Page 1

MC2000-03 / MC2000A-03

Motorcycle Trailer, V-Twin

MC2000-03 Motorcycle Trailer V-Twin

4300254

6845603 Frame Bundle MC V-Twin

3510039 Axle Dexter Torsion MC Trailer

6845703 Hardware Box MC V-Twin

65069 Lit Packet - ShoreLand’r

3310050 Jack 800 lb. Swivel

ST215/75R14C GY OWL Mod Rim Chrome

MC2000A-03 Motorcycle Trailer V-Twin

4300227 ST215/75R14C GY OWL Alum Star Rim

6845603 Frame Bundle MC V-Twin

3510039 Axle Dexter Torsion MC Trailer

6845703 Hardware Box MC V-Twin

65069 Lit Packet - ShoreLand’r Utility

3310050 Jack 800 lb. Swivel

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com M312045

MC2000-03 / MC2000A-03 Specifications:

Capacity: 2000 lbs.

GVWR: 2995 lbs.

GAWR: 2995 lbs.

Ship Wt: 994 lbs.

Frm Size: 2X4 (11 Ga)

Tire Size: ST215/75R14-C

Rim Size: 14 X 6 Alum.

Brake: Disc (Optional)

Coupler: 2” Class III

Safety Chn: Class III 5000 lb.

Suspension: Torsion

Tongue Size: 3X3X10 ga. X 9’-3”

Page 1 of 6

Page 2

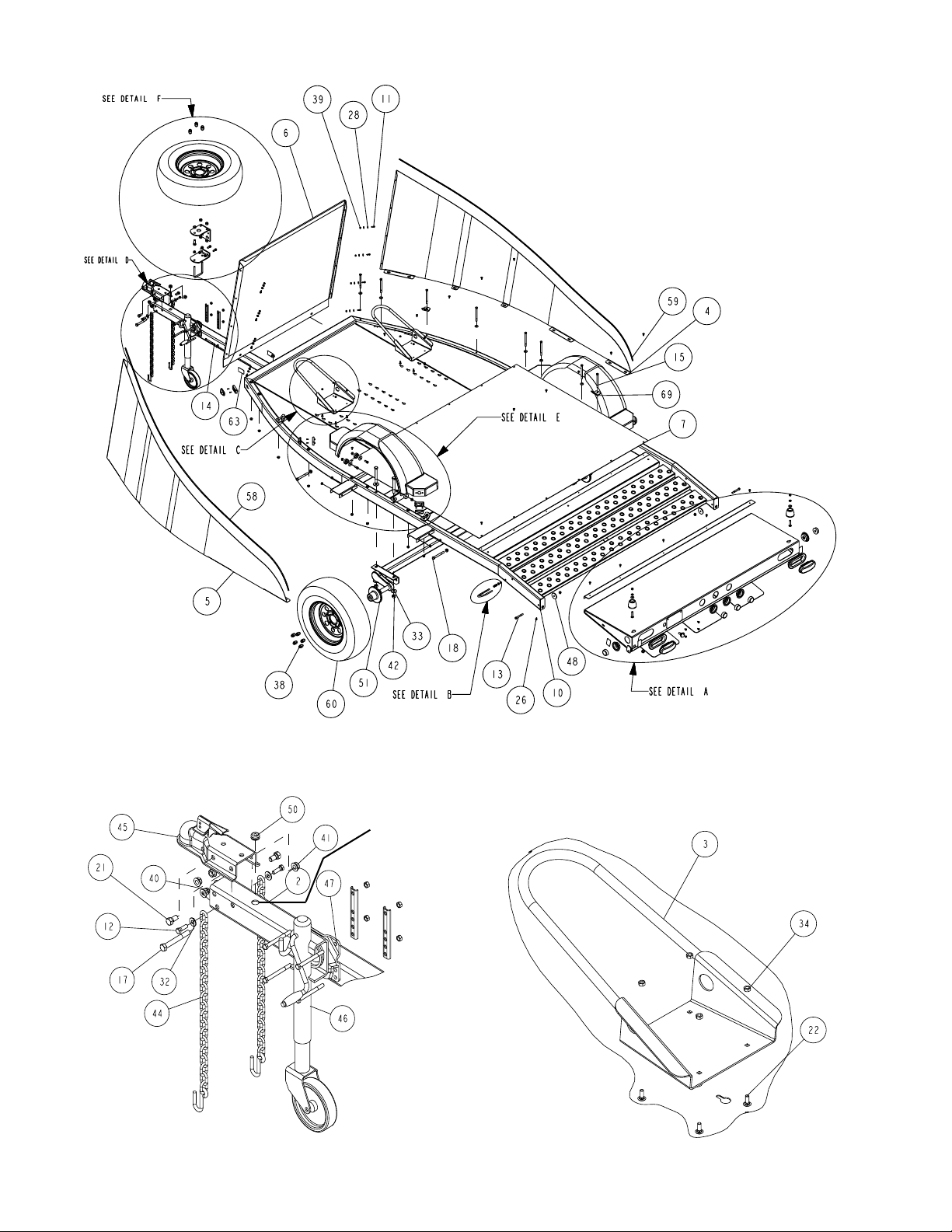

Diagram A

Insert the tongue wire harness down

inside the tongue through this hole.

Detail D

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com M312045

Detail C

Page 2 of 6

Page 3

MC2000-03 MOTOR CYCLE

TRAILER, V-TWIN

Position it under the frame so that the

axle end units that have the spindles

after 50 miles of driving and then

periodically thereafter.

welded to them is pointing towards the

Two people are required to properly

assemble this trailer.

CARE MUST BE TAKEN NOT TO

SCRATCH OR DAMAGE THE SIDE

SHIELD PANELS WHEN REMOVING

THEM FROM THEIR SHIP POSITION AND

INSTALLING THEM ON THE TRAILER.

Carefully remove the banded parts and

hardware bag from the frame bundle.

Sort all the items in the hardware bag

by size.

ASSEMBLY INSTRUCTIONS

Axle Assembly

Place the frame on four sawhorses or

something comparable in height and

strength for the assembly process.

Locate the torsion axle assembly.

rear of the trailer as shown in Diagram

A. Place a 5/8” flat washer on each of

the four 5/8” x 5-1/2” hex bolts and drop

them in the holes in the side frames as

shown in Detail E on page 4. (See Item

# 9). With a jack, hoist, or two people,

raise the axle assembly up under the

bottom side of the trailer frame. Align

the holes in the axle mounting brackets

with the

5/8” x 5-1/2” bolt just installed. Place on

another 5/8” flat washer and secure with

5/8” hex flange lock nuts. Tighten.

Tire and Wheel Assembly

Mount the tire and wheel assemblies

using the 1/2” fine threaded tapered lug

nuts provided. Tighten to 80-90 ft/lb. of

torque using the rotation pattern as

shown in the ShoreLandr’s Owners

Manual. Re-torque the lug nuts

Tongue Assembly

Locate the tongue wire harness in the

hardware bag and unwind. Locate the

four-prong end of the harness. This end

of the harness will plug into the trunk

harness of the tow vehicle. Place the

other ends of the harness into the hole

in the top of the tongue located just

behind where the coupler is to be

mounted. See Detail D. Route the wire

backward in the tongue approximately

42 inches and then bring the harness

back out of the hole provided in the top

of the tongue at this location. Pull the

wire harness out the this hole

approximately 8 inches at this time

which should be plenty harness to make

the connection with the frame harness

later.

Place the coupler on the end of the

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com M312045

Page 3 of 6

Page 4

tongue and align the holes. Place a 1/2” x 4 hex bolt into the

rear hole of the coupler and secure with a 1/2” flange lock

nut. Place a 1/2” x 1” hex bolt into the front hole on one side

of the coupler and tongue and secure with a 1/2” hex flange

lock nut. Repeat this on the other side of the tongue. Tighten

all bolts at this time.

Safety Chains

Place a 3/8” flat washer on a 3/8” x 1-1/4” hex bolt, the insert

the bolt into the last link of one of the safety chains. Attach

the safety chain to the tongue by then inserting the bolt into

the hole provided in the side of the tongue as shown in Detail

D. Place another flat washer on the bolt on the inside of the

tongue and secure with a 3/8” hex flange lock nut. Tighten.

Repeat this process on the other side of the tongue.

Attaching the tongue assembly to the frame.

Place the tongue assembly under the front of the trailer. Align

the tongue with the mounting channels on the frame. Raise

the tongue into position and secure to the frame using

two- 1/2” x 4-1/2” hex bolts and hex flange lock nuts. Tighten.

Once the tongue is installed in its permanent position the

wire harness can now be connected to the frame harness.

Match the tongue harness wire colors with those in the frame

harness and plug the two together. Attach the white ground

wire from the tongue harness to the frame with a 1/4” x 3/4”

self-tapping screw. Note that a pilot hole is provided for this

screw. It is located approximately 3” of the right of the tongue

and on the back side of the front cross member of the frame.

Once it is installed, all excess wire harness can be pushed

into the hole on the top of the tongue. Place one of the

rubber grommets provided into the hole on the top of the

tongue to shield the wire harness from any sharp edges. The

second rubber grommet can now be placed in the hole on

the top side of the tongue located just behind the coupler.

Detail F

Detail E

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com M312045

Page 4 of 4

Page 5

Side Panels and Front Shield

Locate the 16- 3/8” x 5” hex bolts provided in the hardware

bag. Next locate the four tie down brackets also supplied in

the hardware box. Insert four of the bolts through the smaller

hole in the tie down brackets so the bent leg of the bracket

will point upward along side the head of the bolt. Place a 3/8”

flat washer also provided on the balance of the bolts just

mentioned.

matching the next pair of holes upward in the panels and

securing them together with the 1/4” x 3/4” bolts provided

using the process just described for the bottom holes.

Repeat this process until all four of the bolts have been

installed on each side panel.

Once all of the bolts have been installed, all bolts attaching

the side and front panels together and to the trailer can be

tightened.

With the assistance of another person raise one of the side

panels into position on the top side of the trailer side frame.

Starting on the back end of the side panel, align the slotted

holes in the formed over mounting legs of the side panel with

the holes provided in the trailer side frame. While one person

holds the side panel in its proper position, the other person

will place in the attaching bolts. Beginning at the rear of the

side panel, the first bolt to install will have one of the tiedown

brackets on it. Insert this bolt assembly down through the

rear slotted hole in the formed tab of the side panel, then

down through the holes provided in the side frame. Once the

bolt is fully inserted, secure it on the bottom side of the frame

with a 3/8” hex flange lock nut. DO NOT TIGHTEN.

Insert one of the 3/8” x 5” hex bolts with the flat washer in the

next slotted hole forward in the side panel. Place it down

through the frame and secure with a 3/8” hex flange lock nut

as on the first bolt. Continue to move forward placing three

(3) more bolts with flat washers (total of (four) 4) in the other

slotted holes. As you move forward on the side panel it will

have to be pushed inward to the centerline of the trailer to

align the holes in the side panel with the holes in the frame.

Once a total of four bolts with flat washers are installed, the

next bolt has to be one with a tie down bracket on it. This is to

be positioned as the sixth bolt from the rear or else the third

position from the front. Note that this is only a recom-

mended position that will work on most bikes. It may be

placed either forward or backward to best adapt to your

bike and its tie-down location. Continue to place in the

remaining bolts with flat washers until all eight (8) bolts holding the side panel to the frame are installed.

Remove the chrome edge trim from the hardware box and

unwind. This trim is to be placed on the edge of the side

panels not only for appearance but also for protection when

you lean over the panel. Pry one end of the trim open just

enough so that it can be started on the edge of the side panel.

Starting at the front of the side panel where it connects to the

front panel, slip the edge trim onto the side panel. Slowly slip

the edge trim onto the edge pushing it completely down over

the side panel as you move towards the rear. The edge trim

has an adhesive inside so once it is pushed completely over

the side panel it will begin to adhere itself. Cut off any excess

edge trim that you may have once you reached the rear end

of the side panel. Repeat this process on the other side panel.

Tailgate Bumpers

Locate a 3/8” x 2” carriage bolt. Insert it into one of the rubber

bumpers as shown in Detail A on page 6. Next place on a flat

washer, lock washer and hex nut. Thread nut on only enough

to start on the threads so it don’t come off when handling.

Position the assembly as shown in Detail A. Align the square

portion of the carriage bolt head with the slot in the tailgate.

Insert the carriage head bolt into the round portion of the key

hole slot, then slide the square of the bolt head into the long

portion of the key hole slot.Raise the assembly matching the

square of the bolt with the slot while you tighten the hex nut

on the bolt to secure in this position.

Repeat this process on the other bumper assembly.

Wheel Chocks

Repeat the above process on the other side panel.

Locate one of the wheel chocks that is shipped with the trailer.

Place a 1/4” x 3/4” carriage bolt in each of the four holes from

Locate the front panel. Place a flat washer on two (2) 3/8” x

3-3/4” hex bolts. Align the slotted holes in the front panel with

the bottom side as shown in Detail C. Place a 1/4” hex lock

nut on each of the bolts just installed.

the holes in the front cross member of the welded frame and

insert the two (2) 3/8” x 3-3/4” hex bolts. Secure with 3/8”

hex flange lock nuts. DO NOT TIGHTEN.

The wheel chock assembly will fit on either side or else on

the centerline of the trailer. It is also adjustable front to rear in

either location depending on which holes it is mounted in.

Attach the side panels to the front panel with the 1/4” x 3/4”

hex bolts provided. Place a flat washer on one of the 1/4” x

3/4” hex bolts. While one person moves the front panel either

forward or backward to align the bottom hole in the front panel

with the mating hole in the side panel, a second person will

Note that the axle on the trailer is not adjustable for tongue

weight. The tongue weight of the trailer is controlled by the

placement of the motorcycles on the trailer. Select the proper

location that will give you the best fit for your motorcycle and

give you the proper tongue weight for proper towing.

insert the bolt through the matched holes from the rear of the

trailer towards the front. Once the bolt is inserted in the holes

place on a second flat washer. Secure with one of the 1/4”

kep nuts provided. Repeat this process on the bottom hole of

the other side panel and front panel. DO NOT TIGHTEN.

Once identified, place the wheel chock assembly onto the

deck of the trailer aligning the four carriage heads of the bolts

with the key slots in the deck. Drop the heads below the deck

and then slide the assembly forward until the flat portion of

the carriage heads are in the slots. Tighten the nuts to

Continue attaching the front panel to the side panels by

secure in place.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com M312045

Page 5 of 6

Page 6

Spare Tire Bracket and Tire Wheel Assembly

See Detail F.

Locate the 3/8” x 3 7/16” x 4 1/8” square U-bolt Part No.

0310090 that fits the tongue of your trailer. Place the U-bolt

up and around the tongue from the bottom side. Locate Item

Detail A

Detail B

Ramp Latch

Handle Assembly

# 9 spare tire bracket with two (2) holes. Align the holes in the

bracket with the legs of the U-bolt and place on the

U-bolt. Secure in place using 1/2” hex flange lock nuts.

Position the bracket on the tongue so it is located at the

approximate center of where the spare tire will be located

when installed and tighten in position.

Locate Item No. 10 spare tire bracket with three (3) holes.

Place it in position as shown and secure it to the bracket just

installed using two- 3/8” x 1” hex bolts and hex flange lock

nuts. The bottom set of holes in the bracket will raise the

bracket into its highest position and will adapt to the larger

tires. Tighten.

Locate the three- 1/2” x 1-1/2” hex bolts. Place them into the

upper bracket as shown from the bottom side. Secure into

place using 1/2” fine threaded nuts. Tighten. The bracket is

now ready for mounting the spare tire to it.

Place the spare tire onto the bracket by aligning the holes in

the wheel rim with the three bolts just installed. Once aligned

allow the spare tire to rest onto the bracket. Secure the wheel

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com M312045

to the spare tire bracket using the three- 1/2” lug nuts

provided. Tighten.

Jack With Caster Wheel

See Detail D.

Locate the jack with caster wheel. Note that it will fit various

size tongues. Place two- 3/8” x 4” hex bolts into the holes in

the mounting plate as shown in the diagram. Hold the jack up

to the tongue so that the two bolts just installed are resting

on the topside of the tongue. Check to make sure that there

is a set of holes directly under the tongue. If there is, place a

channel mounting bracket onto the two bolts. Secure using

3/8” lock washers and hex nuts.

Place two more 3/8” x 4” hex bolts in the holes located

directly under the tongue running them through the jack

mounting plate and the channel mounting brackets as well.

Secure using 3/8” lock washers and 3/8” hex nuts. Tighten.

Assembly is complete.

Page 6 of 6

Loading...

Loading...