Shopsmith 555970 User Manual

MARK V – MOUNTED OVERARM PIN ROUTER 555970

MARK V

MOUNTED O VERARM PIN R OUTER

555970

TABLE OF CONTENTS

INTRODUCTION ........................................................................................................................2

SAFETY ......................................................................................................................................3

TYPES OF ROUTER BITS.........................................................................................................8

TERMS TO KNOW ...................................................................................................................10

OVERARM ROUTER ASSEMBLY ........................................................................................... 11

ALIGNMENT AND ADJUSTMENT ...........................................................................................16

OVERARM PIN ROUTING OPERATIONS...............................................................................18

GENERAL GUIDELINES FOR BOTH TYPES OF OVERARM ROUTING ..............................18

ROUTER DUPLICATION USING SHOP MADE FIXTURES....................................................20

CONVENTIONAL ROUTING OPERATIONS WITH THE OVERARM ROUTER .....................30

CARING FOR YOUR SHOPSMITH OVERARM PIN ROUTER...............................................39

MAINTENANCE........................................................................................................................41

TROUBLESHOOTING GUIDE .................................................................................................42

1

555970 MARK V – MOUNTED OVERARM PIN ROUTER

INTRODUCTION

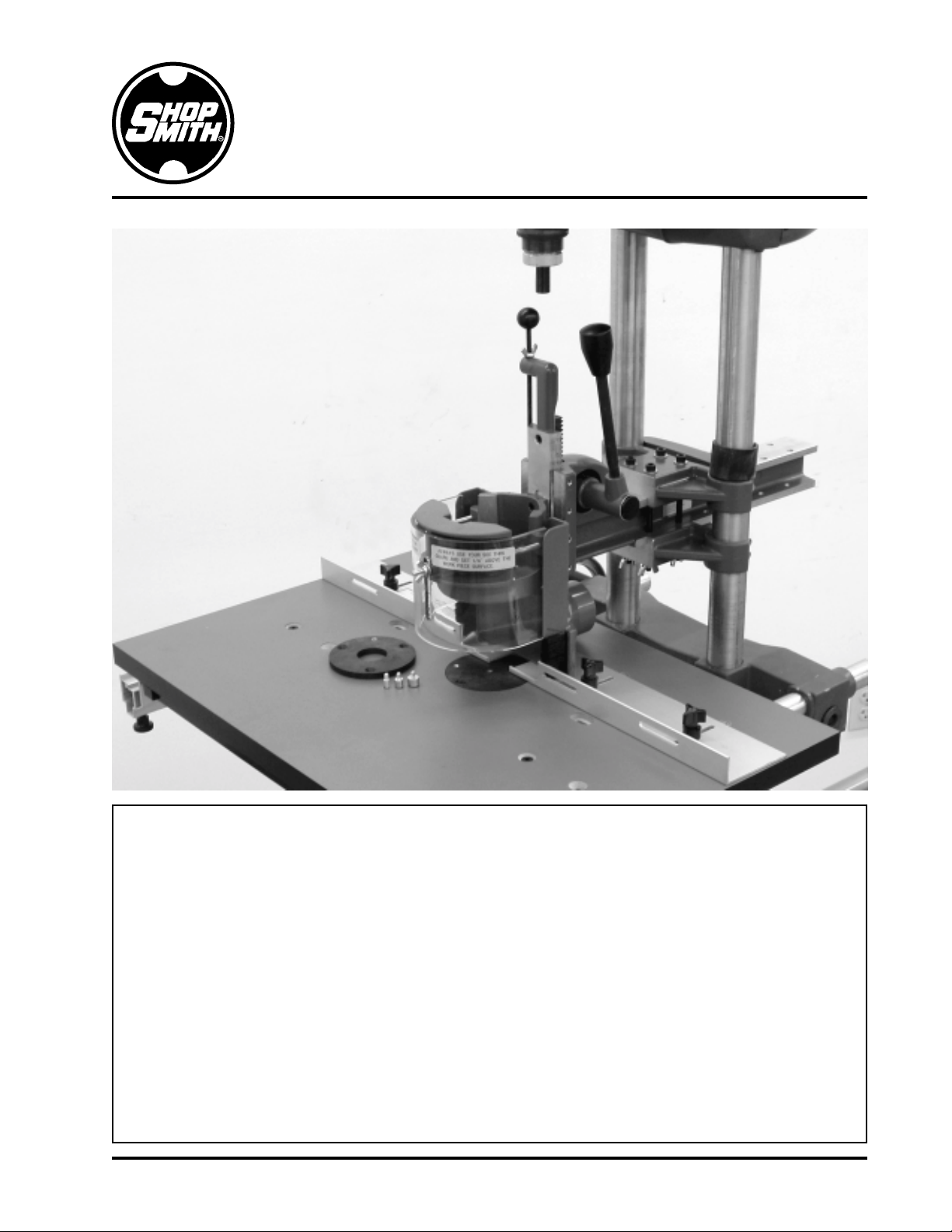

Shopsmith’s MARK-V Mounted Overarm

Pin Router can perform many jobs that are

normally intended for other tools...and it

can usually perform these operations much

faster and with far greater precision and repeatability than you could hope to achieve

using more conventional methods.

It’s called an Overarm Router because it operates with the rotating bit

workpiece rather than below it...providing

a clear view of what’s going on at all times

while you’re cutting...unlike a typical router

table set-up where the bit makes its cuts on

the underside of your workpiece.

This approach also means that you won’t

need a costly, under-table router motor lift

to help you make precise depth-of-cut adjustments. With the MARK-V Mounted

Overarm Pin Router, these adjustments are

made using your Overarm Router’s Quill

Lever, just as you would when drilling holes

or performing similar operations with a drill

press or your MARK V.

WHAT CAN I DO WITH THIS TOOL?

Those who are familiar with Pin Routers often believe that the only operation such a

machine will perform is duplicate routing,

This simply isn’t true!

In fact, Shopsmith’s Overarm Pin Router will

perform any operation that can be performed with a typical router table. As a result, you’ll soon find yourself reaching for

your Overarm Router for a multitude of

woodworking operations, including:

• Basic straight-line routing operations

• Routing decorative edges and surface designs on straight, round or curved

workpieces of all types, including furniture, cabinets, tabletops, etc.

• Cutting precision dadoes, grooves, rab-

above the

bets, dovetails and other types of structural joints

• Making all types of stopped cuts

• Repairing furniture and veneers

• Jointing the edges of workpieces

• “Sawing” straight and irregular shapes

• Drilling holes

• Pin routing duplicate workpieces with

matchless repeatability

WHAT IS PIN ROUTING?

Pin Routing is a simple operation through

which you can quickly and easily make

many duplicate copies of a particular project

and have each one turn out exactly the same.

In fact, prior to the introduction of CNC

(computer numerically controlled) Routers,

this was one of the primary processes used

by most furniture manufacturers when cutting-out odd-shaped project components.

In a nutshell, here’s how it works:

• A template or fixture is created by cutting

3/8" deep grooves (1/4", 3/8" or 1/2"

wide) that exactly match the shape of the

workpieces you’re making

• A straight router bit is then inserted into

your router motor.. .which is mounted in

the Overarm Router

• A tracing pin (same size as your straight

bit: either 1/4", 3/8" or 1/2") is inserted

into the Overarm Router’s Table Plate –

and the pin and router bit are aligned perfectly with one another

• A workpiece blank is temporarily attached

to the back side of the template containing

the pattern groove

• The template or fixture is flipped over

(workpiece attached) and its groove

dropped over the tracing pin

• The router is turned on and the bit lowered into the workpiece while the groove

2

2

MARK V – MOUNTED OVERARM PIN ROUTER 555970

is traced over the table pin, creating a finished piece that’s exactly the same size and

shape as the groove in your template or

fixture

• Remove the workpiece, replace with a new

blank and repeat the process above...as

many times as you like

Once you’ve made a template or fixture, cut

out as many parts as you like, then set the

template aside until the next time you want

to make more of the same project. It will be

ready when you are.

We know that you’re eager to get started using your Overarm Router, but please take the

time to read this manual before you begin.

Then keep it handy for future reference.

OVERARM ROUTER

SPECIFICATIONS:

Maximum router motor HP..........................3 hp

Diameters of router motors

accepted (round motors only)................. 2-1/2" to 4"

Throat depth (router bit

centerpoint to Way T ubes)*.........10-1/2" to 18-1/2"†

SAFETY

WARNING

Read this safety section and complete

the Assembly procedures BEFORE operating your Shopsmith Overarm Pin

Router

Shopsmith’s MARK V-mounted Pin Router

offers many built-in safety features. However, the effectiveness of these features depends on you. Power tool safety requires

good common sense, and misuse of this

tool can cause serious injury.

To protect yourself from injury:

• READ, UNDERSTAND AND FOLLOW

ALL the information in this Owners

Manual.

• Also, READ, UNDERSTAND AND FOLLOW ALL the information in the Owners Manual that came with your router

motor.

Vertical motor travel (lever-controlled)............ 3-1/2"

Maximum workpiece thickness ............. Approx 11"‡

Worktable size

(laminate-covered MDF).......18-1/2" d x 28" w x 3/4"

Fence size (2) .......................... 13-1/4" w x 1-1/4" h

Guide pin diameters furnished ...... 1/4", 3/8" and 1/2"

Starter pin diameter furnished .......................... 1/4"

Maximum router bit diameter (with insert) ...... 1-3/8"

Maximum router bit diameter (without insert) ....... 2"

Dust port diameter ....................................... 2-1/4"

* With a 3-1/2" diameter router motor. Distances will

vary , depending on router motor diameter .

† Maximum dimensions, based on which set of four

Arm mounting holes are used

‡ V aries, depending on router motor and bit used

• READ, UNDERSTAND AND FOLLOW

ALL the information in the MARK V

Owners Manual.

3

555970 MARK V – MOUNTED OVERARM PIN ROUTER

Throughout this manual, we list WARNINGS, CAUTIONS, and NOTES. We advise

that when you come to one of these listings,

please read and understand it fully. Their

meanings are:

WARNING

A WARNING is given when failure to

follow the directions is likely to result

in injury, loss of limb, or life.

CAUTION

A CAUTION is given when failure to follow the directions is likely to result in

damage to the equipment.

HEARING PROTECTION

Prolonged exposure to high intensity noise

from high speed power tools will damage

your hearing.

• Hearing protectors screen out certain frequencies and noise levels that can damage your hearing. For that reason, we

recommend that you ALWAYS wear hearing protection when using your Overarm

Pin Router.

GUARDING FOR ROUTING

Most shop accidents happen to woodworkers who fail to follow instructions, or fail to

use guards and safety devices. Although

proper use of guards and safety devices often requires additional setup, the protection

for you and your family is well worth the

effort.

NOTE

A NOTE is used to highlight an important

procedure, practice or condition.

EYE PROTECTION

Always wear eye protection when you use

power tools. Use goggles, safety glasses or a

face shield to protect your eyes.

• Goggles completely surround and protect

your eyes. Many goggles will also fit over

regular glasses. Be sure your goggles fit

closely, but comfortably.

• Safety glasses don’t fog as easily as

goggles and can be worn all the time.

Regular glasses normally have only impact resistant lenses. They are not safety

glasses.

• A face shield protects your entire face, not

just your eyes.

DRESS

Loose hair and clothing which could be entangled in rotating bits are very hazardous.

• Tuck long hair under a hat or tie it up. Do

not wear ties, gloves, loose clothing, rings

or other jewelry. Roll sleeves up above

your elbows.

ELECTRICAL REQUIREMENTS

Follow the electrical requirements that appear in the Owners Manual that came with

your router. Do not overload your electrical

circuits.

ROUTER MOTOR — OVERARM

Use the following specifications required to

mount a router in the OVERARM:

4

MARK V – MOUNTED OVERARM PIN ROUTER 555970

NOTE

Customer Service representatives and Store

personnel will help you select the proper

motor.

• Use only UL Approved router motors.

• Motor housing must be round, not square,

for router arm.

• Motor must be 2-1/2" to 4" in diameter.

• Motor power cord must be located so it

comes out the top section of the router.

• Motor power cord should be securely attached to the top of the Arm during operation with tape or rubber bands to keep

it safely out of your way during routing.

• Switch must be located so that it can be

positioned toward the front of the Overarm Router and be easily accessible during operations.

• You must be able to remove the handles

and base from the motor without removing the switch.

• Motor must properly mount on the Overarm Router so that base locating pins on

the motor housing do not interfere with

the router motor holding clamps.

• Motor must not exceed 3 hp.

SA WDUST AND CHIPS

Sawdust and chips can be a fire hazard and

breathing sawdust can be a health hazard.

The sawdust from some woods is toxic. To

help protect yourself from sawdust:

• Attach your Overarm Pin Router to a dust

collection system to help capture flying

chips and debris.

• Or wear a close-fitting dust mask. Clean

or replace the filters in the mask regularly.

Also, open a window or use a fan to ventilate your shop.

MOUNTING ROUTER BITS

• Turn off and unplug the router motor before mounting router bits.

• Follow the recommendations of the router

motor manufacturer as to the sizes and

types of router bits to use.

• Make sure the router bit is secured properly in the collet. Loose bits could work

free and cause serious injury. Insert the bit

all the way into the collet and retract it

about 1/8" to avoid the transition between

shank and cutter.

• If your using an arbor-style bit with interchangeable cutters, be sure the cutting

edge is facing to the

on the arbor.

• Listen for chatter or signs of looseness at

start-up. If you hear, see or suspect problems, stop the tool immediately, unplug it,

and check the tool thoroughly. Correct any

problem before proceeding. If you are unable to locate the problem, you can contact your Shopsmith Service Representative or store personnel for advice. Never

operate the Overarm Router if it is not

functioning properly.

• Keep bits clean, maintained and sharp.

• Don’t try to make your own collet adapter

to hold different sized bits. Balance is important at high speeds, so always buy

appropriately sized collets.

left when mounted

GENERAL SAFETY RULES

FOR POWER TOOLS

• Know your power tool. Read the owners

manual. Learn its application and limitations as well as the specific potential

hazards peculiar to this tool.

• Ground all tools (unless double insulated). If tool is equipped with an approved 3-conductor cord and a 3-prong

grounding type plug to fit the proper

5

555970 MARK V – MOUNTED OVERARM PIN ROUTER

grounding type receptacle, the green conductor in the cord is the grounding wire.

Never connect the green wire to a live

terminal.

• Wear proper eye and ear protection. Also,

wear a dust mask.

• Keep guards in place. Always keep

guards in working order and in proper

alignment and adjustment. Most injuries

occur on unguarded power tools.

• Remove adjusting keys and wrenches.

• Wear proper apparel. Do not wear loose

clothing, ties, gloves, rings or other jewelry. Roll sleeves up above your elbows,

wear nonslip footwear, and tuck long

hair under a hat.

• Do not operate power tools if you are

tired, taking medication, or under the influence of alcohol or drugs.

• Avoid dangerous environments. Don’t

use power tools in damp, wet or explosive atmospheres.

• Keep work areas well lit, clean, and free

from clutter.

• Do not force the tool. It will do the job

better and safer at the rate for which it

was designed.

• Use the right tool. Don’t force a tool or

accessory to do a job for which it is not

designed.

• For direction of feed — ALWAYS feed the

workpiece into the cutter against the rotation of the cutter. NEVER feed the

workpiece into the cutter with the rotation of the cutter.

• Check damaged parts. A damaged guard

or part should be properly repaired or replaced before further use. If a strange

noise or vibration develops, immediately

turn off the power, unplug the machine

and correct the problem. Never operate

a power tool that is not functioning

properly.

• Secure workpieces. Use clamps, fixtures,

and other devices to hold workpieces

when practical. It’s safer than using your

hands and it frees your hands to operate

the tool.

• Do not overreach. Keep proper footing

and balance at all times.

• Turn off the tool and wait until it comes

to a complete stop before removing

workpieces and scraps.

• Do not try to stop the tool by grabbing

the workpiece or any part of the tool.

Turn off the tool and let it come to a complete stop by itself.

• Do not leave the tool running unattended. Turn power off. Don’t leave tool

until it comes to a complete stop.

• Avoid unintentional starting. Make sure

the switch is in the “off” position before

plugging in or unplugging the tool.

• Disconnect tools. Turn off and unplug

tools before changing accessories and setups, making adjustments, and performing maintenance and repair.

• Do not stand or lean on the tool. You

could fall onto the tool or it could tip

over injuring you and/or damaging the

tool.

• Maintain tools. Keep parts and tools

sharp, clean and maintained according to

the Owners Manual.

• Make your workshop childproof. Use

padlocks, master switches or remove

starter keys.

• Keep children away. All visitors should

stay a safe distance from power tools, and

wear eye and ear protection.

• Do not permit anyone who is inexperienced to use your power tools without

supervision.

6

MARK V – MOUNTED OVERARM PIN ROUTER 555970

SAFETY RULES FOR THE

SHOPSMITH OVERARM ROUTER

• Be sure to read and understand this entire

Owners Manual before using the Overarm

Router. Also, do not use the Overarm

Router unless you are sure it is assembled

properly, all safety devices are installed,

and you understand the operations you

are attempting to perform.

• Keep the guard in place and in working

order. Always set the guard no more than

1/4" above the workpiece.

• Keep your hands, fingers and other parts

of your body at least 3" away from the

rotating bit.

• Use a push stick, push block, featherboard(s), miter gauge with safety grip,

fixtures, or other safety devices to maneuver a workpiece into a rotating bit. If a

kickback occurs, these devices help to

protect your hands and fingers.

• Use only Shopsmith parts and accessories on your Overarm Router. NEVER use

non-Shopsmith replacement parts or accessories. They are not designed like

Shopsmith parts. Using non-Shopsmith

parts may create a hazardous condition

and will void your warranty. Follow your

router manufacturer’s recommendations

as to replacement of router parts.

• Do not rout second-hand lumber. If you

hit a nail, screw, or other foreign object,

you could be hit by pieces of metal or

there could be kickback.

• Do not “freehand” rout stock less than

12" X 12" or equivalent.

• Support long boards and sheet materials

with a roller stand(s) placed 1' -4' from

the worktable.

• Avoid taking deep cuts. With the exception of single-pass dovetail cuts, limit

depth-of-cut to 1/4" for each pass when

using bits up to 1/2" diameter in hard-

wood. Limit depth-of-cut to 3/8" for each

pass when using bits up to 1/2"

diameter in softwood. When using bits

over 1/2" diameter, limit depth-of-cut to

half the recommended depths for 1/2"

diameter bits.

• Always use a fixture, fence, and/or starter

and guide pins to help control the

workpiece.

• Always feed the workpiece against the

rotation of the bit, not with it. Otherwise

the bit will grab and throw the

workpiece.

• Keep a firm grip on the workpiece at all

times and never hold the workpiece with

your hands in line with the router bit.

• Always clamp a straight piece of scrap

stock to your worktable surface for use

in holding your workpiece against the

fence during straight-line routing operations. Also use a long piece of scrap stock

to feed a narrow workpiece underneath

the guard to complete a cut.

• Cut with the grain instead of against the

grain. You will get a smoother cut and

the operation will be safer.

• Avoid standing in-line with the

workpiece being fed. In the event of a

kickback you could be hit.

• Feed the workpiece slowly. Use extra care

in routing workpieces that contain figured grain or knots, as these may cause

kickbacks.

• When you are routing stock up to 10"

wide across the grain, use a piece of scrap

stock cut at a 90° angle to guide the

workpiece through the cut. The

workpiece must extend 5-1/2" away from

router bit.

• When stop routing, always use stop

block(s) to control the length of cut. Failure to use stop block(s) could cause the

bit to grab and throw the workpiece.

7

555970 MARK V – MOUNTED OVERARM PIN ROUTER

• When routing oversize stock, always use

at least one push block to help control

the workpiece firmly against the fence.

• Do not work with stock that is too small

or too large to handle safely; that is

warped, bowed or cupped; or that has

loose knots or other defects.

• Plan the operation before you begin. If

you are in doubt about how to complete

an operation safely, do not attempt it. You

can contact your Shopsmith Customer

Service Representative or Store personnel for advice.

• Secure the router, overarm assembly,

depth stop rod, depth control handle,

worktable, accessories, safety devices,

fences, and fixtures before turning on the

motor.

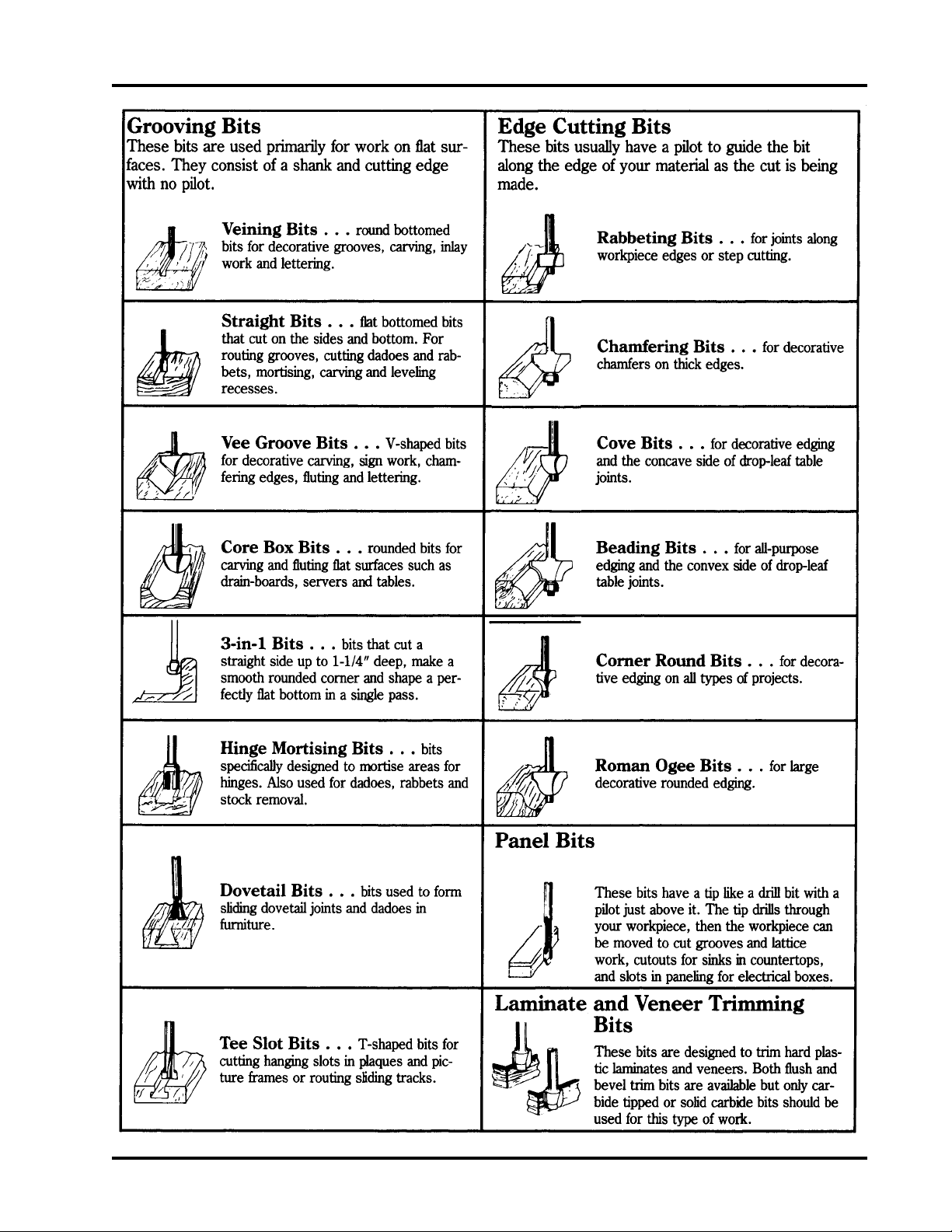

TYPES OF

ROUTER BITS

Router bits come in a wide variety of shapes

and sizes designed to be used at very high

speeds.

speed steel bits are heat treated for extra

hardness and to hold keen cutting edges.

Carbide bits (solid or tipped) are the finest

bits available today. Although more expensive, they will outlast high speed steel bits

at a 15 to 1 ratio on softwoods and are highly

recommended for use on hardwoods, plastic laminates, plywood and particleboard.

Router bits are generally classified into four

different categories — grooving bits, edge

cutting bits, panel bits and laminate and veneer trimming bits. (See Chart.)

CARE AND MAINTENANCE

You’ll enjoy longer use of your router bits if

you make it a point to handle, use and

sharpen them properly.

• Use your router bits only for the job they

are intended to do.

• Make sure the bit is mounted rigidly in

the collet.

• Learn to cut your workpiece at the proper

speed to prevent heat buildup that can

cause the loss of bit hardness.

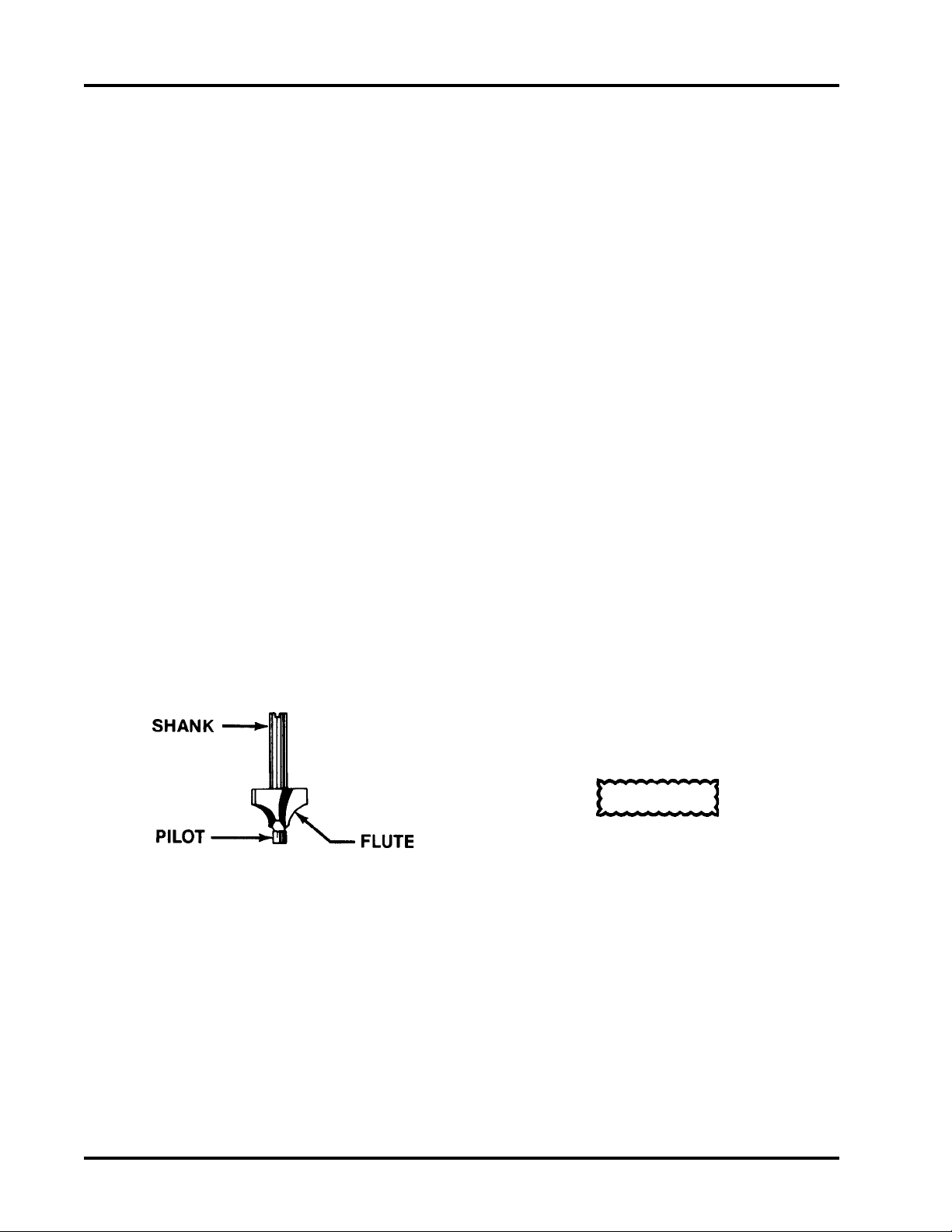

The part of the bit mounted in the router

chuck is called the shank and the rounded

extension beyond the cutter on some bits is

called the pilot. The cutting edge of the bit

is called a flute. Router bits have one, two

or three flutes and the more flutes there are

on the bit, the more cuts that can be made

per minute. A higher number of flutes reduces the load on the motor and produces a

smoother cut.

Quality bits are made of high speed steel,

solid carbide or carbide-tipped steel. High

• Between operations, set your bits in a safe

place where they will not fall or get hit.

CAUTION

Never use solvent on a bearing piloted

bit without first removing the bearing.

• After use, clean bits thoroughly.

• Sharpen your bits with a small slip-stone

or oilstone with oil. Hone the face of each

cutter with light strokes in one direction.

Never hone the outside edge because it reduces the diameter of the cutter. Hone

each cutter edge with the same number

of strokes.

• If the cutting edge is nicked, take the bit

to a professional sharpening service.

8

MARK V – MOUNTED OVERARM PIN ROUTER 555970

9

555970 MARK V – MOUNTED OVERARM PIN ROUTER

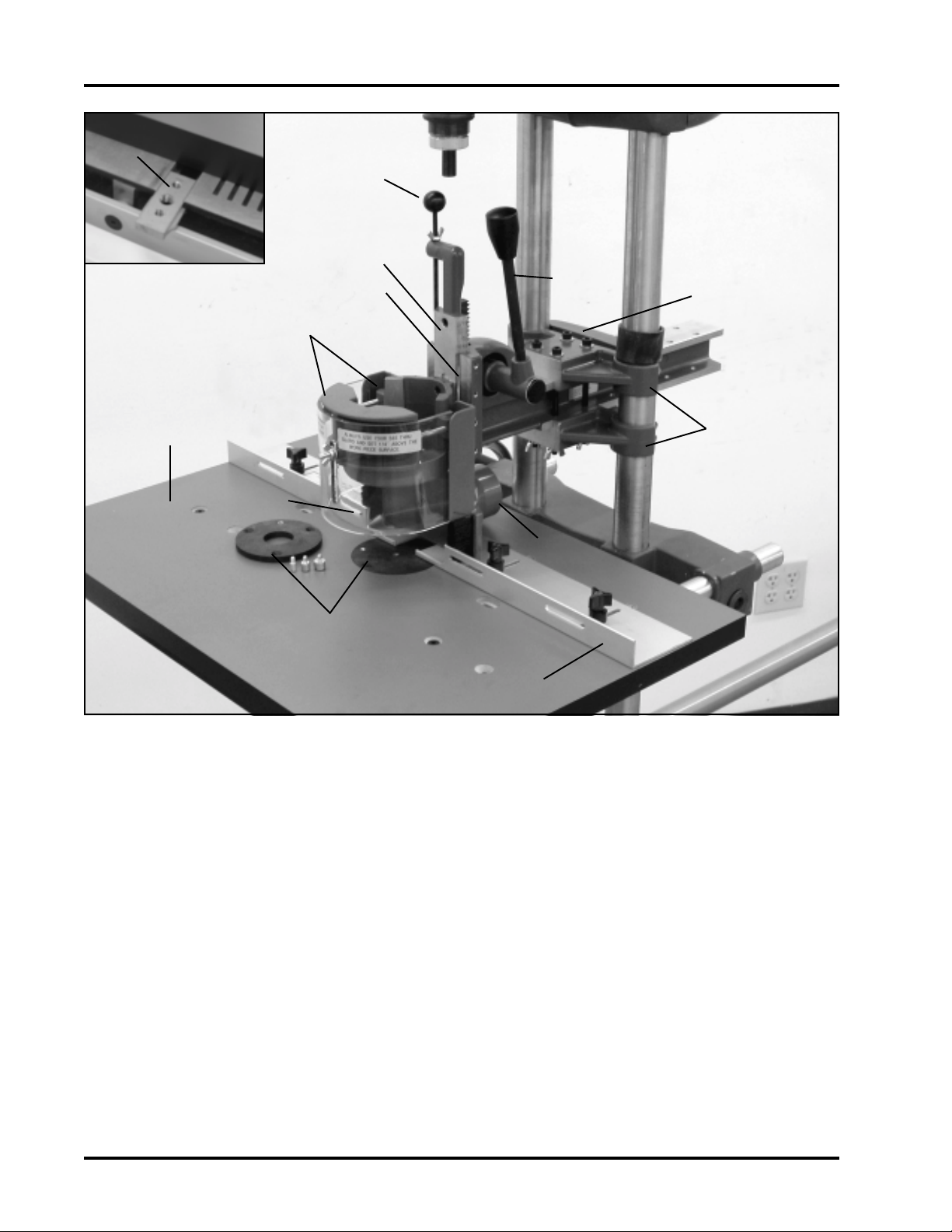

T-NUT

WORKTABLE

MOTOR

BRACKETS

GUARD

ASSEMBLY

DEPTH

STOP ROD

DOVETAIL

ASSEMBLY

BRASS GIB

DEPTH

CONTROL

HANDLE

DUST

CHUTE

MOUNTING

BRACKET

CLAMPS

WAY TUBE

MOUNTING

BRACKETS

CIRCULAR

TABLE INSERTS

TWO-PIECE

ROUTER FENCE

TERMS TO KNOW

It’s important that you become familiar with

all of your Overarm Router‘s functions and

parts before you begin to use it.

The functioning parts of the Router Arm are:

1. Worktable – Made of a durable laminate-covered MDF (medium density

fiberboard) the Overarm Router’s Worktable mounts to your MARK’s Worktable in one of two ways:

Models 505, 510 and 520 – Mounts

into the right-hand Worktable Miter

Gauge slot with two sliding T-Nuts

and setscrews.

Model 500 – Mounts into the two

threaded Table Insert mounting

holes in your Model 500 MARK V

with two buttonhead setscrews and

washers through the elongated

travel slots in the Overarm Router

Table surface.

Two sets of threaded inserts are provided in the Worktable surface for attaching the two-piece Router Fence.

2. Guard Assembly – The clear guard protects your fingers and hands, keeps

chips away from you and gives you a

clear, open view of the surface being

routed at all times.

3. Dust Chute – Your dust collection system attaches to the chute to help collect

sawdust and chips.

10

MARK V – MOUNTED OVERARM PIN ROUTER 555970

4. Motor Brackets – Firmly hold any

round, hand-held router motor from

2-1/2" to 4" in diameter. These dimensions are for the motor only (the router

base is removed during operations).

5. Brass Gib – Adjusts with four Allen set

screws to eliminate side-to-side movement of the motor while allowing

smooth, vertical movement of the dovetail slide.

6. Depth Stop Rod – Locks into any position to limit your depth-of-cut during

operations.

7. Dovetail Assembly – Moves up-anddown by means of a steel rack-and-pinion gear mechanism. The dovetail slide

provides 3-1/2" of vertical motor travel.

8. Depth Control Handle – Conveniently

raises and lowers the router motor. A

simple twist locks the handle in place.

9. Circular Table Inserts – Two provided:

One with a 1-3/8" diameter center hole

and an offset threaded insert for the

Starting Pin (included)...and another

with a center threaded insert for the

three interchangeable Overarm routing

Guide Pins (three included: 1/4", 3/8"

and 1/2" diameters).

10. Two-Piece Router Fence – Adjustable

aluminum Fences attach to the Worktable mounting holes with threaded

plastic Knobs, Spacers and washers for

straight-line routing operations.

11. MARK V Way Tube Mounting Brackets – Upper and lower Mounting Brackets attach to the Overarm...then around

the MARK V Way Tubes with mating

Clamps, supporting the Overarm

Router above the Worktable.

head capscrews, threaded into the holes

on the back sides of the Mounting

Brackets.

13. SLIDING T-Nuts – Used to attach your

Overarm Router Table to your Model

505, 510 or 520 MARK V Worktable.

OVERARM ROUTER

ASSEMBLY

WARNING

Your safety and the ability to use your

new Shopsmith Overarm Pin Router

properly depends on your following

these assembly and use instructions

exactly.

NOTE

Reference numbers that appear in parentheses following the part names correspond

with the numbers on the figures in this section and the exploded view in the Parts List

section of this Manual.

TOOLS & SUPPLIES NEEDED:

• 1/8" Allen wrench

• 5/32" Allen wrench

• 1/4" Allen wrench

• 5/16" Allen wrench

• 7/16" Open end wrench

• Furniture or floor paste wax (do NOT use

car wax or spray furniture polish)

• Mineral spirits

• Fine file or emery cloth (optional)

12. Mounting Bracket Clamps – Clamp

around the “back side” of your Way

Tubes with 3" long x 3/8" dia. socket

11

555970 MARK V – MOUNTED OVERARM PIN ROUTER

BEFORE YOU BEGIN...

It’s a good idea to clean all major metal parts

with mineral spirits to remove any dirt or

grease residue. Any burrs found on parts

should be removed with a fine file or emery

cloth. If required, clean your router motor

according to the instructions in its Owner’s

Manual.

Wax and buff the Worktable surface, applying the wax sparingly, then buffing it out

thoroughly. If you apply too much wax or

fail to buff it out properly, the wax will mix

with the sawdust you generate, impede the

movement of the Overarm Router’s parts

and leave residue on your workpieces.

Remove all accessories from the MARK V’s

Headstock and prepare the machine as you

would for Drill Press operations. Remove the

Worktable from the Carriage (this will make

it easier for you to raise the machine to vertical position).

sitions in the Brackets. For most operations,

the 2nd and 3rd set of holes nearest the business-end of the Arm are used as shown in

Figure 1. If you need more throat depth,

choose the four holes that best suit your

needs.

Figure 1. Normal Mounting Position

NOTE

Slide the Headstock all the way to the left

until it rests against the Way Tube Tie Bar.

Tighten the Headstock Lock lever.

Position the Carriage so the distance between

the Carriage and the Headstock is about 15".

Tighten the Carriage Lock Handle. Raise the

MARK V into Drill Press position. NOTE:

Shopsmith’s Lift-Assist Accessory will make

this task much easier.

WHICH MOUNTING HOLES ?

Before mounting the Overarm Router to the

MARK V, the two Mounting Brackets (11)

must be bolted to the Arm of the tool with

four 5-1/4" long x 5/16" dia. socket head cap

screws, washers and wing nuts (finger-tight

only at this time). Do not install your router

motor yet.

There are six pairs of mounting holes in the

Arm, providing a total of five mounting po-

When mounting, drop the capscrews

through the TOP of the Brackets and into

the Arm, with flat washers and wing nuts

on the bottom. This way, the bolts won’t

drop out of position when you remove the

wing nuts and washers to change Arm positions.

INSTALL THE

DEPTH STOP ROD (6)

Thread the 1/4"-20 wing nut onto the Depth

Stop Rod, then thread the Rod (with wing

nut) into the threaded hole in the top of the

Dovetail Slide.

Once the Brackets are mounted to the Arm,

use the Depth Control Handle (8) to “lower”

your Motor Brackets (4) to the “bottom” of

their travel in the Dovetail Assembly

(7)...and unscrew the Depth Stop Rod (6)

so it is all the way to the “top” of its travel.

12

MARK V – MOUNTED OVERARM PIN ROUTER 555970

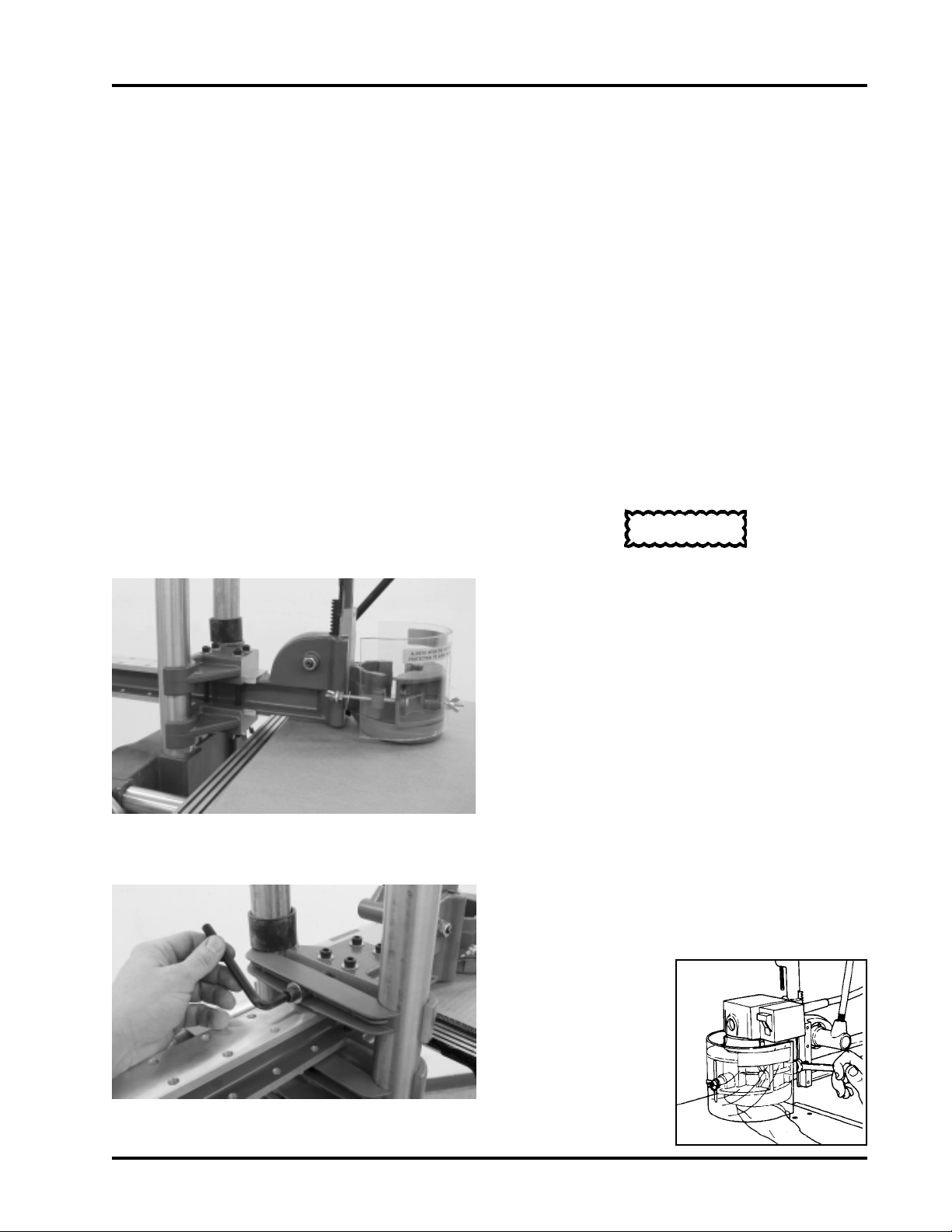

RE-INSTALL THE MARK V

WORKTABLE

Loosen the Table Tilt Lock Lever, tilt your

Table to 90° (as you would when setting up

for Drill Press) and tighten the Lever. Install

the Worktable in the Carriage, slide it “back”

until its edge is 3" from the Way Tubes.

Tighten the Table Height Lock.

Place a piece of scrap plywood or cardboard

on your table. With the Overarm Router’s

Deflector (20) resting on your MARK V’s

Worktable surface (See Fig. 2), position the

semi-circular cut-outs of the Brackets (29)

against the Way Tubes. Hold the assembly

in position while you screw the two 3" long

x 3/8" dia. socket head capscrews through

the Clamps (30) and into the threaded holes

in the Mounting Brackets (29). See Fig. 3.

Adjust the Overarm’s position so the Depth

Stop Rod Knob doesn’t collide with the end

of the MARK V’s Quill when the Stop Rod

is adjusted to its full “up” position and

tighten the two large capscrews using a

5/16" Allen wrench.

INSTALL YOUR ROUTER MOTOR

IN THE OVERARM

Remove your Router motor from its base (see

instructions included with your router.)

Place the motor between the front and rear

motor Brackets on the Overarm until it bottoms out against the Deflector (20). ..then

raise it approximately 1/8" to allow for

proper air circulation.

CAUTION

Figure 2. Attaching the Overarm Router

to the MARK V

Always position the Router Motor so it is

raised about 1/8" off the Deflector to allow for proper airflow and cooling during operation. Without this 1/8" clearance,

overheating and damage to your router

motor will result.

Use a 7/16" open end wrench to tighten the

two Motor Bracket nuts (See Fig. 4). Be sure

your router’s switch is located for easy accessibility during operations...and that none

of the small lugs or other protruding parts

on the motor’s housing interfere with a good

“seating” in the Motor Brackets. When positioning your router motor, be sure its collet

or bit locking nuts are accessible without the

need for additional motor adjustments.

Figure 3. Tighten the Clamp capscrews

with the 5/16" Allen wrench.

Figure 4. Install the

router motor in

the Overarm.

13

555970 MARK V – MOUNTED OVERARM PIN ROUTER

CAUTION

Over-tightening the Motor Bracket nuts

may cause damage to the motor and/or

housing of your router.

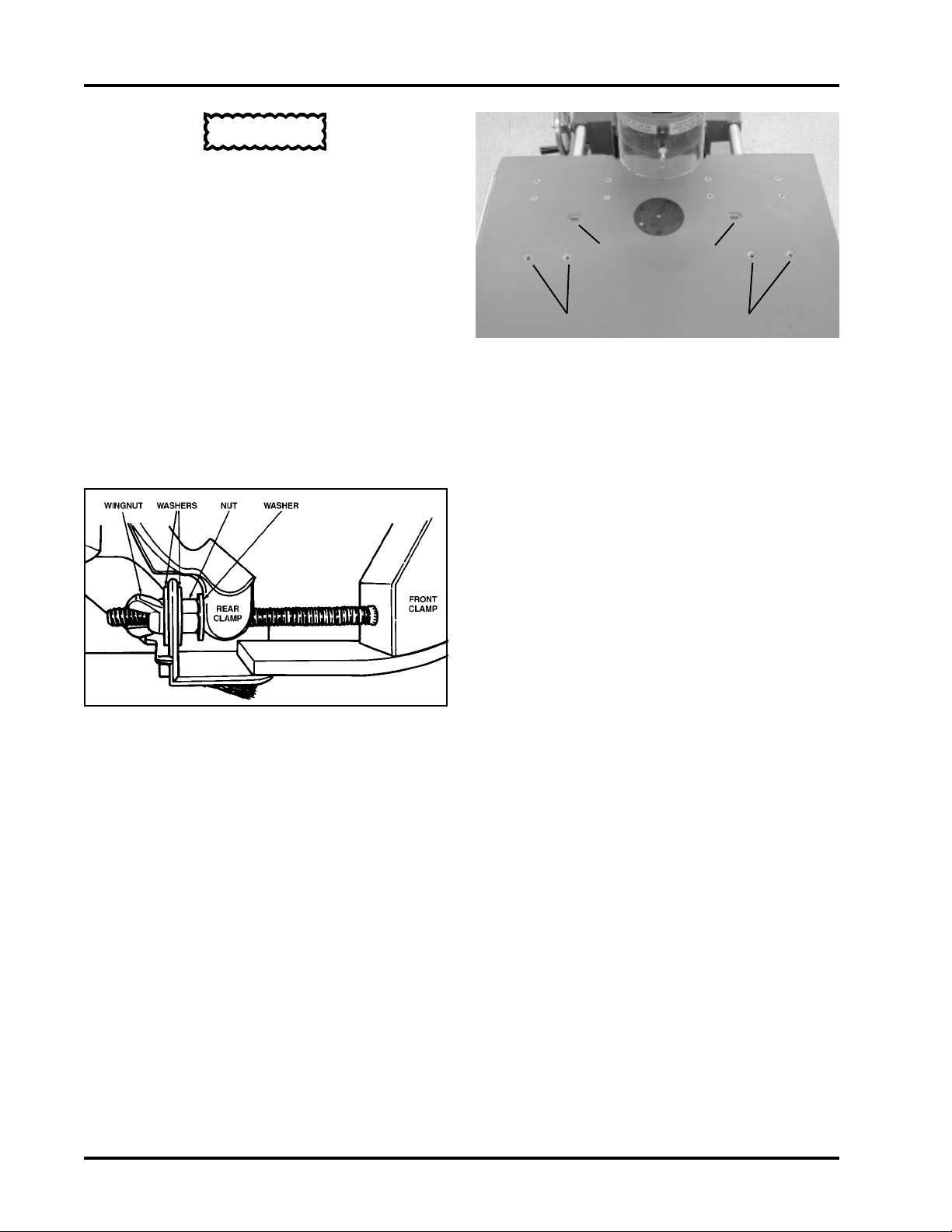

FOR MODEL 500

INST ALL THE REAR GUARD AND

DUST COLLECTOR ASSEMBLY

FOR MODELS 505, 510,520

Install a flat washer over each stud of the

front Motor Clamp, and then slip the rear

guard/dust chute with strip brushes onto

the clamp studs and secure with two more

flat washers and wing nuts. See Figure 5 for

correct assembly order.

Figure 5. Overhead view of proper motor

clamp hardware assembly order

(looking down from above).

MOUNT THE OVERARM ROUTER

TABLE ONTO THE MARK V

WORKTABLE

Model 500

Remove the MARK V Table Insert. Use the

two buttonhead Allen capscrews with washers to mount the Overarm Router Table to

the MARK V Worktable by inserting them

through the two elongated mounting holes

in the Router Table and threading them directly into the Model 500 MARK V Table Insert mounting holes (See Fig. 6).

Figure 6. Use the left hole of each pair

when mounting the Worktable on

Model 505, 510 and 520 MARK V’s for

most applications. Use counterbored

slots for Model 500.

Models 505, 510, 520

Use the sliding T-nuts and 1/4"-20 flat head

machine screws provided. Lay the Router

Table right-side-up on a flat surface in front

of you with the eight threaded insert holes

away from you. You will notice two pairs of

countersunk holes in the Table surface, about

7-1/2" in from the “front” edge of the Table

(See Fig. 6). These are the holes you will use

to mount your Overarm Router’s Table to

your Model 505, 510 or 520 MARK V’s Worktable.

For the majority of your conventional and

pin routing operations, you will use the two

left holes in each pair to mount the Table to

the “front” Miter Gauge slot in your MARK

V’s Worktable. This approach will provide

the maximum workpiece support in “front”

of your Router bit and motor.. .and allow

you to use your Two-Piece Router Fence (included).

If you would prefer to have more workpiece

support “behind” your Router bit and motor, use the two right holes in each pair to

mount the Table to the “back” Miter Gauge

slot in your MARK V’s Worktable. When using this approach, the Table must be rotated

180° and installed with the eight threaded

Fence inserts toward the “front” of the Table.

14

Loading...

Loading...