Page 1

MODEL M1024

TAPER ATTACHMENT

FOR USE WITH MODEL M102 0

INSTRUCTION MANUAL

Phone: 1-360-734-3482 • On-Line Technical Support: tech-support@shopfox.biz

COPYRIGHT © JANUARY, 2005 BY WOODSTOCK INTERNATIONAL, INC.

WARNI NG: NO PO RTION OF THI S MANUA L MAY B E REPRO DUCED IN ANY S HAPE OR F ORM WITHOU T

#6726 BL

THE WRI TTEN AP PROVAL OF WO ODSTO CK INTERNATIONA L, INC.

Print ed in Tai wan

Page 2

M1024 Taper Attachment

-2-

Page 3

M1024 Taper Attachment

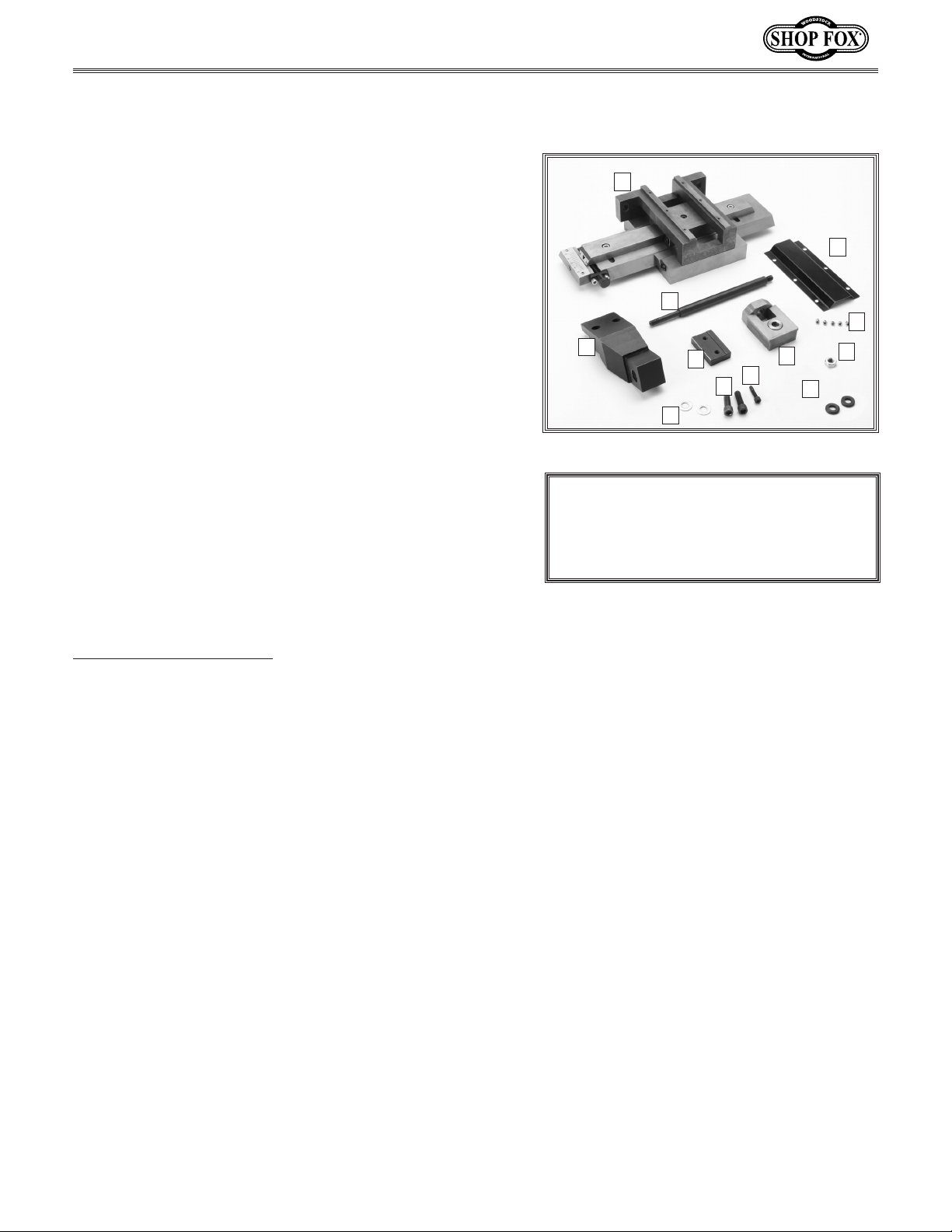

INVENTORY

The following is a description of the main components

shipped with the

Attachment. Lay the components out to inventory them.

Box Contents (Figure

QTY

A. Taper Attachment Body ..................................1

B. Clamping Bracket ..........................................1

C. Clamping Jaw ..............................................1

D. Support Rod ................................................1

E. Top Cover Plate ...........................................1

F. End Block ...................................................1

G. Cap Screws M10-1.5 x 35 .................................2

H. Cap Screw M6 x 25 ........................................1

I. Hex Nut M10-1.5 ...........................................2

J. Flat Washers 10mm .......................................2

K. Spacers 12mm ..............................................2

L. Phillips Head Screws M5-1 x 6 ...........................6

If any parts appear to be missing, examine the packag

ing carefully to be sure those parts are not among the

packing materials. If any parts are missing, find the

part number in the back of this manual and contact

Woodstock International, Inc. at 360-734-3482 or at

tech-support@shopfox.biz

SHOP FOX

1)

®

Model M1024 Taper

-

A

E

D

L

B

Figure 1. Main contents.

C

G

J

F

H

I

K

NOTICE

When ordering replacement parts, refer

to the parts list and diagram in the back

of the manual.

-3-

Page 4

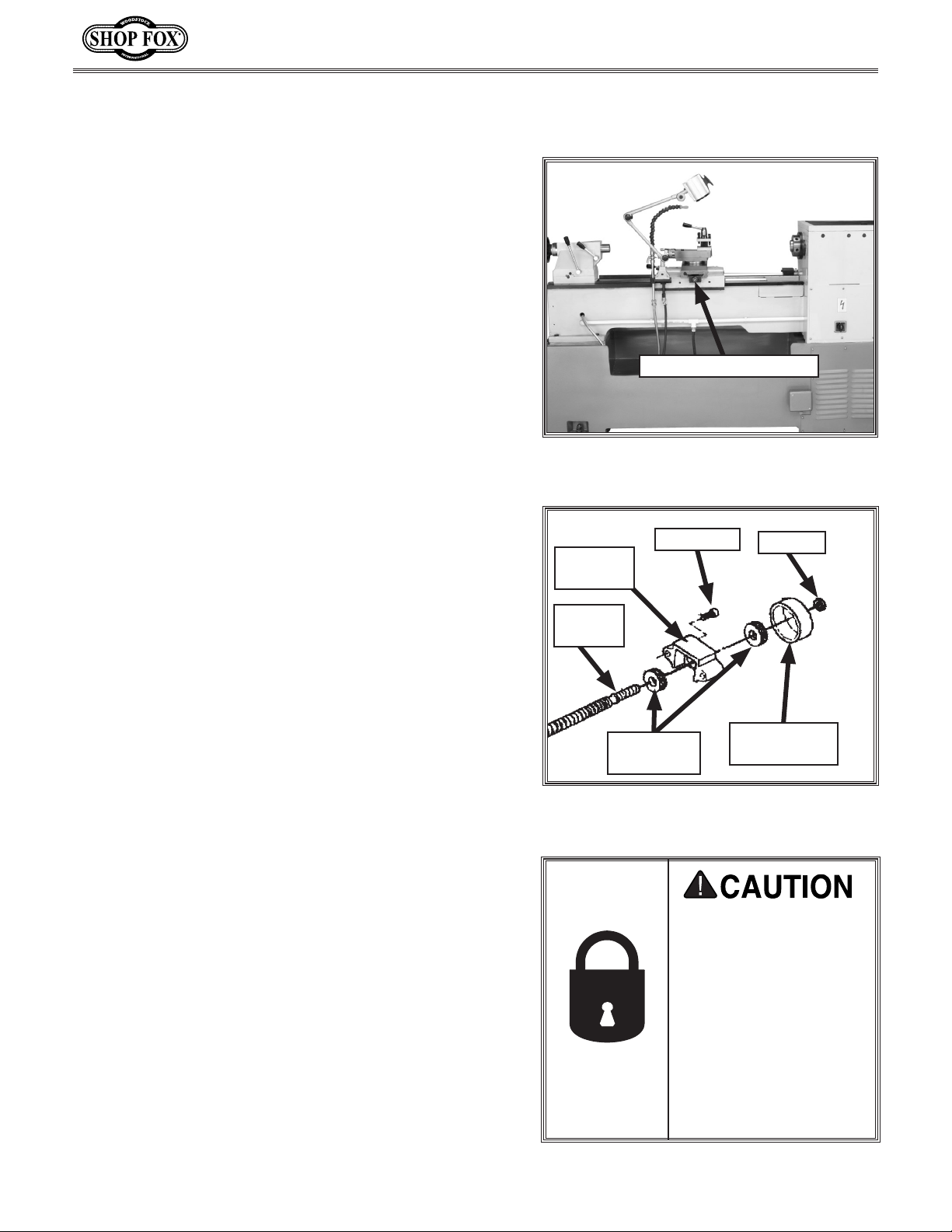

INSTALLATION

The Model M1024 Taper Attachment mounts quickly to

the back of the carriage and bed way of the Model M1020

Gear Head Lathe. Accurate tapers up to 6" can be pro

duced without repositioning the attachment. The Model

M1024 features a scale for reading degrees.

adjusting screw with fine threads achieves precise control

when setting tapers. Another feature is the ability to use

it without disengaging the cross slide nut. This will allow

it to be functional at any time by simply tightening the

deadman.

The Model M1024 comes carefully packaged and coated

with grease for rust protection. You will need to clean

all pieces thoroughly prior to installation and use. Use a

solvent cleaner or citrus-based degreaser. For optimum

performance from your machine, make sure you clean

all moving parts or sliding contact surfaces that are

coated. Avoid chlorine-based solvents and gasoline as

they may damage painted surfaces should they come in

contact. Always follow the manufacturer’s instructions

when using any type of cleaning product.

An angle

-

M1024 Taper Attachment

Cross Slide Lead Screw

Figure 2. Back of lathe with splash guard

removed.

Cap Screw

Bearing

Housing

Hex Nut

Installing the Taper

Attachment

To install the taper attachment, do these steps:

1. Disconnect the lathe from its power source!

2. Remove the splash guard from the back of the lathe

(Figure 2). If the lathe must be moved to allow

access to the splash guard, consult the lathe manual

for safe moving information.

: If you move the lathe, be sure to re-level it

Note

after returning the lathe to its final location.

3. Remove the hex nut that holds the bearings in place

at the end of the cross slide lead screw (Figures 2 &

3).

4. Remove the bearing dust cover and thrust bearing

from the end of the lead screw.

Lead

Screw

Thrust

Bearings

Figure 3. Cross lead screw components on

lathe.

MAKE your shop “child

safe.” Ensure that your

workplace is inacces

sible to youngsters by

closing and locking all

entrances when you

are away. NEVER allow

untrained visitors in

your shop when assembling, adjusting or

operating equipment.

Bearing Dust

Cover

-

-4-

Page 5

M1024 Taper Attachment

5. Remove the two cap screws securing the bearing

housing. Leave the remaining thrust bearing on the

lead screw (

6. Remove the six Phillips head screws from the top

cover plate of the taper attachment body. Set the

screws and cover aside for later use.

7. Remove the cap screw and end block from the taper

attachment body (

8. Slide the end block and the thrust bearing over the

lead screw.

9. Thread the end nut onto the end of the lead screw

(Figure 6) and tighten the nut while holding the

cross slide handwheel

To check, turn the end block. Only a small amo

of resistance should be felt. Adjust the nut as need

ed.

Figure 4).

Figure 5).

. Do not over-tighten the nut.

unt

-

Bearing

Housing

Bearing

Dust Cover

Hex Nut

Thrust Bearing

Figure 4. Lead screw component

identification.

Lead Screw

Cap

Screws

Thrust

Bearing

Pieces

End block

Figure 5. Removing end block from main

body.

Figure 6. Installing end block onto lead

screw.

-5-

Page 6

Mounting Taper

Attachment Body

The taper attachment is heavy and could cause serious injury if it drops on you. To minimize this possi

bility, have an assistant hold the main body while it

is being attached to the lathe

To mount the taper attachment, do these steps:

1. Remove any paint or debris from the two threaded-

holes on the rear of the lathe carriage. Debris could

cause the taper attachment bolts to not screw in

completely.

.

M1024 Taper Attachment

-

2. With the help of an assistant, align the the two holes

on the taper attachment body with the thread holes

on the lathe carriage. Use two M10-1.5 x 35 cap

screws to loosely fasten the main body to the lathe.

A long-handled, ball end 8 mm

best for this step (

3. Tighten the two cap screws adjacent to the lathe on

the underside of the taper attachment body (

8).

4. Turn the cross slide handwheel to align the hole

in the end block with the hole in the taper slide

(Figure 9).

Note: The dovetail ways of the cross slide must clear

the top of the taper attachment and line up with the

dovetails on the taper attachment. The mounting

holes in the taper attachment are oversized to allow

for minor height adjustments.

5. Adjust the taper attachment for clearance and check

that the cross slide moves in and out, along its full

range of motion, without increased resistance. When

the cross slide moves unobstructed and smoothly,

tighten the mounting screws.

Figure 7).

hex wrench works

Figure

Figure 7. Mounting main body onto lathe

while tightening cap screws.

Figure 8. Tightening cap screws under

main body.

Cross Slide

Mounting

Screws

Main

Slide

6. Reassemble the top cover plate, using the six

Phillips© head screws.

-6-

Taper

Bar

Figure 9. Tightening cap screw on end

block.

Taper

Slide

Page 7

M1024 Taper Attachment

Deadman Installation

The deadman is composed of a solid cast clamping bracket and a loose clamping jaw. The bracket has two holes

for clamping screws that attach the clamping jaw (Figure

10).

Clamping

Screw

To attach the deadman, do these steps:

1. Place the clamping bracket over the lathe bed way

and slide the clamping jaw underneath the bracket.

2. Place clamping screws into the two holes on the

clamping bracket and tighten them.

3. Adjust the clamping screws until the clamping jaw

and bottom of the bed way are parallel. If these surfaces are not parallel, loosen the clamping screws

and adjust them as needed.

4. Fasten the short threaded end of the support rod

into the hole on the left side of the taper attachment body and turn the rod counterclockwise until it

fits tightly (

5. Place a washer over the longer threaded end of the

support rod.

6. Loosen the clamping screws enough to slide the support rod through the hole in the clamping bracket.

Figure 11).

Clamping

Bracket

Bed

Way

Clamping Jaw

Figure 10. Deadman components.

Deadman

Support Rod

7. Slide a second washer over the threads, and fasten a

M10-1.5 nut to the end of the rod.

8. Adjust the position of the clamping bracket until

the support rod is parallel with the lathe bed and

tighten the clamping screws on the clamping bracket

(Figure 12).

Note: Position the deadman as close to the main

body as possible for the best stability

9. Re-attach the splash guard to the lathe and reposition the lathe as needed.

.

Figure 11. Installing support rod onto

taper attachment.

Figure 12. Deadman installed onto taper

attachment.

-7-

Page 8

OPERATIONS

Angle Adjustments

The taper angle is adjusted by loosening the two cap

screws at the ends of the taper bar on the taper attach

ment. The angle adjusting knob allows for fine control

of the angle (Figure 13). A scale on the left side of the

taper (labeled in degrees) allows you to get close to the

desired taper, but finer adjustments should be made

with an indicator and test bar. Once the desired setting

is reached, tighten the two cap screws. Double check the

setting to ensure accuracy.

-

Scale

M1024 Taper Attachment

Cap Screw

on Taper

Bar

Angle

Adjusting

Knob

Deadman Adjustments

To use the taper attachment, tighten the clamping screws

on the deadman to secure it to the lathe bed. When

not in use, loosen the clamping screws. Removal of the

deadman or the taper attachment is not necessary when

changing from taper turning to straight turning.

Figure 13. Angle adjustment scale.

Always wear safety glasses when operating the lathe. Failure to comply may

result in serious personal injury.

-8-

DO NOT investigate problems or adjust

the lathe while it is running. Wait until

the machine is turned off, unplugged

and all working parts have come to a

complete stop before proceeding!

Page 9

M1024 Taper Attachment

Top Gib Adjustments

The top gib, shown in Figure 14, is mounted to a taper

that moves along the taper bar on the taper attach-

slide

ment. The slide maintains the motion of the cross slide

to produce the taper. If the gib is too loose, the angle

can be affected and the finish will suffer. If the gib is too

tight, the slide will not move freely.

To adjust the top gib, do these steps:

Top

Gib

Screw

Top

Gib

1. Adjust the taper bar angle to zero.

2. To tighten the gib, loosen the gib screw on the left

side of the taper slide (as viewed from the front of

the lathe) and tighten the right screw (see

14). To loosen the gib, loosen the right screw and

tighten the left screw.

3. The gib is properly adjusted when the taper slide

can be moved by hand with moderate force.

Figure

Bottom Gib Adjustments

The bottom gib, shown in Figure

back inside edge of the main body casting. If the gib is

too loose, finish problems will occur. If the gib is too

tight, the main slide will not move smoothly.

To adjust the bottom gib, do these steps:

1. To tighten the gib, loosen the gib screw on the left

(as viewed from the front of the lathe) and tighten

the right screw. To loosen the gib, loosen the right

screw (Figure 14

) and tighten the left screw.

14, is mounted on the

Bottom

Gib

Screw

Figure 14. Gibs and gib screws.

Bottom

Gib

2. Double-check the main slide to ensure that it moves

smoothly. Re-adjust if necessary.

3. Re-attach the support rod to the taper attachment

body.

-9-

Page 10

M1024 Taper Attachment

PARTS

-10-

Page 11

M1024 Taper Attachment

REF PART # DESCRIPTION REF PART # DESCRIPTION

1 XM1024001 CLAMPING JAW 21 XM1024021 SUPPORT SPACER

2 XM1024002 CLAMPING BRACKET 22 XM1024022 PINNED KNOB

3 XPSB40M CAP SCREW M8-1.25 X 35 23 XPRP61M ROLL PIN 3 X 12

4 XPN02M HEX NUT M10-1.5 24 XM1024024 TAPER SLIDE GIB

5 XM1024005 SPACER 12MM 25 XM1024025 TAPER SLIDE

6 XM1024006 SUPPORT ROD 26 XM1024026 GIB SCREW M8-1 X 20

7 XM1024007 SCALE PLATE 27 XM1024027 GIB

8 XPS49M PHLP HD SCR M3-.5 X 5 28 XPSB12M CAP SCREW M8-1.25 X 40

9 XM1024009 INDICATOR PLATE 29 XM1024029 BLOCK

10 XPS49M PHLP HD SCR M3-.5 X 5 30 XPSS26M SET SCREW M5-.8 X 6

11 XM1024011 TAPER BAR 31 XM1024031 COVER

12 XPN03M HEX NUT M8-1.25 32 XPS19M PHLP HD SCR M5-.8 X 6

13 XPSB31M CAP SCREW M8-1.25 X 25 33 XPSB84M CAP SCREW M10-1.5 X 35

14 XPSB58M CAP SCREW M8-1.25 X 12 34 XPW04M FLAT WASHER 10MM

15 XM1024015 PIVOT BLOCK 35 XM1024035 TAPER ATTACHMENT BRACKET

16 XM1024016 MAIN SLIDE 36 XPSB06M CAP SCREW M6-1 X 25

17 XM1024017 BLOCK NUT 37 XM1024037 SHOULDER BUSHING

18 XM1024018 TAPER ANGLE LEADSCREW 38 XM1024038 SLIDE BLOCK

19 XM1024019 BLOCK 39 XM1024039 END BLOCK

20 XPSB01M CAP SCREW M6-1 X 16 40 XPSB01M CAP SCREW M6-1 X 16

Parts List

-11-

Page 12

Loading...

Loading...