Shogun Motorsports CBR600F2, CBR600F3 User Manual

Honda CBR600F2/F3 (91-98) Frame Slider

Installation Instructions

Part Numbers: 750-3109 & 750-3100

MADE IN THE USA!

Carefully read instructions in their entirety before the install

Professional installation is recommended. Always use proper safety measures during the install of this

product. Do not try to install this product without proper tools, recently calibrated torque wrench,

correct torque specifications from factory service manual, safety goggles and gloves. The motorcycle

must be in a fixed secure position before the install process begins. DO NOT remove both engine studs

at the same time. Shogun is not responsible for any part of your motorcycle for any reason. Precisely

measure location of cut and if in doubt at any point please call us before the install process has begun.

Replacement Parts List: Left Side Components (as if you were sitting on the bike)

QTY Price each Part Numbers Descriptions

1 $20.00 99-FS-750-3109-L Black Left Side Puck

1 $20.00 99-FS-750-3100-L White Left Side Puck

1 $3.50 99-HB-SH101250100 Socket Cap 10 X 1.25 X 100 Main Engine Stud

Replacement Parts List: Right Side Components (as if you were sitting on the bike)

1 $20.00 99-FS-750-3109-R Black Right Side Puck

1 $20.00 99-FS-750-3100-R White Right Side Puck

1 $3.50 99-HB-SH10125090 Socket Cap 10 X 1.25 X 90 Main Engine Stud

Frame Sliders: Left and Right frame sliders are the SAME length.

Installation Steps:

1. Some photos in this section are used for illustration examples only. It is up to you how you

decide to cut your motorcycles bodywork to accept the frame slider there are many different

ways customers go through this process. Shogun is not responsible for any part of your

motorcycle for any reason. Precisely measure location of cut and if in doubt at any point please

call us before the install process has begun. Professional installation is recommended. Always

use proper safety measures during the install of this product. Do not try to install this product

without proper tools, recently calibrated torque wrench, correct torque specifications from

factory service manual, safety goggles and gloves.

2. Body Prep. Use masking tape to completely mask off the area on the body where you will be

working. We usually will tape off approximately 6 to 8 inches around the though hole area and

any other edges that could get bumped or scratched while working. Tip: In some locations you

may want to double up the thickness of the masking take to give extra protection.

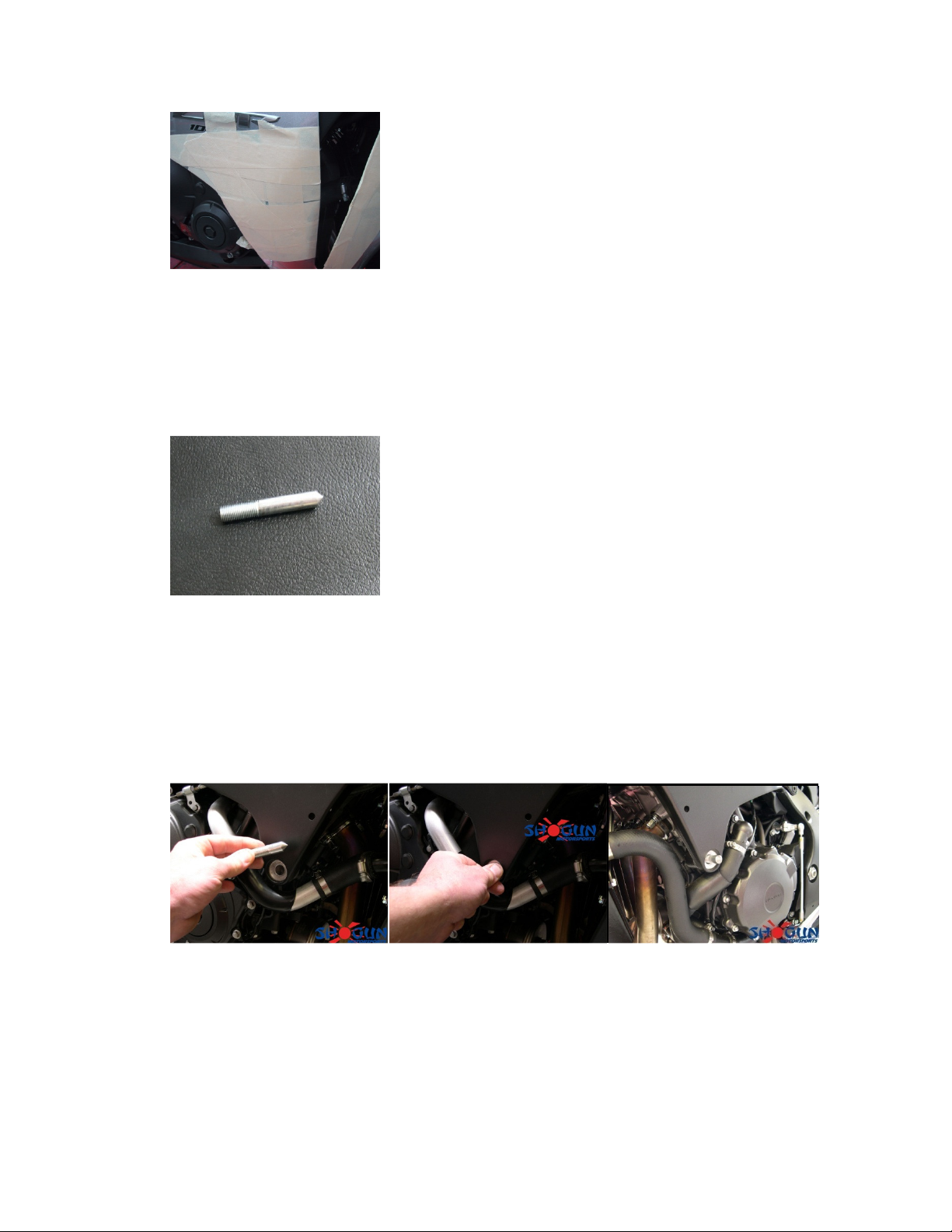

3. Locating and cutting the body. This is a simple illustration of how most of us install the product

here. It takes a bit longer but our end results have been more consistent with a better overall fit

and finish. We start with (99-SPOT-1012560) Shogun Spot tool. It’s nothing special just a 10mm

socket cap bolt with a 1.25 pitch that we cut the head off of and sharpen to a point. You can

purchase the tool for $12.99 or go to your local hardware store and make your own. Keep in

mind Metric 10 or 12mm X 1.25 pitch bolts (most common sportbike engine studs) are fairly

hard to find. Make sure you know the size and that the bolt you’re buying is a 1.25 pitch bolt.

With the body removed, thread in by hand your spot tool. Make sure you have the spot tool

screwed in enough to clear the body on the inside.

4. Loosely mount your bodywork and adjust the spot tool out to lightly touch the inside of the

body. Make sure you have at least 15mm of thread engagement, without that the spot tool will

tend to sag down giving you a false location. With the body mounted in the correct location use

a soft micro fiber cloth over the spot tool location and softly tap to leave a spot mark on the

inside of the body. Be careful not to scratch or chip the body.

5. Remove the bodywork and double check location of spot mark the tool has created.

Loading...

Loading...