Shopsmith 10ER Owners Guide

SHOPSMITH

MULTI-PURPOSE

POWER

TOOL

MOD

EL

N

O. 10·ER

ART.

25

T

MG

34

8 4((J)· P·68·

70A·71A

MODEL

MULTI-PURPOSE

NO.

IO·ER

ARTIClE

NOS.

25

TMG·3471A.

POWER

3470A

TOOL

•

-

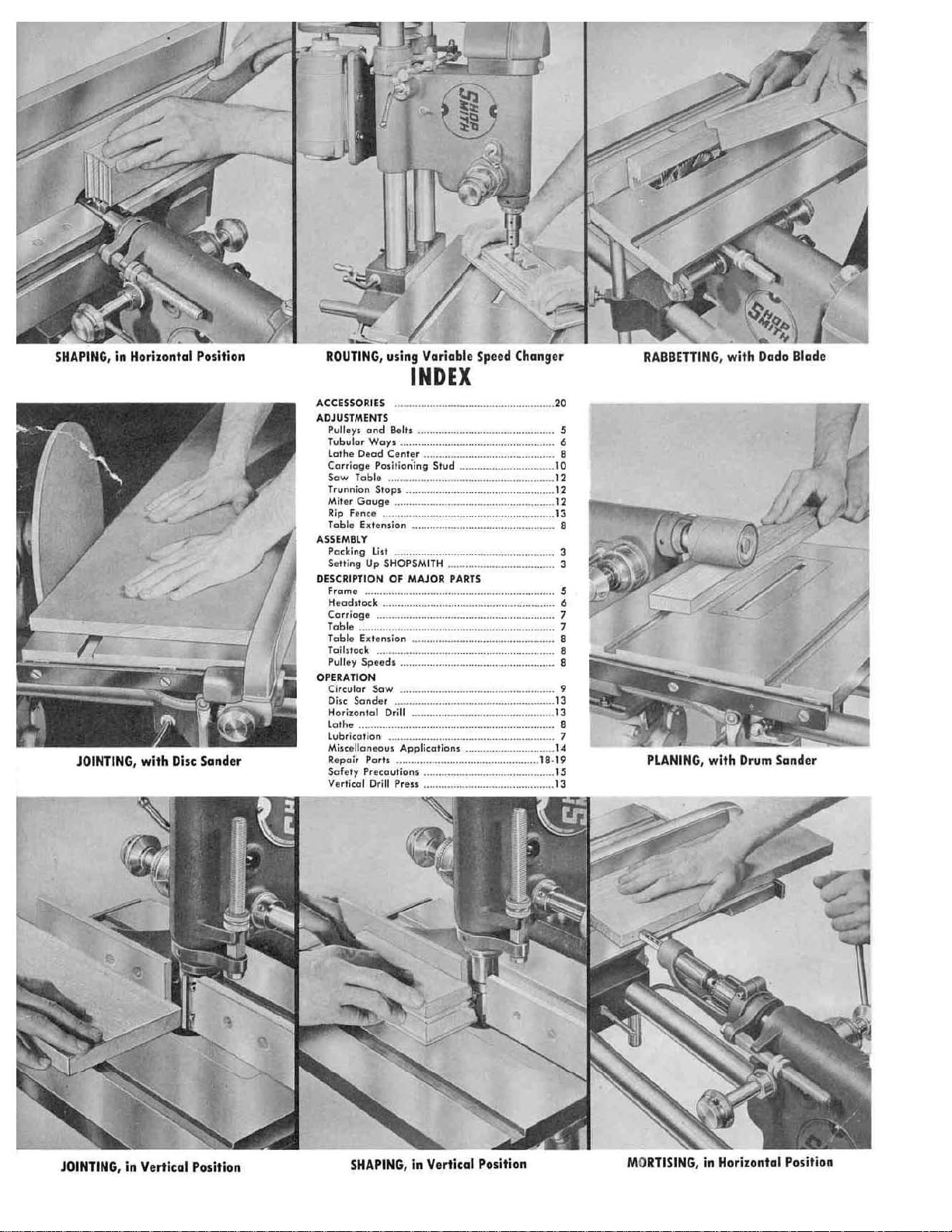

SHAPING,

JOINTING

in

Horb:ontol Position

, with

Disc

Sonder

ROUTING

, using Vorioble

Speed

(honger

INDEX

ACCESSORIES

ADJUSTMENTS

Pulle~.

lubuk

l

athe Dead

Cgrriage Pa.hioning

Saw

T

runnion

Miler

Rip Flnce ..••....

Tobie

ASSEMB

Pocking li.t

S.

"in9

OESCRIPTI

F

,gm

Hl

od,

Co"ioga

Tobl

Table

loi1olock .............. .................................. 8

Pull.)

OPERATION

Cifeu"',

Oi"

Horizonlol

lOlh

lubricotion

Mi,.

Re poir

Safet

V.,ticd

•

gnd

Bel" . ..

..

Way.

r"ble

SlOP' .... ........ ............... . ..•... 12

Goull

E~len.ian

LY

Up SHOPSMITH ..• _ 3

ON

l ......

..••

lock .•....

._ ..

•.

. ..

E"len,ion

Speed

Sow

S"nd.,

e .

ellon.

ou,

Parh

y P"

."ulio"1

D,ill P,e ...

....................•. . .....

...... . .....

Cenler

Siud ....

....•.•.•........•.•.. _................. . ...•..

e .

•.••

.

. ............................. ....•.• 3

OF

MAJOR

.....

........

••.

, 8

•.•.••••.....

Drill ..••..•.

•.•...... _ .....•.....•.. _

Appli."lion,

.

. ............ ....•....•..

.........

........••..•........••.•..

..

....

..................

.......................... _

PARTS

••..

...............

... ......... 13

. ..•.

. ........... 13

.. .1:>

. ... 18 .

20

_.. 6

....... 8

10

•.

12

12

•.

. .. 6

••.••.

13

..

1.

19

......

1.5

.5

B

,

7

7

8

•

,

,

RABBETTING

PLANING

, with

, with

Drum

Dodo

Sander

Blade

JOINTING, in

Vertical Position

SHAPING, In

Vertical Position

RTISING, in

MO

Horizontal Posit

ion

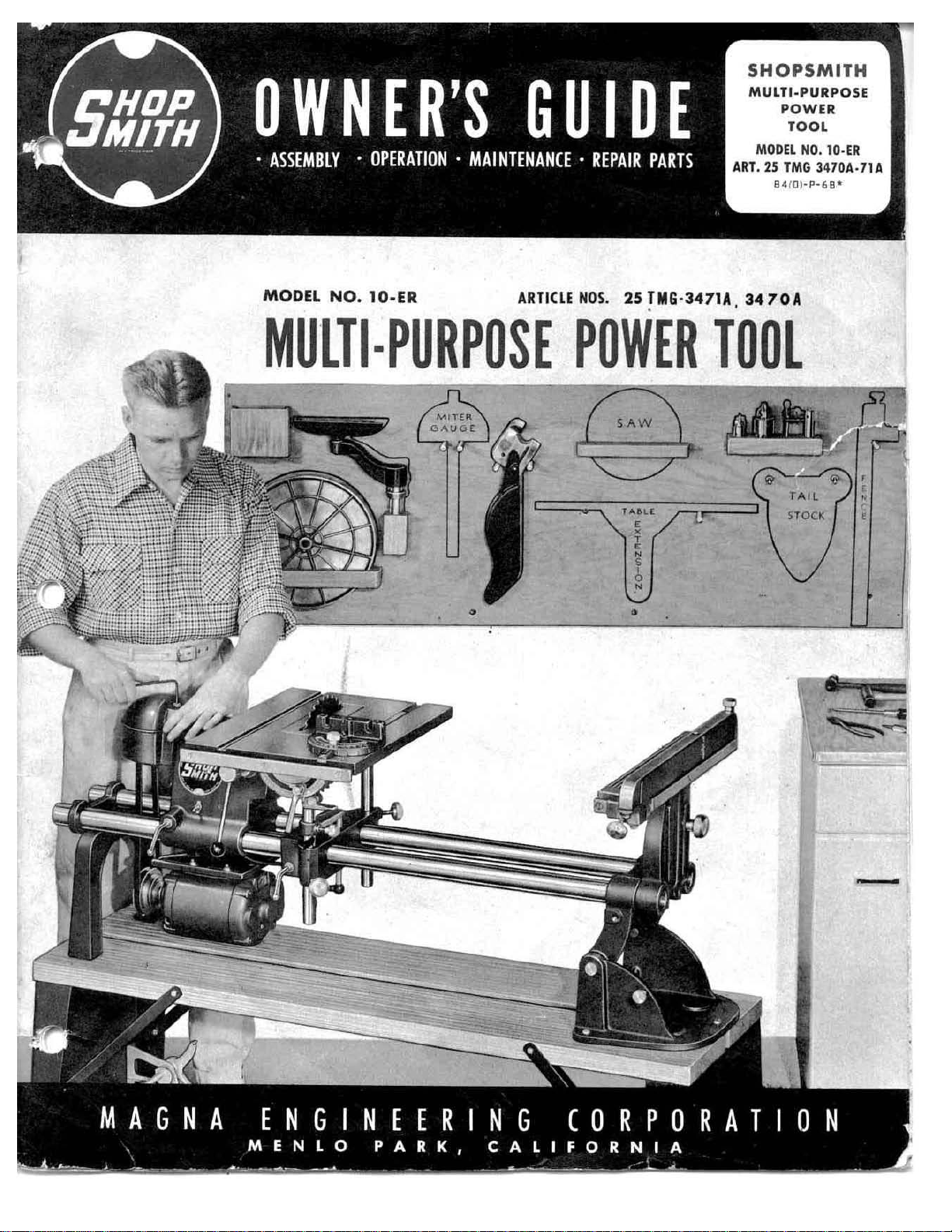

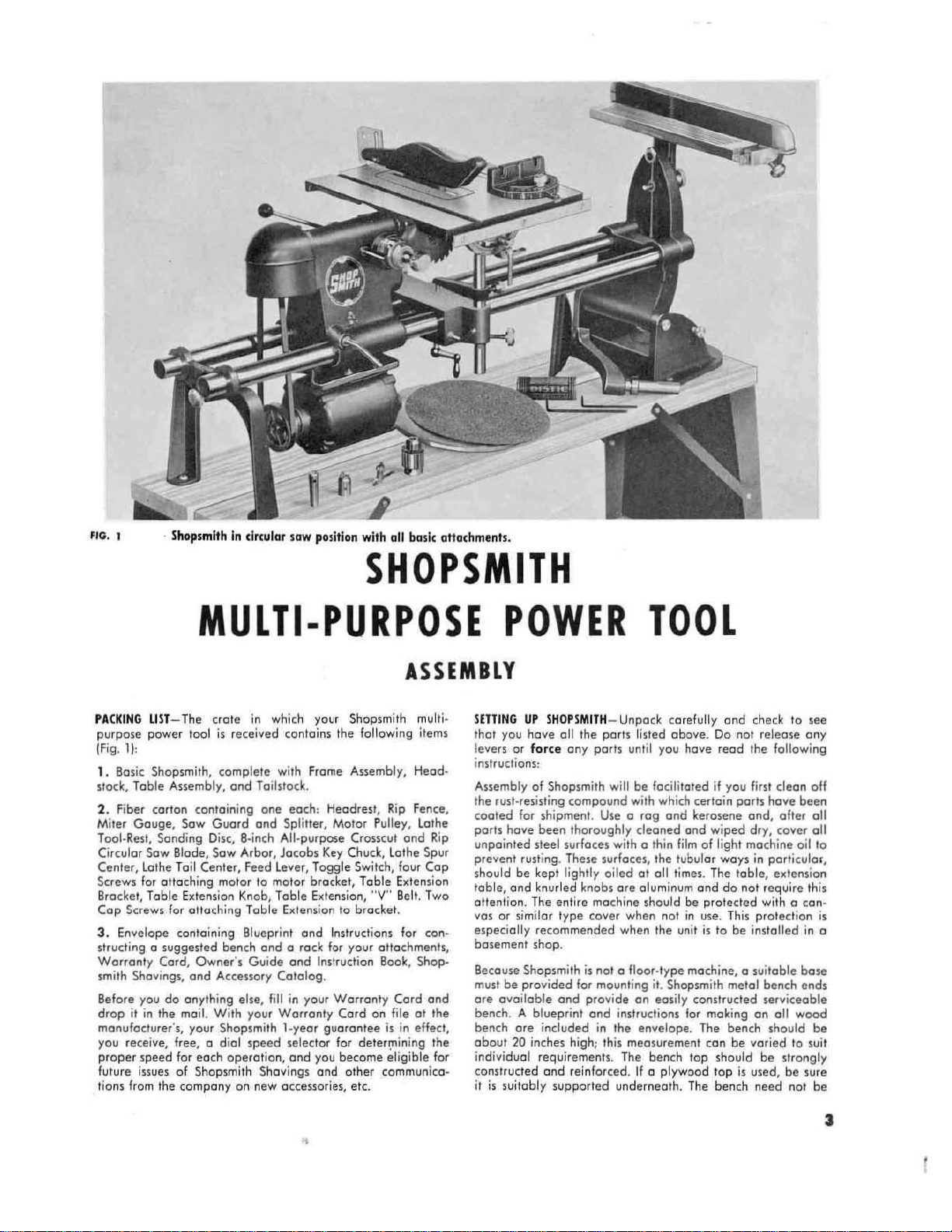

fIG

. 1

Sjw)psmlth

.

In

circular saw p

osi

tion with all basic attachments.

SHOPSMITH

MULTI-PURPOSE

ASSEMBLY

PACKING

purpose power tool

IFig. I):

1.

stock, Table Assembly,

2. Fiber carlon containing one each: Headresl, Rip Fence,

Miter Gouge. Sow

Toal.Rest, Sanding D

Circular Sow Blade, Sow Arbor, Jacobs

Center,

Screws

Brockel, Table Extension

Cop Screws

3. Envelope conta ining Blueprint

structing a suggested bench and a rock lor your attachments,

Warranty Cord,

smith

Before

drop

manufacturer's. your Shopsmilh I-year guarantee

you receive, free, a dial speed selector

proper speed lor each operation, and

future issues of Shapsmith Shavings and other communications

LIST

-The

craIe

in

which

yo~'

r

is

received contains the following items

Basic

Shopsmi!h, complete with

Lalhe

Toil

for

allaching motor

for

Shavings.

you

do a nything else,

it

in the moil. With your Warranty Cord on lile at the

from

the company on new accessories, etc.

and

Tailstack.

Guard

and

isc,

Cenler, Feed l ever, Toggle Switch,

attaching Table Extension

Owne"s

and

Accessory Catalog .

Spliller, Motor Pulley,

8-inch

AII

.purpose Crosscut

10

motor brocket, Table Extension

Knob,

Table Extension.

and

Guide

and

fill

in

Shopsmi!h

Fro

me

Assembly, Head-

Key

Chuck.

"V"

to

brockel.

Instructions for con-

Ins

truction

your Warranty Cord and

you

Book

for

is

determini

become eligible

lat

four

Belt.

in

multi

lathe

and

he

Spur

Cop

Two

. Shop·

effect,

ng

Rip

the

for

POWER

·

SITTING

that you have all the

levers or force any ports

instructions:

Assembly of Shopsmilh

Ihe rust.resisting compound with which certain ports have been

coated

ports have been thoroughly cleaned and wiped dry, cover all

unpainted sleel surfaces with a thin

prevent rusting. These surfaces. the tubular ways

should be kept lightly oiled

table, and knurted knobs

attention. The entire machine should be protected with a canvas or similar type cover when not

especially recommended when the

bosement shop.

Because Shopsmith

must

are

bench. A blueprint

bench

abo

individual requirements .

constructed

it is suitably supported underneath.

UP

SHOPSMIlH

for

shipment.

be

provided

available

are

included

ut

20

inches high; this measurement can

and

Use

is

not a floor.type machine, a suitable bose

for

mounting it. Shopsmith metal bench ends

and

provide on easily constructed serviceable

and

in

reinforced.

TOOL

- Unpack carefully and check to see

parh

listed above.

until

you hove read the following

will

be

facilitated

a rag and kerosene

01

aU

are

aluminum and

instructions

the envelope. The bench should be

The

bench top should be strongly

If

a plyw:)od top is used, be sure

Do

if

you f

film

of light machine

times. T

he

do

in

use.

unit is

This

to be installed

for

making on all

be

The

bench need not be

not release any

irs

and,

in

table, extension

not require t

protection

voried to suit

t clean off

after all

oil

particular,

to

his

in

wood

is

a

3

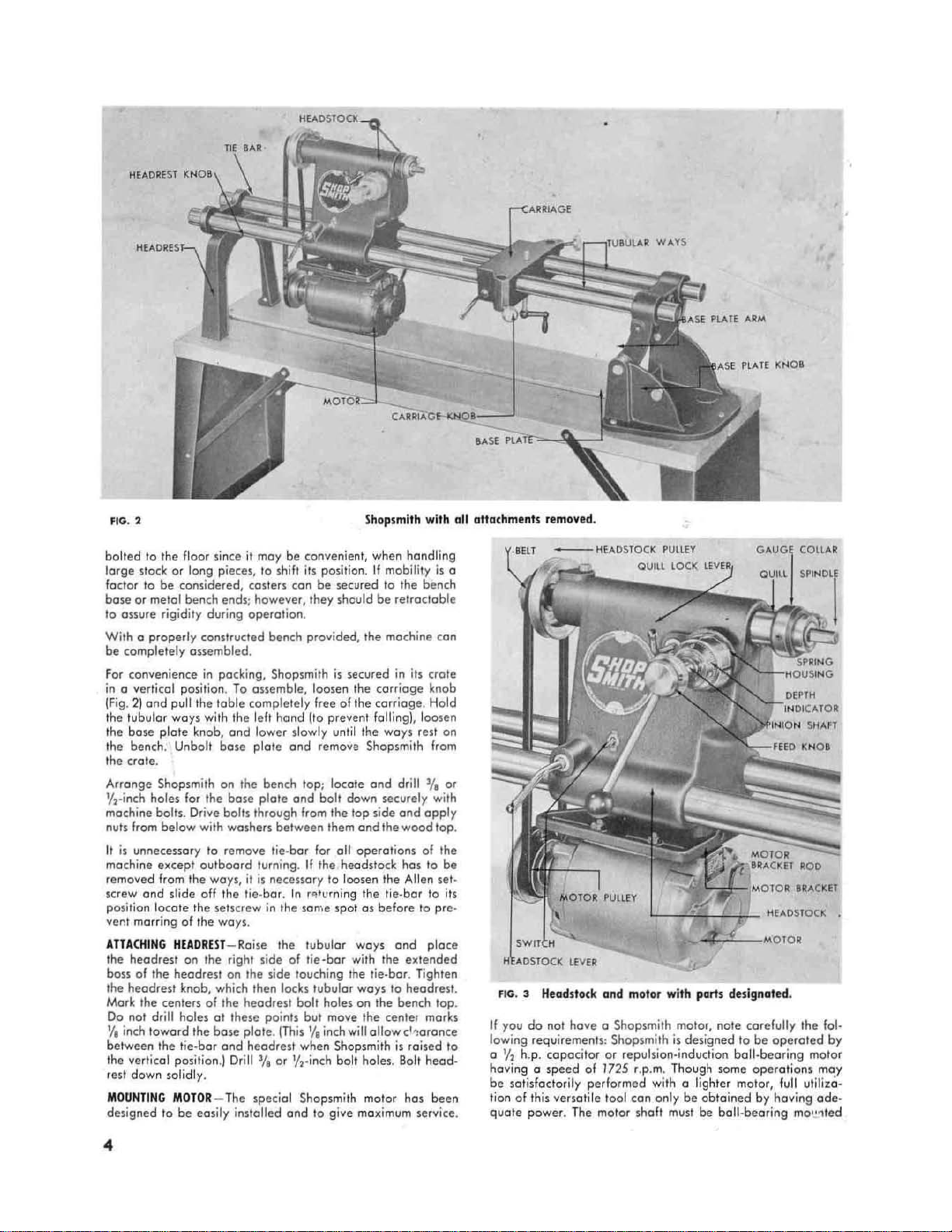

HEADREST

Shop

fiG . 2

bolted to the floor since

large stock or long pieces,

factor

to

be considered, costers can be secured

it

may be convenient, when handling

to

shift its position. If mobility

smith with

to

Ihe bench

is

base or metal bench ends; however, they shculd be retractable

to assure rigidily during operation.

With a properly construct.d bench provided. Ihe machine con

be

completely assembled.

For

convenience

in

a vertical position. To assemble, loosen the carriage knob

!Fig. 2)

and

in

pocking, Shopsmith

is

secured

in

its

crot!

pull the table completely free of the carriage . Hold

Ihe tubular ways with the left hand (to prevent falling). loosen

t

he

bose plate knob.

t

he

bench. Unbolt bose plate

and

lower slowly

unti

and

l Ihe ways rest on

remove Shopsmith

from

the crate.

Arrange Shopsm

'/1-inch holes

mochine bolts. Drive bolts through

nuts

from

It

is

unnecessary to remove tie·bar

machine except outboord turning.

removed

screw and slide

position locole t

veI"';l

marring of the ways.

ATTACHING

the headrest on Ihe right side of

it

h on Ihe bench top; locate

for

the bose plote

and

from

bolt down securely with

ond

the lop side

drill 'Ii or

ond

apply

below with washers between them and the wood top.

for

011

opera lions of the

the headstock has

to

loosen the Allen set-

Ihe tie-bar

with the e)(tended

to

to

to

pre·

from

HEADR

the ways,

he

it

is

011

the tie-

setscrew

EST

necessory

bar

. In

r~Il'Tning

in

the son\e spot os before

- Raise the tubular ways and place

lie-bar

II

be

its

boss of the headresl on the side touching the lie·bor . Tighten

the headrest knob. which Ihen locks lubular ways to headrest.

Mark the centers of the headrest bolt holes on the bench top.

Do

not drill holes

III

inch

toward the bose plole.

between the tie·bor ond heodrest when Shops

the vert

ical position.)

at

these points

bUI

(This

Drill '/. or '/1·inch bo

II.

move

the cente! morks

inch

will

lt

holes.

allowct'loronce

mith

is

raised 10

Bolt

head-

rest down solidly.

MOUNTING

designed to

MOTOR

-The

be

easily inSlolied

special Shapsmi th motor hos been

and

to give

ma)(imum

service.

011

attothm!nls

r!mond

--

a

FIG

. 3 H!udstutk and motor with purts deslgnoted.

If

you

do

not have a Shopsmith motor. note carefully the

lowing requirements: Shopsmith

111 h.p. capacitor or repulsion . induction boll-bearing motor

a

having a speed

be sotislactorily performed with

tion of this versotife

quote power. The motor sha

.

HEAD

STOC

K

PUllEY

QUILL

LOCK

'--

--'1

,.,.-':...,"-

"._4

is

designed

01

1725 r.p.m. Though some

a lighter motor, l

1

001

can only be obtained by having

ft

musl

be

;;:;jC',.-"'.

HEAOSTO

'-"'-_M

ball-beoring

10

be

ope

OTOII

operated

ra tions may

ull

SHAft

KN

utiliza -

mO"'l

Oll

CK

fol-

by

ade·

ted

4

bolf'i'I/')

re"

d~d

CO

NNE

CT CURRE

TO S

Wt

TCH\ '

CONNECl "P

TO

FI

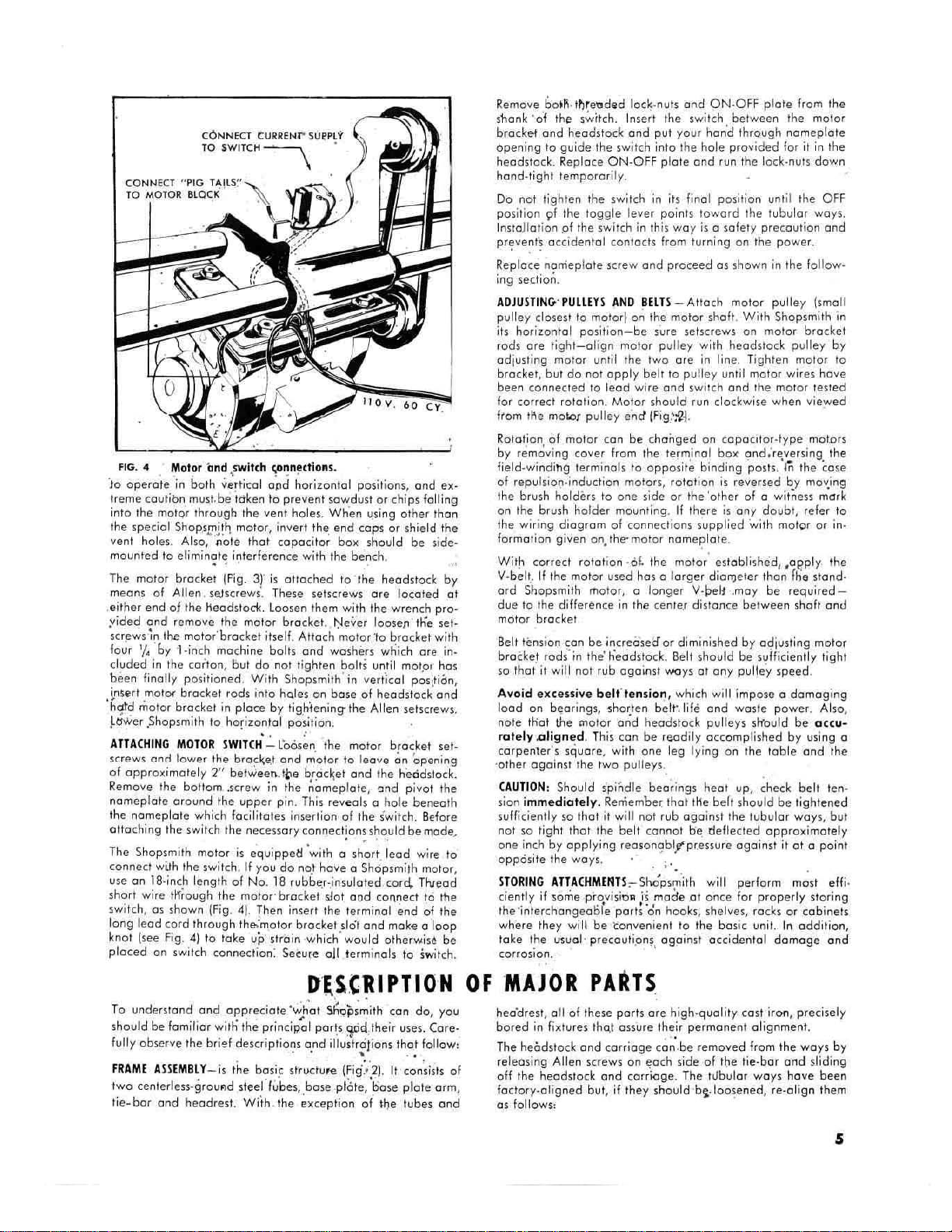

G, 4

"a

operate

treme caution mvst .be 'Idken to prevent sawdust or chips falling

in

to the motor through the vent holes, Wh'en u,sing other than

the special Shap,

vent holes. Also,

mounted to

The mo tor brocket

means of Allen . se.!screws'. These setscrews

either

end

,vided

scr~ws

four '/. ' oy l·inch machine bolts

cluded

been finally positioned, With Shopsmith '

,~nser

t

,motor brocke t rods into hales on bose of headstock

hqtd motor bracket

~

O'wer

ATTACHING

screw~

of

opproximotely 2"

Remove the bottom ,screw

nameplate

the nameplate which facili tates insertion

attaching the swi t

The Shopsm

connect with the switch ,

vse a n

short wire I

swifc:h, as

long

lead

knot (see

placed

IG TAilS"

MOTOR B

lQci

' '

Mol~r

and

,switch

in

bOlh

vertical o(ld

srn!!i't

motor, invert the,

fl

ole

elimin~tE;

of the Headstock,

and

remove the motor brocket. Never

~n

the motor'brocket itse l

in

the carton, out do not tight

.shopsmith to

MOTOR

(Inn

lower the

around

ith

18·inc.h

fI'rough

shown

cord through !ha.·motor bracket

Fig.

on

~witch

ir;terference with the bench ,

(Fig,

in

place by tig,h'lening the Allen setscrews,

hori~ontal

SWITCH''':'

broc~~t

betW:eer..I!1a

the upper pin.

ch

the necessary

motor

is

length of No.

the motor' brocket

(Fig. 4!

4~

to toke up· strain which' would

conne~tion:

Nr SUPPLY

~,!n!!ct;o"s

that c::opacitor

3)'

is

attached

loo

L'oOs~n

ond

in

Ihe

equipped

If you do

18

, Then insert the terminal

Seeur.f!

,

hariwntal

sen the m with Ihe wrench pro·

f,

AUach 'motor 10 brocket with

and

position,

m'otor to l

broc~et

~~meplate,

This

connecl!on~

'with a short

noJ

rubbe:r·insulot

positions, and ex,

end

cops or shield the

bax-

should be side·

to the

are

100se(1

woshers which are in·

en

bolti un.til motp, has

in

vertical pos,tion,

the motol blocket set·

eave

and

reveals a hole beneath

of

the switch, Bef

s~o.uld

have a Shtipsmith motor,

ed

!.lo

t o

Dd

steit

and

all

terminals to switch.

headstod

located

th'

e set·

and

~n ~pen;n9

the hecidslock.

~nd

pivo t the

ore

be

mode

lead wire

card,. Tfve:od

cOrjnect to the

end

of

make a l

otherwi5~

oop

by

the

be

at

to

Remove

~han

k

·0', the s';"itch, Insert the switch between the mot

bracke-t

and

opening to guide the

headstock. Replace

hond·tight t

Do not tighten rhe switch

position

Insta

llation pf the switch

pr~vent~

Replace

ing section.

ADJUSTlNv'PULLEYS

pulley dosesl to moto r) on the motor shaft, W ith Shopsmilh

its horizonta l positi

rods a re tigh t

adjusting motor until the two

brocket, but

been connected to

for correct rolotion, Mot

Itom

Ro

tot,ion, of molar can be

by removing cover

field·winditlg terminals to opposi te binding posts .

of

repulsion.induction molors, ro tati

the brush ho lders to

on the brush nolder mou nting.

the

wi

forma tion given on. the-motor

Wi

t!'!

V,belt,.

ord

due to the difference

motor brac ket

Be

lt

tension can

braCke,t ro

so Iho

oid exc

Av

load on b"orings, shorten belt·. life

note tnat the motor

rately.olign

corpentel'S square, with

'

othe

CAUTION

sian imm e

sufficiently so that

not so tight tha I the be

~

one

opposite the ways. ;'

HORING

cienlly

the 'interchangea!)I'e po

wh

ere Ihey w

toke the

corrOSion,

heodstock

emporar

~f

the t

a~cidento

namep

late screw

-a

do

t~

e

mok)r pulley

ring

diagram

correct rotat ion ·

If the motor used has a larg er

Sflopsmith moTor, 0 longer V·pelf ,may be lequired -

ds"in

t it will not rub

ess

ive b e If tens

ed. T

r against the two pulley s.

: Should spindle

diat

ely ,

inch by applying

AHA(;HMEI'HS

if

some provisio

ill

usu

al,

lock·nuts

and

swi

tch into the hole provided lor it

ON·OF

ily.

ogg

le lever points

in

l

contacts 'rom turning on the

AND

on-be

lign mot

not

apply belt

lead

wire

or

end

from

one

of connec tions supp lied with motor or in.

6L

in

the cente.r

be

in~reo'sei:f

the' h·eadstock. Belt

agolflsl

and

his

con be

Reniembe

it

will not rub against the tubul

lt

reoson9bltpreHure

;-

ll

rt

be

tonvenient to the basic unit.

precouti.on~

and ON·O FF pla

put your hon'd through nam

F pl

ate

and

run

in

its final position unt

this

ond

BELTS

or

should run

(F"ig,'9

changed

the term.ina l box'

side

ihe motor' establish

ion

headstock pulleys sh'ould

one

bear

connol

sho"

is

s 'on hooks,

toward

wo

y

is 0 so

pro~eed

sure setscrews on motor bracke t

pulley wi

to pulley until motor wires have

and

name~late

or

ways

, which

readily

leg lying on the t

~

that

ps'~;

mode

.

against accidental da

0$

shown

- Attach motor pulley (sma

th

are

~

or

II

diminished by adjvsting motor

ings heat up, check belt ten·

i t

headstock pulley by

in

line. Tight

switch

and

~Iockwise

on copOCltor·type motors

on

is

reversed by moving

the 'other of a witn

there

is

,

dian;r

dislafl~e

should be s,!fficiently tight

at

any pultey

will

impo se a

and

waste power, Also.

acc

omplished by using a

tHe

belt should be tightened

be

deflect

against it a t a po i

h

will

.01

once for properly storing

shelve~,

re

from

the lock·nuts down

il

the Tubul

lety precaution

r;Jnd :

any doubt, refer to

elcr than fho stand·

between shaft

ed

perform

ra

the OFF

ar

power

in

the follow·

en mot

the morar rest

wh('n vi('wed

r~versing.

If, the

eH

ed, .o,?ply the

speed

damaging

be

able

and

ar

ways, bul

approximately

m~s

ch

or cobinets

In

addi tion,

mage

the

or

eplate

in

the

ways

and

.

in

or

to

ed

the

case

m'ar

and

.

occu

the

t

ell

and

ll

k

-

nt

i.

DlS.CllIPTlON

To

understand

shovld be familiar with the

fully observe the brief descriptions

FRAME

two centerless· groufld steel'I;;bes, bo se pl6 le, 'case plale arm, foctor y.oligned but,

tie_bar ond he

and appreciate

ASSEMBLY

adrest, With . the

_is

the ba

·wh'a t

princi

p~1

part5

and ili

...

.

sic

strvcturc (Fil;{.·2J.

~xception

~

op

;~i

t

h

~d,th

usirci

Jions that follow:

of tbe tub es and

can

do, you hea'drest, all

eir

uses, Care·

It

con'

sis

ts of o

OF

MAJOR

bored

in

Th

e

heodsto~

releasing Allen screws on each side of

ff

the he

as

follows:

of

fixlvre s

k

odstod

PARTS

these parts

thc.t

assvre their permanent a lignment.

and

carriage

and

corr'iage, The rrJbulor wa ys have been

if

they shovld b"

a~e

high.quality cosl iron, precise

c~n·.be

removed from the ways by

t

~e

ti

e· ba r and $Iiding

..

lao~ene

d

,

re·olign them

ly

5

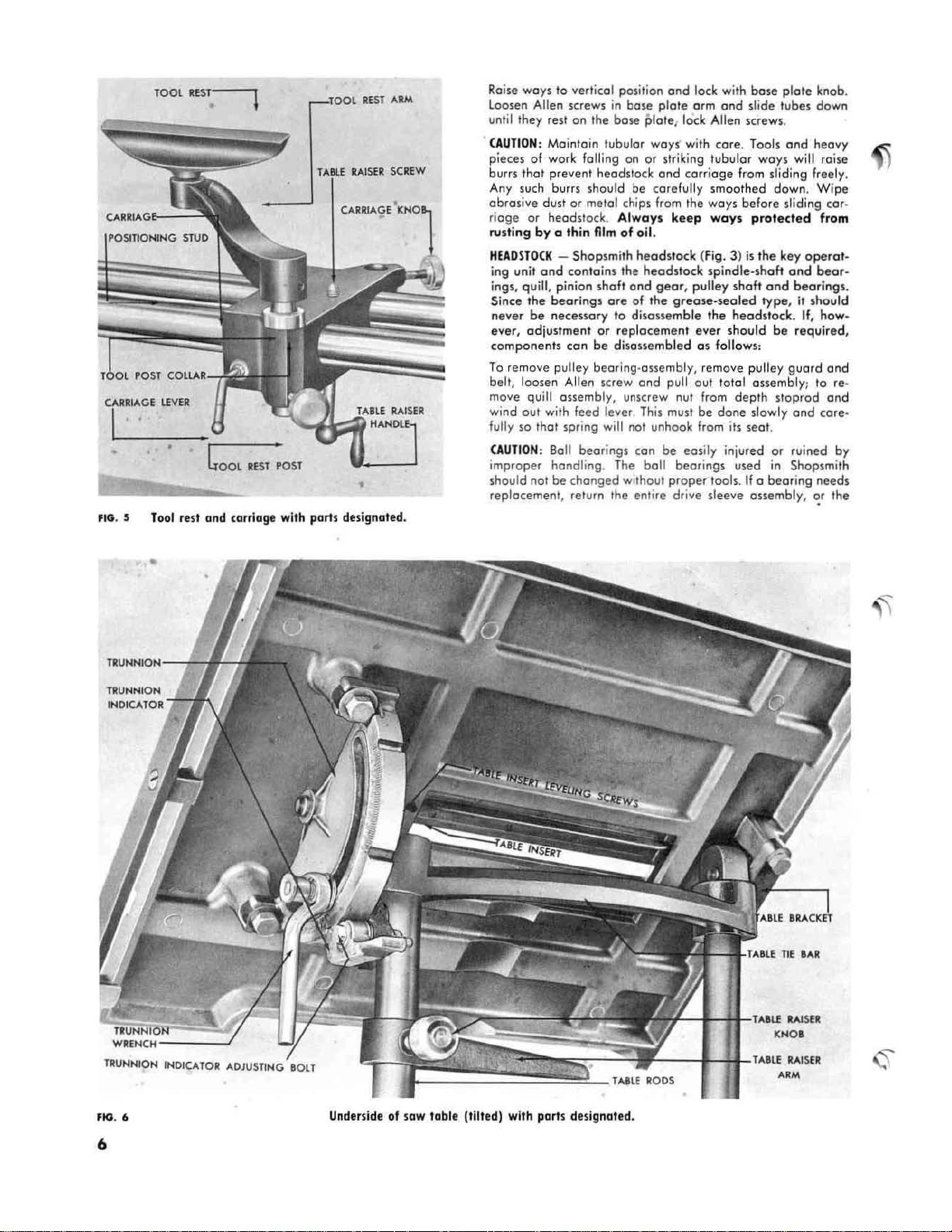

FIG. 5

TOOL

POST COI

Tool res

REST~

...

"--;

COOL

REST

POST

lOOl

REST

RAISER

•

t and (arrloge with parts designated.

AIIM

SCREW

Ra

ise ways 10 verticol position

Loosen Allen screws

in

unlil Ihey rest on the bose

CAUTION; Ma

inta

in

'ubular ways wilh core . Too ls

pieces of work falling

burrs that prevenl headstock

Any such

abras

rioge or h

ru

sting

HEADHOC

ing unil

ings, quill, pinion

Sinc:e

never

bum

iv

e dust or metal chips

by

should be carefully smoothed down. Wipe

ea

dstock. Alw

a thin

flIm

af

K - Shopsm ith headstock (Fig. 3)

and

contoins the headstock spindle·shaft

sh

the

bearings arc

be

necessary to disassem

ah

ever, adjustment or replo(ement

an

be

components c

To

remove pulley beoring·assembly, remove pulley guord

disossembled as follows:

belt, loosen Allen screw

move quill ossembl

y,

wind out wilh feed lever T

fully so thai spring

CAUTION; Ba

will

ll

bearings ca n be easily injured

improper handling. The ball bearings used

should not be changed Wllhout proper lools.

nt

replaceme

, return the entire dri

and

bose plate a

pl

on

or striki

lock wilh bose plole knob.

rm

ole;

and

from

and sli

lock All

en screws.

ng

tubular ways

carriage

from

the ways before sliding cor·

ays keep ways protect

oil.

ond

gear

and

his

, pulley shaft

grease.sea

ble

pull

must

Ihe

head

ever

should

Qut

10101

from

be

done slowly

led

depth staprod

from its seo

ve

sleeve assembly, or Ihe

of Ihe

unscrew nut

not unhook

de tube

sliding freely.

is the

ond

type

stock. If, how-

be

assembly; 10 reo

l.

Of

in

If a

bea

s down

and

heavy

will rais

ed from

key

opero

ond

bear

bearing

,

il

should

required,

and

core·

ruined by

Shopsmilh

ring needs

e

t-

-

s.

and

and

•

TRUNNION

TIIUNNION INOICATOII AOJUSnNC; 1

fIG

. 6

0lT

Underside of saw

h:Jbl

e (tilled) with ports designated.

-----t

__

~-"'.l'UIUR

.oM

6

Loading...

Loading...