Page 1

Model D1700/D1701

Moulding Head

Instruction Sheet

Phone #: (360) 734-3482 • Online Tech Support: tech-support@shopfox.biz • Web: www.shopfox.biz

To reduce risk of serious personal injury when using

moulding head:

• Always wear ANSI-approved eye and hearing

protection when using moulding head.

• Never use on

• Never operate with only one knife installed.

• Always ensure BOTH knives are firmly secured in

place BEFORE starting shaper.

• Never feed lumber with rotation of moulding

head.

• Follow safety guidelines of shaper manufacturer.

1

⁄2" spindle.

Introduction

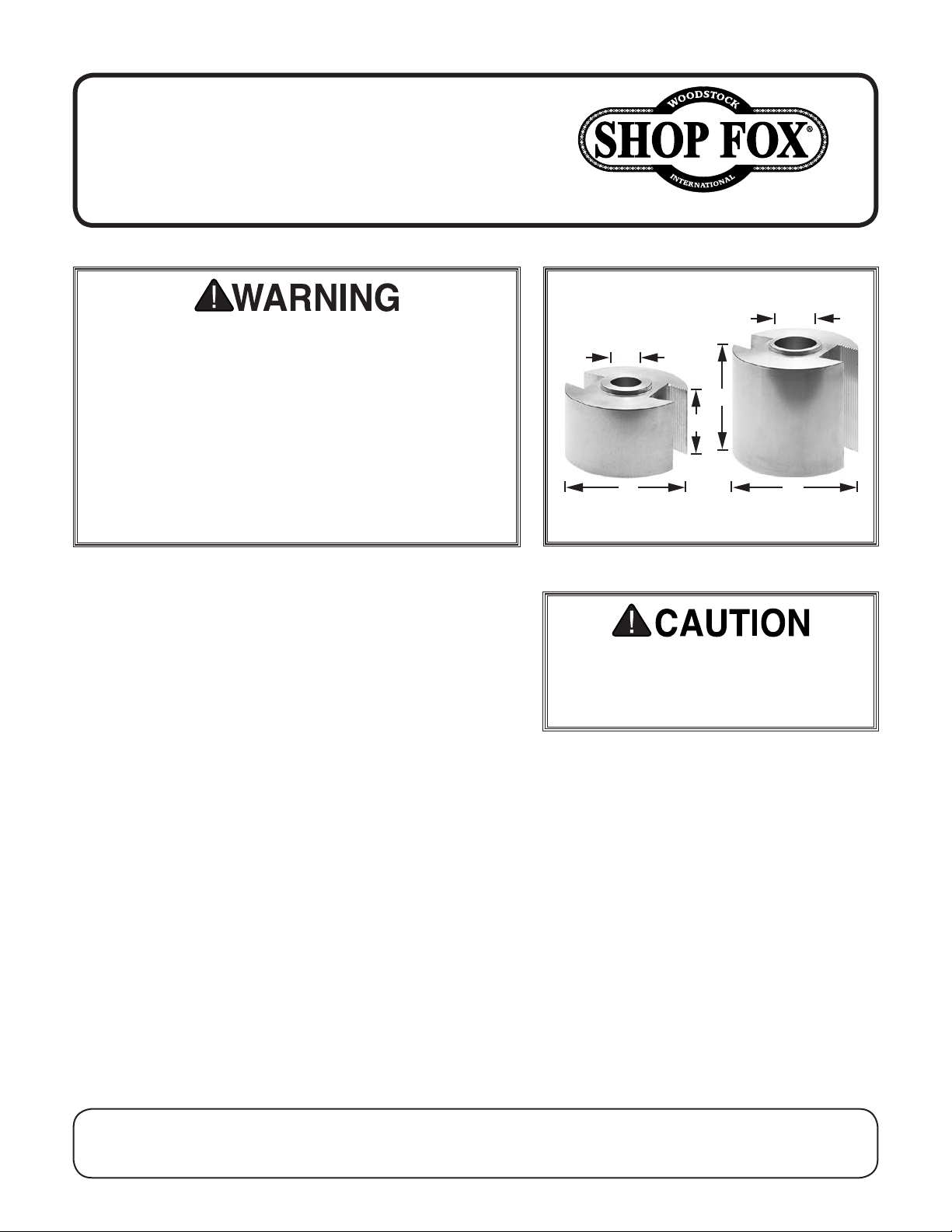

The D1700/D1701 2-Knife Moulding Head (see Figure 1) is

designed to be used on a vertical spindle shaper. It is made

of the highest quality aircraft aluminum and machined to

exact tolerances. The moulding head accepts matched

pairs of interchangeable, corrugated-backed high-speed

knives (not included). The moulding head will use either

60˚ or 90˚–cut corrugations that are spaced

The knives lock into position by wedge-type gibs for maximum safety.

1

⁄16" apart.

1"

¾"

3"

2"

D1700

3"

Figure 1. Moulding head dimensions.

Moulding knives have sharp edges. Use

care while removing them from package.

Remove oily film to help ensure knives

securely mount in moulding head.

D1701

3"

DO NOT use this moulding head on any machine other than

one equipped with a

spindle for the D1701. The shaper should have at least a

1

⁄2 HP motor. We also recommend operating a power

1

feeder when using the moulding head, as it helps feed the

workpiece steadily and consistently for best cutting

results, while at the same time helping you keep your

hands a safe distance away from the cutter.

Important: These instructions and drawings are intended

for explanation and clarification purposes only as they

pertain to the moulding head. You must apply all safety

measures as they relate to shaping operations and your

specific equipment. Review and apply all safety measures

before you use this moulding head.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

3

⁄4" spindle for the D1700, or 1"

COPYRIGHT © SEPTEMBER, 2015 BY WOODSTOCK INTERNATIONAL, INC.

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Printed in USA#17705BL

Page 2

• DISCONNECT SHAPER FROM POWER before

installing or adjusting knife.

• Keep all guards and anti-kickback devices in

place.

• Double-check moulding head to insure it is tight

and secure in spindle.

• Always inspect lumber and other wood materials

for cracks, knots, or other imperfections that

could cause lumber to kick or shatter while

shaping.

Installing Knives

3

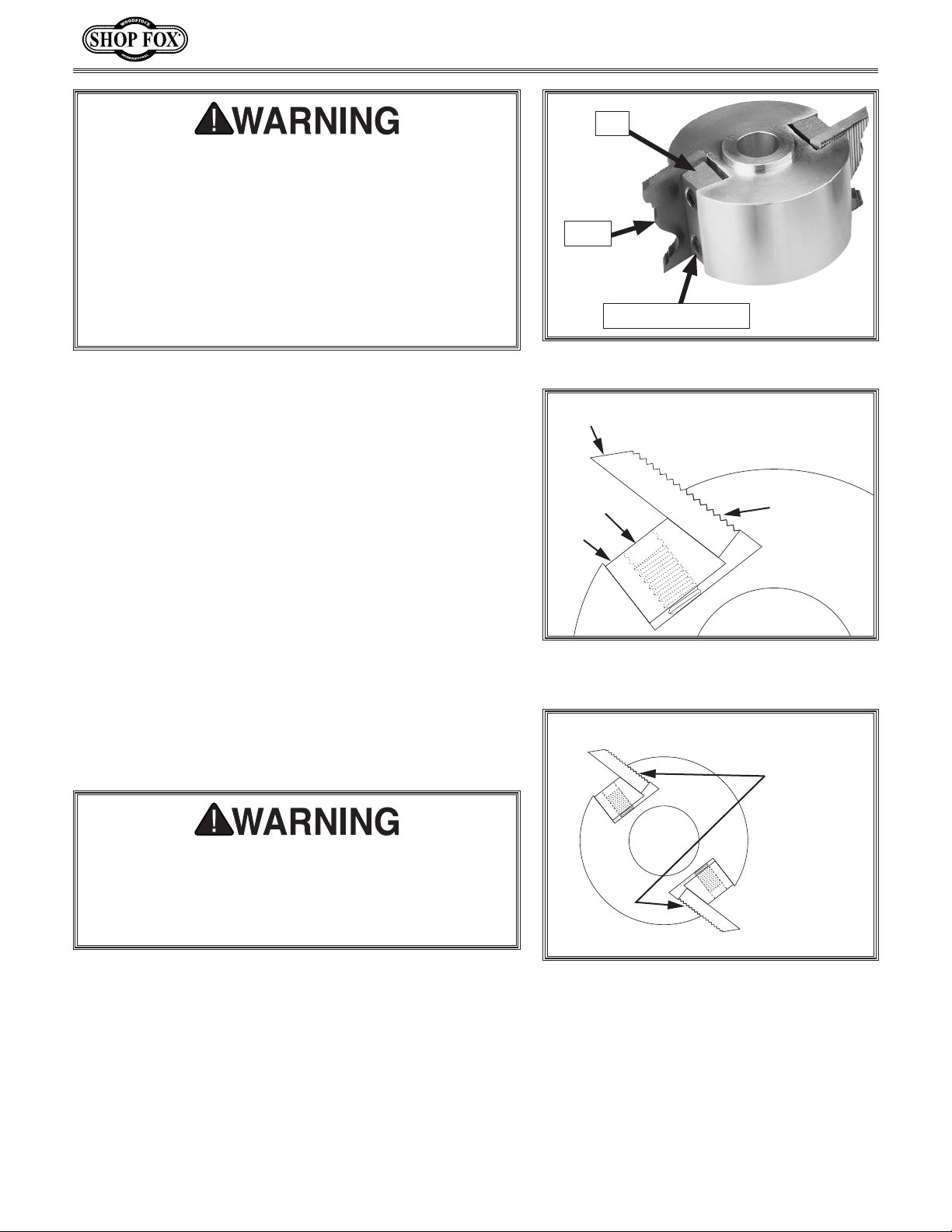

1. Thread (2) included

(see Figure 2) so set ends of screws are flush with

bottom of gib.

⁄8"-16 x 1⁄2" set screws into gib

D1700/D1701 Moulding Head (Mfd. Since 10/94)

Gib

Knife

Set Screw (1 of 2)

Figure 2. Knife installed in moulding head.

Knife

(Top View)

2. While holding gib in moulding head, slide knife

corrugations into moulding head corrugations and

center knives on moulding head body. Make sure all

corrugations are engaged (see Figure 3).

3

3. Tighten set screws with a

⁄16" hex wrench, but DO

NOT over-tighten. Use only enough force to secure

knife snugly in position, so you can adjust knives in

next section.

4. Repeat Steps 1–3 to insert second knife in moulding

head. Make sure position of corrugations on first and

second knives is the same (see Figure 4) so both

knives are an equal height.

Improperly secured knives can fly out of moulding

head and hit operator or bystanders, causing

serious personal injury. Recheck all adjustments and

tightening sequences, and ensure both knives are

properly secured before installing moulding head.

Set Screw

Corrugations

Engaged

Gib

Moulding

Head

Figure 3. Moulding head corrugations

engaged.

Corrugations

Match

If you need help with your new moulding head, call our

Technical Support at: (360) 734-3482.

-2-

Figure 4. Position of knife corrugations

match.

Page 3

D1700/D1701 Moulding Head (Mfd. Since 10/94)

Adjusting Knives

1. DISCONNECT SHAPER FROM POWER!

2. Install moulding head onto spindle and secure as

detailed in your shaper manual.

3. Choose a reference point on first knife you installed,

and adjust spindle height until this point is even

with table top, as shown in Figure 5. (The reference

point can be the bottom corner of the knife or any

feature that allows vertical alignment with table

top).

Table Top

4. Adjust second knife until corresponding point on it is

same height as first one relative to table.

5. Tighten one set screw on a gib a small amount, then

tighten nearby set screw same amount. Repeat until

all set screws are tight on both gibs. DO NOT overtighten set screws.

Spindle Mounting Tips

• Mount moulding head as low as possible on spindle.

• Add a spacer(s) on top of moulding head to ensure

that spindle nut does not rest on moulding head

shoulder.

• Secure the moulding head assembly with a locking

washer and nut, or two nuts locked together.

• Ensure your shaper is in top running condition and all

guards are in place.

General Procedures

A wide selection of knife profiles make the moulding head

a versatile addition to your shaper. The moulding head

operates on the same principle as other shaper cutters

and can be used for straight shaping, as well as irregular

shaping. Since the moulding head is larger in diameter

than most cutters, it must be operated at speeds ranging

between 4,000 to 7,000 RPM. Please refer to your shaper

manual if you are unsure about operating speeds.

Reference

Points

Figure 5. Reference points on knives

aligned with table top.

ALWAYS feed stock against moulding head direction of

rotation. The moulding head must come to a complete

stop and SHAPER MUST BE DISCONNECTED FROM POWER

before making any inspections or adjustments.

-3-

Page 4

D1700/D1701 Moulding Head (Mfd. Since 10/94)

Straight Shaping

For straight shaping, use the fence assembly of your

shaper. Refer to the fence adjustment section in your

shaper manual for fence alignment instructions. Make sure

all guards are in position and functioning correctly.

To perform straight shaping, do these steps:

1. DISCONNECT SHAPER FROM POWER!

2. Select appropriate knife profile and install it into

moulding head (refer to Installing Knives on Page

2).

3. Secure moulding head onto spindle, then check

that moulding head rotates in desired direction and

knives are oriented correctly, as shown in Figure 6.

4. Adjust spindle height.

To reduce operator exposure to knives

and prevent laceration or amputation

injuries, make sure moulding head

comes to a complete stop and POWER

IS DISCONNECTED before making any

inspections or adjustments.

Outfeed

Fence

Cutterhead

Rotation

5. Position outfeed fence (see Figure 6) for depth of

cut.

6. Use hold-downs, jigs or anti-kickback devices to

secure workpiece during shaping operation. Refer to

shaper manual for specific safety information about

straight shaping operations.

7. Always make a sample cut on a piece of scrap wood

before shaping workpiece. Readjust moulding knives

if necessary.

8. Follow recommended operating procedures for

shaping end of stock. Refer to shaper manual for

specific safety information regarding this type of

shaping operation.

Feed

Direction

(Guards &

Anti-Kickback

Devices Removed

for Clarity)

Figure 6. Moulding head set up correctly

for straight shaping.

-4-

Page 5

D1700/D1701 Moulding Head (Mfd. Since 10/94)

Irregular Shaping

Irregular shaping (freehand) takes a high degree of skill

and manual dexterity to perform. The fence assembly is

not used in irregular shaping and should be removed. Rub

collars must be used. Choose the correct diameter for

the appropriate depth of cut. When doing freehand work,

a starting pin must be used. The purpose of the starting

pin is to support the workpiece. The starting pin acts as a

pivot point and gives the operator more control during the

beginning of the cut.

Rub collars can be positioned on top (see Figure 7) or

below the moulding head, depending on the type of work.

Plan ahead and determine which rub collar position will

work best for your needs.

To perform irregular shaping, do these steps:

1. DISCONNECT SHAPER FROM POWER!

2. Remove fence assembly.

To reduce operator exposure to knives

and prevent laceration or amputation

injuries, make sure moulding head

comes to a complete stop and POWER

IS DISCONNECTED before making any

inspections or adjustments.

• Always use starting pin/block and

rub collar for freehand work.

• Use guards and hold-downs, and

verify they function correctly.

• Follow all safety guidelines of

shaper manufacturer for freehand

work while operating shaper with

moulding head.

3. Choose appropriate moulding knives, secure in

moulding head (refer to Installing Knives on Page

2), then install rub collar and spindle nuts (see

Figure 7).

4. Check direction of moulding head rotation.

5. Lock spindle height after aligning knives to

workpiece.

6. Insert starting pin into table surface; choose

appropriate hole position. See owner’s manual for

location. If a starting pin is not available, use a

starting block, as shown in Figure 8.

7. Inspect stock or pattern for any irregularities which

may cause a miss-cut.

8. Use some type of hold-down(s), fixtures and guards

when performing freehand work (see Figure 8).

Rub Collar

Template

Workpiece

Figure 7. Rub collar positioned above

moulding head.

Moulding

Head

Spindle

Nuts

Starting

Block

Clamps

-5-

Workpiece

Figure 8. Typical setup for performing

irregular shaping.

Page 6

9. Place workpiece in starting position using starting

pin for support (see Figure 9).

10. Gradually swing work into moulding knives, keeping

workpiece against starting pin (see Figure 10).

D1700/D1701 Moulding Head (Mfd. Since 10/94)

Starting Pin

Workpiece

Figure 9. Workpiece in starting position

(Guard removed for clarity).

11. After workpiece is supported by rub collar, swing

workpiece free of starting pin (see Figure 11).

Always feed against rotation of knives.

12. Always make a sample cut on a piece of scrap wood.

Readjust moulding knives if necessary.

Figure 10. Swinging workpiece into knife

and against pin.

Figure 11. Feeding workpiece against

moulding head knife.

-6-

Loading...

Loading...