Shopify MotoMask PRO User Manual

USER'S MANUAL

CONTENTS

Brief description

2

Attention

2

Parts overview

3

Masking roller assembly

7

Frame assembly procedure

10

Attaching the frame to the wall

22

Testing the product

24

How to retrofit the masking roller

25

Size and measurement overview

28

Masking system setup

30

BRIEF DESCRIPTION

2

Thank you for purchasing the multi masking MotoMask PRO screen.

The masking system is retrofittable and can be purchased and installed later on.

FEATURES

• Separate frame and masking system.

• Built-in wireless RF receiver, as well as RS485 for smart home setups.

• Automatically stops if an obstacle is met to protect the motor.

• The position of the masking can be fine tuned and stored using the remote.

• For the 16:9 version, you can even close the entire masking fabric

while not in use.

• Professional grade quality for maximum rigidity even for very large screen

XXL sizes.

ATTENTION

Please read following instruction before installation of the product:

• Please handle with care.

• During installation, please choose a suciently sized, clean area.

• Lifting and attaching this very heavy screen system to the wall after

assembly normally requires 3 or more people.

PARTS OVERVIEW

3

Outer

frame

Frames>3m in width are divided.

The quantity of sections depends

on the size of the frame.

Inner

frame

Frames>3m in width are divided.

The quantity of sections depends

on the size of the frame.

DrawingItem Description

"L" shape

connection part 1

Used for connecting the inner and outer frame.

Quantity depends on the size of the frame.

L" shape

connection part 2

Used for connecting the corners

of both inner and outer frame.

Quantity: 16 PCS

“U” shape

connection

part 1

Used for connection of the inner and outer

frame. Quantity depends on the size

of the frame.

“U” shape

connection

part 2

Used for fixing the supporting bar.

Quantity depends on the size of the frame.

Supporting

bar

Diameter: 30 × 30mm

Quantity and length depends on the size

of the frame.

Lower wall

mounting bracket

Used for mounting the lower section

of the frame. Quantity depends on the size

of the frame.

Upper wall

mounting bracket

Used for mounting the upper section

of the frame. Quantity depends on the size

of the frame.

4

Preinstalled

metal 1

Used for fixing the supporting bar

connector. (Preinstalled in support

bar). Quantity depends on the size

of the frame.

Preinstalled

metal 2

Preinstalled in inner and outer frame.

Quantity depends on the size

of the frame.

Corner connector 2

for upper outer

frame.

Used for connecting the upper corners

of the outer frame. Please notice the

dierence from the other included

corner connectors.

Quantity: 2PCS

Preinstalled

metal 3

Used for fixing the supporting bar.

Quantity depends on the size

of the frame.

Connector

parts

Used for connecting the inner

and outer frame >3m wide. Quantity

depends on the size of the frame.

Corner connector 1

for upper outer

frame.

Used for connecting the upper corners

of the outer frame. Please notice the

dierence from the other included

corner brackets. Quantity: 2PCS

Grip rail

Used to attach the UltraWeave

screen fabric. Quantity depends

on the size of the frame.

DrawingItem Description

3mm inner

hexagon

spanner

4mm inner

hexagon

spanner

Quantity: 4PCS

Corner connector 3

for the lower corners

of the outer frame.

Used for connecting the lower two

corners of the outer frame. Please notice

the dierence from the other included

corner connectors. Quantity: 4PCS

Quantity: 4PCS

5

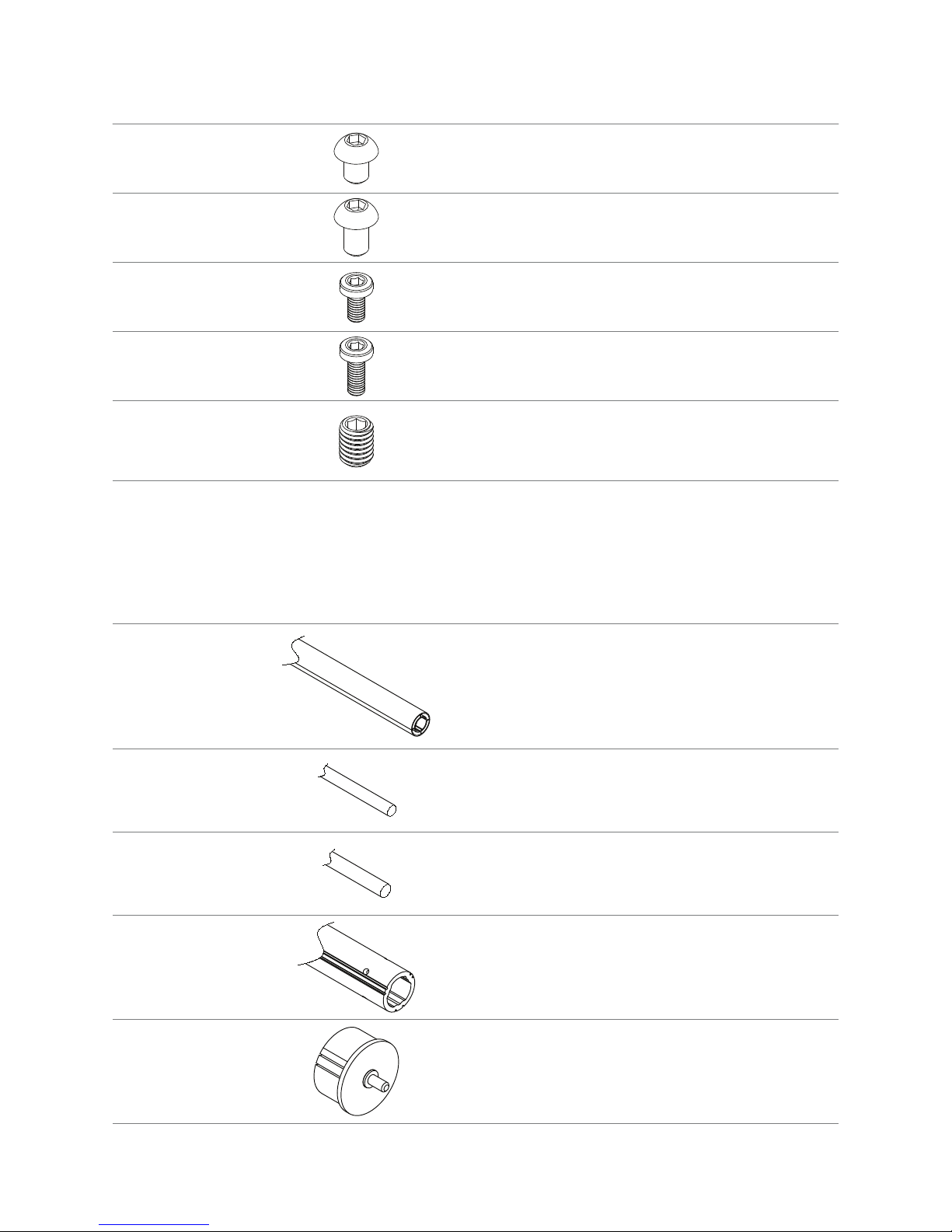

M6*8 screws

Quantity depends on the size

of the frame.

M6*8 set screws

Used for fixing metal in the frame

(most are pre-installed). Quantity

depends on the size of the frame.

DrawingItem Description

Gloves

Quantity: 2

Tail

plug

Please make sure the tail plug is installed

on the correct side before securing it into

the masking roller.

Quantity depends on the size of the roller.

Weight

steel rod

Roller

connection

parts

70mm

diameter

roller

Masking rollers>3m

are divided in two or more parts.

Quantity depends on the size of the roller.

MASKING ROLLER PARTS OVERVIEW

Glass fiber

bar

Quantity depends on the size of the roller.

Length: 300mm.

Pre-installed in divided rollers.

Quantity depends on the size of the roller.

M6*10 screws

Quantity depends on the size

of the frame.

M6*12 screws

Quantity depends on the size

of the frame.

M6*20 screws

Quantity depends on the size

of the frame.

6

DrawingItem Description

Cross screwdriver

Used for the 70mm diameter roller.

(Only supplied for divided masking rollers.)

Right masking

roller bracket

Installed on the (right) motor side.

Quantity:1PCS

Left masking

roller bracket

Installed on the tail (left) side.

Quantity:1PCS

Bottom

bar

Bottom bars >3m

are divided in two or more parts.

Quantity depends on the size of the roller.

Bottom bar

connection

parts

Length: 120mm

Used to connect the bottom bars if divided.

Quantity depends on the size

of the masking roller.

Tubular motor

Motor and integrated control system

110V (US) or 220V.

Power cable

EU or US type.

Fabric for the

masking roller

Only supplied separately for the divided

masking rollers, pre-installed for the

non-divided version (<3m).

Quantity:1PCS

M4*6 screws

Used for the bottom bar.

(Only supplied for divided masking rollers.)

MASKING ROLLER ASSEMBLY

(only applicable for divided rollers, <3m rollers are pre-assembled)

7

Required tools for the installation.

• Fabric for the masking roller (supplied)

• 3M double sided tape (supplied)

• Cross screwdriver (supplied)

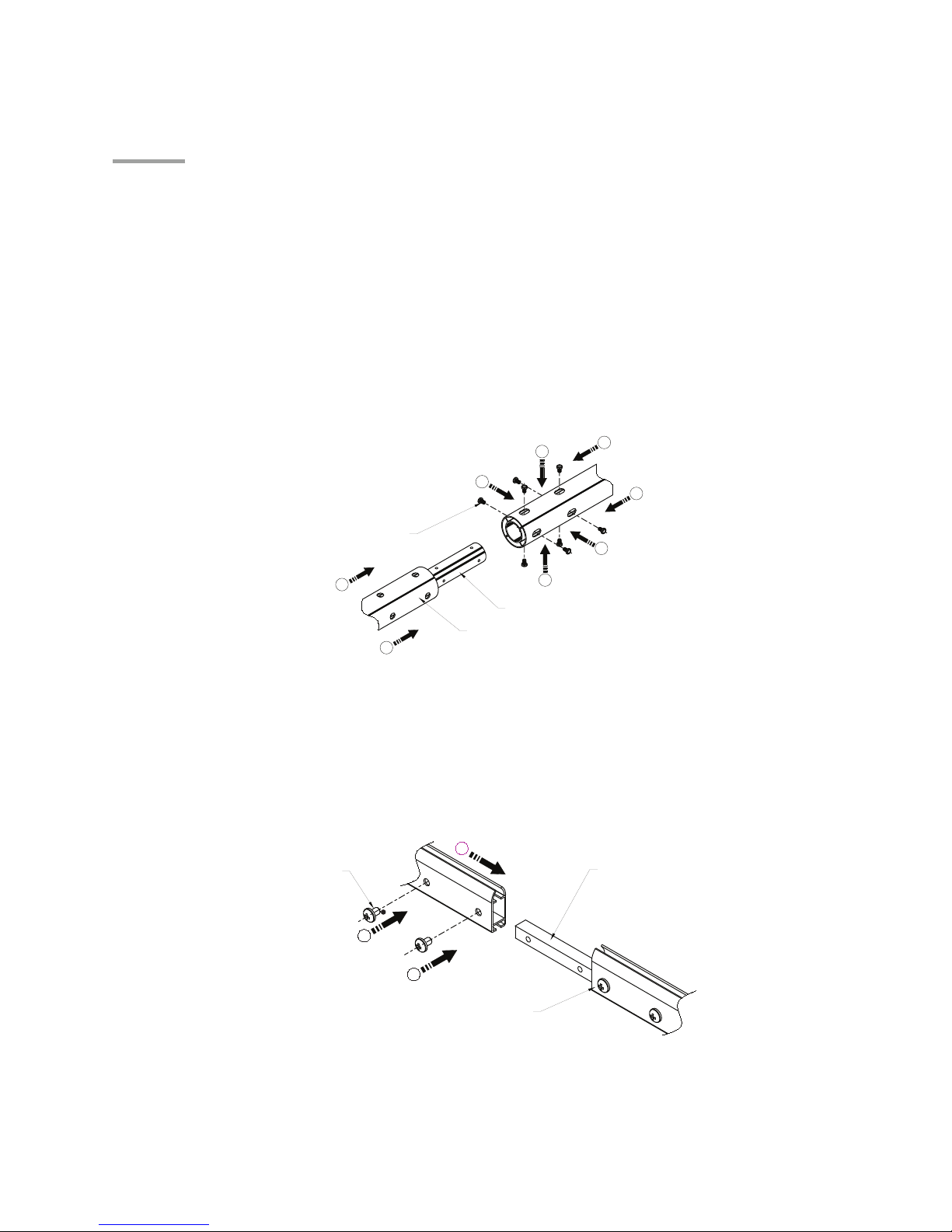

Step 1: Connect the divided roller.

• Most of the parts required for connecting the masking roller is already pre-installed.

• Align the two parts, slide the parts together and then secure them with the included screws.

Sliding the two parts together can sometimes be a bit tricky as the spacing is very tight

(it has to be to ensure sucient rigidity). If needed, please use a rubber hammer

or a similar device to help sliding the parts together.

Drawing 4-1

Step 2: Connect the divided bottom bar.

• The connection parts are already fixed.

• Insert the connecting piece into the other lower bar part and then tighten the screw to complete

the connection of the divided bar. (Note: the screw used for securing the bottom bar must be

facing the back (i.e. not the audience) of the screen.)

This side

has been fixed

1

Connection

parts

2

2

Drawing 4-2

M4*6 screws

Step 3: Fixing the masking fabric to the roller.

1. Please make sure you find a clean and suciently sized area to perform the installation.

Connection parts

M6*10 Screws

These parts are pre-fixed

1

1

1

1

2

2

2

2

8

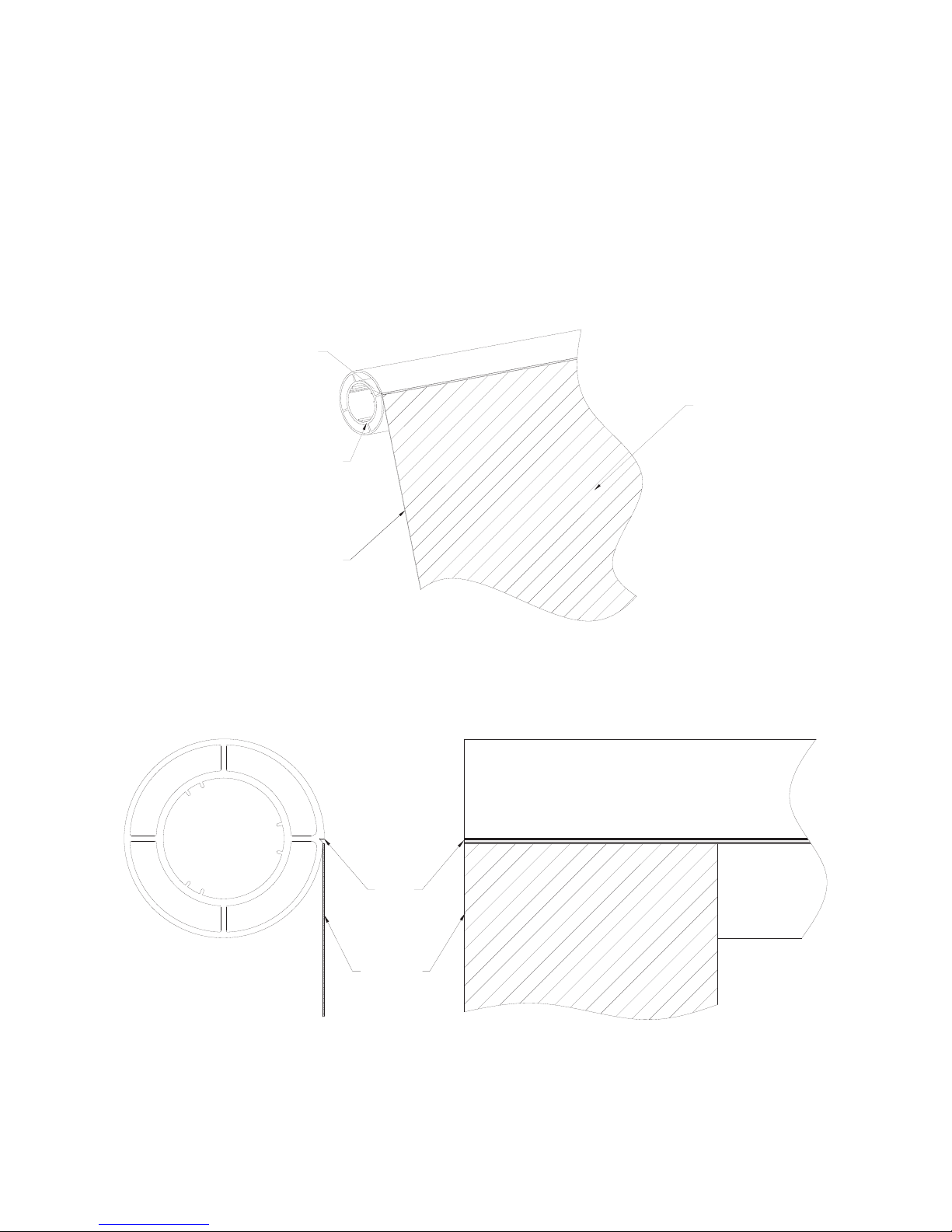

2. Please attach the included 3M double sided tape to the masking roller, just below the small step

found in the roller.

3. Place the roller tube with the motor side to the left and tail side to the right. Please note that

when installing the masking roller into the frame later on, this direction is opposite (seen from

the back of the frame), i.e. the motor is on the right side and tail on the left.

4. Install the fabric flush with the edge at the left side and install it towards the right as per

drawing 4-3. There will be an approximate gap of 5mm left on the right (tail) side.

For the 2.40:1 2-way masking systems, please attach the left side flush, but use a 5mm gap

on the right (tail) side as well, as per drawing 4-5.

Masking fabric

Edge of the masking fabric

Edge of the roller

Drawing 4-3

Step

Drawing 4-4

Step

Masking

fabric

9

5. Please insert the glass fiber bars into the lower pocket of the masking fabric as per drawing 4-6.

6. Please insert the weight steel rod in the cavity just below as per drawing 4-6. Please note that

the connection piece might block the passage, so you might need to lift and navigate a little

at this section.

Drawing 4-6

Drawing 4-5

Step

Masking

fabric

5mm

Back side

step

Weight

steel rod

Glass fiber bar

Bottom bar

Bottom bar connection parts

Viewing side

10

How to distinguish the placement of corner connection parts and position

of the masking roller.

Drawing 4-5 (Viewed from the back of the frame.)

Motor sideTail plug side

Corner connector 1

Corner

connector 2

Corner connector 1

Corner

connector 2

M6

M6

M6

M6

FRAME ASSEMBLY PROCEDURE

Step 1: Put the inner and outer frame parts according to the layout in drawing 5-1-1.

All parts have corresponding numbers attached to them.

• The frame section parts are labeled as per drawing 5-1-1.

• For smaller frames, the numbers are corresponding to the number of parts that make out the

frame, always starting with part 1 from the right short side. For example, for a <3m non-divided

frames, the total number of components of both the outer and inner frame is 4 (per frame

section), the right short side has #1, the lower long side has #2, the left short side #3 and finally

the upper long side #4.

Loading...

Loading...