ShoreLand'r LUXR40TCBXLW User Manual V.1

®

LUXR40TCBXLW

LUXR40TCBLW 2X4 Lund Trailer

69082 Literature Bag - Trailers (Brakes)

66473__ Axle Assy 80 Wide

80517-- Frame Bundle - LUXR40TCBLW

TA0028-__ Spare Tire Kit 2X4 & 2X5 Frames

LU0106-__ Loadguide Lund 2X4 Frame (5-Hole)

TA0991-__ Winch Stand Kit - 9” W/Hardware

3310050 Jack 800 lbs. - Swivel

4610048 Spring, 5-Leaf Hook

ShoreLand’r offers their product line a painted nish. When ordering

parts it is important that you specify the nish or color you have on

your product. The ve (5) digit number along with a two (2) digit space

_ _, note the parts which can be purchased with various nishes.

When ordering these items use the ve (5) digit number along with

a two (2) digit sufx for the proper nish.

01..........White

03..........Black

14..........Blue

22..........Red

24..........Majestic Red

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003676

REV B 02/09/2009

Page 1

ST215/75R14C OWL Alum Star Rim

LUXR40TCBLW Specications

Capacity 4000lbs.

GVWR: 5920 lbs.

GAWR: 2960 lbs.

Ship Wt: 1052 lbs.

Frm Size: 2X4 (11 Ga)

Tire Size: ST215X75R14-C

Rim Size: 14 X 6 “J”

Brake: Surge Hydraulic

Coupler: 2” Actuator, 7000 lbs.

Suspension: 5 Leaf Hook Springs

Tongue Size: 3X5X65” Swing Tongue

Table of Contents

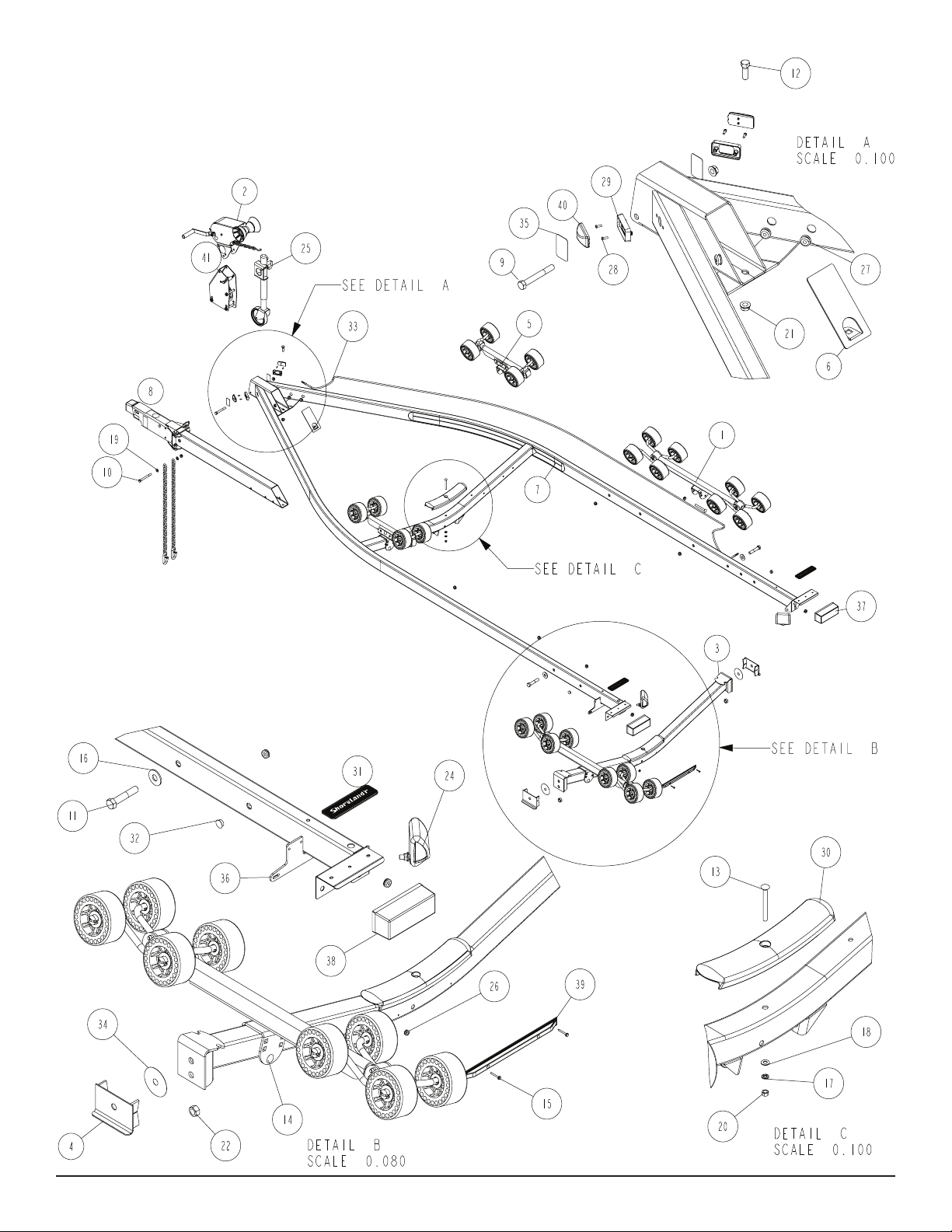

Frame Drawing & Bill of Materials .........................................2-3

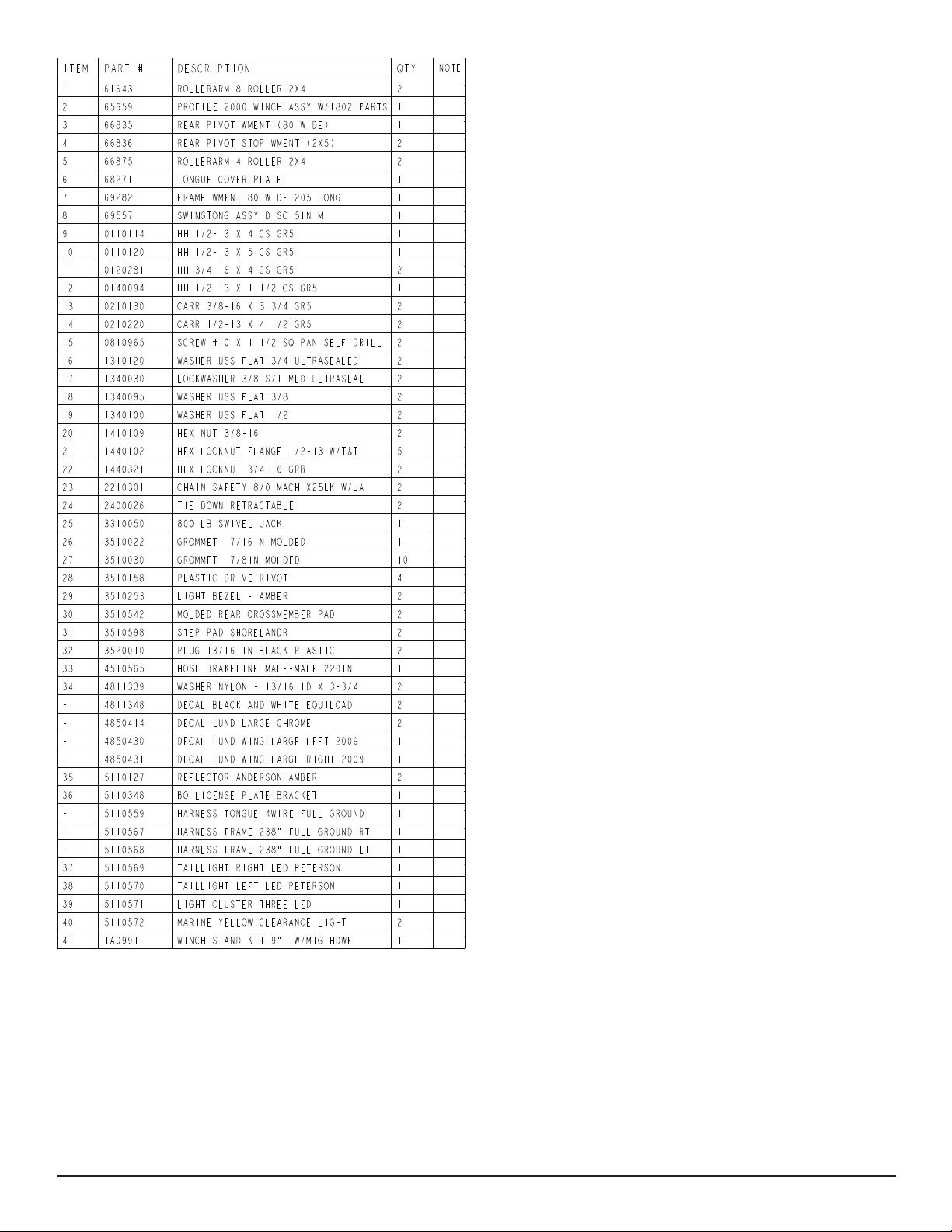

Swing Tongue, Actuator, Safety Chain (Disc) ........................4

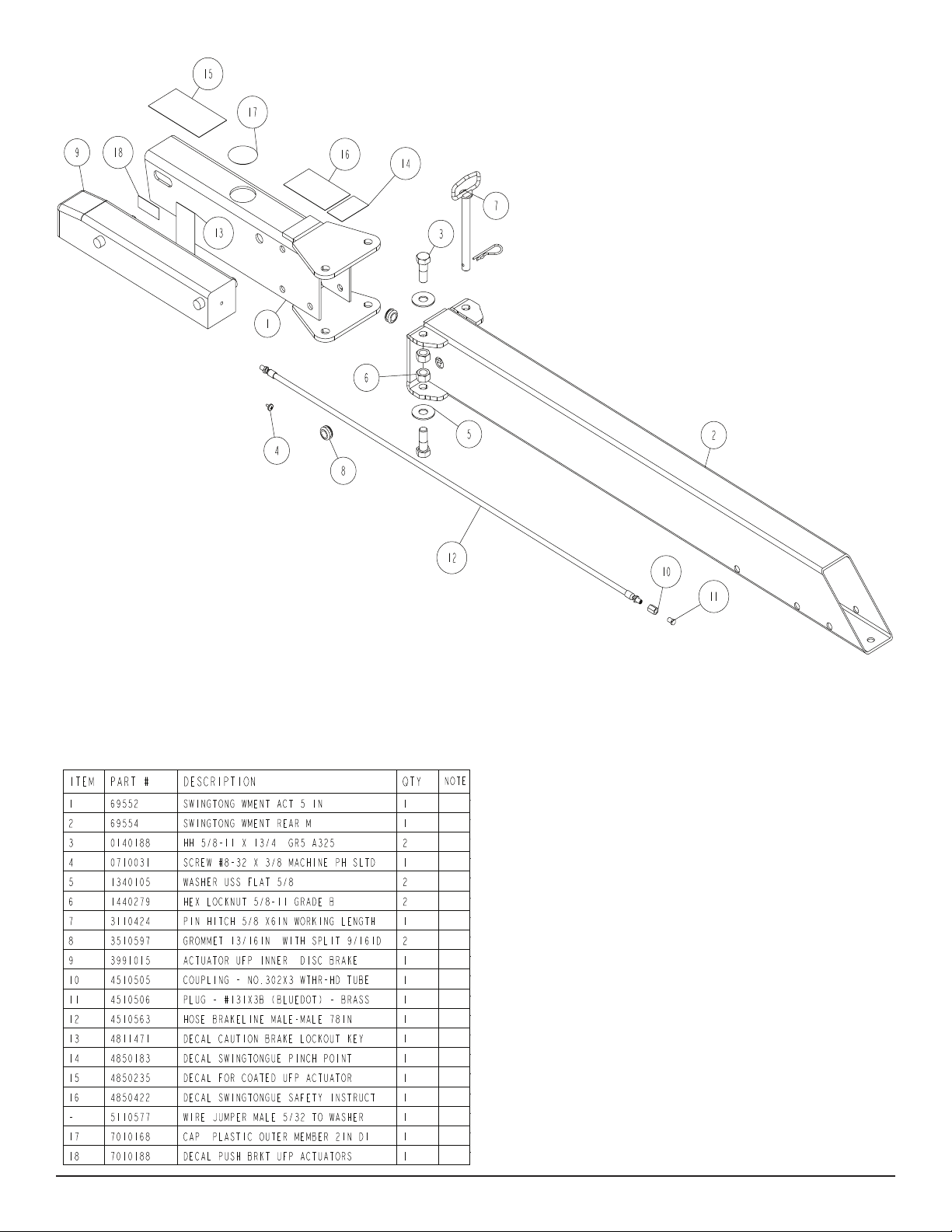

Prole 2000 Winch / Post Drawing & BOM ..........................5-6

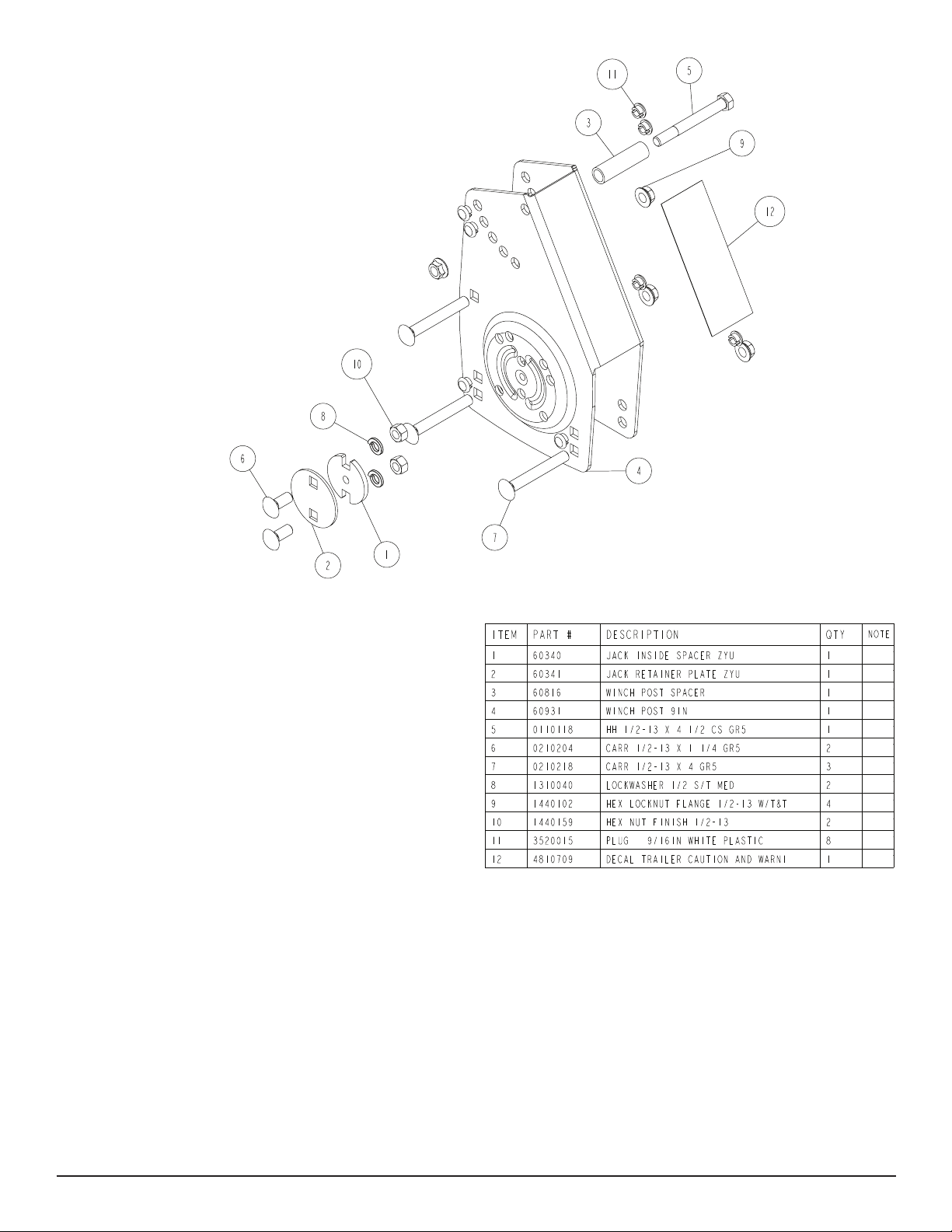

Axle Assembly Dwg / BOM (Disc) .........................................7-9

Roller Assemblies..................................................................

Loadguide.......................................................................................12

Tire Info / Tire Size & Carrying Capapcity Chart ...................13

Spare Tire Bracket ................................................................14

Trailer Adjustments.............................................................13&15

10-11

Diagram A

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003676

REV B 02/09/2009

Page 2

Remove the wire harness from the rear of the tongue. Place the

wire harness and the brake hose through the hole provided in the

tongue cover plate.

Secure the tongue cover plate in position with the same 1/2” x 11/2” hex bolt that secures the back on the tongue to the tongue

channel of the frame. Secure with a 1/2” lock nut. Tighten both bolts

just installed.

Plug the tongue wire harness ends into the frame harnesses by

matching colors and ends. Push the extra wire provided into the

rear of the tongue. The wire should be positioned so the only thing

exposed to the outside of the tongue and side frame is the black

wire loom.

TONGUE BRAKE HOSE CONNECTION

Locate the brass brake line coupling. Remove the plastic cap from

the tting on the end of the tongue hose. Thread into one end of the

coupling. Remove the hose from the side frame enough to reach

into the rear of the tongue. Remove the plastic cap from the tting

on the side frame hose, then thread into the other end of the coupling. Tighten.

Push the excess hose back inside the tongue so that the coupling

just installed is located inside the rear of the tongue.

SAFETY CHAINS

Locate the 1/2” x 5” hex bolt. Slip the bolt through a 1/2” at washer,

then place through the last link of one of the safety chains.

Place the bolt with chain attached through the hole provided in the

bottom front of the actuator mount on the tongue. Place the second

chain on the portion of the bolt extending through the other side

of the tongue. Place on another 1/2” at washer and hex lock nut.

Tighten.

FINAL ASSEMBLY INSTRUCTIONS

Remove all banded items and the hardware bag from the frame.

Remove the parts and sort by size.

TONGUE

Locate the tongue and install by sliding it in the front of the tongue

channel.

RETRACTABLE TIE DOWNS

Locate the two retractable tie downs. Next locate one of the 7/16”

x 1 ½” ne threaded bolts supplied with the retractable tie down.

Insert it into the bottom hole on the retractable tie down so the bolt

is pointing through the back side of the tie down. Insert the bolt

through the hole provided in the taillight bracket just inside the side

frame. Secure with the 7/16” ange lock nut. Tighten.

Repeat the above process on the other tie down.

WINCH POST ASSEMBLY

Your trailer may have come with the jack already installed on the

winch base. However, in the event that it did not, use the following

instructions to attach the jack to the winch base before it is installed

on the tongue.

ASSEMBLY & MOUNTING INSTRUCTIONS

JACK - PROFILE 2000 WINCH BASE

The Prole 2000 winch base used on the 2” x 4” and 2” x 5” frame

trailers is formed so that the jack can be mounted directly to it eliminating the need for other mounting hardware for attaching the jack

to the tongue. The jack required for mounting does not require the

mounting base or any of the original mounting hardware components.

Line the holes in the tongue with the holes in the tongue channel.

Install the 1/2” x 4” hex bolt in the front cross hole and secure with

a 1/2” ange lock nut.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003676

REV B 02/09/2009

Page 3

Diagram B

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003676

REV B 02/09/2009

Page 4

Diagram C

Assemble as follows:

The jack must be mounted to the winch base before it is installed

on the trailer tongue. If the winch base is already mounted on the

tongue, it will have to be removed for the jack installation.

Locate the hardware bag and sort all items by size.

Lay the Prole 2000 winch base on its side so the side that the jack

is going to be mounted on is up.

Place the inside jack spacer on the winch base so the center pro-

trusion ts down into the indent in the winch base.

Position the jack mounting plate so it is centered around the inside

jack spacer just positioned.

Lay the jack retainer plate on top of the jack mounting plate aligning

the holes in it with the holes in the winch base.

Insert the two ½” and 1 ¼” carriage bolts into the holes just aligned

in the jack retainer plate and the winch base. Secure in place with

½” lock washers and hex nuts. Tighten.

Once tightened, rotate the jack through its normal pivoting range to

make sure it is free to travel and is not binding up.

If jack pivots, place it on the tongue and secure in place with the

bolts and hardware provided with the trailer. Complete the assembly of the winch head to the winch base. Assembly is complete.

WINCH POST INSTALLATION

The height that the bow eye is placed in your boat will determine

the length winch post required. Once this is determined, attach the

winch base to the tongue with three 1/2” x 4” carriage bolts and

lock nuts.

Align the holes in the Prole 2000 mounting channel with the holes

in the top of the winch base. Attach the front of the winch head

mounting channel to the base by placing a 1/2” x 4-1/2” hex bolt

through the hole closest to the front of the winch base. Secure with

a lock nut. Do not tighten.

Note that the winch head can now be rotated either up or down.

Identify the correct hole combination to use to position the bow eye

roller just above the bow eye of your boat. When determined, secure in this position by placing the bushing as shown in Diagram D

inside the winch base so it aligns with the hole just identied for the

proper adjustment. Insert another 1/2” x 4-1/2” hex bolt through the

determined mounting hole in the mounting channel and winch base

making sure the bolt passes through the bushing as well. Secure

with a 1/2” lock nut. Tighten all bolts.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0003676

REV B 02/09/2009

Page 5

Loading...

Loading...