Page 1

®

LUVE22LTSH

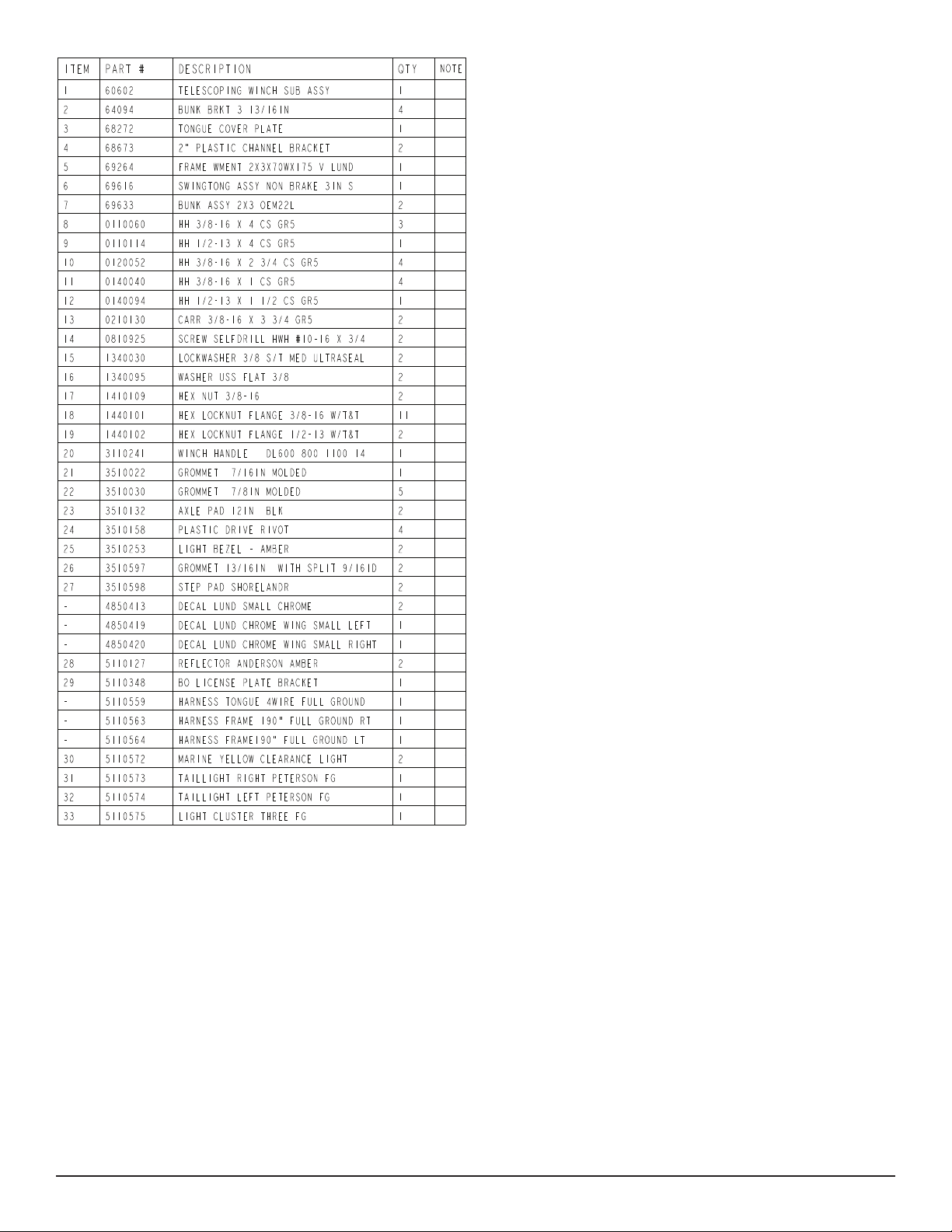

LUVE22LTSH Lund 2X3 Trailer

62340 Literature Packet - Trailers

80604_ _ Frame Bundle LUVE22L

61395 Coupler Bag w/Chains

3310050 Jack 800 lb. Swivel

3310053 Jack Mounting Hardware Bag

*ST185/80D13C Bias Tire / Dir Rim

*Check with your dealer/customer service representative for current tire/rim assembly part number.

ShoreLand’r offers its product line in painted nishes. When

ordering parts, it is important that you specify the nish or

color you have on your product. The 5-digit number along

with a 2-digit space _ _, note that the parts can be purchased

in various nishes.

03..........Black

39..........Galvanized w/Silver Plastic Components

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004036

REV A 01/05/2009

Page 1

Page 2

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004036

REV A 01/05/2009

Page 2

Page 3

the wire harness through the hole in the tongue cover plate.

(See Detail A) Secure the tongue cover plate in position with a 1/2”

X 1-1/2” hex bolt and 1/2” lock nut. Tighten. Plug the tongue wire

harness ends into the frame harnesses by matching colors and ends.

Push the extra wire into the rear of the tongue or remove the grommets in the side frame and place the extra wire in the side frame.

Replace grommets just removed.

SAFETY CHAINS

Mount the safety chains to the front of the tongue by placing

a 3/8” at washer onto a 3/8” X 1-1/4” hex bolt, then insert the

bolt through the last link of the safety chain. Put the bolt through

the hole on one side of the tongue as shown. Place on another

at washer and secure with a 3/8” hex ange nut. Tighten. Repeat on the other chain on the other side of the tongue.

WINCH POST

Place the winch post assembly o n the tongue and secure

wi th thre e 3/ 8” X 4” h ex bolt s an d h ex flange lock n uts.

Place the nuts on the bolts but do not tighten because they

will have to be readjusted once the boat is on the trailer.

Remove the winch handle nut from the shaft. Align the hole in the

winch handle with the at surfaces on the shaft. Slide in position and

secure with the nut just removed. Tighten.

JACK

It is recommended that the jack be mounted on the right side of the

tongue. This will place it on the opposite side of the winch handle

to eliminate the possibility of the two interfering when being operated.

ASSEMBLY INSTRUCTIONS

Remove all items from the frame. Locate the hardware bag and sort

all items by size.

SWING TONGUE

The tongue comes shipped incorrectly in the frame. Slide the

tongue out from it’s shipping position and reinstall in the front

tongue channel. Line the holes in the tongue with the holes

in the tongue channel. Secure with a 1/2” X 4” hex bolt and

1/2” lock nut in the front cross hole.

Locate the coupler bag. Place the coupler on the end of the

tongue, align holes and secure with one 1/2” X 4” hex bolts and

hex ange lock nuts in the rear coupler hole. Place two 1/2” X

1” hex bolts into the front holes of the coupler and secure to the

each side of the tongue with 1/2” ange lock nuts. Tighten.

WIRE HARNESS

Locate the wire harness. Push the two triangular plugs in the hole

on the top of the tongue, then out the rear of the tongue. Place

Remove the hardware bag from the jack and sort all items by size.

Note that the jack mounting plate has only one pair of holes on one

side of the plate while the other side has holes punched to accommodate either 3”, 4”, or 5” tongue.

Place a 3/8” x 4” hex bolt into the single hole of the mounting plate

so the head of the bolt is on the jack side of the plate.

Once inserted, place one of the mounting channels onto the bolt so

the legs of the mounting channel are pointing away from the jack.

Place on a 3/8” at washer and hex nut. Thread on only far enough

to secure in place.

Repeat the above process on the other single hole of the mounting

plate.

Place the jack on the tongue so that the two bolts just installed are on

the top side of the tongue with the jack on the right side of the tongue

and the mounting channels on the other side of the tongue.

Visually check which of the bottom three holes in the plate will align

just under the bottom side of the tongue. Insert the remaining two 3/8”

x 4” hex bolts into these holes and then through the mating holes in

the mounting channel. Secure with 3/8” at washers and hex nuts.

Rotate the jack into the up position. Slide the jack forward or backward on the tongue to make sure it will not hit the frame of the trailer

when in the up position.

Tighten all of the mounting bolts to secure the jack assembly to the

tongue.

Always rotate the jack in the up position before towing the trailer.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004036

REV A 01/05/2009

Page 3

Page 4

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004036

REV A 01/05/2009

Page 4

Page 5

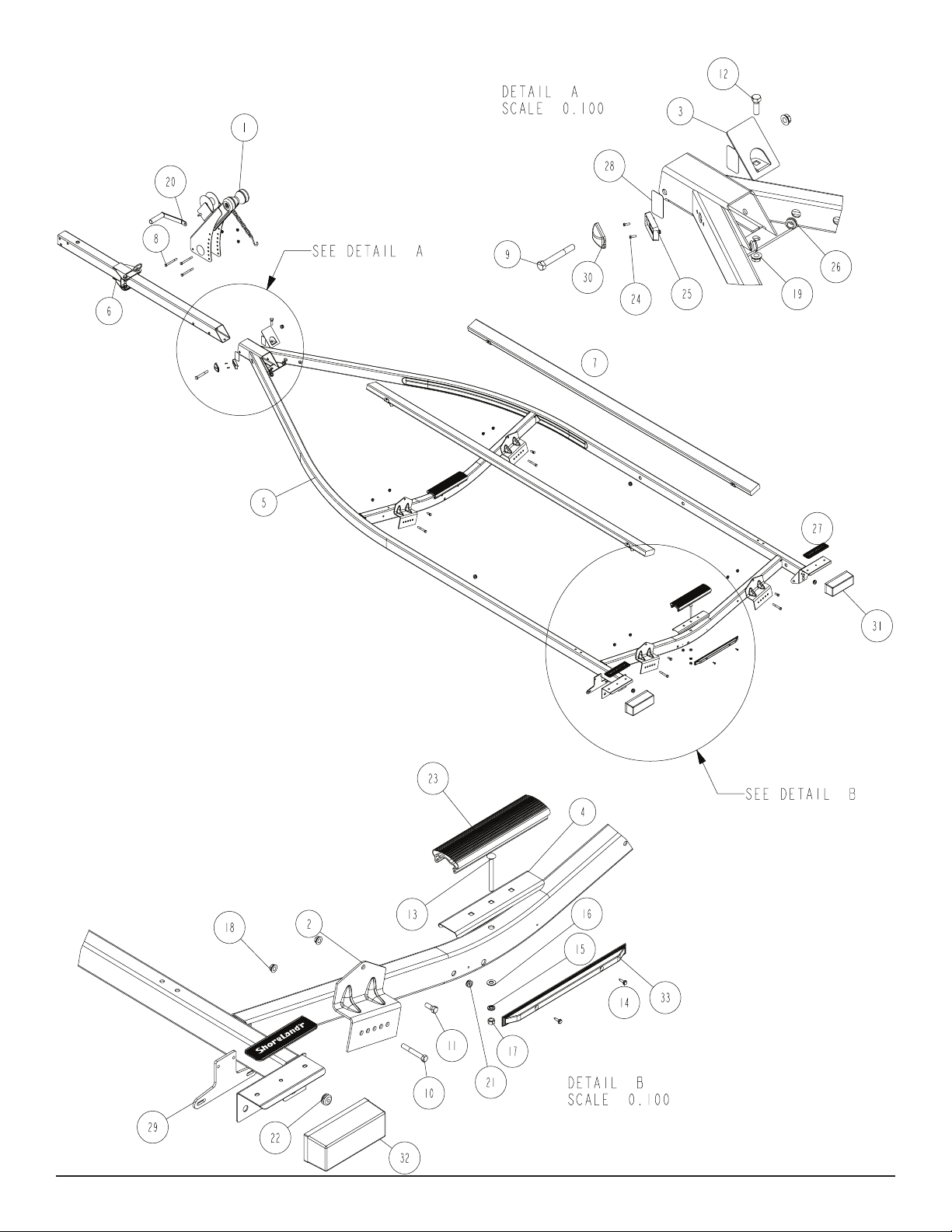

V-BUNK ASSEMBLY (V-SERIES)

Position the bunks so that they are above the bunk brackets attached to the front and rear cross members. (See Detail B) Secure

the brackets on the bunk to the upright brackets with 3/8” X 1” hex

bolts and hex lock nuts. Tighten but do not over tighten because the

bunks must be able to rotate to conform to the boat bottom.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004036

REV A 01/05/2009

Page 5

Page 6

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004036

REV A 01/05/2009

Page 6

Page 7

SPRINGS

Positions the axle so that it is aligned with the trailer.

Place the springs on the top side of the spring pads welded to the axle.

(See chassis diagram on page 4.) The hook end of the spring must be

mounted to the rear of the trailer. Place a spring clamp on the top center

of the spring. Place the 1/2” X 6-1/2” U-bolts over the top of the spring

clamp, spring and axle. Place the spring and axle U-bolt plate onto the

ends of the two U-bolts. Secure in place with 1/2” lock nuts. Tighten.

AXLE

Place a spring bracket bushing (Ref.#9, Detail E) into the rear of the

spring bracket and secure with a 9/16” x 3-1/4” hex bolt and hex lock nut.

Repeat in the other spring bracket. Position the axle under the frame,

hook the hook loop of the spring around the bushings just installed.

Note: If the axle is positioned too low, the hooks will not hook around the

bushings.

Raise the front of the springs up so they align with the front hole of

the spring bracket. Secure in place with 9/16” X 3-1/4” hex bolts and

lock nuts. Tighten all axle U-bolts and spring bolts.

TIRE & WHEEL ASSEMBLY

Mount the tire and wheel assemblies using the 1/2” ne threaded tapered lug nuts provided. Tighten to 85-95 ft./lb. of torque using the rotation pattern as shown in the ShoreLandr’s Owners Manual.

Re-torque the lug nuts a ft er 50 miles of driving and then

periodically thereafter.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004036

REV A 01/05/2009

Page 7

Page 8

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004036

REV A 01/05/2009

Page 8

Page 9

TRAILER ADJUSTMENTS

Axle Adjustment

The amount of tongue weight on your trailer can be adjusted as

follows: To lower the tongue weight, adjust the axle assembly

forward. To increase the tongue weight, adjust the axle assembly

backward. The distance that the axle assembly has to be moved will

vary because it is directly related to the weight and center of gravity

of the boat placed on it. Best towing is achieved when the tongue

weight is 5-7% of the total gross load of the complete unit.

NOTE: The wire harness will need care when moving the

assembly.

Rear Support System

Place the boat on the trailer so that the transom is located

at the en d of t he bun k. Th e center of the re ar rolle rs on

the roller rack should be approximately 4” from the transom. This gives you maximum support on the transom.

The bunks must be positioned far enough apart to give your boat

as much stability as possible while transporting. Position the bunks

so they are located just to the outside of the boat’s strake. This will

help center your boat and assist when loading.

FRONT SUPPORT SYSTEM

Bunk

The front bunks should be adjusted either in or out so that the bunk

will continue to run just to the outside of the strake of the boat. Adjust

the bunks up so that there is approximately 1” clearance between

the keel of the boat and the center cross member pad.

Winch Post Adjustment

Slide the winch post assembly back towards the boat. The bow stop

roller needs to be located directly above the boat bow eye to prevent

your boat from moving froward in the event of a sudden stop.

Note t h at the o u ter w i n ch bas e h as sev e ral ho l e s of

adjustment. Changing the bolt location will change the angle of the

winch post and will raise or lower the height of the bow roller. Choose

the bolt location which best matches it to the bow eye height.

Th e in ner and oute r wi nch post ch ann els can te les cope

either i n or o ut with r es pe ct to each o th er to lengthen o r

shorten the overall length of the post. Loosen the two bolts

located on the back, inside of the channels. Attach the winch

strap into the bow e ye and crank the w inch s tr ap in u nt il

the bow eye is located in it’s proper position just above the

bow eye. Slide the inner post in or out to a desired length.

Once the bow stop roller is located in it’s proper position above the bow

eye, tighten the bolts that secure the assembly to the tongue.

Attach the bow eye safety chain into the bow eye as well.

This is another level of protectio n to keep your trailer and

bo at to gethe r a s on e u nit . I t m ay be used to keep yo ur

boat on the trailer while loading and unloading at the ramp,

especially with a roller trailer.

Adjustments are now complete. Double check your boat

for t. If desired t has been achieved, tighten all fasteners that may have either been left loose or have been

loosened to do the adjusting.

See your ShoreLand’r Owner ’s Guide f o r further

tec hni c al info rma t ion reg ard ing you r tr a ile r an d it s

components.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004036

REV A 01/05/2009

Page 9

Page 10

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004036

REV A 01/05/2009

Page 10

Loading...

Loading...