SPECIFICATPONS

CAPACITY____________________________.

Width of

Depth of

Ra

DIMENSIONS______________________._

FENCE

FENCE

TlLT_________I____________________________________________________________________________________________________________

STOPS__________________________________________________________________________________________________________________

lnfeed

Outfeed

Overall Table

Fence_..___....___..___________________________________________________________________3”

Cutter Head

Rabbeting

Jointer

KNIVES._________________________________________________________________________________________________________________________._____

BEARINGS________________________________________________________________________________________________________________________

SPEED

_________________________________________________________________________________________________________________________________

SHIPPING

WEIGHT________________________________________________________________________________________________________47

Cut____________________________________________________________________4”

Cut..____________________________________________._____________________5/

bbet

Cut________________________________________-______________________________~5/

Table______________________________________________________________________

Ta

ble__________________________________________________________________4-1/2”

Length________________________________________________________.Z8”

Diameter____________________________________________________2-~~”

Ledge______________________________________________________________Z-~

(overall)__________________________________________________________________

16”

16”

5-,/z”

x I3-1/4”

x I

3-1/4”

highx 2 I

”

wide

7”

kgh

long

45 degrees

right

adiustable

90

and 45 degrees

-3/4” long

x 9”

wide x

left +o 45

auto-stops at 45,

3 (precision-ground

32-1/2”

degrees

steel)

2 (lubricated for life)

5000

rpm [recommended)

lbs., 12 oz.

HOW TO OPERATE AND MAINTAIN

Magna 4” Jointer--Model 4E

Purchase of the

toward proficient woodworking. Like SHOPSMITH, the

Jointer is designed to accomplish quickly and accurately

many operations requiring tedious hours of labor if done

by hand. Basically, it is a rotary cutter which will plane

edges smooth and square, ready for gluing or assembling.

It will also do a fine job on light surfacing cuts but should

not be confused with the Thickness Planer as Jointers often

are. The latter is a very heavy industrial machine designed

to dress stock to exact thicknesses.

The basic usefulness of the Jointer is illustrated by a

quick preview of standard operational procedure on a

saw-jointer combination such as you have available with

SH6PSMITH.

MAGNA 4”

When cutting

JOINTER

stbck

is

another step

to width you first

establish a smooth, s uare

jointing cut on one

the rip fence during the rip cut on the saw. Then the

second edge is jointed. The rip cut is made oversize to

compensate for stock removal when making the second

jointer cut. Thus

sions and also

no further attention.

Complete information for mounting the MAGNA 4”

JOINTER on SHOPSMITH is contained in the MOUNTING KIT

in the MOUNTING KIT carton.

should be all set, ready for simultaneous operation with

the SHOPSMITH table saw to make homeworkshop

ity

(accessory no.

still easier, more professional and more productive.

3

e

ou

have sized your stock to exact dimen-

oitained

“work-edge“ by making a

ge of the stock. This edge rides

smooth, square edges requiring

I I

52 I)

instruction sheet packed

At

this stage the Jointer

activ-

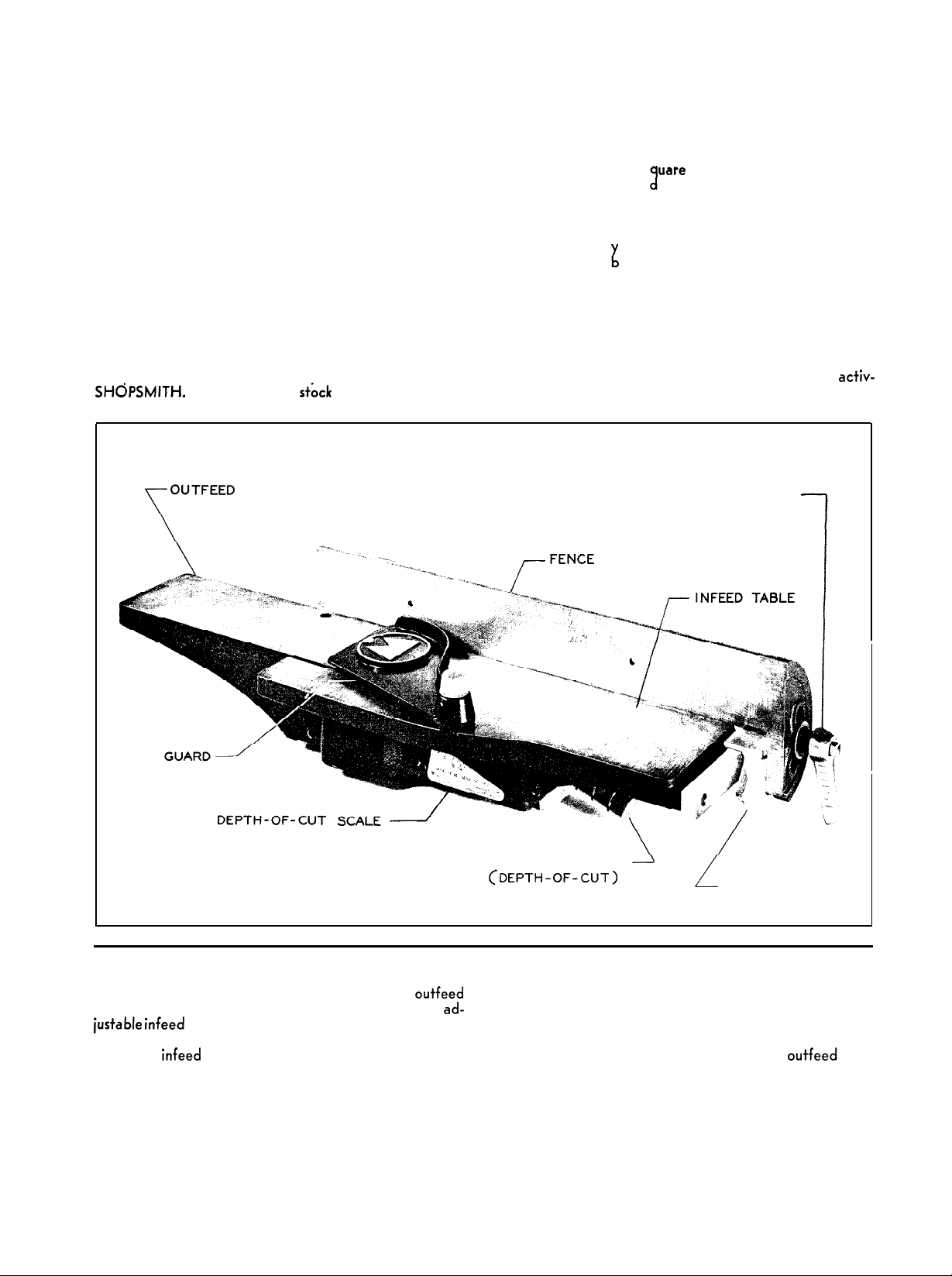

OUTFEED

TABLE

ADJUSTMENT KNOB

(DEPTH-OF-CUT)

TWO-SOCKET WRENCH

-

QUADRANT

JOINTER

The MAGNA

table (cast integrally with the Jointer base) and an

justable

settings with an easy-to-grip hand knob. How far you

lower the

which is removed during the pass. On the MAGNA

JOINTER this setting does not have to be measured; it

may be taken directly from the indicator scale.

nomenclature

4” JOINTER

infeed

table which is controlled for depth-of-cut

infeed

table determines the amount of wood

(Fig. I), has a fixed

outfeed

ad-

A dual purpose “two-socket” wrench is used to lock the

fence in any position across the tables and at any degree

of tilt.

The guard, which should be positioned as shown for

most operations, may also be located on the outfeed, table

to cover the exposed cutter head behind the fence when

doing rabbeting operations. On very wide rabbets, where

little of the cutter head is exposed, this is not necessary.

2

HOW TO ADJUST THE JOINTER

The Jointer has been factory adjusted and tested for accuracy. It will operate to high standards if used and maintained correctly. Correct procedures for adjustment and periodical checking are described in the following paragraphs. READ THE INSTRUCTIONS CAREFULLY. The MAGNA 4” JOINTER

deserves the best of care.

is a valuable, precision machine which

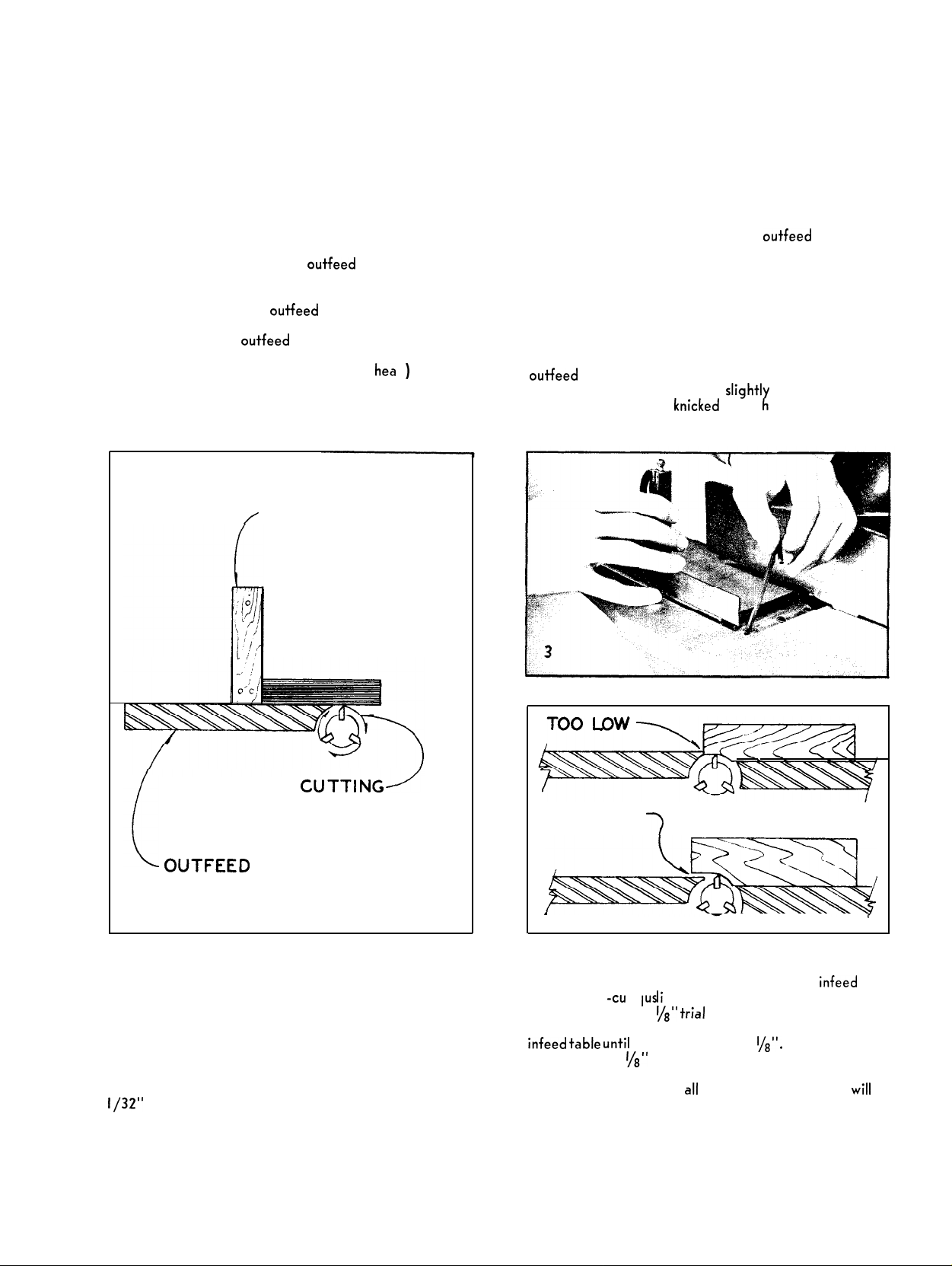

Knife adjustment

The combination of fixed

adjusted knives in the MAGNA 4” JOINTER make the

one critical Jointer adjustment a very simple matter. The

horizontal plane of the

to the cutting circle of the knives. Check this by placing a

straight edge on the

the cutter head. Turn the cutter head by hand

-use hands on the belt, not the cutter

knife is at the top-most point of the cutting circle. The

knife should bare yIscrape the straight edge. If it lifts

the straight edge, the knife is set too high. If it does

not touch at all, the knife is set too low (Fig. 2).

outfeed

/

STRAIGHT

outfeed

outfeed

table so that is juts out over

table and easily

table must be tangent

CAUTION

6

)

until one

hea

EDGE

does not the work will not clear the

a rabbet cut.

Lock

The check on blade height and blade position in the cutter

head should be made on all three knives.

alignment are these (Fig. 4): If, after passing over the

cutter head, the edge of the work hits the edge of the

outfeed

set too low. If the work drops

the pass resulting in a knicked end,

high.

the wedge in place with the three Allen screws.

Operational danger signals which will indicate mis-

table and must be forced across, the knives are

slight1

outfeed

K

t

table during

at the very end of

e

knives are set too

CUTTING1

CIRCLE

OUTFEED

TABLE

2

Make this

is required, loosen the three Allen screws which lock the

knife-retaining wedge. Adjust the two Allen screws on

which the knife rests (Fig. 3). If the knife is too high the

screws should be lowered-if the knife is too low the

screws should be raised.

After the knife is adjusted for height,

tion in the cutter head. The forward edge of the knife

(edge nearest the rabbeting ledge), should extend about

l/32”

check

at both ends of the knife. If adjustment

check

it for posi-

beyond the ron ef t dge of the out-feed table. If it

TOO HIGH

-I

1

4

,

Adjusting for depth-of-cut

Turning the hand knob clockwise lowers the infeed table

for depth- f t d’ to

the pointer, make a l/e”

sure the cut in the wood and, if necessary, adjust the

infeed table until

exactly on the l/e”

which should be made periodically consistent with proper

machine maintenance,

correct.

-cu

a

ius

ments. To check the accuracy of

trial

cut in a piece of stock. Mea-

the cut is exactly I/B”. Set the pointer

mark (Fig. 5). After this adjustment,

aII

other pointer settings

wiII

be

Adjusting the guard

The cap on the guard of the MAGNA 4” JOINTER

contains a spring which supplies the pressure that automatically keeps the guard over the cutter head. During

the pass, the guard covers the unused section of the

cutter head while the work itself covers that area which

is cutting. The side pressure of the guard also helps to

keep the work against the fence. NEVER WORK WITH-

OUT THE GUARD UNLESS

SARY. It was designed for your safety.

IT IS ABSOLUTELY

NECES-

Fence adjustments

In normal operating position the fence should be

perpendicular to the horizontal plane of the tables. To

check, follow this procedure. Use the two-socket wrench

to loosen the nut which secures fence tilt. Set the fence

on the quadrant “zero”

square (Fig. 7). If the fence should require a slight adjustment

loosen the two slotted screws which hold the fence

bar to the Jointer. Adjust the bar until the fence checks

out exactly square to the tables. Lock the slotted screws.

mark and lock it. Check with a

To put the guard in place

(Fig. 6) and slip the hex shaft in t

of the rabbeting ledge while you hold the cap. It is never

necessary to apply excessive spring pressure on the guard

-one full revolution of the cap is sufficient for virtually

all operations.

THEN SET POINTER EXACTLY ON

mere1

‘18

turn the cap clockwise

x

e

hex hole at the front

IN. DEPTH OF CUT

b’;

5

TURN CAP CLOCKWISE

ONE REVOLUTION

The auto-stop for the 90 degree position may be adjusted now (Fig. 8). Bring the stop forward and thread the

screw down until its

screw setting with the nut. Now, when the fence has been

tilted and you want it back to the 90 degree setting,

simply bring the stop forward and tilt the fence up until

the

adiustment

cedure with the fence tilted forward 45 degrees and again

with the fence tilted back 45 degrees. Thus you have

accurate, automatic stops at the three most used fence

positions.

To move the fence across the table loosen the locking

nut (Fig. 9) set the fence where needed and lock the nut.

ADJUST SCREW

LOCK

JAM NUT

end

bears against the stop. Lock the

screw hits the stop. Follow this same pro-

FENCE

\

STOP IN FORWARD

POSITION

8

MOVEMENT ACROSS TABLE LOCKED WITH THIS NUT

9

\

STOP IN NEUTRAL

POSITION

FENCE TILT LOCKED WITH THIS NUT

I-

TWO WAY SOCKET WRENCH

OPERAT ION

The Jointer is used to plane edges square and smooth

and to accomplish other cuts such as those shown in

Fig. IO. Jointing-planing the edge of a board-should

always be done with the grain of the wood. Working

against the grain seldom produces a satisfactory surface

and also increases the danger of kickback (Fig.

Depth-of-cut settings on jointing operations should

never exceed

I/

16”

does a good job and wastes less wood.

Although the jointing operation is a smooth movement

from start to finish it is best shown in three steps. The

best side of the stock is placed against the fence with

the work edge down on the

should be placed as shown to hold the work down on the

table and snug against the fence. THE GUARD SHOULD

BE IN PLACE AT ALL TIMES AS SHOWN. The guard

is removed in some of the photos but this is only to show

the operation more clearly.

t/s”.

Normally, a setting of from

infeed

table (Fig. 12). Hands

I I).

l/32”

to

RIGHT

WRONG

I I

DIRECTION OF FEED

As the work advances over the cutter head the guard

moves aside to permit its passage. The left hand does

most of the work of keeping the stock snug against the

fence and down on the tables (Fig.

hand moves it forward. Some operators object to passing

either hand over the cutter head but if the work is wide

enough and the guard is used, there is little danger if

the hands are positioned as shown. It also eliminates the

need for repositioning the hands during the pass-a procedure which could be more dangerous.

At the

end

of the cut (Fig.

about the same position. Avoid heavy downward pressure

at the end of the cut since this might tilt the work into

the cutter which would result in a gouged end.

l3),

while the right

14)

the hands are still in

5

The two holes in the Jointer fence permit mounting a

J/4”

plywood auxiliary fence when a quantity of extra wide

boards must be jointed. Attach it with two I” F. H. screws

inserted from the back side of the Jointer fence (Fig. 15).

Jointing end grain requires two passes (Fig.

the first pass to the point where the work has passed about

I” across the cutter head. Then turn the work around and

complete the pass as shown.

The Jointer may also be used to do light surfacing

operations. Depth-of-cut should never exceed

work is placed flat on the

the cutter head as in jointing (Fig.

the combination pusher-hold down. This tool, which you

can easily make yourself (Fig.

surfacing operations.

infeed

table and advanced over

IT).

Notice the use of

l8),

should be used on all

16).

I /

16”.

Make

The

Rabbeting

Rabbeting is done by bringing the fence across the

table and locking it a distance away from the ends of the

knives equal to the width of the rabbet required.

of-cut for the rabbet is gauged by lowering the

table. The

cutter

to

5/l

wide (over

tion so that t e same maximum depth-of-cut adjustment

should be observed. However, the full depth-of-cut can be

achieved by making successive passes lowering the table

after each pass until the cut is complete.

For rabbets that are

cut can be attained in two passes. Full depth-of-cut on

rabbets under t/z”

Support for the work is provided by the

and rabbeting ledge regardless of whether the work is

held flat on the table (Fig.

ass is made by advancing the work over the

hea

cf

as in jointing. Rabbet cuts may be made up

6”

deep and 4” wide. When the rabbet is extra

the action is similar to a surfacing opera-

I” ,

I,

to

I”

l/z”

can be accomplished in a single pass.

wide the full

19),

or on edge (Fig. 20).

depth-of-

infeed

Depth-

infeed

table

lb

FIRST PASS

SECOND PASS

Bevel cuts

To make bevel cuts, tilt the fence to the angle desired

(Fig. 2

1)’

and pass the work across the cutter head while

maintaining full contact with the fence. It is

sary to make more than one pass before the Level is

complete.

6

usual1

neces-

Recessing

A

recess cut (often called stop

most often

in base members and t

stand legs. It is formed by using sto

ends

of the cut. The work

a

block and d

vanced

Then it is turned

shown in Fig.

23.

until it hits the rear block (Fig. 22).

and a second pass made.

is

R

place

ed

chamfering) is used

e

bottoms of

table and

blocks to gauge the

B

against the forward

The result is

NOTE: CENTER MAY BE CUT OR SANDED OFF

-

OR RETAINED AS DECORATIVE DETAIL.

CARE OF JOINTER KNIVES

With proper care and occasional honing the Jointer knives will function for a long time without regrinding. Occasionally the

knives should be cleansed of the gum and pitch which will adhere to them. If this accumulates it will reduce the efficiency of the knives.

A good way to clean them is to spray them with SHOPSMITH RUST PREVENTIVE (accessory no.

minutes and then wipe off with a rag.

To hone them, wrap an

covered end of the stone on the table so that the exposed end juts out over the cutter head (Fig. 24). The cutter head should be

turned to allow the stone to rest flat on the bevel of the knife. Hold the cutter head in this position (by gripping the drive belt) and

move the stone back and forth across the knife. Hone an equal amount on each knife.

When knives are chipped or otherwise dulled beyond resharpening by honing they must be removed from the cutter head and

refinished on a grinding wheel. Through the use of special homemade jigs this can be accomplished on the table saw (Fig.

losing

SHOPSMITH as a tool sharpener (Fig. 26). (Note-Figs.

FOR EVERYONE.)

Knives that have been reground enough to bring the knife width down to less than I

recommended.

oilstone

in paper leaving about I”

of it exposed. Lower the

25 and 26 are from the new book POWER TOOL WOODWORKING

l/16”

I2

049).

Let this soak in for a few

infeed

table about l/g” and rest the

should be discarded. Further use is not

25)’

paper-

or by

GENERAL MAINTENANCE AND LUBRICATION

The two grease-sealed bearings on which the cutter head revolves do not require lubrication.

attention for the life of the Jointer.

The ground surfaces of the fence,

occasional coating of hard paste wax will do a good job.

If the Jointer is idle for long periods of time the surfaces should be coated with SHOPSMITH RUST PREVENTIVE SPRAY.

Occasionally, place a few drops of light machine oil on the fence bar, in the semi-circular groove in the quadrant, and on the

infeed

table inclined ways.

The MAGNA JOINTER

many people who still do not own a SHOPSMITH

is given in Fig. 27.

as exceptionally long tables for a 4” Jointer. For this and other reasons which mark it a superior machine,

h

infeed

table and

outfeed

table should be protected to insure clean, smooth operation. An

h

ave requested information for mounting it as a single-purpose tool. This information

They will function without further

4”

JOINTER STAND

ASSEMBLE WITH GLUE AND FINISHING NAILS.

MOUNT JOINTER WITH 3,

3,

‘/4” SQ.

NUTS, AND

INSTALL STOPS WITH N0.8~1” FLAT HD

USE 45 INCH. BELT.

LEG SECTION

I

..I

SIDE

PANEL

FRONT

LEG,

\ 3/8”X450 )

+---

/

‘14 it

0.

V4

”

WASHERS.

I5 ”

- 14”

2 ” STD.

----A

-----I

SQ.

-- SLIDE STOPS

HD. BOLTS,

WOOD SCREWS.

DRILL 3,

5/16”

SEE DETAIL B FOR

LOCATION OF HOLES

TOP,

3/4”

PLYWOOD

SLIDE,

3/8”

SIDES,

l/2” ”

BACK,

l/2* ”

SHEU; 7/8”

LEGS, I

l/2 0

SLIDE STOPS . . . . . .

l/2 ‘I.

. STOCK

SHELF STOPS. . . . . .

V8”O xl2

”

”

HOLES.

I’2

,-‘--

*Tiiu

SECTION A - A

/------

7

I7

v$--pd

DETAIL

B

27

/STONE

24

WITH END WRAPPED IN

INFEED TABLE

’

P 6306

B 2906

P I

I26

B 2904 _

p

--_-

-------

___.__

MAGNA 4” JOINTER PARTS LIST

_,

/-----6307

Asm bly.

NQ.

B 2959

P 1653

A 2951

A 2950

A 2960

P

1385

B 2793

P 6308 Screw--Machine

P 1404

A

2912

P

1507

P

A

2961 Washer-Spring

P

I15140

B

2906

B 2902

P 6306

A 3050

P 6307

P 1529 Washer-Lock

B 3051

P 1014

II5130

D

2921

P 6300 Screw---Set

P

1449 Nut-Jam

P 6304 Screw-Hex. Cap

B 2924 Wrench--Fence Lock

P 1450 Nut-Hex.

P

1528 Washer

B 3076

I15131

II5150

KIescription

Indicator---Depth

Screw-Drive

Screw--Depth

S+Iid-Table Mourit

Pointer-Depth

Screw--Pan Head

Bar-Fence

Not-Square

Knob-Adjusting

Washer

1451

Nut-Hex.

1917

Key-Allen

CUTTER HEAD ASSEMBLY

Blade

Wedge

Screw-Sot. Set

Screw-Set

Screw-Hex. Cap

Puliey

Screw---Sot. Set

FENCE ASSEMBLY

Fence

Pin-dowei

Qtladrant

GUARD ASSEMBLY

. . . . . .

. . . . . . , .

. . . . . . . . . . 3

. . , . . . . . . 3

. . . . . . . . .

. . . . . . . . . . I

. . . . . . . . .

Assembly

. . . . . . . . I

. . . ~ . . . .

. . . . . . ~ . I

. . . . . . . .

. . . . . . .

. . . . . . . .

. . . . . . . .

. . . . . . I

. . . . . . .

. . . . . . f I

. . I .

. . . . . , .

. . . . . I

. . . . , .

. I . . . .

. . . . . .

. . . . . .

. . . . . .

. . . . . ~ .

. . . . . .

. . . . .

. . . . . . . .

. . . . .

. . . .

. . . . .

.

.

. . I

.-

3

3

9

6

2

I

3

2

I

2

I

I

I

I

I

I

I

I

I

I

2

2

15.95 7

4.95 8

I

.20 5

.I0

_

.25

_. IO

.I5

I

.05

3

.lO.

3

I .OO _

.I0

__ 3

.05

3

.05 3

.05

.lO.

3

.I0 ._..

.lO.

3

.I0

3

7.95 IO

.lO.

3

.05

3

.05

.05

.

3

3

IO

When ordering parts from the above list be sure to supply part

number and description for each item plus the model and serial

3

3

3

number of your machine. This information should be provided to the

dealer from whom you purchased the Jointer.

Because the

aligned it is not advisable to supply them separately. Should it ever

become necessary to replace either of the tables, ship the entire

chine, less mounting kit, guard and fence to the factory nearest you.

MAGNA ENGINEERING CORP.

Berkeley, California

tory job.

order a new cutter head assembly

one to us for rebuilding.

When it is necessary to return parts directly to the factory be

sure to package securely, insure sufficiently and ship prepaid.

Parts which are

called out

require factory trained help for replacement-therefore they cannot

be supplied as replacement parts.

infeed

table and

2550 Ninth Street

If the bearings or the

shown in the exploded views but which are not

in the parts list are either permanently assembled or

outfeed

table must be perfectly

MAGNA CORPORATION

12819 Coit Road

Cleveland, 0 hio

cutter head ever need replacing,

( # I

I5I40),

or return the old

ma-

Should you desire further information on Jointer techniques and procedures as well as detailed instructions

for all power tool applications, see the new

R. J.

DeCristoforo,

which is available through your local SHOPSMITH dealer.

book,

Magna Engineering Corporation

8 53

9048

Copyright

1953---Magna

Engineering Corporation

POWER TOOL WOODWORKING FOR EVERYONE by

PLANTS IN BERKELEY AND CLEVELAND

Loading...

Loading...