Shopsmith A-34 Owners Guide

MODEL

ARTICLE

NO.

NO.

A·34

84-3452

~HDP

.,MITH

JIGSAW

MAGNA

ENGINEERING

CORPORATION

or-

JIGSA

W FRAME ASSEMBLED

E-!'"

LEVELING SCREWS

MOUNTING BOLT

MOUNTING

BOLT SPACER

Fig

, I

JIGSAW TABLE INSERT

SHOPSMITH

The

jigsaw,

most satisfactory power tools

and

perform th e

circular

precision. And when the jigsaw blade

file

or sanding drum, wood, metal or plastic can

PACKING

see if you

ding

che

1. Jigsaw

2. Jigsaw table insert.

3. Mounting

4. Mounti

fr

ame is.removedl.

5.

Setscrew and jam nut leveling screws

~Is·o

known

.n

scroll

s~w,

is one

to use. While it canno t

hoavy cutting jobs

saw

, it shapos irregular contours with easo and

LIST-Aft

have

all

Fig

. I.

fr~me

bolt.

ng

bolt spacer (for

er unpac

parts, which

assembled.

which

are

is

king

your jigsaw check to

you

can eas

s~ber

sawing when upper

INTRODUCTION

of the safest

so

easy for the

replaced

be

with

fab-

a

INSTALLATION

ily identify by

(2).

PREPARING SHOPSMITH TO

SAW-

I. Facing the

extreme

extreme right.

2.

3.

below E 8b99, move the

end of th e

This

SMITH

JIGSAW

ricated or finish ed speedily and with little effort.

Evon

~n

amateur can

fully

utililo and enjoy the many special features of the

SHOPSMITH

set up. Before using your jigsaw, read the f

structio

ns

left e

Remove tho

Important:

is

not

is

JIGSAW,

caro

fully

.

SHOPSMITH

nd

of the ways and the law table

pull

ey guard and pulloy guard scr

If

your

quill protrudes beyond tho gaugo collar

necessary

above E 8b99.

use

tho jigsaw

it

is

ossential that it

MOUNT

, position the head ·stock at

SHOPSMITH

gauge

collar (102-3) back unt

if

the serial number of your

has

skillfully,

~

be

ollowi

THE JIG-

seri~1

but

correctly

ng in-

at

the

ew.

number

il

th e

¥e

".

SHOp

to

·

2

4. Loolen th e

5.

Rem

6. T

urn

flot on the spindl

MOUNTING

ove·the

the hea

quill

lock

tab

le

insert plate.

d,t

ock pulley by

e tip isfocing

THE

JIGSAW-

lever.

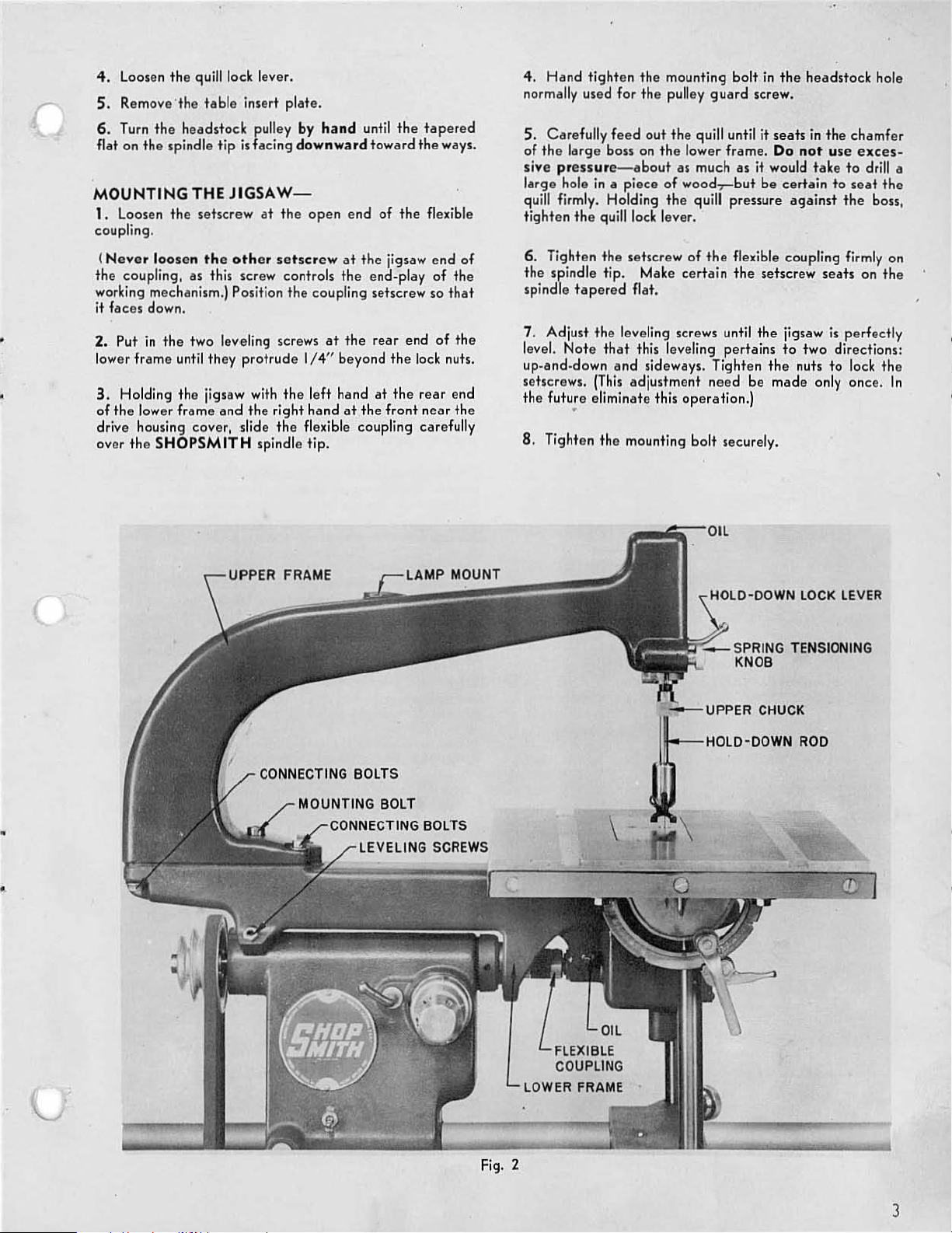

1. Loosen the setscrew at the

lin

coup

g.

hand

until

downward

ope

toward the ways.

n end of the flexible

the

tap

ered

4.

Hand tighten the mounting bolt

normally used for the pulley guard screw.

5.

Care

full

y feed out the q

of the large boss on the lower frame. Do

sive press

large hole

quill

ti

ghten th e quill l

urc-about as much as

in a pi

ece of woodT"but be certain

firml

y.

Holding the quill pressure

ock

uill

lever.

in

the headstock hole

until it seats

it

would take

in

not

aga

inst the b

the chamfer

use

exces

to

drill a

to

seat the

oss,

-

( N

eve

r loosen

coupling. as th

the

working mechanism .,

it facel down

2. Put

low

in

er frame until they protrude 1/ 4" beyond the

3. Holding the

low

of the

drive housing cove

over th e

SHOPSMITH

the

other

setscrew

is

screw controls the end-play of the

Pos

ition the coupling setscrew so thot

.

the two leveling scre

jig

saw

with

er frame and the right ha

r,

slide the flexibl e coupling carefully

spindle tip.

ws

the left hand

FRAME

at the jigsaw end of

at

the rear end of th e

nd

at the front near the

at

the r

lock

ear

nuh.

end

6. Tighten the le

the spindle tip.

spindle

tap

hcr

ew

of

the flexible coupling firmly on

Make certa in the setscrew seats

ered flat.

7. Adjust the leveling screws until the jigsaw

lev

el.

Note that

up-and-down a

setscrewi.

the futu

:e

8. Tighten th e mounting bo

this leveling pertains to two directions:

nd

sideways. Tighten the nuts to

(This

adjustment

eliminate this operation.)

need

be mad e on

lt

securely.

c

HIOllD-'.O.'"

S

PRING

KNOB

LOCK LEVER

TENSIONING

on

is

perfectly

lock

ly

once.

the

the

In

•

•

C

ONNECTING

MOUNTING

BOLTS

BOLT

LEVELING

BOLTS

SCRE

WS

\

_--UPPER

I!--

HOLD

CHUCK

-DO

WN

ROD

•

Fig

. 2

3

Loading...

Loading...