Page 1

MC2000-03 / MC2000A-03

Motorcycle Trailer, V-Twin

MC2000-03 Motorcycle Trailer V-Twin

4300254

6845603 Frame Bundle MC V-Twin

3510039 Axle Dexter Torsion MC Trailer

6845703 Hardware Box MC V-Twin

65069 Lit Packet - ShoreLandʼr

3310050 Jack 800 lb. Swivel

ST215/75R14C GY OWL Mod Rim Chrome

MC2000A-03 Motorcycle Trailer V-Twin

4300227 ST215/75R14C GY OWL Alum Star Rim

6845603 Frame Bundle MC V-Twin

3510039 Axle Dexter Torsion MC Trailer

6845703 Hardware Box MC V-Twin

65069 Lit Packet - ShoreLandʼr Utility

3310050 Jack 800 lb. Swivel

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com M406105

Page 1 REV A 9/07/04

MC2000-03 / MC2000A-03 Specifications:

Capacity: 2000 lbs.

GVWR: 2995 lbs.

GAWR: 2995 lbs.

Ship Wt: 994 lbs.

Frm Size: 2X4 (11 Ga)

Tire Size: ST215/75R14-C

Rim Size: 14 X 6 Alum.

Brake: Disc (Optional)

Coupler: 2” Class III

Safety Chn: Class III 5000 lb.

Suspension: Torsion

Tongue Size: 3X3X10 ga. X 9ʼ-3”

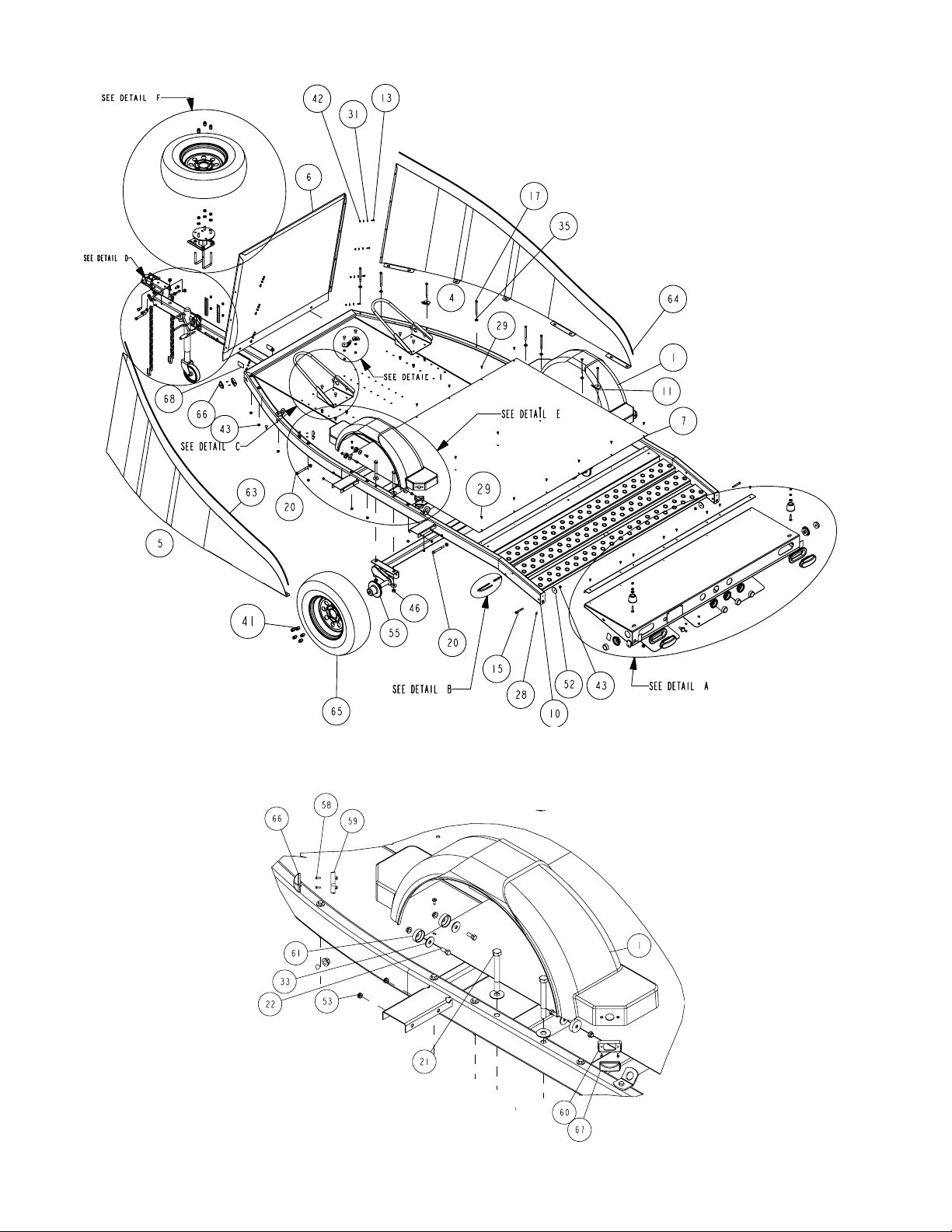

Page 2

Diagram A

Detail E

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com M406105

Page 2 REV A 9/07/04

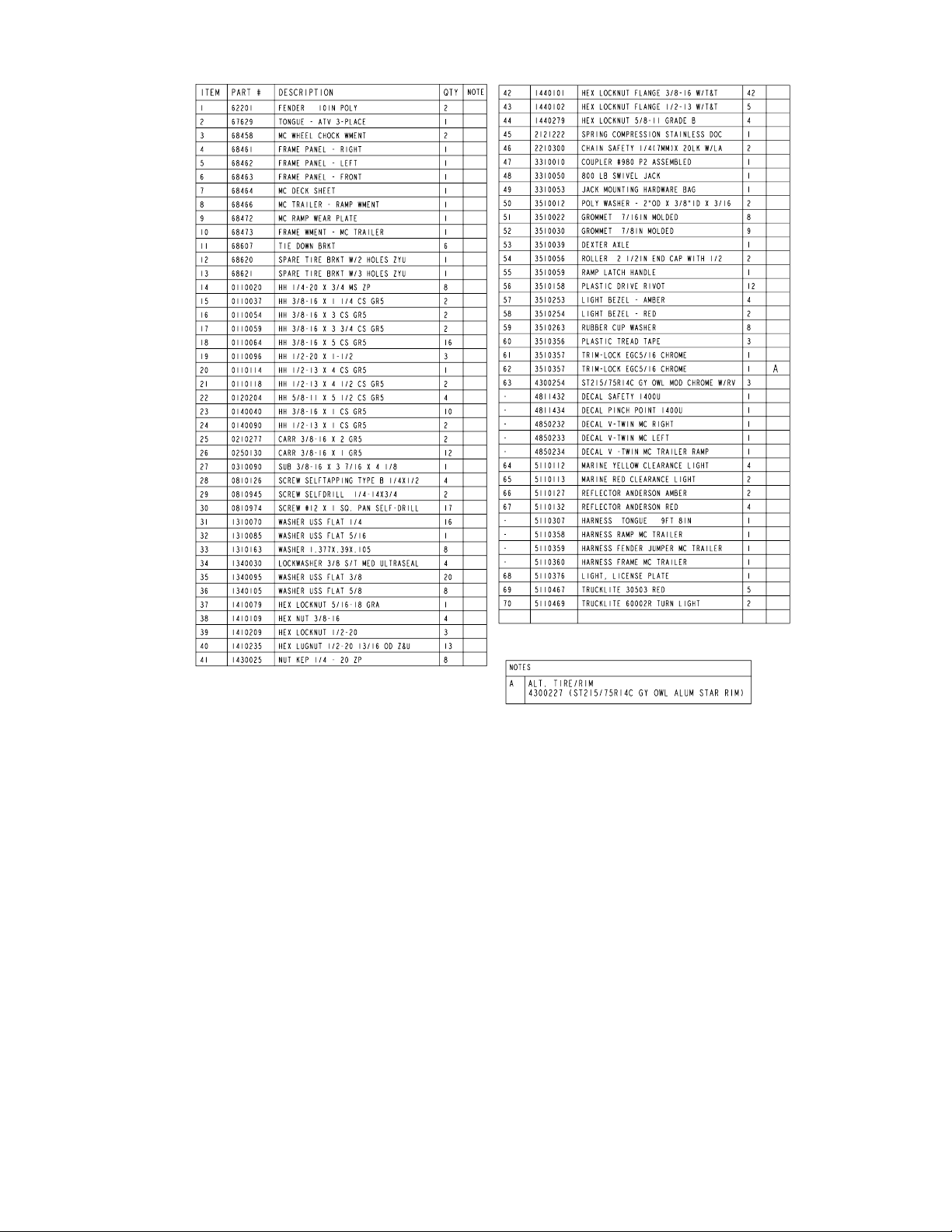

Page 3

MC2000-03 MOTOR CYCLE

TRAILER, V-TWIN

Tw o p e o p l e a r e r e q u i r e d t o

properly assemble this trailer.

CARE MUST B E TAKEN NOT TO

SCRATCH OR DAMAGE THE SIDE

SHIELD PANELS WHEN REMOVING

THEM FROM THEIR SHIP POSITION

AND INSTALLING THEM ON THE

TRAILER.

Carefully remove the banded parts and

hardware bag from the frame bundle.

Sort all the items in the hardware bag

by size.

ASSEMBLY INSTRUCTIONS

Locate the torsion axle assembly.

Position it under the frame so that the

axle end units that have the spindles

welded to them is pointing towards the

rear of the trailer as shown in Diagram

A. Place a 5/8” flat washer on each of

the four 5/8” x 5-1/2” hex bolts and drop

them in the holes in the side frames as

shown in Detail E on page 4. (See Item #

9). With a jack, hoist, or two people, raise

the axle assembly up under the bottom

side of the trailer frame. Align the holes

in the axle mounting brackets with the

5/8” x 5-1/2” bolt just installed. Place on

another 5/8” flat washer and secure with

5/8” hex flange lock nuts. Tighten.

Brakes

tional brake kit available. The Optional

Brake kit No. is TA0012-13. It includes

all the brake components, brake hoses,

line fittings and brake line tubing cut

to length. See your local dealer or call

Midwest Industries, Inc. for further

details. Phone 1-800-859-3028.

Tire and Wheel Assembly

Mount the tire and wheel assemblies

using the 1/2” fine threaded tapered

lug nuts provided. Tighten to 80-90

ft/lb. of torque using the rotation pattern

as shown in the ShoreLandr’s Own-

ers Manual. Re-torque the lug nuts

after 50 miles of dri ving and the n

periodically thereafter.

Your trailer does not come standard

Axle Assembly

with brakes. Check your state towing

laws regarding the brake requirements.

Place the frame on four sawhorses or

something comparable in height and

strength for the assembly process.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com M406105

Page 3 REV A 9/07/04

In the event that brakes are required or

you would like to install brakes on your

trailer for added safety, there is an op-

Page 4

Insert the tongue wire harness

down inside the tongue through

this hole.

Detail D

Jack With Caster Wheel

See Detail D.

Locate the jack with caster wheel. Note that it will fit various

size tongues. Place two- 3/8” x 4” hex bolts into the holes

in the mounting plate as shown in the diagram. Hold the

jack up to the tongue so that the two bolts just installed are

resting on the topside of the tongue. Check to make sure

that there is a set of holes directly under the tongue. If there

is, place a channel mounting bracket onto the two bolts.

Secure using 3/8” lock washers and hex nuts.

Place two more 3/8” x 4” hex bolts in the holes located

directly under the tongue running them through the jack

mounting plate and the channel mounting brackets as well.

Secure using 3/8” lock washers and 3/8” hex nuts. Tighten.

Place the coupler on the end of the tongue and align the

holes. Place a 1/2” x 4 hex bolt into the rear hole of the

coupler and secure with a 1/2” flange lock nut. Place a 1/2” x

1” hex bolt into the front hole on one side of the coupler and

tongue and secure with a 1/2” hex flange lock nut. Repeat

this on the other side of the tongue. Tighten all bolts at this

time.

Safety Chains

Place a 3/8” flat washer on a 3/8” x 1-1/4” hex bolt, the insert

the bolt into the last link of one of the safety chains. Attach

the safety chain to the tongue by then inserting the bolt into

the hole provided in the side of the tongue as shown in Detail

D. Place another flat washer on the bolt on the inside of the

tongue and secure with a 3/8” hex flange lock nut. Tighten.

Repeat this process on the other side of the tongue.

Attaching the tongue assembly to the frame.

Place the tongue assembly under the front of the trailer.

Align the tongue with the mounting channels on the frame.

Raise the tongue into position and secure to the frame using

two- 1/2” x 4-1/2” hex bolts and hex flange lock nuts.

Tighten.

Once the tongue is installed in its permanent position the

wire harness can now be connected to the frame harness.

Match the tongue harness wire colors with those in the frame

harness and plug the two together. Attach the white ground

wire from the tongue harness to the frame with a 1/4” x 3/4”

self-tapping screw. Note that a pilot hole is provided for this

screw. It is located approximately 3” of the right of the tongue

and on the back side of the front cross member of the frame.

Once it is installed, all excess wire harness can be pushed

into the hole on the top of the tongue. Place one of the

rubber grommets provided into the hole on the top of the

tongue to shield the wire harness from any sharp edges. The

second rubber grommet can now be placed in the hole on the

top side of the tongue located just behind the coupler.

Aluminum Diamond Plated Decking

Shipping Information

Assembly is complete.

Tongue Assembly

Locate the tongue wire harness in the hardware bag and

unwind. Locate the four-prong end of the harness. This end

of the harness will plug into the trunk harness of the tow

vehicle. Place the other ends of the harness into the hole in

the top of the tongue located just behind where the coupler is

to be mounted. See Detail D. Route the wire backward in the

tongue approximately 42 inches and then bring the harness

back out of the hole provided in the top of the tongue at this

location. Pull the wire harness out the this hole approximately

8 inches at this time which should be plenty harness to make

the connection with the frame harness later.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com M406105

Page 4 REV A 9/07/04

The aluminum diamond plated decking is shipped upside

down to protect it from damage during shipping. It is attached upside down with six (6) mounting screws.

The aluminum diamond plated decking must be removed

and installed correctly using the following process:

Remove and discard the six (6) screws installed for shipping

purposes.

Reverse the aluminum decking so it now has the shiney

tread side up. Note that the decking has the mounting holes

punched symmetrical so there is no front or rear position.

Once the decking is positioned, re-attach it to the frame using fifteen (15) mounting screws that are provided in the hardware bag.

Page 5

Side Panels and Front Shield

Locate the 16- 3/8” x 5” hex bolts provided in the hardware

bag. Next locate the four tie down brackets also supplied in

the hardware box. Insert four of the bolts through the smaller

hole in the tie down brackets so the bent leg of the bracket

will point upward along side the head of the bolt. Place a

3/8” flat washer also provided on the balance of the bolts just

mentioned.

With the assistance of another person raise one of the side

panels into position on the top side of the trailer side frame.

Starting on the back end of the side panel, align the slotted

holes in the formed over mounting legs of the side panel with

the holes provided in the trailer side frame. While one person

holds the side panel in its proper position, the other person

will place in the attaching bolts. Beginning at the rear of the

side panel, the first bolt to install will have one of the tiedown

brackets on it. Insert this bolt assembly down through the rear

slotted hole in the formed tab of the side panel, then down

through the holes provided in the side frame. Once the bolt is

fully inserted, secure it on the bottom side of the frame with

a 3/8” hex flange lock nut. DO NOT TIGHTEN.

Insert one of the 3/8” x 5” hex bolts with the flat washer in

the next slotted hole forward in the side panel. Place it down

through the frame and secure with a 3/8” hex flange lock nut

as on the first bolt. Continue to move forward placing three

(3) more bolts with flat washers (total of (four) 4) in the other

slotted holes. As you move forward on the side panel it will

have to be pushed inward to the center line of the trailer to

align the holes in the side panel with the holes in the frame.

Once a total of four bolts with flat washers are installed, the

next bolt has to be one with a tie down bracket on it. This is

to be positioned as the sixth bolt from the rear or else the

third position from the front. Note that this is only a recom-

mended position that will work on most bikes. It may be

placed either forward or backward to best adapt to your

bike and its tie-down location. Continue to place in the

remaining bolts with flat washers until all eight (8) bolts holding

the side panel to the frame are installed.

Repeat the above process on the other side panel.

Locate the front panel. Place a flat washer on two (2) 3/8” x

3-3/4” hex bolts. Align the slotted holes in the front panel with

the holes in the front cross member of the welded frame and

insert the two (2) 3/8” x 3-3/4” hex bolts. Secure with 3/8”

hex flange lock nuts. DO NOT TIGHTEN.

using the process just described for the bottom holes.

Repeat this process until all four of the bolts have been

installed on each side panel.

Once all of the bolts have been installed, all bolts attaching

the side and front panels together and to the trailer can be

tightened.

Remove the chrome edge trim from the hardware box and

unwind. This trim is to be placed on the edge of the side panels

not only for appearance but also for protection when you lean

over the panel. Pry one end of the trim open just enough so

that it can be started on the edge of the side panel. Starting

at the front of the side panel where it connects to the front

panel, slip the edge trim onto the side panel. Slowly slip the

edge trim onto the edge pushing it completely down over the

side panel as you move towards the rear. The edge trim has

an adhesive inside so once it is pushed completely over the

side panel it will begin to adhere itself. Cut off any excess edge

trim that you may have once you reached the rear end of the

side panel. Repeat this process on the other side panel.

Wheel Chocks

Note that the trailer has holes provided in the deck so either

one bike can be carried in the center of the trailer or two bikes

can be carried, one on each side of the trailer.

Locate one of the wheel chocks shipped with the trailer and

place it on the trailer deck. Determine the desired location

forward and backward to create the proper tongue weight for

the trailer as well as the desired positioning for transporting

your bikes.

Once determined, align the holes in the wheel chock with the

holes provided in the deck of the trailer. Locate four (4) 3/8”

x 1” carriage bolts provided in the hardware box. Insert one

of the bolts into the aligned holes in the wheel chock. Secure

the bolt in place using a 3/8” lock washer and 3/8” hex nut

on the bottom side of the deck. Repeat this process on the

three remaining bolts. Note that the wheel chock may be positioned so that one of the bolts is located in the slotted hole

provided in the deck. Should this be the case, place one 3/8”

flat washer provided on the bolt before the 3/8” lock washer

and 3/8” hex nut are installed. Once all bolts are installed

they can be tightened.

Repeat the above process on the remaining wheel chock if

two are being installed on the trailer.

Attach the side panels to the front panel with the 1/4” x 3/4”

hex bolts provided. Place a flat washer on one of the 1/4” x

3/4” hex bolts. While one person moves the front panel either

forward or backward to align the bottom hole in the front panel

with the mating hole in the side panel, a second person will

insert the bolt through the matched holes from the rear of the

trailer towards the front. Once the bolt is inserted in the holes

place on a second flat washer. Secure with one of the 1/4”

kep nuts provided. Repeat this process on the bottom hole

of the other side panel and front panel. DO NOT TIGHTEN.

Continue attaching the front panel to the side panels by

matching the next pair of holes upward in the panels and

securing them together with the 1/4” x 3/4” bolts provided

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com M406105

Page 5 REV A 9/07/04

Detail C

Page 6

Detail A

Tailgate Bumpers

Locate a 3/8” x 2” carriage bolt. Insert it into one of the rubber

bumpers as shown in Detail A on page 6. Next place on a flat

washer, lock washer and hex nut. Thread nut on only enough

to start on the threads so it donʼt come off when handling.

Position the assembly as shown in Detail A. Align the square

portion of the carriage bolt head with the slot in the tailgate.

Insert the carriage head bolt into the round portion of the key

hole slot, then slide the square of the bolt head into the long

portion of the key hole slot. Raise the assembly matching the

square of the bolt with the slot while you tighten the hex nut

on the bolt to secure in this position.

Repeat this process on the other bumper assembly.

Detail B

Ramp Latch

Handle Assembly

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com M406105

Page 6 REV A 9/07/04

Page 7

Spare Tire Bracket and Tire Wheel Assembly

See Detail F.

Locate the 3/8” x 3 7/16” x 4 1/8” square U-bolt Part No.

0310090 that fits the tongue of your trailer. Place the U-bolt

up and around the tongue from the bottom side. Locate

Item #9 spare tire bracket with two (2) holes. Align the holes

in the bracket with the legs of the U-bolt and place on the

U-bolt. Secure in place using 1/2” hex flange lock nuts.

Position the bracket on the tongue so it is located at the

ap pro ximat e c ent er of where the spar e ti re will be

located when installed and tighten in position.

Locate Item No. 10 spare tire bracket with three (3) holes. Place

it in position as shown and secure it to the bracket just installed

using two- 3/8” x 1” hex bolts and hex flange lock nuts. The

bottom set of holes in the bracket will raise the bracket into its highest position and will adapt to the larger tires. Tighten.

Locate the three- 1/2” x 1-1/2” hex bolts. Place them into

the upper bracket as shown from the bottom side. Secure

into place using 1/2” fine threaded nuts. Tighten. The

bracket is now ready for mounting the spare tire to it.

Place the spare tire onto the bracket by aligning the holes in

the wheel rim with the three bolts just installed. Once aligned

allow the spare tire to rest onto the bracket. Secure the

wheel to the spare tire bracket using the three- 1/2” lug nuts

provided. Tighten.

Detail F

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com M406105

Page 7 REV A 9/07/04

Page 8

Tie Down Brackets

Two additional tie down brackets are provide d in t he

ha rdw are box. Once th e wh eel choc ks are prop erly

positioned, place the bike or bikes on the trailer. Determine

the desired location for the tie downs as follows:

One Bike Tie Down Location

If one bike is being transported on the trailer and the tie down

brackets installed with the side panels are not properly located

for your bike, the additional tie down brackets provided can be

positioned anywhere on either the inside row or outside row of

holes provided in the trailer deck for attaching the outside wheel

chocks. Once determined, attach the tie down to the trailer deck

by placing a 3/8” x 1” carriage bolt in the square hole of the tie

down bracket and then inserting it in the determined hole in the

deck. Secure using a 3/8” lock washer and 3/8” hex nut. Rotate

the bracket to the desired position and tighten in place.

Two Bike Tie Down Location

If two bikes are going to be transported on the trailer the tie

downs can be positioned anywhere in the holes provided for

attaching the wheel chock in the center location. Identify the

holes that will best adapt to each individual bike. Note that

they may each have their own location forward or backward.

Once determined, attach the tie down to the trailer deck by

placing a 3/8” x 1” carriage bolt in the square hole of the tie

down bracket and then inserting it in the determined hole in

the deck. Secure using a 3/8” lock washer and 3/8” hex nut.

Rotate the brackets to the desired position and tighten in place.

The two bike tie down system would incorporate the two tie

downs installed with the side shields as well. These tie downs

can be moved to another bolt that attaches the side shields

to the trailer frame if they are in the wrong location for your

bike.

Cleaning

The trailer can be washed with warm soap and water to remove

dirt and road film. A standard automotive wax can be used to

protect the painted parts of the trailer.

NEVER clean the aluminum parts on the trailer with Windex

or other harsh cleaners like Orange Clean. They will damage

the finish on the aluminum parts. To clean use an aluminum

cleaner that can be purchased at a local auto parts store or else

the automotive section in your larger chain stores.

Detail I

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com M406105

Page 8 REV A 9/07/04

Loading...

Loading...