITH DISC BRAKES

Many ShoreLand’r

equipment. This system is designed to brake in both forward and

reverse, therefore the brakes must be disengaged to back up.

®

trailers come with disc brakes as standard

USING A 4-PRONG PLUG

If the tow vehicle is equipped with a 4-prong plug, the trailer can

still be moved using the solenoid to lock out the brakes. Though not

ideal, this is acceptable for backing trailers in either a storage yard

or a shop environment where the tow vehicle is not the normal vehicle that will be used with the trailer. Before backing, simply unplug

the trailer’s 5-prong harness from the tow vehicles 4-prong trunk

harness. Turn the harness 90 degrees and plug the blue wire on

the 5-prong harness into the brown wire on the 4-prong harness. To

activate the solenoid, turn on the tow vehicle’s lights. The power for

operating the running lights will operate the solenoid, disengaging

the brakes so the trailer can be backed up.

UFP ACTUATOR WITH LOCKOUT KEY

Turn plug to connect the blue wire to the brown wire.

BRAKE SERVICE AND MAINTENANCE

WARNING: Trailer brakes must be maintained in good working

conditions. Loss of adequate braking could result in serious injury or property damage.

IMPORTANT: To properly operate this system the tow vehicle

MUST be equipped with a matching 5-prong trunk harness to

power the solenoid. Otherwise, a lockout key must be used (this

key is provided with your actuator).

TRAILER’S 5-PRONG WIRE HARNESS REQUIREMENTS

Required 5-prong trunk harness on tow vehicle.

HOW THE SOLENOID LOCKOUT WORKS

The disc brake actuator has a lockout solenoid that is activated by

the tow vehicle’s back-up lights. When the vehicle is put in reverse,

the solenoid redirects the brake uid back into the actuator reservoir

rather than applying pressure to the brake calipers. Then, when the

tow vehicle is put into park, neutral or a forward gear the solenoid

returns to its original position allowing the brakes to function normally during travel.

ALTERNATIVES TO THE 5-PRONG HARNESS

As stated above, the best way to operate the solenoid is with a

5-prong wire harness on the tow vehicle that matches the wire harness plug of the trailer. This allows the solenoid to be plugged in

at the same time the trailer lights are connected for towing. If a

5-prong harness is not available there are a number of short-term

xes that will allow you to use the trailer.

UFP ACTUATOR LOCKOUT KEY

UFP actuators are shipped with a lockout key attached to the side

of the actuator on a short cable. The round end of the key is simply

inserted in the slot on the side of the actuator. When the key is in

the slot, the trailer can be backed without the brakes engaging.

When the trailer is moved forward, the key will fall out of the slot.

The key ts very loosely to insure that it will not remain in the slot

after backing. Leaving the lockout key in the slot would disable the

brake system during normal use, which could result in a serious

accident.

The braking systems are covered in much greater detail in the

Brake Information Packet that pertains to brake systems and

brake components only. Contact your local dealer or contact

Shoreland’r

This trailer is equipped to meet applicable U.S. Federal safety standards. Check local and state requirements regarding

brakes and any additional equipment that may be required.

Any modications or additions including load equalizing

hitches, without written factory consent: usage in an abnormal manner including overloading voids all manufacturers

warranties and liability.

®

directly to receive a copy of this information.

ADDING A 5TH WIRE & PLUG

A separate wire and plug can be wired into the tow vehicle back-up

lights that can be plugged into the fth wire of the trailer harness.

The solenoid will work as described above, however this new wire

will have to be plugged into the trailer harness separately.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 11 REV B 4/11/2008

Page 12

TIRE INFORMATION

TIRES AND TIRE PRESSURES

STEPS FOR DETERMINING CORRECT LOAD LIMIT

• Locate the statement “The weight of cargo should never

exceed XXX kg or XXX lbs.” on your vehicle’s placard.

• This gure equals the available amount of cargo and luggage

load capacity.

• Determine the combined weight of luggage and cargo being

loaded on the vehicle. That weight may not safely exceed the

available cargo and luggage load capacity.

The trailer’s placard refers to the Tire Information Placard attached

adjacent to or near the trailer’s VIN (Certication) label at the left

front of the trailer.

Steps for Determining Correct Load Limit – Trailer

(For Trailers Over 10,000 lbs. GVWR):

1. Determine the empty weight of your trailer by weighing the

trailer using a public scale or other means. This step does not

have to be repeated.

2. Locate the GVWR (Gross Vehicle Weight Rating) of the trailer

on your trailer’s VIN (Certication ) label.

3. Subtract the empty weight of your trailer from the GVWR

stated on the VIN label. That weight is the maximum available

cargo capacity of the trailer, and may not be safely exceeded.

Steps for Determining Correct Load Limit – Tow Vehicle

(For Tow Vehicles 10,000 lbs. GVWR or Less):

1. Locate the statement, “The combined weight of occupants and

cargo should never exceed xxx lbs.,” on your vehicle’s

placard.

WARNING: Keep tires properly inated. Failure to maintain cor-

rect tire pressure may result in tire failure and loss of control

resulting in serious injury or property damage.

TIRE SAFETY

The most common cause of trailer tire failure is under-ination. It

is important, therefore, that you always maintain the specied air

pressure, as indicated by the tire manufacturer on the tire’s side

walls. This information can also be found on the tire label or the

manufacturers certication label. Most tire manufacturer’s have the

air pressure molded on the tire side wall.

Maintaining proper tire pressure, observing all tire and trailer maximum carrying capacities, avoiding road hazards, and inspecting

the tires for cuts, slashes and other irregularities are the most

important things you can do to avoid tire failure. These practices,

along with other care and maintenance, can improve handling, help

protect you and others from avoidable breakdowns and accidents,

improve fuel economy, and increase the life of your tires.

Make tire safety a regular part of your trailer maintenance routine.

The time you spend is minimal compared to the amount of time,

inconvenience, and potential safety hazards that can occur from a

at tire or failure.

BASIC TIRE MAINTENANCE

Properly maintained tires improve the load-carrying capability of

your trailer. You can help avoid at tires and tire failures by maintaining proper tire pressure, observing tire and trailer capacity limits, avoiding road hazards, and inspecting your tires regularly.

IDENTIFYING YOUR RECOMMENDED TIRE PRESSURE AND

MAXIMUM LOAD CARRYING CAPACITY FOR YOUR TRAILER

2. Determine the combined weight of the driver and passengers

who will be riding in your vehicle.

3. Subtract the combined weight of the driver and passengers

from xxx kilograms or xxx pounds.

4. The resulting gure equals the available amount of cargo and

luggage capacity. For example, if the “xxx” amount equals 1400

lbs. and there will be ve 150 lb. passengers in your vehicle,

the amount of available cargo and luggage capacity is 650 lb.

(1400 – 750 (5 x 150) = 650 lbs.)

5. Determine the combined weight of luggage and cargo being

loaded on the vehicle. That weight may not safely exceed the

available cargo and luggage capacity calculated in Step # 4.

6. If your vehicle will be towing a trailer, load from your trailer will

be transferred to your vehicle. Consult the tow vehicle’s manual

to determine how this weight transfer reduces the available

cargo and luggage capacity of your vehicle.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 12 REV B 4/11/2008

Both the tire placard and the VIN label are permanently attached

to the side frame of your trailer and have the required information printed on them. They also list the maximum load that can be

placed on the trailer without exceeding the load limits of the tires or

the trailers other components. These labels indicate the manufacturers information including:

• Recommended tire size

• Recommended tire ination pressure

• The maximum weight the trailer is designed to carry

• Gross vehicle weight rating of the trailer

• Gross axle weight rating of the trailer

UNDERSTANDING TIRE PRESSURE AND LOAD LIMITS

Tire ination pressure is the level of air in the tire that provides it

with the load-carrying capacity and affects the overall performance

of the trailer. The tire ination pressure is a number that indicates

the amount of air pressure that is inside the tire. It is measured in

pounds per square inch (PSI). The tire must be inated to the air

pressure as designated on the labels. Also listed on the labels is

the air pressure in kilopascals (kPa), which is a metric measurement.

Tire manufacturers determine the air pressure to maximize the

amount of weight the tires can safely carry. The proper tire pressure

for your trailer tires is referred to as the “recommended cold ination pressure.” It is difcult to obtain the recommended tire pres-

Page 13

sure if your tires are not cold when the reading is taken because

the air will expand when it is warmed by towing down the road, thus

increasing the air pressure inside. If air is added to a tire that is low

the air pressure should never exceed the recommended pressure.

It is important to check your trailer’s tire pressure at least once a

month for the following reasons:

• Most tires will naturally lose air over time.

• Tires can lose air suddenly if driven over an object that

punctures or cuts the tire. Sometimes a sharp blow from a

pothole or curb can knock the tire loose from the rim causing

immediate deation.

• Radial tires have an appearance of being under-inated

because of the design and a visual inspection will not always tell

you whether the air pressure inside is below its proper operating

range.

MAINTAINING PROPER TIRE PRESSURE

Locate the recommended tire pressure on the trailer’s tire 1.

information placard, certication label or else in the owner’s

manual.

Record the tire pressure of all tires.2.

If the tire pressure is too high in any of the tires, slowly release 3.

air by gently pressing on the tire valve stem with the edge of

your tire gauge until you get the correct pressure.

If the tire pressure is too low, note the difference between the 4.

measured tire pressure and the correct tire pressure. These

“missing” pounds of pressure are what you will need to add.

Add the missing pounds of air pressure to each tire that is 5.

under inated.

Check all tires to make sure they have the same air pressure. 6.

If you have been towing your trailer and think that a tire is under

inated, ll it to the recommended cold ination pressure indicated

on your trailer’s tire label placard or the VIN label. You can also

check the sidewall of the tire for a correct tire ination pressure.

Your tire will have a slightly lower air pressure because the tire is

warm when you are inating it, but it will be much better than to

continue to tow it with the under ination it may have had. Once the

trailer has been parked long enough to allow the tires to cool down,

recheck the tire pressure and add additional air to return the tire

pressure to the recommended level.

TIRE SIZE

To maintain the trailer’s carrying capacity and safety, purchase only

the same size tires as what were originally supplied on the trailer.

The tires on the trailer are an ST rated tire. This means that they

are a Special Trailer service tire that has more load carrying capacity than a comparable size tire automotive grade tire. The carrying

capacity molded on the side wall of an automotive tire must be

reduced by 10% if it is going to be used on a trailer.

in braking in the event that your trailer is equipped with brakes.

Tires are not as safe when the tire tread is worn down to less than

1/16 inch tread. This is easily identied because most tires are

manufactured with tread, wear indicators that let you know when

the tires are worn to the point they should be replaced. These indicators are raised sections spaced intermittently in the bottom of the

grooves. When the tread has worn down to the point that they appear to be even with the outside of the tread it is time to replace the

tire. Another method for checking tread depth is to place a penny

in the tread with Lincoln’s head upside down and facing you. If you

can see the top of Lincoln’s head, you are ready for new tires.

TIRE BALANCE AND WHEEL ALIGNMENT

To avoid vibration or shaking of the trailer when it is towed, the

tires must be properly balanced. Unbalanced tires, when rotate,

will cause vibration. The more they are out of balance, the more

the vibration will be. This vibration can be eliminated by positioning

weights on the wheel to counterbalance heavy spots on the wheel

and tire assembly. Most any tire store or service station that deals

with tires has the capability of balancing tires.

The wheels must be aligned so they are rotating in the same plane

as what the trailer is being towed. They must be positioned so that

they rotate in the same line as the trailer rather than at some slight

angle either inward or outward from this line. If they are not aligned

correctly, they will have a tendency to skid down the road causing the tread to wear off quickly and crooked. Correct alignment

maximizes the life of your tires and are preset when the axles are

welded during manufacturing. This alignment is correct and will

remain correct when towed under most towing conditions. Hitting

curbs and large pot holes with the trailer tires may distort the axle

and cause the spindle position to be knocked out of alignment.

TIRE REPAIR

The proper repair of a punctured tire requires a plug for the hole

and a patch for the area inside the tire that surrounds the puncture

hole. Punctures through the tread can be repaired if they are not

too large, but punctures to the side wall should not be repaired.

Tires must be removed from the rim to be properly inspected before

being plugged and patched.

TIRE FUNDAMENTALS

Federal law requires tire manufacturers to place standardized in-

formation on the side wall of all tires. This information identies

and describes the fundamental characteristics of the tire and also

provides a tire identication number for safety standard certication

and in case of a recall.

Look at the tire information placard, the owner’s manual, or the

side wall of the tire you are replacing to nd this information. If you

have any questions about the correct size to choose, consult your

ShoreLandr’s

®

dealer or local tire dealer for assistance.

TIRE TREAD

The tire tread provides a gripping action to the road to prevent it

from sliding on the road surface when cornering and also to help

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 13 REV B 4/11/2008

Page 14

INFORMATION ON PASSENGER VEHICLE TIRES

Please refer to the diagram below.

The “ST” indicates the tire is a special trailer tire.

The “LT” indicates the tire is a light truck tire.

NEXT NUMBER

This three-digit number gives the width in millimeters of the tire

from side wall edge to side wall edge. In general, the larger the

number, the wider the tire.

UTQGS (Uniform Tire Quality Grading System) INFORMATION

TREADWEAR NUMBER

This number indicates the tire’s wear rate. The higher the tread

wear number is, the longer it should take for the tread to wear

down. For example, a tire graded 400 should last twice as long as

a tire graded 200.

TRACTION LETTER

This letter indicates a tire’s ability to stop on wet pavement. A higher graded tire should allow you to stop your car on wet roads in a

shorter distance than a tire with a lower grade. Traction is graded

from highest to lowest as “AA”, “A”, “B”, and “C”.

TEMPERATURE LETTER

This letter indicates a tire’s resistance to heat. The temperature

grade is for a tire that is inated properly and not overloaded. Excessive speed, under-ination or excessive loading, either sepa-

rately or in combination, can cause heat build-up and possible tire

failure. From highest to lowest, a tire’s resistance to heat is graded

as “A”, “B”, or “C”.

ADDITIONAL INFORMATION ON LIGHT TRUCK TIRES

NEXT NUMBER

This two-digit number, known as the aspect ratio, gives the tire’s

ratio of height to width. Numbers of 70 or lower indicate a short side

wall for improved steering response and better overall handling on

dry pavement.

R

The “R” stands for radial. Radial ply construction of tires has been

the industry standard for the past 20 years. A “D” stands for bias

ply construction.

NEXT NUMBER

This two-digit number is the wheel or rim diameter in inches. If you

change your wheel size, you will have to purchase new tires to

match the new wheel diameter.

U.S. DOT TIRE IDENTIFICTION NUMBER

This begins with the letters “DOT” and indicates that the tire meets

all federal standards. The next two numbers or letters are the

plant code where it was manufactured, and the last four numbers

represent the week and year the tire was built. For example, the

numbers 3197 means the 31st. week of 1997. The other numbers

are marketing codes used at the manufacturer’s discretion. This

information is used to contact consumers if a tire defect requires

a recall.

TIRE PLY COMPOSITION AND MATERIALS USED

The number of plies indicates the number of layers of rubber-coated fabric in the tire. In general, the greater the number of plies, the

more weight a tire can support. Tire manufacturers also must indicate the materials in the tire, which include steel, nylon, polyester,

and others.

Please refer to diagram below.

Tires for light trucks have other markings besides those found on

the side walls of passenger tires.

LT

The “LT” indicates the tire is for light trucks.

MAX. LOAD DUAL kg (lbs.) AT kPa (psi) COLD

This information indicates the maximum load and tire pressure

when the tire is used as a dual, that is, when four tires are put on

each rear axle (a total of six or more tires on the vehicle).

MAX. LOAD SINGLE kg (psi) AT kPa (psi) COLD

This information indicates the maximum load and tire pressure

when the tire is used as a single.

LOAD RANGE

This information identies the tire’s load-carrying capabilities and

its ination limits.

SNOW TIRES

In some heavy snow areas, local governments may require true

snow tires, those with very deeply cut tread. These tires should

only be used in pairs or placed on all four wheels. Make sure you

purchase snow tires that are the same size and construction type

as the other tires on your vehicle.

MAXIMUM LOAD RATING

This number indicates the maximum load in kilograms and pounds

that can be carried by the tire.

MAXIMUM PERMISSIBLE INFLATION PRESSURE

The number is the greatest amount of air pressure that should ever

be put in the tire under normal driving conditions.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 14 REV B 4/11/2008

Page 15

GLOSSARY OF TIRE TERMINOLOGY

ACCESSORY WEIGHT

The combined weight (in excess of those standard items which

may be replaced) of automatic transmission, power, steering, power brakes, power windows, power seats, radio and heater, to the

extent that these items are available as factory-installed equipment

(whether installed or not).

BEAD

The part of the tire that is made of steel wires, wrapped or rein-

forced by ply cords and that is shaped to t the rim.

BEAD SEPARATION

This is the breakdown of the bond between components in the

bead.

BIAS PLY TIRE

A pneumatic tire in which the ply cords that extend to the beads are

laid at alternate angles substantially less than 90 degrees to the

centerline of the tread.

CARCASS

The tire structure, except tread and side wall rubber which, when

inated, bears the load.

CHUNKING

The breaking away of pieces of the tread or side wall.

COLD INFLATION PRESSURE

The pressure in the tire before you tow.

CORD

The strands forming the plies in the tire.

INNERLINER SEPARATION

The parting of the inner liner from cord material in the carcass.

INTENDED OUTBOARD SIDEWALL

The side wall that contains a white-wall, bears white lettering or

bears manufacturer, brand, and/or model name molding that is

higher or deeper than the same molding on the other side wall of

the tire or the outward facing side wall of an asymmetrical tire that

has a particular side that must always face outward when mounted

on a vehicle.

LIGHT TRUCK (LT) TIRE

A tire designed by its manufacturer as primarily intended for use on

lightweight trucks or multipurpose passenger vehicles.

LOAD RATING

The maximum load that a tire is rated to carry for a given ination

pressure.

MAXIMUM LOAD RATING

The load rating for a tire at the maximum permissible ination pressure for that tire.

MAXIMUM PERMISSIBLE INFLATION PRESSURE

The maximum cold ination pressure to which a tire may be inated.

MAXIMUM LOADED VEHICLE WEIGHT

The sum of curb weight, accessory weight, vehicle weight, and production options weight.

MEASURING RIM

The rim on which a tire is tted for physical dimension requirements.

CORD SEPARATION

The parting of cords from adjacent rubber compounds.

CRACKING

Any parting within the tread, side wall, or inner liner of the tire extending to cord material.

CT

A pneumatic tire with an inverted ange tire and rim system in which

the rim is designed with rim anges pointed radially inward and the

tire is designed to t on the underside of the rim in a manner that

encloses the rim anges inside the air cavity of the tire.

CURB WEIGHT

The weight of a motor vehicle with standard equipment including

the maximum capacity of fuel, oil, and coolant, and if so equipped,

air conditioning and additional weight optional engine.

EXTRA LOAD

A tire designed to operate at higher loads and at higher ination

pressures than the corresponding standard tire.

GROOVE

The space between two adjacent tread ribs.

INNERLINER

The layer(s) forming the inside surface of a tubeless tire that con-

tains the inating medium within the tire.

NON-PNEUMATIC RIM

A mechanical device which, when a non-pneumatic tire assembly

incorporates a wheel, supports the tire, and attaches, either integrally or separably, to the wheel center member and upon which

the tire is attached.

NON-PNEUMATIC SPARE TIRE ASSEMBLY

A non-pneumatic tire assembly intended for temporary use in place

of one of the pneumatic tires and rims that are tted to a passenger

car in compliance with the requirements of this standard.

NON-PNEUMATIC TIRE

A mechanical device which transmits, either directly or through a

wheel or wheel center member, the vertical load and tractive forces

from the roadway to the vehicle, generates the tractive forces that

provide the directional control of the vehicle and does not rely on

the containment of any gas or uid for providing those functions.

NON-PNEUMATIC TIRE ASSEMBLY

A non-pneumatic tire, alone or in combination with a wheel or wheel

center member, which can be mounted on a vehicle.

NORMAL OCCUPANT WEIGHT

This means 68 kilograms (150 lbs.) times the number of occupants.

OCCUPANT DISTRIBUTION

The distribution of occupants in a vehicle as specied.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 15 REV B 4/11/2008

Page 16

OPEN SPLICE

Any parting at any junction of tread, side wall, or inner liner that

extends to cord material.

OUTER DIAMETER

Then overall diameter of an inated new tire.

SIDEWALL

That portion of a tire between the tread and bead.

SIDEWALL SEPARATION

The parting of the rubber compound from the cord material in the

side wall.

OVERALL WIDTH

The linear distance between the exteriors of the side walls of an

inated tire, including elevations due to labeling, decorations, or

protective band or ribs.

PLY

A layer of rubber-coated parallel cords.

PLY SEPARATION

A parting of rubber compound between adjacent plies.

PNEUMATIC TIRE

A mechanical device made of rubber, chemicals, fabric and steel

or other materials, that, when mounted on an automotive wheel,

provides the traction and contains the gas or uid that sustains the

load.

PRODUCTION OPTIONS WEIGHT

The combined weight of those installed regular production options

weighing over 2.3 kilograms (5 lbs.) in excess of those standard

items which they replace, not previously considered in curb weight

or accessory weight, including heavy duty brakes, ride levelers,

roof rack, heavy duty battery, and special trim.

RADIAL PLY TIRE

A pneumatic tire in which the ply cords that extend to the beads are

laid at substantially 90 degrees to the centerline of the tread.

RECOMMENDED INFLATION PRESSURE

This is the ination pressure provided by the vehicle manufacturer

on the Tire Information Label and the Certication/ VIN tag.

REINFORCED TIRE

A tire designed to operate at higher loads and at higher ination

pressures than the corresponding standard tire.

RIM

A metal support for a tire or a tire and tube assembly upon which

the tire beads are seated.

RIM DIAMETER

This means the nominal diameter of the bead seat.

RIM SIZE DESIGNATION

This means the rim diameter and width.

RIM TYPE DESIGNATION

This means the industry of manufacturer’s designation for a rim by

style or code.

TEST RIM

The rim on which a tire is tted for testing, and may be any rim

listed as appropriate for use with that tire.

TREAD

That portion of a tire that comes into contact with the road.

TREAD RIB

A tread section running circumferentially around a tire.

TREAD SEPARATION

Pulling away of the tread from the tire carcass.

TREAD INDICATORS (TWI)

The projections within the principal grooves designed to give a visual indication of the degrees of wear of the tread.

VEHICLE CAPACITY WEIGHT

The rated cargo and luggage load plus 68 kilograms (150 lbs.)

times the vehicles designated seating capacity.

VEHICLE MAXIMUM LOAD ON THE TIRE

The load on an individual tire that is determined by distributing to

each axle its share of the maximum loaded vehicle weight and dividing by two.

VEHICLE NORMAL LOAD ON THE TIRE

The load on an individual tire that is determined by distributing to

each axle its share of the curb weight, accessory weight, and normal occupant weight divided by two.

WEATHER SIDE

The surface area of the rim not covered by the inated tire.

WHEEL CENTER MEMBER

In the case of a non-pneumatic tire assembly incorporating a wheel,

a mechanical device which attaches, either integrally or separable,

to the non-pneumatic rim and provides the connection between the

non-pneumatic rim and the vehicle; in the case of a non-pneumatic

tire assembly not incorporating a wheel, a mechanical device which

attaches, either integrally or separately, to the non-pneumatic tire

and provides the connection between tire and the vehicle.

WHEEL-HOLDING FIXTURE

The xture used to hold the wheel and tire assembly securely during testing.

RIM WIDTH

This means the nominal distance between rim anges.

SECTION WIDTH

The linear distance between the exteriors of the side walls of an

inated tire, excluding elevations due to labeling, decoration, or

protective bands.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 16 REV B 4/11/2008

Page 17

CHANGING TIRE

It is desirable that you carry a jack that will work on your trailer in

the event that you have a at tire. A small board or block can also

be very benecial in the event you are jacking on soft dirt or hot

asphalt. The jack, depending on the style, may be placed under

the side frame in back of the wheel or also under the axle. When

placing the jack under the axle, the following precautions should

be taken:

The jack must be placed under the axle as close to the •

spring as possible.

If your trailer is equipped with a channel axle, a 2 x 4 x 8” wood •

block must be placed between the jack and the axle positioned so

that the wood block contacts both vertical legs of the axle channel.

Any other jacking procedures may cause damage to the axle •

and void warranty.

EXCESSIVE TIRE WEAR

Each axle that ShoreLand’r® manufactures has been preset when

welded for proper caster and camber. If you are experiencing excessive tire wear, it is possible that your axle has been knocked

out of alignment by hitting a curb or large pothole. The caster and

camber can be checked out and may be corrected by a mechanic

with wheel aligning equipment.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 17 REV B 4/11/2008

Page 18

REPORTING SAFETY DEFECTS

If you believe that your vehicle has a defect which could cause

a crash or could cause injury or death, you should immediately

inform the National Trafc Safety Administration (NHTSA) in ad-

dition to notifying us.

If NHTSA receives similar complaints, it may open an investigation,

and if it nds that a safety defect exists in a group of vehicles, it may

order a recall and remedy campaign. However, NHTSA cannot become involved in individual problems between you, your dealer, or

us.

To contact NHTSA, you may either call the Vehicle Safety

Hotline toll-free at 1-888-327-4236 (TTY: 1-800-424-9153); go to

http://www.safercar.gov; or write to: Administrator, NHTSA, 1200

New Jersey Avenue SE, Washington D.C. 20590.

To contact us: call toll-free 1-800-859-3028, or write to: Midwest

Industries, Inc., Customer Service Department, Box 235, Ida

Grove, Iowa 51445.

WARRANTY

Warranty information is within your owner’s packet. Contact your

dealer for service or information on warranty. If warranty, or other

information was not included with your trailer, you may request

this information at www.shorelandr.com or call Midwest Industries

(home of ShoreLand’r

®

) directly at 800.859.3028.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003513

Page 18 REV B 4/11/2008

Loading...

Loading...