Circularly Polarized FM

Broadcast Antenna

Versa2une (SLV)

1 to 4-bay, full-wave-spaced

Instruction Manual

Installation, Operation, &

Maintenance

Congratulations!

Thank you for purchasing one of the finest FM broadcast antennas on the

market today. The Shively Labs Versa2une is the top-of-the-line in its class for

its simplicity, superior performance and durability.

Your purchase is backed by the best technical support in the industry. Shively

is a leading manufacturer in the broadcast industry, providing an extensive

range of antennas, transmission line and components. Our technical staff has

a wealth of experience in the broadcast industry and is standing by to serve

you in any way.

This manual is intended to give you a good basic understanding of your

antenna: its proper and safe installation, startup, and operation, and trouble

shooting and maintenance information to keep it working satisfactorily for

years to come.

Please have everyone involved with the antenna read this

manual carefully, and keep it handy for future reference.

Meanwhile, please feel free to contact your sales representative at Shively

Labs at any time if you need information or help. Call or write:

-

Publication No. im-SLV_1-4_fw (150915)

IMPORTANT

Please read this manual in its entirety before beginning

installation of your antenna!

Failure to follow the installation and operation

instructions in this manual could lead to failure of your

equipment and might even void your warranty!

This manual applies only to one- to four-bay SLV antennas

(SLV-1 to SLV-4) with full-wave bay spacing. For six- to

twelve-bay antennas (SLV-6 to SLV-12) or any size half-wave-

spaced versions, refer to the appropriate manual on our

Web site.

Table of Contents

Chapter 1 Preparation........................................................................1

Check the shipment...............................................................................1

Torque specifications................................... ..........................................1

Table 1 Torque specifications .......................................................... 1

Check the parts.....................................................................................1

Prepare the mounting location. ..............................................................2

Figure 1 Tower layout, single-bay antenna....................................... 2

Figure 2 Tower layout, two-bay antenna.......................................... 3

Figure 3 Tower layout, four-bay antenna..........................................4

High-band or low-band? ....... .................................................................5

Determine "A" dimension.......................................................................5

Figure 4 Low-band and high-band "A" dimension values....................5

Chapter 2 Arm Assembly....................................................................7

Assemble arms. ....................................................................................7

Figure 5 Arm assembly a.................................................................7

Figure 6 Arm assembly b ................................................................ 7

Figure 7 Arm assembly c................................................................. 7

Figure 8 Arm assembly d ................................................................ 7

Figure 9 Arm assembly e.................................................................7

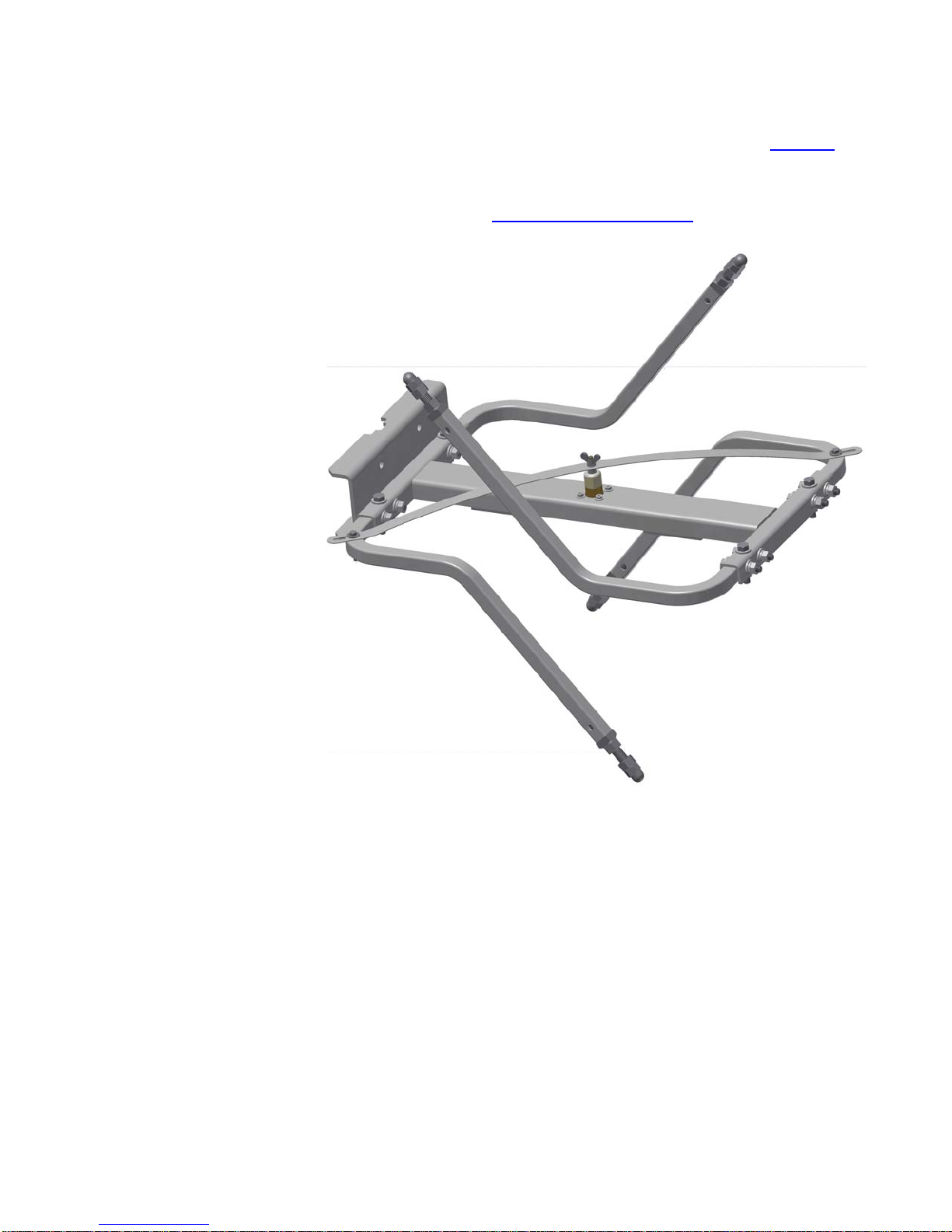

Figure 10 Arm assembly - complete...... ........................................... 8

Chapter 3 Bay Assembly (without radomes) .....................................9

Attach the arms to the radiator. .............................................................9

Figure 11 Arm hole selection...........................................................9

Figure 12 Position first arms............................................................9

Figure 13 Channel attachment....................................................... 10

Figure 14 Vertical bolts................................................................. 10

Figure 15 Arm attachment - complete............................................ 11

Install the feedstrap. ........................................................................... 11

Figure 16 Remove wingnut .................... ....................................... 11

Figure 17 Feedstrap to endseal ..................................................... 12

Figure 18 Feedstrap to arms ......................................................... 12

Connect the coax cable........................................................................13

Figure 19 Form coax cable............................................................ 13

Figure 20 Attach coax cable to antenna input ................................. 13

Figure 21 Finished antenna bay assembly ...................................... 14

Chapter 4 Bay Assembly (with radomes).........................................15

Attach the mount channels to the radome back half. .............................15

Figure 22 Mount channels and clamp halves to radome................... 15

Attach the arms to the radiator. ........................................................... 16

Figure 23 Arm hole selection......................................................... 16

Figure 24 Position inner arms........................................................ 16

Figure 25 Radome, inner arms to radiator ......................................17

i

Table of Contents

(continued)

Install the feedstrap. ........................................................................... 18

Figure 26 Remove wingnut .................... ....................................... 18

Figure 27 Feedstrap to endseal ..................................................... 18

Figure 28 Feedstrap to arms ......................................................... 19

Figure 29 Feedstrap ends bent down ............................................. 19

Attach the coax cable.......................................................................... 20

Figure 30 Form coax cable............................................................ 20

Figure 31 Attach coax cable to antenna input. ................................ 20

Install the radome front half. ............................................................... 21

Figure 32 Radome front half installation......................................... 21

Figure 33 Seal around radome openings. ....................................... 21

Figure 34 Finished antenna bay assembly with radome, back view

..................................................................................... 22

Chapter 5 Mounting the Antenna Bay(s) .........................................23

Mount the antenna bay on the tower leg or pole. ....... ...........................23

Figure 35 Mount the antenna bay(s).............................................. 23

Figure 36 Mount the antenna bay(s) (with radomes)....................... 24

Figure 37 Adjust the heading. ....................................................... 24

Figure 38 Tighten mounting hardware. .......................................... 25

Chapter 6 Connecting the Antenna (single-bay)..............................27

Connect the coax feedline cable. ..........................................................27

Figure 39 Secure feedline cable..................................................... 27

Connect the transmission line cable.................... ..... .. .. .... .. .. .. ..... .. .. .. .... 28

Figure 40 Transmission line connection.......................................... 28

Chapter 7 Connecting the Antenna (2 or more bays) ......................29

Mount the power divider(s)..................................................................29

Figure 41 Power divider mounting (two-bay).................................. 29

Figure 42 Power divider mounting (four-bay) ................................. 30

Secure the coax feedline cables............................................................31

Figure 43 Secure the feedline cables....................................... ....... 31

Connect the transmission line cable.................... ..... .. .. .... .. .. .. ..... .. .. .. .... 32

Figure 44 Transmission line cable connection ................................. 32

Chapter 8 Startup.............................................................................33

Optimize VSWR........................................... .... .. ... .. .... .. .. .. .. ..... .. .. .. .... .. 33

Figure 45 Apply the signal............................................. ................ 33

Adjust to minimize reflected power if necessary.....................................33

Operate..............................................................................................33

Chapter 9 Troubleshooting...............................................................35

Broad Spectrum RF Noise .................. .................................................. 35

High VSWR ........................................................................................35

Change in Coverage ..................................... ...................................... 35

ii

Table of Contents

(continued)

Chapter 10 Maintenance ..................................................................37

Log ................................................................................................... 37

Inspection ......................................................................................... 37

Paint ................................................................................................. 37

Return Policy ........................ .. .. .... ... .. .. .... .. .. .. .. ..... .. .. .. .. .... .. ... .. .... .. .. .. 37

Chapter 11 Parts ................................ ..............................................39

Parts list............................................................................................. 39

Table 2 Parts List ........................................................................39

iii

Preparation

1 Preparation

Check the shipment.

Torque specifications.

As soon as you receive your antenna,

a. Check to be sure all the material has arrived.

b. Check for evident damage to any of the boxes.

c. If any boxes are missing, or if any are obviously damaged, describe the

problem in a WRITTEN note on the shipping papers BEFORE signing them.

Then call Shively right away, and we’ll do everything we can to correct the

situation.

BEFORE

signing for the shipment:

Important!

Never store the antenna system outdoors, boxed or otherwise. Take

pains to keep the antenna components dry. You will need to purge mois

ture from the interior of the antenna components before applying transmitter power, and purging will be much more time-consuming if the

components get wet.

NOTE

Use an anti-seize compound to minimize galling on stainless steel

threads.

Table 1. Torque specifications

Hardware size Torque (dry) Torque (lubricated)

M5 stainless steel 3.75 lb-ft (0.52 kg-m) 3.4 lb-ft (0.47 kg-m)

M8 stainless 16 lb-in (2.2 kg-m) 14 lb-ft (1.9 kg-m)

M12 stainless 54 lb-ft (7.5 kg-m) 48 lb-ft (6.6 kg-m)

Antenna input fitting 18 - 22 lb-in (21 - 25 cm-kg) n/a

-

Check the parts.

Check to be sure all the parts shown in Table 2 on page 39 have arrived in

good condition.

NOTE

Item callouts are consistent across all the illustrations in this technical

sheet.

1

Prepare the mounting

location.

Figure 1. Tower layout, singlebay antenna

Remember!

It is YOUR responsibility to

ensure that your installation meets all applicable

codes and the centerlineof-radiation requirements

of your FCC construction

permit.

Preparation

2

Figure 2. Tower layout, two-bay

antenna

Preparation

3

Figure 3. Tower layout, four-bay

antenna

Preparation

4

Preparation

High-band or lowband?

Determine "A"

dimension.

Figure 4. Low-band and highband "A" dimension values

87.5 - 98 MHz = Low-band

98.1 - 108 MHz = High-band.

5

Arm Assembly

2 Arm Assembly

Assemble arms.

Figure 5. Arm assembly a

Figure 6. Arm assembly b

Figure 7. Arm assembly c

a. Screw the acorn nut (Figure 5, 1) onto the 230 mm threaded rod (2) as far

as it will go.

b. Screw a M12 hex nut (Figure 6, 3) tightly against the acorn nut.

c. Insert the threaded rod into the arm (Figure 7, 4 or 5).

Figure 8. Arm assembly d

Figure 9. Arm assembly e

d. (Figure 8) Set the "A" dimension (from Figure 4) to a tolerance of ± 1/8"

(3 mm).

e. (Figure 9)Screw the hex nut against the square nut at the end of the arm to

secure the threaded rod and the "A" dimension.

7

Arm Assembly

Figure 10. Arm assembly complete

f. (Figure 10

) Repeat for the other 3 arms.

g. Repeat for the other bays, if applicable.

8

Bay Assembly (without radomes)

3 Bay Assembly (without radomes)

Attach the arms to the

radiator.

Figure 11. Arm hole selection

Figure 12. Position first arms

NOTE

This step may be made easier by clamping the radiator to a surface or

mounting it temporarily on a vertical pole.

a. (Figure 11) Identify the mounting holes to be used.

CAUTION

Parts 5, with the feedstrap mounting holes, must be mounted diagonally

across from each other as shown.

b. Position the first arms (Figure 12, 4 and 5) on the radiator (6).

9

Bay Assembly (without radomes)

Figure 13. Channel attachment

Figure 14. Vertical bolts

c. Attach the channel mount (Figure 13

9

, 10, and 11), finger-tight only.

, 7) and arms, using M8 hardware (8,

CAUTION

To ensure proper arm alignment, always tighten the nuts on the vertical

bolts before tightening the horizontal ones.

d. Secure each arm with a vertical M8 bolt and hardware (Figure 14, 8, 9, 10,

and 11

). Torque in accordance with Table 1 on page 1.

e. Tighten the nuts on the horizontal bolts. Torque in accordance with Table 1.

f. Repeat to attach the other two arms in their correct positions (Figure 15

).

10

Figure 15. Arm attachment complete

Bay Assembly (without radomes)

Install the feedstrap.

Figure 16. Remove wingnut

a. Remove the wingnut (Figure 16, 12), the top lockwasher, and the topmost

flat washer from the endseal (13

b. Secure the feedstrap (Figure 17, 14) to the endseal.

11

). Leave the second flat washer in place.

Figure 17. Feedstrap to endseal

Bay Assembly (without radomes)

Figure 18. Feedstrap to arms

c. Using the M5 hardware (Figure 18, 15, 16, 17, and 18), secure the feedstrap

to the innermost holes in the arms.

12

Bay Assembly (without radomes)

Connect the coax

cable.

Figure 19. Form coax cable

Figure 20. Attach coax cable to

antenna input

CAUTION

Stressing a coax connection after assembly can detune the system.

Therefore, never make a connection and the n bend or twist the cable, or

use the connector to force the coax into shape. Form the cable first,

then attach it to the connector.

CAUTION

The minimum bending radius for 1/2" coax is 3" (8 cm). Do not bend it

too tightly; you may damage it.

a. Form the cable (Figure 19, 19) to the desired shape.

CAUTION

Do not overtighten the connectors. Overtightening may damage them.

b. (Figure 20) Attach the elbow on the cable to the antenna input. Torque to

18 - 22 lb-in (21 - 25 kg-cm).

c. Seal the joint thoroughly with splice tape (20).

13

Figure 21. Finished antenna bay

assembly

Bay Assembly (without radomes)

This completes assembly of your antenna bay without radomes (Figure 21 on

page 14).

If your antenna has multiple bays, repeat this chapter for the remaining bays.

Then please proceed to Mounting the Antenna Bay(s) on page 23.

14

Bay Assembly (with radomes)

4 Bay Assembly (with radomes)

Attach the mount

channels to the

radome back half.

Figure 22. Mount channels and

clamp halves to radome

a. Attach a center mount channel (Figure 22, 7) and two end mount channels

(21

) to the radome back half (22), using the threaded rods (2) and M12

hardware (3

b. Loosely attach the clamp halves (25

, 23, 24) as shown.

) to the threaded rods.

15

Bay Assembly (with radomes)

Attach the arms to the

radiator.

Figure 23. Arm hole selection

Figure 24. Position inner arms

NOTE

This step may be made easier by clamping the radiator to a surface or

mounting it temporarily on a vertical pole.

a. (Figure 23) Identify the mounting holes to be used.

CAUTION

Parts 5, with the feedstrap mounting holes, must be mounted diagonally

across from each other as shown.

b. Position the inner arms (Figure 24, 4 and 5) on the radiator (6).

16

Figure 25. Radome, inner arms

to radiator

Bay Assembly (with radomes)

c. Attach the radome assembly (assembled above) and the inner arms (Figure

25, 4 and 5) to the radiat or (6), using M8 hardware (8, 9, 10, and 11), finger-

tight only.

NOTE

The channel of the radiator fits into the rectangular slot in the back of

the radome half.

CAUTION

To ensure proper arm alignment, always tighten the nuts on the vertical

bolts before tightening the horizontal ones.

d. Secure each arm with a vertical M8 bolt and hardware (8, 9, 10, and 11).

Torque in accordance with Table 1

on page 1.

e. Tighten the nuts on the horizontal bolts (Figure 25). Torque in accordance

with Table 1

f. Repeat to attach the other two arms in their correct positions.

.

17

Bay Assembly (with radomes)

Install the feedstrap.

Figure 26. Remove wingnut

Figure 27. Feedstrap to endseal

a. Remove the wingnut (Figure 26, 12), the top lockwasher, and the topmost

flat washer from the endseal (13

b. Using the wingnut, secure the feedstrap (Figure 27, 14) to the endseal.

). Leave the second flat washer in place.

18

Bay Assembly (with radomes)

Figure 28. Feedstrap to arms

c. Using the M5 hardware (Figure 28

to the innermost holes in the arms.

, 15, 16, 17, and 18), secure the feedstrap

Figure 29. Feedstrap ends bent

down

d. (High-band only) Bend the ends of the feedstrap down over the arms to

allow clearance inside the radome (Figure 29

).

19

Bay Assembly (with radomes)

Attach the coax cable.

Figure 30. Form coax cable

CAUTION

Stressing a coax connection after assembly can detune the system.

Therefore, never make a connection and the n bend or twist the cable, or

use the connector to force the coax into shape. Form the cable first,

then attach it to the connector.

CAUTION

The minimum bending radius for 1/2" coax is 3" (8 cm). Do not bend it

too tightly; you may damage it.

a. Form the cable (Figure 30, 19) to the desired shape.

b. Insert the elbow end of the coax feedline cable (Figure 31, 19) in through

the round hole in the back of the radome half (22

of the endseal (13

page 1.

). Torque the cable fitting in accordance with Table 1 on

), and connect it to the base

Figure 31. Attach coax cable to

antenna input.

c. Seal the joint thoroughly with splice tape (20).

20

Bay Assembly (with radomes)

Install the radome

front half.

Figure 32. Radome front half

installation

a. Using the 1/4" hardware (Figure 32, 27), attach the radome front half (28)

to the radome back half (22

b. Using splice tape (Figure 33, 20, provided with the antenna) and Dow

Corning 744 adhesive-sealant (26

).

), seal:

Figure 33. Seal around radome

openings.

• The perimeter of the center mount channel on the back of the

radome, and

• The hole in the radome back half around the coax cable.

21

Figure 34. Finished antenna bay

assembly with radome, back

view

Bay Assembly (with radomes)

This completes assembly of your antenna bay with radomes (Figure 34 on

page 22).

If your antenna has multiple bays, repeat this chapter for the remaining bays.

Then please proceed to Mounting the Antenna Bay(s) on page 23.

22

Mounting the Antenna Bay(s)

5 Mounting the Antenna Bay(s)

Mount the antenna bay

on the tower leg or

pole.

Figure 35. Mount the antenna

bay(s).

NOTE

If the supporting structure is non-metallic (for example, a chimney or a

tree), run a ground cable (customer-supplied) from the antenna mount

to a post driven into the ground.

a. Using the M12 hardware (Figure 35, 3, 23, 24), secure the threaded rods (2)

to the mount channel, with the end of the threaded rod extending

approximately one inch beyond the surface of the channel, as shown.

b. Then use the threaded rods with M12 hardware and clamp half (25

the antenna to the tower leg or pole at the location you marked and cleared

of paint. Do not tighten fully at this time.

) to clamp

23

Figure 36. Mount the antenna

bay(s) (with radomes)

Mounting the Antenna Bay(s)

c. (With radomes only) Similarly, clamp the upper and lower end mount

channels (21

) to the tower leg or pole (Figure 36). Do not tighten fully.

Figure 37. Adjust the heading.

d. (Figure 37) Adjust the antenna heading.

24

Mounting the Antenna Bay(s)

Figure 38. Tighten

mounting

hardware.

e. (Figure 38

threaded rods (2

) Tighten the mounting hardware (Figure , 3, 23, 24) on the

). Torque in accordance with Table 1 on page 1.

f. Retouch the tower paint as necessary.

g. (2-bay or 4-bay) Repeat this chapter for the remaining bays.

25

Connecting the Antenna (single-bay)

6 Connecting the Antenna (single-bay)

Connect the coax

feedline cable.

Figure 39. Secure feedline cable

CAUTION

Stressing a coax connection after assembly can detune the system.

Therefore, never make a connection and the n bend or twist the cable, or

use the connector to force the coax into shape. Form the cable first,

then attach it to the connector.

CAUTION

The minimum bending radius for 1/2" coax is 3" (8 cm). Do not bend it

too tightly; you may damage it.

CAUTION

Do not overtighten the connectors. Overtightening may damage them.

a. Secure the cable (Figure 39, 19) to the mounting pole or tower leg, using tie-

wraps (29

) or customer-supplied cable clamps.

27

Connecting the Antenna (single-bay)

Connect the

transmission line cable.

Figure 40. Transmission line

connection

You need to provide a transmission line cable from your transmitter, terminated with a female 7/16 DIN connector.

CAUTION

The antenna is non-pressurized. If you are using pressurized cable, you

must install a gas stop at the coax cable input.

a. (Figure 40) Connect the transmission line cable to the coax cable input, with

a gas stop if necessary. Torque to 18 - 22 lb-ft (2.4 - 3 Pa). Seal with splice

tape.

b. Secure the transmission line cable to the mounting pole or tower leg, using

customer-supplied cable clamps.

Installation of your Versa2une is complete. Please proceed to Startup.

NOTE

If you have any problems with installation, call Shively and talk with a

designer or Sales.

28

Connecting the Antenna (2 or more bays)

7 Connecting the Antenna (2 or more bays)

Mount the power

divider(s).

Two-bay antenna:

Figure 41. Power divider

mounting (two-bay)

Using two power divider mounting kits (Figure 41, 30), mount the power

divider (31) to the mounting structure with its outlet ports roughly halfway

between the antenna bays. Locate the mounts as close to the ends of the

power divider as you can.

29

Connecting the Antenna (2 or more bays)

Four-bay antenna:

Figure 42. Power divider

mounting (four-bay)

Using two power divider mounting kits (Figure 41, 30), mount the power

divider (32) to the mounting structure with its outlet ports roughly halfway

between the antenna bays. Locate the mounts as close to the ends of the

power divider as you can.

30

Connecting the Antenna (2 or more bays)

Secure the coax

feedline cables.

Figure 43. Secure the feedline

cables

CAUTION

Stressing a coax connection after assembly can detune the system.

Therefore, never make a connection and the n bend or twist the cable, or

use the connector to force the coax into shape. Form the cable first,

then attach it to the connector.

CAUTION

The minimum bending radius for 1/2" coax is 3" (8 cm). Do not bend it

too tightly; you may damage it.

CAUTION

Do not overtighten the connectors. Overtightening may damage them.

a. Connect the input ends of the antenna bay cables (Figure 43, 19) to the

power divider outputs.

b. Secure the cables to the mounting pole or tower leg, using tie-wraps (29

customer-supplied cable clamps.

) or

31

Connecting the Antenna (2 or more bays)

Connect the

transmission line cable.

Figure 44. Transmission line

cable connection

CAUTION

The antenna and power divider are non-pressurized. If you are using

pressurized transmission line cable, it

tion.

a. Connect the transmission line cable from the transmitt er to t he input of the

power divider (Figure 44

, 31 or 32), with an adapter if necessary.

MUST

include a gas stop termina-

b. Secure the transmission line cable to the mounting pole or tower leg, using

customer-supplied cable clamps.

Installation of your Versa2une is complete. Please proceed to Startup.

NOTE

If you have any problems with installation, call Shively and talk with a

designer or Sales.

32

Startup

8Startup

WARNING

Whenever a rigger is on the tower in the area of the antenna, shut off

the signal and lock it off so that it cannot be turned on accidentally. RF

emissions at close range are hazardous.

NOTE

The Versa2une does not require pressurization or purging.

Optimize VSWR.

Figure 45. Apply the signal

(Figure 45) Apply a low-power signal to the antenna and read reflected power

(VSWR). VSWR should be below 1.2:1.

Adjust to minimize

reflected power if

necessary.

Operate.

a. Loosen one jam nut on one arm of one antenna element and lengthen that

arm by 10 mm (3/8"). With personnel clear, check VSWR again.

b. If the VSWR (reflected power) has increased, return that arm to its original

setting. Then shorten ALL arms by 3 mm (1/8").

c. If the VSWR has decreased, return that arm to its original setting. Then

lengthen ALL arms by 3 mm (1/8").

d. Repeat steps a - c until VSWR is below 1.2:1.

e. Secure all the arms by tightening their jam nuts.

Once the antenna has been installed and VSWR has been confirmed, simply

apply the transmitter signal. Don’t exceed the rated power of the antenna.

33

Troubleshooting

9 Troubleshooting

Broad Spectrum RF

Noise

High VSWR

Change in Coverage

This indicates that some component is not in good electrical contact with the

tower. Make sure mounts are tight, that tower paint has been removed from

under the mounts, and that components of other systems are likewise in good

contact with the tower.

This is caused by any factor that changes the impedance match between the

antenna and the transmitter. Look for:

• Defective RF connector. Make sure connectors are in good shape,

and that center pins are not bent over.

• Damage to any antenna components.

• Paint on radiators.

• Ice buildup on radiators.

• Interference from other tower components, especially components

broken by wind or ice.

This may be caused by the same factors that can cause high VSWR. Look for

VSWR changes as well.

Do recognize, however, that apparent changes in coverage may be due to subjective factors or faults of the receiving equipment. Before doing more than

checking the VSWR, be sure that an actual coverage change has occurred.

35

Maintenance

10 Maintenance

WARNING

Whenever a rigger is on the tower in the area of the antenna, shut off

the signal and lock it off so that it cannot be turned on accidentally. RF

emissions at close range are hazardous.

Log

Inspection

Paint

Return Policy

We recommend that you keep a log of VSWR readings and any other performance notes and maintenance history for your antenna. Such a record can be

invaluable for troubleshooting.

Whenever a rigger is on the tower for any reason, it is a good idea to have

him check your antenna for general condition, looseness of connectors and

mounts, and electrical damage.

The radiator should never be painted; this will affect the VSWR.

When returning any material to the factory, be sure to call your salesperson

and obtain an returned materials authorization (RMA) number first. Material

may be refused and sent back to you at your expense if you don’t do this.

37

Parts

11 Parts

Parts list.

Item callouts are consistent across all the illustrations in this technical

sheet.

Table 2. Parts List

Description without radomes with radomes

1

bay2 bays4 bays1 bay2 bays4 bays

1. "Acorn" nut, M12 x

1.75

2. Threaded rod, M12 x

1.75 x 230 mm (9 in)

long

3. Hex nut, M12 x 1.75 15 52 104 26 52 104

4. Arm without feedstrap hole

(marked with 2 UP

sticker)

5. Arm with feedstrap

hole

(marked with 1

DOWN sticker)

4 8 16 4 8 16

6 12 24 10 20 40

2 4 8 2 4 8 99350-G505

2 4 8 2 4 8 99350-G506

NOTE

Shively P/N Appearance (not to scale)

6. Radiator subassembly with end seal

(number stickers

indicate arm loca

tions)

7. Center mount channel

8. Hex bolt, M8 x 1.25

x 45

(in hardware kit)

9. Hex nut, M8 x 1.25

(in hardware kit)

10. Flat washer, M8

(in hardware kit)

-

1 2 4 1 2 4 99350-G502

1 2 4 1 2 4 99351-01

13 26 52 13 26 52

15 30 60 15 30 60

27 54 108 27 54 108

39

Description without radomes with radomes

11. Lock washer, M8

(in hardware kit)

12. Wing nut (shipped

on endseal, item 13)

Parts

Table 2. Parts List (continued)

1

bay2 bays4 bays1 bay2 bays4 bays

15 30 60 15 30 60

1 2 4 1 2 4

Shively P/N Appearance (not to scale)

13. Endseal (part of radi -

ref ref ref ref ref ref

ator)

14. Feedstrap 1 2 4 1 2 4 99350-04

15. Hex bolt, M5 x 0.8 x

3 6 12 3 6 12

35 (in hardware kit)

16. Hex nut, M5 x 0.8

3 6 12 3 6 12

(in hardware kit)

17. Flat washer, M5

6 12 24 6 12 24

(in hardware kit)

18. Lock washer, M5

3 6 12 3 6 12

(in hardware kit)

19. Coax cable section,

1 2 4 1 2 4 99349-G510

10 ft (~3 m) long

with elbow connec

tor on output end

and 7/16 DIN male

connector on input

end

20. Splice tape 1 2 4 1 2 4 92042-01

21. End mount channel n/a n/a n/a 2 4 8 99351-02

22. Back radome half

n/a n/a n/a 1 2 4 99348-01

(cable hole & slot for

radiator channel)

23. Flat washer, M12 6 12 24 18 36 72

24. Lock washer, M12 4 8 16 12 24 48

40

Parts

Table 2. Parts List (continued)

Description without radomes with radomes

1

Shively P/N Appearance (not to scale)

bay2 bays4 bays1 bay2 bays4 bays

25. Clamp half 1 2 4 3 6 12 SCP

26. Dow Corning 744

adhesive-

n/a n/a n/a 1 1 1 DO 88060

sealant, cartridge

27. Radome flange bolt

kit

n/a n/a n/a 1 2 4 93585-G504

(contains 24 1/4-20

bolts, 24 nuts, 48

flat washers, 24 lock

washers)

28. Front radome half

n/a n/a n/a 1 2 4 99348-02

(overlapping flange)

29. Tie-wrap 36 72 144 36 72 144 TY529MX

30. Power divider

0 2 2 0 2 2

mounting kit

31. Power divider, 2-way 0 1 0 0 1 0 99332-G502

32. Power divider, 4-way

0 0 1 0 0 1 99385-G501

(with mounting

clamps)

41

Loading...

Loading...